Professional Documents

Culture Documents

Claronpolyseal: Claron As A Manufacturer of Hydraulic Pressure Seals in A Huge

Uploaded by

Ahmed Baha Mahjoub0 ratings0% found this document useful (0 votes)

10 views3 pagesjuiko

Original Title

1

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentjuiko

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views3 pagesClaronpolyseal: Claron As A Manufacturer of Hydraulic Pressure Seals in A Huge

Uploaded by

Ahmed Baha Mahjoubjuiko

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

ClaronPolyseal®

The operating temperature of the sealing media affects the

choice of sealing materials. Normal operating temperatures

At first glance, there are almost as many seal designs as there are usually between 80°C and sometimes 100°C. The

are applications. In practice there are only a few principles to optimum functional temperature for seals and oil stability is

apply to any application design and thereafter the constraints of between 40°C and 50°C. At low temperatures the seal

material choice, production technique and acceptable cost material will stiffen and may become brittle although it will

designate a suitable type of seal. Refinements to various relax as the temperature rises. With high temperatures the

aspects of seal geometry, material properties and housing seal material will become more elastic and lose

designs can however have a significant effect on the compression set. The higher temperatures will also reduce

performance and capability of the seal. the viscosity of the oil resulting in accelerated wear of the

seals. For PTFE seals the effect of temperature will be

Claron as a manufacturer of hydraulic pressure seals in a huge based on the seals energiser.

variety of designs and materials ensure that the products

offered are based upon the sound knowledge of performance

and suitability for any given application, rather than upon the

limitations of availability. Seals ride on a film of lubricant between the seal lip and

Whatever the demand and complexity of the required sealing moving surface. The fluid is drawn under by movement and

system every seal has the same basic function, to prevent or is known as hydrodynamic drag. Friction will depend upon

minimise leakage between the two parts. the thickness of this lubricating film which will be squeezed

When selecting a seal a series of requirements are made by to its minimum thickness when there is no movement, and

those using seals and these should be given consideration creates stiction. Frictional force begins to decrease with an

before final selection is made. increase in velocity as more lubricating fluid is then drawn

between the seal and moving surface. There is a point

Environmental Serviceability reached with increasing velocity that the frictional force

Simple Installation again rises and the seal will begin to wear. PTFE seals have

Operational Reliability an extremely low coefficient of friction when moving on other

Tolerance to the sealing media surfaces and may be a possible exception to this rule.

Frictional requirements

Ability to function within a temperature range

Good sealing at high and low pressures

Resistance to extrusion between mating parts

The operating life of a seal is greatly influenced by the

Consideration and evaluation of these demands within the seals considerations of the dynamic surface and the method used

operating conditions is important as are the influencing factors to produce this surface texture. For instance honing and

of pressure, temperature, speed, and surface finish. roller burnishing may give the same surface finish value but

the surface profile would differ. The aim of all types of

surface finish is to provide a surface which causes the

minimum wear to the seal. Rod seals because of their

position in the sealing system are prone to contaminants

entering from the atmosphere and therefore rods should have

a surface resistance to corrosion and similar to the best

hard chrome. The static surfaces of the seal housing are

important as the sealing media may pass over the seal if not

within the recommended surface finish.

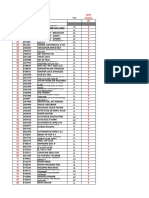

Pressure affects the seal by forcing it into the gap which exists Figure 2 shows a diagrammatic representation

between toleranced machined parts at the non pressure side of of average roughness value Ra.

the seal. When the gap is too large the heel of the seal will Figure 2

show “nibbling” and result in premature seal failure. This

extrusion will increase if the seal is in a condition of side

loading. To minimise extrusion whilst maintaining reasonable

machining tolerances seals fitted with

anti-extrusion wear rings should be selected. The use of

bearing rings will also reduce potential maximum extrusion

gaps. Permissible extrusion gaps / pressure graphs are shown

for all piston and rod seals within this catalogue.

