Professional Documents

Culture Documents

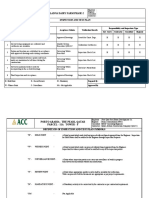

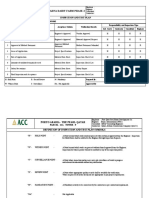

INSPECTION AND TEST PLAN

Uploaded by

Joseph Perez0 ratings0% found this document useful (0 votes)

31 views1 pageSample Format for reference

Original Title

ITP LTS_v3

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSample Format for reference

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

31 views1 pageINSPECTION AND TEST PLAN

Uploaded by

Joseph PerezSample Format for reference

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 1

INSPECTION AND TEST PLAN -

Developer: Coordinator: Site Representative:

Contractor: Constructor Site Representative:

Welding Supervisor:

Case No: Sub-contractor: Witness, Hold & Surveillance points added to ITP

Works classification: Field Tester:

Works description: ITP Prepared by: Reviewed by: Client Representative:

Date / / Date / / Date / /

No Construction/Inspection Inspection Procedure & Acceptance Criteria contrac client Record Comment

Activity tor

1 Prestart/Site establish Visual check. X H S Checklist

2 Approved materials on Visual check approved materials. Quantity and condition. Checklist completed. X W S Checklist

Site and delivered

3 Accredited personnel on site Check Accreditation (ensure that accreditation for welding is checked) X H S Checklist

4 Welding technician for each Visual check that pilot welds are done, Welds to be checked to DVS standard X H S Checklist

welding machine and each

pipe size

5 Welding procedure Butt welding/Electro fusion welding to DVS STANDARD X H S Checklist

prequalification

7 Welding on site Welding to be carried out to pre-approved procedure X W S Pgcc ms

9 Selecting Welds for testing Ensure that test welds are taken X H S Checklist

10 Testing Pressure (100%), deflection, Testing of sample welds X W S Test Results

11 Pre-Connection Inspection – Visual inspection to all parties standards H H H Sewer Main

Main Flow Management procedures as per Job Specific Schedule Letter Connection

Report

Validation No Amendment Date Reviewed Symbol Legend

I certify that the works have been X Inspection by

constructed in accordance with

Standards and the Inspection and H Mandatory Hold Point

Test Plan.

Coordinator W Option given to inspect

Date / /

S Surveillance

Page 1 of 1

You might also like

- Baladna Dairy Farm Phase 2 Blinding Concrete Inspection PlanDocument3 pagesBaladna Dairy Farm Phase 2 Blinding Concrete Inspection PlanMelih SENTURKNo ratings yet

- Project: Baladna Dairy Farm Phase-2: Inspection and Test PlanDocument3 pagesProject: Baladna Dairy Farm Phase-2: Inspection and Test PlanMelih SENTURKNo ratings yet

- Project: Baladna Dairy Farm Phase-2: Inspection and Test PlanDocument4 pagesProject: Baladna Dairy Farm Phase-2: Inspection and Test PlanMelih SENTURKNo ratings yet

- Project: Baladna Dairy Farm Phase-2: Inspection and Test PlanDocument3 pagesProject: Baladna Dairy Farm Phase-2: Inspection and Test PlanMelih SENTURK100% (1)

- Appendix 11, Electrical Inspection and Test PlanDocument1 pageAppendix 11, Electrical Inspection and Test PlanBraulio MartinezNo ratings yet

- Appendix K ChecklistsDocument11 pagesAppendix K Checklistsmayu mayutharanNo ratings yet

- Electrical Inspection and Test PlanDocument1 pageElectrical Inspection and Test PlanJames Pol JumarangNo ratings yet

- Project: Baladna Dairy Farm Phase-2: Inspection and Test PlanDocument3 pagesProject: Baladna Dairy Farm Phase-2: Inspection and Test PlanMelih SENTURKNo ratings yet

- ITP LTS - v3Document2 pagesITP LTS - v3fargoNo ratings yet

- Inspection & Test Plan for Masonry WorksDocument3 pagesInspection & Test Plan for Masonry Worksiman arief100% (4)

- Inspection & Test Plan FOR Wrapping / Coating of External Metal Surface (C.S Fire Hydrant Spools)Document5 pagesInspection & Test Plan FOR Wrapping / Coating of External Metal Surface (C.S Fire Hydrant Spools)Daniel Martinez50% (2)

