Professional Documents

Culture Documents

FGDFG

Uploaded by

Eduardo Fernandez Daza0 ratings0% found this document useful (0 votes)

3 views9 pagesgfdgsdgds

Original Title

fgdfg

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentgfdgsdgds

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views9 pagesFGDFG

Uploaded by

Eduardo Fernandez Dazagfdgsdgds

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 9

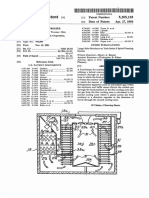

United States Patent 11)

Ammeraal

on 4,203,512

[45] May 20, 1980

[54] HELICAL CONVEYOR

(75] Inventor: Thomas C. M. Ammeraal, Wormer,

Netherlands

[73] Assignee: Ammeraal Nederland B. V.,

Wormerveer, Netherlands

[21] Appl. No: 932,664

[22] Filed: Aug. 10, 1978

{30} Foreign Application Priority Data

‘Avg. 12,1977 [NL] | Netherlands va TOROS.

{SI} tat, cl?

(3] US.

[58] Field of Search ..

B6SG 37/00; B6SG 21/18

. 198/594; 198/586,

198/778

w-. 414/139, 144, 145;

198/560, $86, $91, $94, $95, 778

[56 References Cited

U.S. PATENT DOCUMENTS

2,267,970 12/1941 Boal

3595375 7/1971 Kaufman et

198/778

198/778 X

Primary Examiner—Ieffrey V. Nase

Auorney, Agent, or Firm—Kane, Dalsimer, Kane,

Sullivan and Kurucz

bn ABSTRACT

maveyor for transporting cargo or the Il

cal stretch, having a substantially vertical

central axis and equipped with an endless conveyor belt,

the upper run of this conveyor belt following a helical

th and ending at the lower end and at the upper end.

in a substantially horizontal generating line. A feed or

discharge conveyor, which is displaceable with respect

to the helical conveyor, joins the upper run of the con-

veyor belt of the helical conveyor.

20 Claims, 8 Drawing Figures

4,203,512

Sheet 1 of 4

U.S. Patent — May 20, 1980

U.S. Patent May 20, 1980 Sheet 2 of 4 4,203,512

U.S. Patent May 20, 1980 Sheet 3 of 4 4,203,512

U.S. Patent May 20, 1980 Sheet 4 of 4 4,203,512

4,203,512

1

HELICAL CONVEYOR

BACKGROUND OF THE INVENTION

The invention relates to a helical conveyor for the

transport along a helical stretch, with a substantially

vertical central axis and equipped with an endless con-

veyor belt, the upper run of this conveyor belt follow-

ing a helical path and ending at the lower end and at the

upper end in a substantially horizontal generating line.

SUMMARY OF THE INVENTION

It is an object of the present invention to provide a

helical conveyor which is especially suitable for unload-

ing or loading a ships hold or the like, where the cargo

must be supplied to or removed from the helical con-

veyor in many different directions and at different lev-

els

‘According to the invention a feed or discharge con-

vveyor, which is displaceable with respect to the helical

conveyor, joins the upper run of the conveyor belt of

the helical conveyor,

The displaceable feed or discharge conveyor allows

the goods to be supplied to or removed from the helical

conveyor in numerous different directions and at differ-

ent levels.

If the junction of the feed or discharge conveyor to

the upper run of the conveyor belt of the helical con-

vveyor is located above the lower end thereof, the dis-

placeable feed or discharge conveyor may join the

upper run of the conveyor belt of the helical conveyor

through a further belt conveyor for the transport

through a circular bend, said further belt conveyor

being connected to said feed or discharge conveyor, the

direction of motion of said further belt conveyor and

that of the helical conveyor substantially coinciding at

their junction.