These characteristics are defined in DIN EN ISO 4287

along with Rmr, mating surface ratio,

which should be 50-70% for optimum performance.

issue 2 - 20/07/10 1-1

ClaronPolyseal®

The average roughness Ra (CLA an abbreviation of centre

line average height) is the arithmetic and geometric

average value of the profile variation in Y direction from the

middle line within the reference length L

The optimum values of surface roughness for various seal

types is summarised below:-

PTFE Seals optimum Ra : 0.1 - 0.25 µm

Above 0.3µm :Effect dependant upon Rsk (skewness) Why choose P.T.F.E Composite Seals?

Rsk -1: Higher leakage, little wear Composite Seals were originally designed for low- friction or

Rsk < -1: High friction and wear high-temperature applications. The development of PTFE and

Below 0.1µm : Friction and wear increases PTFE Compounds in particular, with these capabilities, has

greatly extended the useful range of these seals far beyond

Rubber Seals Dynamic optimum Ra : 0.1 - 0.25 µm that of conventional Rubber / Elastomer based Lip-seals.

upto 0.4 µm : Slight increase in wear Designs based upon an understanding of lip-geometry and

above 0.4 µm : Wear leakage and friction increase use of the latest developments in material technology have

below 0.05 µm : High friction and wear allowed Composite Seals to become acceptable in the

Rubber Seals Static optimum Ra :< 0.8 µm normal sphere of operation of Lip-seals, not just in the

extremes of duty for which they were originally intended.

Polyurethane Seals optimum Ra: <0.25 µm

above 0.3 µm : Expect high wear and leakage

Axial scores : Do not effect seal performance if less than

0.05 µm in depth The optimum speed range for conventional Lip-seals

is 0.1 - 0.5 m/sec. and whilst speeds of up to 4 m/sec.

can be accommodated this, is only at the expense of

performance and life. Below 0.1 m/sec. and above 0.5 m/sec

Contamination within the system can occur due to the friction values rise sharply due to the breakdown of the

inadequate cleaning of parts before assembly or/and due lubricant film, causing friction and a build-up of heat. At

to operational debris from the seal and bearings. With temperatures above 50°C this additional heat can also

levels of contamination more intensive around the seal adversely affect the sealing material, causing swell, hardness

area than in the system generally. The effect of and mechanical property changes, with a resultant loss of

contamination is that of seal wear and damage usually in performance.

the form of axial scores. The extent of probability of Low-Friction seals are obviously desirable at these extremes

leakage will depend upon seal materials with PTFE being of speed or even through the optimum working range of

more prone to leakage when scored. Containments may Lip-seals when other factors are taken into account.

also lodge under the sealing lip allowing a leak path.

Bearing materials used in conjunction with seals may also

effect oil contamination due to wear debris with metal

bearings producing an increase in leakage probability The Frictional Heat developed per second within sliding

although reducing the surface roughness slightly when contact is :-

used with rods.

Pf = f.p.v.A(Watt)

Where:-

f = coefficient of friction

v = speed (m/sec.)

Hydraulic fluids contain molecules of air which is liberated p = load (N/mm²)

by agitation. Air bubbles then occur and an oil vapour A = dynamic contact area (mm²)

collects usually at the highest point in the system.

Compression of this mixture will result in a temperature

rise causing compression ignition. This process is

repeatable and is known as Diesel effect destroying the

seal if repeated frequently. The sealing arrangement may

be protected with the use of Phenolic or phosphor bronze

rings strategically housed. Sometimes air bubbles will be

forced over the seal face expanding as they move to the

low pressure side of the seal manifesting itself as axial

grooves and resulting in subsequent seal failure.

issue 1 - 20/10/98 1-2

ClaronPolyseal®

The optimum values of surface roughness for various seal types

is shown in the previous section.

Typical examples of the frictional loss of a Hydraulic

Cylinder at various pressures is as follows :-

100mm Ø Piston (fitted with DPW style seal), 60 mm P.T.F.E. Bearing Tape is specifically designed for use with

Ø Rod, 0.1 m/sec. speed P.T.F.E. Composite Seals. The nature of P.T.F.E. allows for a

Within the range 50 - 200 bar the loss attributable to manufactured size giving a tighter fit than ‘harder’ materials such

the DPW seal is fairly constant at around 0.8% of the as Phosphor-Bronze, Meehanite or Polyester Fabric. This

theoretical pulling power of the cylinder. The loss reduction in radial clearance gives a marginal improvement to

attributable to the rod seals is as follows :- the pressure capability of the seal but, more importantly,

protects the seal from contaminant particles within the system.