- ITP For Structural Concrete Works at Birkat Al Awamer Logistic ParkDocument1 pageITP For Structural Concrete Works at Birkat Al Awamer Logistic ParkAshir RIZNo ratings yet

- Inspection Test Plan (Itp) at Shop: Natural Gas Transportation Development Project - Siak RiauDocument4 pagesInspection Test Plan (Itp) at Shop: Natural Gas Transportation Development Project - Siak Riauanang_priNo ratings yet

- Inspection Test Plan (Itp) at Shop: Remark No DescriptionDocument2 pagesInspection Test Plan (Itp) at Shop: Remark No Descriptionanang_pri100% (1)

- Attachment 1 - NIG MDG TEN32 - Quality Control Plan For Water Projects.Document15 pagesAttachment 1 - NIG MDG TEN32 - Quality Control Plan For Water Projects.asghar khanNo ratings yet

- China Harbour ITP Inspection and Testing PlanDocument2 pagesChina Harbour ITP Inspection and Testing PlanrajatNo ratings yet

- Toaz - Info Itp For PVC Conduits PRDocument6 pagesToaz - Info Itp For PVC Conduits PRehtesham khanNo ratings yet

- 3.6 Quality Control Plan - Container ManufacturingDocument2 pages3.6 Quality Control Plan - Container ManufacturingJean-Pierre Awu100% (1)

- Revisio N Produced by Checked by Verified by Approved by Name: Name: Name: Name: Sign: Sign: Sign: Sign: Date: Date: Date: DateDocument3 pagesRevisio N Produced by Checked by Verified by Approved by Name: Name: Name: Name: Sign: Sign: Sign: Sign: Date: Date: Date: DateMEELMAHDYNo ratings yet

- ITP For PlasteringDocument2 pagesITP For PlasteringPrasanna KumarNo ratings yet

- 017-W005-2667 - ITP - PDA Test Rev C0Document3 pages017-W005-2667 - ITP - PDA Test Rev C0Mohammad Hadoumi SaldanNo ratings yet

- ITPDocument11 pagesITPMohammad Hadoumi Saldan100% (1)

- Sample of ITP For RO-FEDocument1 pageSample of ITP For RO-FEDaniel DuongNo ratings yet

- Revision Produced by Checked by Verified by Approved by Name: Name: Name: Name: Sign: Sign: Sign: Sign: Date: Date: Date: DateDocument3 pagesRevision Produced by Checked by Verified by Approved by Name: Name: Name: Name: Sign: Sign: Sign: Sign: Date: Date: Date: DateMEELMAHDYNo ratings yet

- Itp For Ug PipelineDocument3 pagesItp For Ug PipelineJustin Alwar100% (1)

- Inspection and Testing Plan (Itp)Document1 pageInspection and Testing Plan (Itp)rajatNo ratings yet

- Inspection and Test PlanDocument1 pageInspection and Test Plansushanta chowdhuryNo ratings yet

- Pipeline repair inspection and test planDocument4 pagesPipeline repair inspection and test planAhmedNo ratings yet

- Inspection Test Plan (Itp) at Site: Natural Gas Transportation Development Project - Siak RiauDocument6 pagesInspection Test Plan (Itp) at Site: Natural Gas Transportation Development Project - Siak Riauanang_pri100% (1)

- Qa&Qc-frm-0021 Quality Inspection Plan - Static Equipment-1Document3 pagesQa&Qc-frm-0021 Quality Inspection Plan - Static Equipment-1Ali Haider100% (1)

- PC-ITP-001 - Backfilling and ExcavationDocument2 pagesPC-ITP-001 - Backfilling and ExcavationHusam zayedNo ratings yet

- Pumps ItpDocument3 pagesPumps Itpkokod9757No ratings yet

- No. Items To Be Checked Main Contractor Client's Consultant Remarks PreparatoryDocument1 pageNo. Items To Be Checked Main Contractor Client's Consultant Remarks PreparatoryKuljinder VirdiNo ratings yet

- Appendix 2 - Inspection & Test Plan, Forms and Check Lsit, and Method of StatementDocument37 pagesAppendix 2 - Inspection & Test Plan, Forms and Check Lsit, and Method of StatementMohammed AlbayatiNo ratings yet

- Item 4 and 5 DatasheetDocument5 pagesItem 4 and 5 DatasheetAJNAZ PACIFICNo ratings yet