If the feed or discharge conveyor has to join the

lower end of the upper run of the conveyor belt of the

helical conveyor according to the invention, a first

solution of the invention consists in that one end of an

intermediate conveyor, which follows a path in a sub-

stantially horizontal plane, adjoins the lower end of the

‘upper run of the conveyor belt of the helical conveyor,

the other end of said intermediate conveyor being re-

‘moved farther than its aforementioned end from the

vertical central axis of the helical conveyor, s0 that

other end of the intermediate conveyor lies outside the

vertical projection of the helical path of the conveyor

belt of the helical conveyor on the aforementioned

horizontal plane, while the feed or discharge conveyor

is displaceable with respect to said intermediate con-

veyor and joins this intermediate conveyor.

‘According to this arrangement, the intermediate con-

veyor may travel through a path of at least 360 degrees,

composed of a plurality of circular bends.

An alternative embodiment of the helical conveyor

according to the invention is characterized in that a first

belt conveyor adapted for the transport through a cir-

cular bend is positioned below the helical conveyor,

while an auxiliary helical conveyor is mounted below

said first belt conveyor, a lower belt conveyor adapted

for the transport through a circular bend being. posi

1ed underneath said auxiliary helical conveyor, the

central axes of the helical conveyor and of the auxiliary

helical conveyor being aligned with each other, while

the centers of the two belt conveyors lie on a line coin-

ciding with these center lines, the first belt conveyor

15

2

0

45

35

©

6s

2

being connected to the auxiliary helical conveyor and

being rotatable together with said auxiliary helical con-

veyor about the central axis of this auxiliary helical

conveyor, the lower belt conveyor joining the feed or

discharge conveyor.

The lower belt conveyor may also be rotatable about

said central axis and may be fixedly connected to the

feed of discharge conveyor.

The lower belt conveyor may be rotatable through a

path of at least 360° and may be coupled over a part of

this path with the auxiliary helical conveyor, so that this

auniliary helical conveyor and said first belt conveyor

follow the rotational movement of the lower belt con-

veyor within said part of the path.

BRIEF DESCRIPTION OF THE DRAWING

The invention will be explained hereinafter with ref-

erence to the drawing, which illustrates several embodi-

ments of a helical conveyor according to the invention

by way of example.

FIG. 1 is a diagrammatic perspective view of a heli-

cal conveyor according to the invention.

FIG. 2 is a diagrammatic lateral view of the lower

part of the helical conveyor according to FIG. 1, which

joins an intermediate conveyor.

FIG. 3 is a diagrammatic top view of the lower part

of the helical conveyor and of the intermediate con-

vveyor according to FIG. 2,

FIG. 4 is a diagrammatic top view of the lower part

of the helical conveyor and of a co-operating disk.

FIG. 5 is a diagrammatic top view of a helical con-

veyor according to the invention, wherein the feed or

discharge conveyor joins this helical conveyor through

a belt conveyor for the transport along a circular bend,

the junction being located above the lower end of the

helical conveyor.

FIG. 6 is a diagrammatic view of a junction for the

feed or discharge conveyor.

FIG. 7is a diagrammatic top view of an embodiment

of an intermediate conveyor construction below the

helical conveyor.

FIG. is a diagrammatic lateral view of the interme-

diate conveyor construction according to FIG. 7.

DESCRIPTION OF SEVERAL PREFERRED

EMBODIMENTS

FIG. 1 is a diagrammatic view of a helical conveyor

for the transport along a helical stretch, with a vertical

central axis 2. Ths helical conveyor 1 has been lowered

into the hold of a ship 3 and serves, in the embodiment

shown in FIG. 1, for removing goods upwardly from

this hold. The upper end of the helical conveyor I joins

2 discharge conveyor belt (not shown), which passes

through a duct 4 which supports the helical conveyor 1.

This discharge duct 4 is carried on a mobile carrier

frame 8. The course of the discharge duct 4 may be

‘modified by means of cables in such a manner that the

height ofits two ends can be independently adjusted.

‘The discharge end of the discharge conveyor belt can

transfer the goods carried thereon to one ofa plurality

of superimposed conveyor belts 6

The helical conveyor 1 is equipped with an endless

conveyor belt 7, the upper run 7 of which follows a

helical path and ends at the lower end 8 in a substan-

tially horizontal generating line.