Rod seal Pressure Frictional Loss A combination of the design of the bearing and the

Style CPI 200 bar 180 Kg characteristics of P.T.F.E. allow the particles to become

150 bar 120 Kg embedded in the P.T.F.E. on the non-working face, thus also

50 bar 75 Kg protecting the steel counterface from scoring.

During use, bearing materials wear, causing debris and

Style CPU 200 bar 280 Kg contamination of the fluid. Extensive tests have shown that

Style CS6 200 bar 130 Kg particulate contamination >15µm within the fluid, increases with

the use of Phosphor-Bronze or Meehanite, and tends to

Style Frictional Loss decrease with the use of P.T.F.E. The harder debris created by

CPI 1% these bearings also has a greater effect upon seal performance.

CPU 2% Particulate contamination in the fluid surrounding the seal can

CS6 0.5% be over 100 times that in the main system due to the bearing

preventing flushing of the seal space. Increased contamination

From this example it can be seen that the CS6 Style in this area will increase the probability of a large enough

Composite Seals have distinct advantages over particle gaining access to the seal interface, causing damage

conventional lip seals in terms of frictional loss. and leakage.

Fluid Transport

It must be emphasised that Composite Seals do not

give as dry a rod as conventional Lip-Seals operating

within their optimum conditions.

The fitting of two single-acting Composite Seals in

tandem or the use of a double-acting wiper seal Style

941 will significantly contribute towards ultimate

performance.

From a practical point of view an absolutely dry rod

cannot be achieved without an increase in friction

causing a considerable reduction in seal life. For any

seal type, oil transport is essential but also variable

dependant upon the velocity, viscosity of the oil and

the surface finish of the contact surfaces.

Careful seal design, particularly in relation to the

contact area profile, optimises the amount of oil that

is transported back to the pressure side on the return

stroke..

Surface finish is an influencing factor on the

performance of a seal. For Composite Seals,

Cylinder bores and Rods should have a surface finish

between 0.1 - 0.4µm Ra.

Within the housing, static sealing surfaces should

have a finish better than 0.8µm Ra.

Even after prolonged use, Bronze Filled PTFE will not

have any significant effect on surface finish values.

Carbon and Glass filled PTFE are more abrasive and

will slightly reduce the surface roughness.

Surface finish can be affected by the use of hard

bearing materials such as Meehanite, Phosphor-

Bronze or Polyester-Fabric.

It is generally recommended that PTFE Bearing

Tape should be used with Composite Seals.

issue 1 - 20/10/98 1-3

You might also like

- Paper Mills Roller Coverings: Chemical ResistanceDocument8 pagesPaper Mills Roller Coverings: Chemical ResistancefapivaNo ratings yet

- Hydro-Turbine Main Shaft Axial Seals ofDocument13 pagesHydro-Turbine Main Shaft Axial Seals ofAnonymous Hy5Ir9QXNo ratings yet

- Hydraulic Seal Catalogue 2022Document423 pagesHydraulic Seal Catalogue 2022tepu msosa100% (1)

- Lexan Process Guide PDFDocument18 pagesLexan Process Guide PDFwantamanual100% (1)

- Rubber Seal - O Rings - IRIDocument35 pagesRubber Seal - O Rings - IRIGnaneshNo ratings yet

- Seal Off Centrifugal Pump ProblemsDocument6 pagesSeal Off Centrifugal Pump ProblemsArturo Valles TerrazasNo ratings yet

- Industrial Coatings XylanDocument3 pagesIndustrial Coatings XylanLiu YangtzeNo ratings yet

- Mechanical Seal Failure ModesDocument9 pagesMechanical Seal Failure Modespmdongre100% (2)

- Mechanical Seal Failure ModesDocument9 pagesMechanical Seal Failure ModesMostafa MahmoudNo ratings yet

- SKF Spectraseal: Sealing Solutions For Extreme Application ChallengesDocument5 pagesSKF Spectraseal: Sealing Solutions For Extreme Application ChallengesmiguelNo ratings yet