- Dayang Enterprise Sdn. BHD.: Inspection and Test Plan (Instrument)Document2 pagesDayang Enterprise Sdn. BHD.: Inspection and Test Plan (Instrument)AmyNo ratings yet

- Inspection & Test Plan (Itp) - Iso 5167 - Fittings (SC / DC)Document1 pageInspection & Test Plan (Itp) - Iso 5167 - Fittings (SC / DC)Guru DevaNo ratings yet

- Checklist For Smoke TestDocument1 pageChecklist For Smoke TestBelal AlrwadiehNo ratings yet

- Inspected by QCP Approval 1-APC 1 - APC 2 - DAR 2 - DAR Al-Handeseh 3 - Negemco 4 - Vendor 5 - Third PartyDocument6 pagesInspected by QCP Approval 1-APC 1 - APC 2 - DAR 2 - DAR Al-Handeseh 3 - Negemco 4 - Vendor 5 - Third PartyAhmad DagamsehNo ratings yet

- Inspection Checklist For Waterproofing WorksDocument4 pagesInspection Checklist For Waterproofing WorkshishamndtNo ratings yet

- Electrical Inspection ChecklistsDocument3 pagesElectrical Inspection ChecklistsrkssNo ratings yet

- Inspection and Test Plan: Order No.: Client: Project: Purchaser: Scope of Supply: Safety Relief Valve Doc No.Document2 pagesInspection and Test Plan: Order No.: Client: Project: Purchaser: Scope of Supply: Safety Relief Valve Doc No.jayendrapatilNo ratings yet

- INSPECTION AND TEST PLANDocument1 pageINSPECTION AND TEST PLANMulPXNo ratings yet

- Itp - Mech - Hrsg-Main Steam Flow NozzleDocument15 pagesItp - Mech - Hrsg-Main Steam Flow NozzleIbadurrahman KahfiNo ratings yet

- Tawazun Industrial Park Tawazun Industrial Park Abu Dhabi, U.A.EDocument1 pageTawazun Industrial Park Tawazun Industrial Park Abu Dhabi, U.A.EProjects INTSNo ratings yet

- Standpipes Installation Monitoring ProcessDocument17 pagesStandpipes Installation Monitoring Processdiego ahumadaNo ratings yet

- CDP RDC Ar Mal Qac 0001Document5 pagesCDP RDC Ar Mal Qac 0001ElvinNo ratings yet

- Inspection & Test Plan for HVAC Duct InstallationDocument1 pageInspection & Test Plan for HVAC Duct InstallationDong VanraNo ratings yet

- Inspection and Test PlanDocument6 pagesInspection and Test PlanReduddboy100% (1)

- QC Inspection and Test PlanDocument9 pagesQC Inspection and Test PlanAlphaNo ratings yet

- Itp For For Excavation, Backfilling & Compaction For Building WorksDocument4 pagesItp For For Excavation, Backfilling & Compaction For Building WorksBleep NewsNo ratings yet

- Inspection Test Plan For: Project TitleDocument1 pageInspection Test Plan For: Project TitleKarthi Keyan100% (2)

- Sample ITPDocument1 pageSample ITPkimura takuyaNo ratings yet

- Itp For Pipeline at SiteDocument3 pagesItp For Pipeline at Siteanang_pri100% (2)

- Electrical Equipment Installation ELE-CL-002Document2 pagesElectrical Equipment Installation ELE-CL-002mujahed_muhammedNo ratings yet

- Inspection Test Plan (Itp) at Site: Natural Gas Transportation Development Project - Siak RiauDocument6 pagesInspection Test Plan (Itp) at Site: Natural Gas Transportation Development Project - Siak Riauanang_priNo ratings yet

- Inspection-and-Test-Plan For Skid FabricationDocument3 pagesInspection-and-Test-Plan For Skid FabricationVinayaga MoorthiNo ratings yet

- ITP For Domestic Water Piping InstallationDocument1 pageITP For Domestic Water Piping InstallationBelal AlrwadiehNo ratings yet

- Tins-Gen-Itp-M-001 To 005-r00 - Mechanical Works (Logo 2)Document4 pagesTins-Gen-Itp-M-001 To 005-r00 - Mechanical Works (Logo 2)achusanachuNo ratings yet

- Well Testing Project Management: Onshore and Offshore OperationsFrom EverandWell Testing Project Management: Onshore and Offshore OperationsNo ratings yet

