Professional Documents

Culture Documents

Computer Simulation of Multiphase Separators For Floating Platforms

Uploaded by

Philippe LAVOISIEROriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Computer Simulation of Multiphase Separators For Floating Platforms

Uploaded by

Philippe LAVOISIERCopyright:

Available Formats

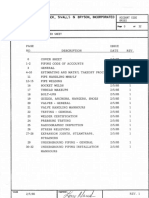

JOURNAL ARTICLES BY FLUENT SOFTWARE USERS

JA148

Computer Simulation of

Multiphase Separators for

Floating Platforms Helps

Shrink Size by 50%

Computer simulation helped Natco to

design an oil-gas separator that is smaller than

previous models by up to 50 percent. The smaller

size permits a reduction in the offshore processing

platform, potentially saving millions in

construction and operating costs. Separating oil,

water and gas is particularly difficult on floating

platforms since wave motion tends to mix the

three phases. Natco previously had to rely on

costly physical testing to evaluate separator

designs, but this did not let them visualize the

liquid phase movement inside the vessel. By using

computational fluid dynamics (CFD) software to

study the hydrodynamics inside a separator,

engineers were able to see what was happening to

the oil, water and gas during even the most

complicated wave motions. They learned that a Test of 3D-Box Motion Simulations: Two-Directional

Diagonally Movement

horizontal baffle configuration that is often used in

separators was ineffective and that conventional

porous baffles had too much porosity to dampen the gas process equipment, from individual wellhead

liquid motion. Their new internal baffle design units to large field production systems, onshore and

dampens wave motion so well that separation time is offshore, around the world. Its product line includes

sharply reduced. "Because it takes less time for oil gas processing equipment for dehydration and

and gas to separate, the vessel can be smaller, which conditioning, oil processing equipment such as oil-

is what our customers are demanding," explains Dr. gas separators, dehydrators and desalters, oily water

Ted Frankiewicz, vice president, Natco Liquid treatment systems, and custom-made vessels.

Process Solutions. Operationally, the Natco Group of companies is

For more than 50 years, Natco has been headquartered in Houston, Texas, with major

providing process equipment and system expertise to operations throughout the United States, Europe and

the oil and gas industry. The company designs, Asia.

builds, and services virtually every type of oil and

Copyright © 2001 Fluent Inc. JA148 • Page 1 of 4

Oil-gas separators employ an arrangement of

internal baffles in an attempt to dampen wave

motion. "The design of the baffles is a critical

issue because the more effective they can be,

the more they can suppress sloshing, which

directly affects separation time," says

Frankiewicz. Baffles can be placed in different

orientations (horizontal or vertical) and at

different locations within the separator. They

can be made of different materials, and the

amount of porosity can vary from low to a high

percentage. Finding the optimal combination of

all these variables is a critical design goal. In

the past, engineers built scale models to

determine how well certain baffle designs

Close-Up of Rocking Table Model performed. The testing was very expensive

however, due to the cost of building the model

Floating separators affected by waves and running the test program. Also, the information

obtained from testing was limited. One reason was

Much oil production is now done on offshore that tests were done on scale models. It wasn't known

platforms that float, such as semi-submersibles, how accurately the results could be applied to a full

tension leg platforms, and floating, production,

storage, and offloading (FPSO) systems. Separating

the oil and water from gas is done in a stand-alone

device called a 3-phase separator that occupies part

of the production platform. Oil companies would like

to make their floating platforms as small as possible

to minimize both the initial construction cost as well

as the on-going operating expenses. Reducing the

weight of the platform by just one pound, for

example, is estimated to save $5 - $8 in construction

costs. As oil companies strive to reduce the size of

the platforms, manufacturers of oil-gas separators,

such as Natco, are forced to shrink the size of their

products as well. This has been difficult, however,

because of the wave motion experienced by floating

platforms. "Weather conditions are normally calm,

but sometimes they are stormy," explains

Dr. Frankiewicz. "The platform can experience six-

degree of wave motion: surge, sway, heave, pitch,

roll, and yaw. This has a natural mixing effect on the

oil, water and gas." The mixing effect increases the

time it takes to separate the oil and gas. Since

separation occurs as the liquids and gas flow through

the vessel The longer it takes to separate the three

phases, the larger the vessel must be.

Photo of Wave Motion Simulator

Copyright © 2001 Fluent Inc. JA148 • Page 2 of 4

size vessel. In addition, even when the model was nature of its interface and because the vendor

made of Plexiglas, it was difficult to visualize and provides strong technical support.

interpret the sloshing or the mixing patterns.