- Basics of DesignDocument10 pagesBasics of DesignKrishna MohanNo ratings yet

- 05348G Sample BuyNowDocument13 pages05348G Sample BuyNowrahittNo ratings yet

- Gland Packing Vs Mech Seals PDFDocument9 pagesGland Packing Vs Mech Seals PDFbratishkaityNo ratings yet

- Gland Packing Vs Mech SealsDocument9 pagesGland Packing Vs Mech SealsbratishkaityNo ratings yet

- Turbine Seal: Shaft SealsDocument4 pagesTurbine Seal: Shaft SealssienlangphiooNo ratings yet

- 3M 3015 VP Vapor Permeable Air Barrier TDS v8!18!17Document4 pages3M 3015 VP Vapor Permeable Air Barrier TDS v8!18!17Hari SantosoNo ratings yet

- Conformal Coating 101Document9 pagesConformal Coating 101khers_zal100% (2)

- Gasket EngineeringDocument28 pagesGasket EngineeringRohit DaveNo ratings yet

- Hydraulics WhitepaperDocument4 pagesHydraulics WhitepaperHUERTANESTORNo ratings yet

- Friction Optimization On Hydraulic Piston Rod Seals PDFDocument8 pagesFriction Optimization On Hydraulic Piston Rod Seals PDFbogdan hodor0% (1)

- An Overview of The Use of Rheology For Adhesive ManufacturersDocument8 pagesAn Overview of The Use of Rheology For Adhesive ManufacturersCublktigressNo ratings yet

- OM 002 Belt Conveyor Idler Instruct 6E74091AB9993Document5 pagesOM 002 Belt Conveyor Idler Instruct 6E74091AB9993Imran DahalanNo ratings yet

- Seal Arm TPE TapesDocument4 pagesSeal Arm TPE TapesJoeNo ratings yet

- Tribology of PolymersDocument8 pagesTribology of Polymerssuman AcharyNo ratings yet

- Gluing Components: Practical GluesDocument4 pagesGluing Components: Practical GluesonafetsNo ratings yet

- PTFE Slide BearingsDocument5 pagesPTFE Slide BearingsUlissipo1955No ratings yet

- Metallically Sealed Demountable Titanium Window of Industrial AcceleratorsDocument7 pagesMetallically Sealed Demountable Titanium Window of Industrial Acceleratorsabhayk99No ratings yet

- 3 MDocument9 pages3 Mriki_scribdNo ratings yet

- Pds-Cpd-Sikaflex Mortar Fix-UsDocument2 pagesPds-Cpd-Sikaflex Mortar Fix-UsBudhi KurniawanNo ratings yet

- Comparative Study of Uncoated Steel and Fluorocarbon Coated Steel in Lubricated Sliding ConditionsDocument4 pagesComparative Study of Uncoated Steel and Fluorocarbon Coated Steel in Lubricated Sliding ConditionsAkash BodhaleNo ratings yet

- Control Valve PackingDocument12 pagesControl Valve Packingmayur mahajanNo ratings yet

- 2016 - Stratmann - Influence of Operating Conditions and Additive Concentration On The Formation of Anti-Wear Layers in Roller Bearings (00000002)Document6 pages2016 - Stratmann - Influence of Operating Conditions and Additive Concentration On The Formation of Anti-Wear Layers in Roller Bearings (00000002)Vijay HumidificationNo ratings yet

- 1 - Coating Solutions For Centrifugal Compressor Fouling (LR)Document4 pages1 - Coating Solutions For Centrifugal Compressor Fouling (LR)Mokhammad Fahmi Izdiharrudin100% (1)

- 10 Hydraulics Tips You Need To Know: Outside Factors Are A Vital Component of Hydraulic SystemsDocument4 pages10 Hydraulics Tips You Need To Know: Outside Factors Are A Vital Component of Hydraulic SystemsGunjanNo ratings yet