The upper end of the upper run 7’ of the conveyor

belt 7 likewise ends ina substantially horizontal generat-

4,203,512

3

ing line, which joins the discharge conveyor belt in the

duct 4

‘In the embodiment according to FIGS. 2 and 3, an

end 9 of an intermediate conveyor 10, which follows a

path of at least 360 degrees in a horizontal plane, adjoins

the lower end 8 of the upper run 7' of the conveyor belt

1Tof the helical conveyor 1.

‘The other end 11 of this intermediate conveyor 10 is

removed farther than its end 9 from the vertical central

axis 2, as FIG. 3 clearly indicates. The end portion 12 of

the intermediate conveyor 10 les outside the vertical

projection 13 ofthe helical path of the conveyor belt 7

Of the helical conveyor 1 on the horizontal plane of the

path of the intermediate conveyor 10.

‘A feed conveyor 14, which is preferably adjustable in

length, is displaceable at its end 15 on a rail 16 along the

intermediate conveyor 10, and is approximately tangen-

tial to this intermediate conveyor 10.

‘As an alternative, the feed conveyor 14 can join the

intermediate conveyor 10 through a further belt con-

veyor (not shown) connected thereto and adapted for

the transport through a circular bend, the direction of

motion of this further belt conveyor and that of the

intermediate conveyor 10 being at least approximately

equal at their junction. In this case, an end ofthe further

belt conveyor for the transport through a circular bend

is naturally displaceable on the rail 16 along the inter-

mediate conveyor 10.

Tn yet another embodiment, the feed conveyor 14 in

its various postions may always be at approximately

right angles to the outer periphery of the intermediate

conveyor 10.

In the embodiment shown in FIGS. 2 and 3, the inter-

mediate conveyor 10 is composed of a frst belt con-

vveyor 10/ which joins the lower end 8 ofthe upper run

of the conveyor belt 7 of the helical conveyor 1, and

which travels through a circular bend of 180 degrees,

With a maximum radius that is approximately equal to

that ofthe vertical projection 13 ofthe outer side of the

helical path of the conveyor belt 7 of the helical con-

veyor 1 on the horizontal plane, and with its center

lying on the vertical central axis 2 of the helical con-

Veyor 1; and of a second belt conveyor 10", which

adjoins the first belt conveyor 10° and which travels

through a circular bend of approximately 220 degrees,

witha different center and with alarger radius than that

ofthe first belt conveyor 10.

In FIG. 3, the feed conveyor 14, in the position

shown in solid lines, approximately adjoins the free

outer end 11 ofthe belt conveyor 10". The goods deliv-

ered by the feed conveyor 14 travel along the two belt

conveyors 10” and 10’ before reaching the lower end 8

of the upper run T' of the conveyor belt 7 of the helical

conveyor 1. Another postion ofthe feed conveyor 16is

shown in FIG. 3 in dash-and-dot-lines.

FIG. 3 shows in part the lower turn 17 of the helical

path of the upper run 7’ of the conveyor belt 7 of the

helical conveyor 1. The goods delivered by the feed

conveyor 14 are marked (a), (b), (c) in FIG. 3, the

004s (€), (D, (@), located below the illustrated part of

the lower turn 17, being indicated in dash-and-dot-lnes.

FIG. 6 shows thatthe end 15 of the feed conveyor 14

(or the end of a belt conveyor connected thereto and

adapted forthe transport along a circular bend) and the

intermediate conveyor 10 may join through a driven

roller conveyor 18 which comprises a transfer roller 19

and which gradually bridges the difference in level

38

©

4

Although in the embodiment shown in FIGS. 2 and 3

the helical conveyor 1 is used for unloading the hold of

a ship 3, it may also be applied for loading purposes.

‘The goods are then transported from a conveyor belt 6

vvia the duct 4 to the helical conveyor 1, whereupon

they are lowered along this helical conveyor 1 to the

intermediate conveyor 10, from where the goods may

bee discharged in any desired direction by means of the

conveyor 14, which in this case operates as a discharge

conveyor. The roller conveyor 18, equipped with the

transfer roller 19, here serves again for bridging the

difference in level.