Problems with previous baffle designs

The search for an alternative to scale model

testing led Natco engineers to CFD. "With CFD, we Natco's first experience in applying CFD to

can simulate the full size vessel and actually see the separator design was to model an existing separator

details of liquid motion," says Frankiewicz. A CFD in the analysis software. The geometry was created

simulation provides fluid directly from Fluent's

velocity and pressure preprocessor,

values throughout the GAMBIT. This

solution domain for time- module also

dependent problems with automatically

complex geometries and produced the

boundary conditions. As geometry meshing.

part of the analysis, a Dr. Chang-Ming Lee,

designer may change the the Natco engineer

geometry of the system or who performs the

the boundary conditions CFD analyses, took

such as the inlet fluid advantage of the

velocity, and view the software's ability to

effect on fluid flow produce both

patterns. CFD is an unstructured and

efficient and effective tool structured meshes.

for generating detailed He placed an

parametric studies, unstructured mesh

significantly reducing the 3D Vortex Formation at Oil-Gas Interface consisting of

amount of experimentation tetrahedral and hybrid

necessary to develop a device. Natco chose FLUENT elements at both ends of the separator, scaling the

CFD software from Fluent Inc., Lebanon, New unstructured mesh to account for differences in the

Hampshire because it is one of the few solvers size of the components being analyzed. In the central

capable of solving multiphase flow problems, a portion of the device, Dr. Lee placed a structured

requirement for this application since it deals with oil, mesh consisting of hexahedral elements. He tried

water and gas flow. The company also prefers this both fine and coarse meshes. The fine mesh had

CFD program to others because of the user-friendly about 126,000 cells while the coarse mesh had

Velocity Vectors Colored by Velocity Magnitude

Copyright © 2001 Fluent Inc. JA148 • Page 3 of 4

approximately 40,000. To represent the wave motion

of the processing platform, Lee created a user-

defined function with assistance from Fluent's

technical support based on known environmental

data. He used FLUENT's Volume of Fluid (VOF)

model to track the free surface interface and liquid-

liquid interface in the vessel, and used the k-epsilon

model for turbulence.

The first separator that Lee analyzed had no

internal baffles. An animated presentation of the

results, created with FLUENT's post-processor, made

it easy to see the severe sloshing inside the vessel.

Next he modeled the separator with baffles, which

2D contour plots of oil volume fraction are used to compare

were specified as porous media, in the vertical liquid sloshing (sea state) without (top) and with (bottom)

orientation, trying different baffle materials, shapes, baffles

and degrees of porosity. He ran multiple CFD analysis to find the best location for these baffles

analyses to find the most effective combination of the within that particular separator. "Since we had the

design variables. One of the interesting findings in specifications about where that separator would be

this set of analyses was that conventional porous located on the platform, we are able to plug that

baffles had too much open area to provide sufficient information into the simulation model," Lee explains.

damping. By using CFD, Lee was able to evaluate Those results, combined with using more effective

varying amounts of open area to obtain more baffles, resulted in a separator that worked more

effective damping. To assess the different designs, he effectively. Because separation time was significantly

compared the amplitude of the fluctuating drag reduced, the size of separator could be reduced as

coefficient on the end wall of the unit, derived from well. "The analyses we ran to optimize baffle

the sloshing motion. A preliminary design that used placement were specific to that one separator's

less open area had a drag coefficient that was 56 location on the platform," Frankiewicz adds. "But

percent of the original value. With subsequent now that we have a CFD model, we have the ability

modifications to the design, Lee was able to reduce to optimize baffle placement in any new offshore

that to about 38 percent of the original value. separators we supply."

Natco has since used the CFD method to By applying CFD analysis to the problem of

design a three-phase separator that completes oil, oil-water-gas separator design, Natco has been able to

water and gas separation in three to four minutes of minimize wave motion within the device, thus

retention time, which is half the volume of previous reducing the time needed to separate oil from gas and

devices. The design uses the new, optimized baffle water. This, in turn, enables the company to build

design and placement that Lee developed based upon smaller separators and meet the oil companies'

his earlier analyses. Natco took advantage of CFD demands. "By letting us visualize the effectiveness of

baffle designs and their

placement in the vessel, CFD lets

us get a level of wave

suppression we couldn't achieve

in the past, "says Frankiewicz.

"CFD is key to properly

designing our separators."

Contour Plot of Velocity Magnitude

Copyright © 2001 Fluent Inc. JA148 • Page 4 of 4

You might also like

- Essai HydratesDocument1 pageEssai HydratesPhilippe LAVOISIERNo ratings yet

- 15 - Construction Estimating Manual 15 - Field Cost SheetDocument5 pages15 - Construction Estimating Manual 15 - Field Cost SheetPhilippe LAVOISIERNo ratings yet

- 1.method Fabrication Spool (r2)Document13 pages1.method Fabrication Spool (r2)sethu109175% (20)

- BG Spec For Piping Reaction Loadings On Eqt NozzlesDocument14 pagesBG Spec For Piping Reaction Loadings On Eqt NozzlesPhilippe LAVOISIERNo ratings yet