- Phe - WTR Area Near Cooling TowerDocument2 pagesPhe - WTR Area Near Cooling TowerJoseph PerezNo ratings yet

- CW298771 Tools Equipment Validity MonitoringDocument1 pageCW298771 Tools Equipment Validity MonitoringJoseph PerezNo ratings yet

- Material Inventory - PVC QSGTLDocument2 pagesMaterial Inventory - PVC QSGTLJoseph PerezNo ratings yet

- Forecast Request Form - PGCCDocument3 pagesForecast Request Form - PGCCJoseph PerezNo ratings yet

- WarsDocument724 pagesWarsJoseph PerezNo ratings yet

- Lifegoals - Ptr. Bong Saquing 250720201Document2 pagesLifegoals - Ptr. Bong Saquing 250720201Joseph PerezNo ratings yet

- Abrasive SupplierDocument1 pageAbrasive SupplierJoseph PerezNo ratings yet

- Men's Ministry 2022: Event Flow SequenceDocument1 pageMen's Ministry 2022: Event Flow SequenceJoseph PerezNo ratings yet

- Purchase Order Form (Sample)Document3 pagesPurchase Order Form (Sample)Joseph PerezNo ratings yet

- GRP Inspection Report SummaryDocument2 pagesGRP Inspection Report SummaryJoseph Perez100% (1)

- Things To Do April - AprilDocument1 pageThings To Do April - AprilJoseph PerezNo ratings yet

- Guide To Solvent Welding PVC and CPVC Plastic Pipe and FittingsDocument24 pagesGuide To Solvent Welding PVC and CPVC Plastic Pipe and FittingsJoseph PerezNo ratings yet

- HDPE Company ProfileDocument1 pageHDPE Company ProfileJoseph PerezNo ratings yet

- JHA SampleDocument1 pageJHA SampleJoseph PerezNo ratings yet

- Hardness Test Report SummaryDocument2 pagesHardness Test Report SummaryJoseph PerezNo ratings yet

- Sample Manpower ListDocument2 pagesSample Manpower ListJoseph Perez100% (2)

- Inspection Report-Hdpec BlankDocument2 pagesInspection Report-Hdpec BlankJoseph Perez100% (1)

- Not ApplicableDocument4 pagesNot ApplicableJoseph PerezNo ratings yet

- Sample List of MachineriesDocument3 pagesSample List of MachineriesJoseph PerezNo ratings yet

- Not ApplicableDocument4 pagesNot ApplicableJoseph PerezNo ratings yet

- Sample DN BlankDocument1 pageSample DN BlankJoseph PerezNo ratings yet

- s04 - VEHICLE MOVEMNETDocument2 pagess04 - VEHICLE MOVEMNETJoseph PerezNo ratings yet

- E-Math: Circulating AreasDocument1 pageE-Math: Circulating AreasJoseph PerezNo ratings yet

- (Sample Checklist 001) : Toilet Cleaning Daily ChecklistDocument1 page(Sample Checklist 001) : Toilet Cleaning Daily ChecklistJoseph PerezNo ratings yet

- s03 - UNIFIED PERMIT TO WORKDocument2 pagess03 - UNIFIED PERMIT TO WORKJoseph PerezNo ratings yet

- Uht 1061 PGCCDocument1 pageUht 1061 PGCCJoseph PerezNo ratings yet

- JSA For Refurbishing and Repainting 23oct2017 (Woqod LPG Plant) UpdatedDocument13 pagesJSA For Refurbishing and Repainting 23oct2017 (Woqod LPG Plant) UpdatedJoseph PerezNo ratings yet

- s02 - TOOL BOX MEETINGDocument1 pages02 - TOOL BOX MEETINGJoseph PerezNo ratings yet

- Hsem ReportDocument1 pageHsem ReportJoseph PerezNo ratings yet

- JSA For Refurbishing and Repainting 23oct2017 (Woqod LPG Plant) UpdatedDocument13 pagesJSA For Refurbishing and Repainting 23oct2017 (Woqod LPG Plant) UpdatedJoseph PerezNo ratings yet

- MechanicalDocument104 pagesMechanicalNguyễn Khánh Tùng100% (1)

- Simufact WeldingDocument7 pagesSimufact WeldingZoran SpiroskiNo ratings yet

- Aft Cantilever On Main Deck of ShipDocument16 pagesAft Cantilever On Main Deck of ShipMago TroncosoNo ratings yet