FIG. 4 shows an embodiment of the helical conveyor

1 according to the invention, in which a rotatably sup-

ported disk 20, which is connected to a drive means (not

shown), joins the lower end 8 of the upper run 7' of the

conveyor belt 7. This disk 20 extends in a horizontal

plane. The radius of the disk 20 is larger than that of the

Vertical projection of the outer side of the helical path

of the conveyor belt 7 of the helical conveyor 1 on the

plane of the disk 20. This vertical projection 13 is tan-

gential to the outer periphery of the disk 20 in the em-

bodiment shown.

The direction of motion of the disk 20 atthe junction

is substantially equal to that of the helical conveyor 1.

‘The lower end of the helical conveyor 1, which joins

the disk 20, may be equipped with a roller conveyor 18

‘which comprises a transfer roller and which bridges the

difference in level.

‘The end 15 of the feed or discharge conveyor 14 is

displaceable on a ral along the outer side of the disk 20.

‘The conveyor 14s approximately tangential to the disk

20 over at least part of its length. In order to bridge the

difference in level, the end 15 of the feed or discharge

‘conveyor 14s again equipped with a roller conveyor 18,

which comprises a transfer roller. The feed or discharge

‘conveyor 14 may be adjustable in length.

‘Asan alternative for the embodiment show, the feed

‘or discharge conveyor 14 may also join the disk 20

‘through a further belt conveyor (not shown) connected

thereto and adapted for the transport through a circular

bend, the direction of motion of this further belt con-

vveyor and that of the disk 20 being approximately equal

to their junction. The further belt conveyor may be

equipped with a roller conveyor which comprises a

transfer roller.

Furthermore, in yet another embodiment, the feed or

discharge conveyor 14 may be approximately radial

‘with respect to the disk 20 in its various positions.

FIG. § shows an embodiment of the helical conveyor

1 according to the invention, in which the displaceable

feed or dischage conveyor 14 joins the upper run 7’ of

the conveyor belt 7 above the lower end 8 thereof,

through a farther belt conveyor 21 connected to the

conveyor 14 and adapted for the transport through a

circular bend, The end of the belt conveyor 21 is again

‘equipped with a roller conveyor 18 which comprises a

transfer roller.

Tn the embodiment according to FIG. 5, the end of

the belt conveyor 21 adapted for the transport through

a circular bend has a width that is smaller than the

‘width of the upper part 7’ of the conveyor belt 7 of the

helical conveyor 1, so that, when the conveyor 16 is,

used as a discharge conveyor, only part of the goods are

discharged by means of this discharge conveyor 14,

while the remaining goods continue to follow the heli-

cal path of the helical conveyor 1, from which they are

‘withdrawn at a different level.

4,203,512

5

Alternatively, the feed or discharge conveyor 14 and

the belt conveyor 21 may have such a width that they

‘can accommodate the complete flow of goods supy

to or discharged from the helical conveyor 1.

FIG. 7 and 8 show another embodiment of the helical

conveyor 1 according to the invention which is pro-

vided with an intermediate conveyor construction be-

tween this helical conveyor 1 and the feed or discharge

conveyor, which intermediate construction has a con-

tour which is not exceeding the contour of the helical

conveyor 1. In this embodiment a first belt conveyor 22

adapted for the transport through a circular bend is

positioned below the helical conveyor 1. An auxiliary

helical conveyor 23 is mounted below this first belt

conveyor 22 while a lower belt conveyor 24 adapted for

the transport through a circular bend is positioned un-

derneath this auxiliary helical conveyor 23.

The central axes of the helical conveyor 1 and of the

ausiliary helical conveyor 23 are aligned with each

‘other, while the centers of the belt conveyors 22 and 24

Tie on a Tine coinciding with these center lines.