- Painting GNDocument3 pagesPainting GNAd FwyNo ratings yet

- Refresh Refresh (Dynamic - Bypass - Reload) Click Here If You Are Not Automatically Redirected. For Assistance, Contact Your Network Support Team.Document10 pagesRefresh Refresh (Dynamic - Bypass - Reload) Click Here If You Are Not Automatically Redirected. For Assistance, Contact Your Network Support Team.Kelvin LimNo ratings yet

- Surface EngineeringDocument27 pagesSurface Engineeringchuahuipeng100% (1)

- AG 15400 Steelmaster+120SB Euk GBDocument10 pagesAG 15400 Steelmaster+120SB Euk GBparathasiNo ratings yet

- Knuuttila1999 13Document9 pagesKnuuttila1999 13Camilo Andrés Vargas JiménezNo ratings yet

- Seals and Sealing TechnologyDocument9 pagesSeals and Sealing Technology1sympatyagaNo ratings yet

- "Vibration Welding Technology": A Presentation OnDocument15 pages"Vibration Welding Technology": A Presentation OnRahul YadavNo ratings yet

- Cpei SopDocument5 pagesCpei SopCorrosion FactoryNo ratings yet

- SF 0010 0 Metco 320NS PDFDocument8 pagesSF 0010 0 Metco 320NS PDFMehdi KoneshlouNo ratings yet

- A Guide To Laminate Rigid FR4 Board To Rigid Heat Sink: Technical Bulletin January, 2005Document3 pagesA Guide To Laminate Rigid FR4 Board To Rigid Heat Sink: Technical Bulletin January, 2005Farid AhmadNo ratings yet

- Seal SelectionDocument8 pagesSeal SelectionDiwakar NigamNo ratings yet

- Characteristics - of Solder - PasteDocument10 pagesCharacteristics - of Solder - PasteselvakumarNo ratings yet

- Composite FabricationDocument8 pagesComposite FabricationAbu Bakar SiddiqueNo ratings yet

- Photoresist CoatingDocument2 pagesPhotoresist CoatinglongsadforNo ratings yet

- Brush Seals and Common Issues in Brush Seal Applications: Mahmut Faruk AksitDocument18 pagesBrush Seals and Common Issues in Brush Seal Applications: Mahmut Faruk AksitАлена ЩщщNo ratings yet

- The Effect of Counter-Face Roughness On The Tribological Behavior of Filled and Unfilled PTFEDocument7 pagesThe Effect of Counter-Face Roughness On The Tribological Behavior of Filled and Unfilled PTFEfacebookdeepuNo ratings yet

- Thermoplastic Polyolefin Based Sheet Roofing: Standard Specification ForDocument3 pagesThermoplastic Polyolefin Based Sheet Roofing: Standard Specification Forasma hamzaNo ratings yet

- LT2662 Loctite Design Guide Bonding Rubber Thermoplastic ElastomersDocument78 pagesLT2662 Loctite Design Guide Bonding Rubber Thermoplastic ElastomersJose Leon Villalobos100% (1)

- Basf Masterseal NP 474 TdsDocument3 pagesBasf Masterseal NP 474 TdsAdnan ČehajićNo ratings yet

- TA - 031 - en General Information For Diaphragm SealsDocument5 pagesTA - 031 - en General Information For Diaphragm Sealstudonghoa tmpNo ratings yet

- Vulkem Athletic Play Surface Application SpecsDocument4 pagesVulkem Athletic Play Surface Application SpecsOgbedande Awo OrunmilaNo ratings yet

- PP Cast FilmDocument4 pagesPP Cast FilmMiguel MarujoNo ratings yet

- Lubrication Model in Forging ProcessDocument10 pagesLubrication Model in Forging Processnimesh singhNo ratings yet

- Seismic Response of Precast Prestressed Concrete Frames With Partially Debonded Tendons (1993)Document12 pagesSeismic Response of Precast Prestressed Concrete Frames With Partially Debonded Tendons (1993)Sofía Córdoba SáenzNo ratings yet

- XOMOX JacketedPlugValveDocument14 pagesXOMOX JacketedPlugValvedsiucNo ratings yet

- 4024q1 Specimen PaperdocxDocument12 pages4024q1 Specimen PaperdocxLeses MayNo ratings yet