- Indestructible Corner Clamp (Jig) For Welding ProjectsDocument1 pageIndestructible Corner Clamp (Jig) For Welding ProjectsTomas Tom MlNo ratings yet

- 1.2 PPT Slides Used in The CourseDocument25 pages1.2 PPT Slides Used in The Courseprince francisNo ratings yet

- Study of Friction WeldingDocument49 pagesStudy of Friction Weldingouterrace100% (1)

- BS en 25817 92 Iso 5817 92 PDFDocument20 pagesBS en 25817 92 Iso 5817 92 PDFgayathri12092002100% (1)

- CAUSES OF MISMATCH DEFECT IN ERW STEEL TUBESDocument5 pagesCAUSES OF MISMATCH DEFECT IN ERW STEEL TUBESabhishektheversatileNo ratings yet

- Page 1 of 11: ECS 10-19-1 Packaged EquipmentDocument11 pagesPage 1 of 11: ECS 10-19-1 Packaged EquipmentFlorin Daniel AnghelNo ratings yet

- Scholar List MechDocument152 pagesScholar List MechM.Saravana Kumar..M.ENo ratings yet

- Machine Design Refresher (TermsDocument30 pagesMachine Design Refresher (TermsIan LlapitanNo ratings yet

- BS 5400-9.2 1983 PDFDocument24 pagesBS 5400-9.2 1983 PDFAnoy100% (1)

- Mexico CatalogueDocument16 pagesMexico CatalogueAnilNo ratings yet

- Common CompetenciesDocument27 pagesCommon CompetenciesRobinson ConcordiaNo ratings yet

- BOHLER E 71T-1C/1M: GMAW Rutile Flux Cored WireDocument2 pagesBOHLER E 71T-1C/1M: GMAW Rutile Flux Cored WirebrayanNo ratings yet

- General Specification FOR Pressure VesselsDocument13 pagesGeneral Specification FOR Pressure Vesselssumit kumarNo ratings yet

- Activity-Based Management: Questions For Writing and DiscussionDocument36 pagesActivity-Based Management: Questions For Writing and DiscussionrpdeniNo ratings yet

- Record of Welder Performance - Qualification Test: Welding ManualDocument43 pagesRecord of Welder Performance - Qualification Test: Welding Manualdreamboy87No ratings yet

- Inspection and Test Plan Steel Sheet Pile DriDocument6 pagesInspection and Test Plan Steel Sheet Pile DriSofda Imela100% (1)

- LANL Engineering Standards Manual PWHT ProcedureDocument6 pagesLANL Engineering Standards Manual PWHT ProcedurevictorbirlanNo ratings yet

- Saudi Aramco Inspection Checklist: Review Procedure - Pressure Testing (All Applications) SAIC-A-2001 1-Dec-06 MechDocument30 pagesSaudi Aramco Inspection Checklist: Review Procedure - Pressure Testing (All Applications) SAIC-A-2001 1-Dec-06 Mechரமேஷ் பாலக்காடு86% (7)

- SAES-A-206 - 2020 - Positive Material IdentificationDocument18 pagesSAES-A-206 - 2020 - Positive Material IdentificationMEHBOOB19786No ratings yet

- Service Manual: ForewordDocument2,364 pagesService Manual: ForewordredNo ratings yet

- Solidification CrackingDocument4 pagesSolidification CrackingMuhammed SulfeekNo ratings yet

- ASME Section VIII Division 1 C - AceptacionDocument9 pagesASME Section VIII Division 1 C - AceptacionAngela Buitrago100% (1)

- EN10255 Pipe SizeDocument3 pagesEN10255 Pipe SizeStefan CristescuNo ratings yet

- 12.1 Carmen Santos V ECC and GSISDocument1 page12.1 Carmen Santos V ECC and GSISluigimanzanaresNo ratings yet

- QW483Document2 pagesQW483Sc TanNo ratings yet

- Coke Drum Repair Welch Aquilex WSI DCU Calgary 2009Document37 pagesCoke Drum Repair Welch Aquilex WSI DCU Calgary 2009Oscar DorantesNo ratings yet

- New Holland DC150.B (Tier 2) Crawler Dozer Service Repair ManualDocument21 pagesNew Holland DC150.B (Tier 2) Crawler Dozer Service Repair ManualggjjjjotonesNo ratings yet