Further the upper runs of the endless conveyor belts

of both belt conveyors 22, 24 lie in approximately hori-

zontal planes, while the cylindrical envelope of the

helical conveyor 1 touches both belt conveyors 22, 24

as well as the ausiliary helical conveyor 23.

The upper belt conveyor 22is connected to the auxil-

iary helical conveyor 23. The upper belt conveyor 22

and the auxiliary helical conveyor 23 may be rotated

together about the central axis of the auxiliary helical

conveyor 23.

In the embodiment shown in FIGS. 7 and 8 the lower

belt conveyor 24 is also rotatable about this central axis

and is fixedly connected to the feed or discharge con-

veyor. Both belt conveyors 22, 24 are adapted for the

transport through a circular bend of 180° but larger belt

conveyors may be applied.

‘The lower belt conveyor 24 may be rotated through

‘8 path of at least 360° and is coupled over a part of this

path—in the embodiment shown over a part of

180°—with the auxiliary helical conveyor 23, so that

this ausiliary helical conveyor 23 and the upper belt

conveyor 22 follow the rotational movement of the

ower belt conveyor 24 over this part of the path.

In the embodiment shown in FIGS. 7 and the feed

‘or discharge conveyor comprises a further belt con-

veyor 25 for the transport through a circular bend. This

farther belt conveyor 25 is connected to the lower belt

conveyor 24 in such manner that the direction of mo-

tion of said further belt conveyor 25 and that of the

ower belt conveyor 24 substantially coincide at their

Junction.

This belt conveyor 25 is connected to a plurality of

straight belt conveyors 26 through a roller conveyor,

which may comprise a transfer roller.

Further, the lower end of the helical conveyor 1

and/or the lower end of the auxiliary helical conveyor

23 may be equipped with a roller conveyor, which may

‘comprise a transfer roller.

Of course, the feed or discharge conveyor may be

constructed in different manners and may be displace-

able with respect to the lower belt conveyor 24, or may

be directed radially

Further, the length of the feed or discharge conveyor

may be adjustable

‘According to the invention, a helical conveyor 1 is

provided, which allows the material to be supplied to or

to be discharged from the helical conveyor 1 in many

2s

30

3

4s

0

55

6

6

different directions and at different levels, use being

made of the feed or discharge conveyor, which is dis-

placeable with respect to the helical conveyor 1 and

which may be equipped with a further belt conveyor

adapted for the transport along a circular bend. As a

result thereof the range of possible applications of the

helical conveyor 1 is very substantially extended.

The invention is not restricted to the embodiments

shown in the drawing by way of example, which may

be varied in various manners within the scope of the

appended claims.

Telaim:

1. A helical conveyor for transporting along 2 helical

stretch, having a substantially vertical central axis and

‘equipped with an endless conveyor belt; an upper run of

said conveyor belt following a helical path and ending.

at a lower end and at an upper end in a substantially

horizontal generating line; one end of an intermediate

conveyor, which follows a path in a substantially hori-

zontal plane, adjoining the lower end of the upper run

of the conveyor belt of the helical conveyor; the other

‘end of said intermediate conveyor being removed far-

ther than its aforementioned end from the vertical cen-

tral axis of said helical conveyor so that said other end

of said intermediate conveyor lies outside the vertical

projection of the helical path of said conveyor belt of

said helical conveyor on the aforementioned horizontal

plane; and a feed or discharge conveyor, displaceable

‘with respect to said intermediate conveyor, joining said

intermediate conveyor.

2A helical conveyor as claimed in claim 1, wherein

the intermediate conveyor travels through a path of at

Teast 360 degrees, which is composed of a plurality of

circular bends.

3A helical conveyor as claimed in claim 2, wh

the intermediate conveyor is composed of two ad

ing belt conveyors each adapted for the transport

through a circalar bend, wherein the first one of said

‘two belt conveyors joins the lower end of the upper run

of the conveyor bel of the helical conveyor and travels.

through a bend of approximately 180 degrees, with its

‘center located on the vertical central axis of the helical

conveyor, while the second one of said two belt con-

veyors travels through a circular bend of approximately

220 degrees with a different center and with a larger

radius than that ofthe first one of said two belt convey-

ors

4. A helical conveyor as claimed in claim 3, wherein

an end of the feed or discharge conveyor is displaceable

along the intermediate conveyor, suid feed or discharge

conveyor being approximately tangential to said inter-

mediate conveyor over at least part of its length.