- Pages From Certificate of Conformance For Lot-2 ASTM A490M Bolts, Nuts &washers (Key's and Clamp)Document1 pagePages From Certificate of Conformance For Lot-2 ASTM A490M Bolts, Nuts &washers (Key's and Clamp)Krishna VachaNo ratings yet

- Design of Slabs: - Types of Slabs - One-Way Slabs - Two-Way SlabsDocument21 pagesDesign of Slabs: - Types of Slabs - One-Way Slabs - Two-Way SlabsSharad SaterneNo ratings yet

- 175 026510Document2 pages175 026510Abu Anas M.SalaheldinNo ratings yet

- Boq For Store ShedDocument8 pagesBoq For Store ShedSaqib NawazNo ratings yet

- AED Design Requirements:: Breaker and Conductor SizingDocument4 pagesAED Design Requirements:: Breaker and Conductor SizingRicky Respondo TindocNo ratings yet

- Vessel Nozzle PDFDocument30 pagesVessel Nozzle PDFEugenia LorenzaNo ratings yet

- Cirebon Power Plant - R0Document213 pagesCirebon Power Plant - R0Teguh Wiradinata0% (1)

- 04 Melt Indexer Primer PDFDocument4 pages04 Melt Indexer Primer PDFNia SyafiqqNo ratings yet

- BecherDocument7 pagesBechervalholNo ratings yet

- Cold Weather Concrete ProceduresDocument1 pageCold Weather Concrete ProceduresVetrivel MuruganNo ratings yet

- Inspection Report PART 3Document53 pagesInspection Report PART 3renzo1221No ratings yet

- Exam Steel DesignDocument2 pagesExam Steel DesignAndrew PortugalNo ratings yet

- 1994 Merriespruit Disaster Paper Fourieetal.01Document14 pages1994 Merriespruit Disaster Paper Fourieetal.01Mart MugoniNo ratings yet

- Needles and Loop CatalogueDocument10 pagesNeedles and Loop CatalogueCamila Carla CapriglioniNo ratings yet

- Sheet MetalDocument46 pagesSheet Metalpreetham shekarNo ratings yet

- Weld Repairs:: Weld Repairs Can Be Divided Into Two Specific Areas: 1) Production Repairs 2) in Service RepairsDocument59 pagesWeld Repairs:: Weld Repairs Can Be Divided Into Two Specific Areas: 1) Production Repairs 2) in Service RepairsThe Engineers EDGE, CoimbatoreNo ratings yet

- Sulfate AttackDocument1 pageSulfate AttackbozarromegustaNo ratings yet

- Click' Chemistry in Polymer and Materials Science: ReviewDocument40 pagesClick' Chemistry in Polymer and Materials Science: ReviewDilip Kumar TiwariNo ratings yet

- Aircraft Metal Structural RepairDocument4 pagesAircraft Metal Structural Repairm sai ravi tejaNo ratings yet

- Copper-Brazed Steel Tubing: Standard Specification ForDocument4 pagesCopper-Brazed Steel Tubing: Standard Specification ForSofiaJabadanEspulgar100% (1)

- Lanco Antifloat D-14, TDSDocument2 pagesLanco Antifloat D-14, TDSZein HayekNo ratings yet

- RRLDocument5 pagesRRLEarl averzosaNo ratings yet

- THE IDEAL GAS (Topic6)Document17 pagesTHE IDEAL GAS (Topic6)ch0k3 iiiNo ratings yet

- For EntingDocument5 pagesFor EntingVicente TanNo ratings yet

- C0051-11 Standard Terminology Relating To Lime and Limestone (As Used by The IndustryDocument5 pagesC0051-11 Standard Terminology Relating To Lime and Limestone (As Used by The IndustryAnonymous YwFJrk0yCNo ratings yet

- (Pha6113 Lec) 1ST Shifting ReviewerDocument28 pages(Pha6113 Lec) 1ST Shifting ReviewerAndrei RoqueNo ratings yet

- Term Test For Class-12th JEE (Main) - 2024 - Term Test-3 - QP - 25-11-23Document10 pagesTerm Test For Class-12th JEE (Main) - 2024 - Term Test-3 - QP - 25-11-23Sai Babu GangulaNo ratings yet