5. A helical conveyor as claimed in claim 3, wherein.

the feed or discharge conveyor joins the intermediate

conveyor through a further belt conveyor for the trans-

port through a circular bend, said further belt conveyor

being connected to the feed or discharge conveyor, the

direction of motion of said further belt conveyor and

that of the intermediate conveyor being substantially

equal at their junction.

‘6. A helical conveyor as claimed in claim 3, wherein

the feed or discharge conveyor is approximately at right

angles to the outer periphery of the intermediate con-

vveyor.

7. A helical conveyor for transporting along a helical

stretch, having a substantially vertical axis and

‘equipped with an endless conveyor belt; an upper run of

said conveyor belt following a helical path and ending

4,203,512

7

at a lower end and at an upper end in a substantially

horizontal generating line; the lower end of the upper

run of the conveyor belt of the helical conveyor joining,

a rotatably supported disk which is connected to a drive

‘means and which extends in a substantially horizontal

plane, said disk having a radius which is larger than that

of the vertical projection of the helical path of the con-

-veyor belt of the helical conveyor on said substantially

horizontal plane, the direction of motion of the disk at

the junction being substantially equal to that of the

conveyor belt of the helical conveyor; and a feed or

discharge conveyor, displaceable with respect to ssid

dia, joining si disk

‘conveyor as claimed in claim 7, wherein

the verueal projection of the helical path of the con-

vveyor belt of the helical conveyor on the disk is at least

approximately tangential to the outer periphery of the

disk.

9. A helical conveyor as claimed in claim 8, wherein

‘an end of the feed or discharge conveyor may be dis-

placed over the disk, said feed or discharge conveyor

being approximately tangential to the disk over at least

part of its length.

10. A helical conveyor as claimed in claim 8, wherein

the feed or discharge conveyor joins the disk through a

further belt conveyor for the transport through a circu-

lar bend, the direction of motion of said further belt

conveyor and that of the disk being approximately

equal at their junction.

‘11. A helical conveyor as claimed in claim 8, wherein

the feed or discharge conveyor extends approximately

radial with respect to the disk.

12. A helical conveyor as claimed in claim 11,

wherein the lower end of the helical conveyor, which

Joins the disk, is equipped with a roller conveyor which

‘comprises a transfer roller.

13. A helical conveyor for transporting along a heli-

‘eal stretch, having a substantially vertical central axis,

‘and equipped with an endless conveyor belt; an uppet

run of said conveyor belt following a helical path and

lower end and an upper end in a substan-

tially horizontal generating line; wherein a first belt

conveyor adapted for transporting through a circular

‘bend is positioned below the helical conveyor; an auxil-

2s

3

8

ing through a circular bend being positioned beneath

said auxiliary helical conveyor, the central axes of the

helical conveyor and of the auxiliary helical conveyor

being aligned with each other, the centers of the two

belt conveyors lying on a line coinciding with said cen-

tral axes, the first belt conveyor being connected to the

auxiliary helical conveyor and being rotatable together

with said auxiliary helical conveyor about the central

axis of the auziliary helical conveyor, the lower belt

conveyor joining a feed or discharge conveyor.

14. A helical conveyor as claimed in claim 13,

wherein the lower belt conveyor is also rotatable about

said central axis and is fixedly connected to the feed or

discharge conveyor.

45. A helical conveyor as claimed in clsim 16,

wherein the lower belt conveyor is rotatable through &

path of at least 360° and is coupled over a part of this

path with the auxiliary helical conveyor, 30 that this

auxiliary helical conveyor and said first belt conveyor

follow the rotational movement of the lower belt con-

vveyor within said part of the path.

16. A helical conveyor #8 claimed in claim 15,

wherein both belt conveyors are each adapted for the

transport through a circular bend of at least 180°.

17. A helical conveyor ss claimed in claim 16,

‘wherein the upper runs of the endless conveyor belts of

both belt conveyors lie in approximately borizontal

planes.

18. A helical conveyor as claimed in claim 17,

wherein the cylindrical envelope of the helical con-

‘veyor touches both belt conveyors as well as the auxil-

iary helical conveyor.

19. A helical conveyor as claimed in claim 18,

wherein the feed or discharge conveyor comprises &

farther belt conveyor adapted for the transport through

a circular bend, said further belt conveyor being con-

nected to the lower belt conveyor in such manner that

the direction of motion of said further belt conveyor

and that of the lower belt conveyor substantially coin-

cide at their junction.

20. A helical conveyor ss claimed in claim 19,

wherein a further belt conveyor is connected to a

straight belt conveyor through a roller conveyor,

inry helical conveyor is mounted below said fist belt 45 which comprises a transfer roller,

conveyor; alower belt conveyor, adapted for transport-

55

6s

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- GHDFGHFGHDocument10 pagesGHDFGHFGHEduardo Fernandez DazaNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Us 5031751Document9 pagesUs 5031751Eduardo Fernandez DazaNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- GHFGDocument4 pagesGHFGEduardo Fernandez DazaNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Us 4944162Document14 pagesUs 4944162Eduardo Fernandez DazaNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- NMVBNMDocument10 pagesNMVBNMEduardo Fernandez DazaNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- HGFHDDocument13 pagesHGFHDEduardo Fernandez DazaNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- NMVBNMDocument10 pagesNMVBNMEduardo Fernandez DazaNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- FGDFGDocument3 pagesFGDFGEduardo Fernandez DazaNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- JGHJFHDocument9 pagesJGHJFHEduardo Fernandez DazaNo ratings yet

- GFGHFDocument8 pagesGFGHFEduardo Fernandez DazaNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- GHFGHDocument15 pagesGHFGHEduardo Fernandez DazaNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- HGFHDDocument8 pagesHGFHDEduardo Fernandez DazaNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- HFGHDocument5 pagesHFGHEduardo Fernandez DazaNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- GFDGDDocument17 pagesGFDGDEduardo Fernandez DazaNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- DGDSFGDocument6 pagesDGDSFGEduardo Fernandez DazaNo ratings yet

- GfdgsDocument10 pagesGfdgsEduardo Fernandez DazaNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- FGDGDocument12 pagesFGDGEduardo Fernandez DazaNo ratings yet

- GDHFGHDocument11 pagesGDHFGHEduardo Fernandez DazaNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- GfdgsDocument10 pagesGfdgsEduardo Fernandez DazaNo ratings yet

- GHDFGHFDocument11 pagesGHDFGHFEduardo Fernandez DazaNo ratings yet

- GDFGDFDocument8 pagesGDFGDFEduardo Fernandez DazaNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- BCVBCDocument10 pagesBCVBCEduardo Fernandez DazaNo ratings yet

- GDFGSDFDocument13 pagesGDFGSDFEduardo Fernandez DazaNo ratings yet

- GFGFHDocument12 pagesGFGFHEduardo Fernandez DazaNo ratings yet

- Wo2007134879a1 PDFDocument19 pagesWo2007134879a1 PDFEduardo Fernandez DazaNo ratings yet

- European Patent Application: Vibratory Flash DryerDocument15 pagesEuropean Patent Application: Vibratory Flash DryerEduardo Fernandez DazaNo ratings yet

- Process Description and Optimization of The Flash Dryers at Polokwane SmelterDocument6 pagesProcess Description and Optimization of The Flash Dryers at Polokwane SmelterEduardo Fernandez DazaNo ratings yet

- Us20100146814a1 PDFDocument12 pagesUs20100146814a1 PDFEduardo Fernandez DazaNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- GDFGDFDocument6 pagesGDFGDFEduardo Fernandez DazaNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)