- A Review of Onshore Flare Systems PLVDocument9 pagesA Review of Onshore Flare Systems PLVPhilippe LAVOISIERNo ratings yet

- 14 - Construction Estimating Manual 14 - Field Construction IndirectsDocument31 pages14 - Construction Estimating Manual 14 - Field Construction IndirectsPhilippe LAVOISIERNo ratings yet

- BSB Desalter 3277 - 001Document10 pagesBSB Desalter 3277 - 001Philippe LAVOISIERNo ratings yet

- Flare LiftingDocument6 pagesFlare LiftingPhilippe LAVOISIERNo ratings yet

- 10 - Construction Estimating Manual 10 - Insulation PDFDocument15 pages10 - Construction Estimating Manual 10 - Insulation PDFPhilippe LAVOISIERNo ratings yet

- 11 - Construction Estimating Manual 11 - PaintingDocument6 pages11 - Construction Estimating Manual 11 - PaintingPhilippe LAVOISIERNo ratings yet

- 12 - Construction Estimating Manual 12 - Site Finishing PDFDocument13 pages12 - Construction Estimating Manual 12 - Site Finishing PDFPhilippe LAVOISIERNo ratings yet

- 13 - Construction Estimating Manual 13 - Freight and ShippingDocument6 pages13 - Construction Estimating Manual 13 - Freight and ShippingPhilippe LAVOISIERNo ratings yet

- 9 - Construction Estimating Manual 9 - Refractory and FireproofingDocument5 pages9 - Construction Estimating Manual 9 - Refractory and FireproofingPhilippe LAVOISIERNo ratings yet

- 10 - Construction Estimating Manual 10 - InsulationDocument15 pages10 - Construction Estimating Manual 10 - InsulationPhilippe LAVOISIERNo ratings yet

- 4 - Construction Estimating Manual 4 - ConcreteDocument64 pages4 - Construction Estimating Manual 4 - ConcretePhilippe LAVOISIERNo ratings yet

- 2 - Construction Estimating Manual 2 - Site PreparationDocument16 pages2 - Construction Estimating Manual 2 - Site PreparationPhilippe LAVOISIERNo ratings yet

- 6 - Construction Estimating Manual 6 - PipingDocument33 pages6 - Construction Estimating Manual 6 - PipingPhilippe LAVOISIERNo ratings yet

- 8 - Construction Estimating Manual 8 - InstrumentationDocument25 pages8 - Construction Estimating Manual 8 - InstrumentationPhilippe LAVOISIER100% (1)

- 7 - Construction Estimating Manual 7 - ElectricalDocument34 pages7 - Construction Estimating Manual 7 - ElectricalPhilippe LAVOISIERNo ratings yet

- 5 - Construction Estimating Manual 5 - BuildingsDocument23 pages5 - Construction Estimating Manual 5 - BuildingsPhilippe LAVOISIERNo ratings yet

- Equipment Piping LayoutDocument39 pagesEquipment Piping Layoutlatshare100% (2)

- 1 - Construction Estimating Manual 1 - Major EqtDocument46 pages1 - Construction Estimating Manual 1 - Major EqtPhilippe LAVOISIERNo ratings yet

- 0 - Construction Estimating Manual - 1985Document13 pages0 - Construction Estimating Manual - 1985Philippe LAVOISIERNo ratings yet

- Supplier Pre-Qualifi-Eval-Criteria-and-WeightingDocument39 pagesSupplier Pre-Qualifi-Eval-Criteria-and-WeightingPhilippe LAVOISIERNo ratings yet

- Checklist For Nozzle OrientationDocument4 pagesChecklist For Nozzle OrientationPhilippe LAVOISIERNo ratings yet

- 1 Piping CostingDocument33 pages1 Piping Costingamoldhole97% (34)

- Modular Pipe Rack ConceptDocument29 pagesModular Pipe Rack ConceptPhilippe LAVOISIERNo ratings yet

- COST PIPING AND SECONDARY STRUCTURE 66904198-GSoN-Metric-Imperial-Norms-Book PDFDocument359 pagesCOST PIPING AND SECONDARY STRUCTURE 66904198-GSoN-Metric-Imperial-Norms-Book PDFPhilippe LAVOISIER100% (2)

- Hydrocyclones A Solution For The PWTSDocument12 pagesHydrocyclones A Solution For The PWTSPhilippe LAVOISIERNo ratings yet

- Sample Work Activities For Separator Vessel ManufacturingDocument3 pagesSample Work Activities For Separator Vessel ManufacturingPhilippe LAVOISIERNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Midterm Answers: T T T 1 T T 2Document5 pagesMidterm Answers: T T T 1 T T 2blackbriar22No ratings yet

- 16K Microwire Compatible Serial EEPROM: 93AA86A/B/C, 93LC86A/B/C, 93C86A/B/CDocument27 pages16K Microwire Compatible Serial EEPROM: 93AA86A/B/C, 93LC86A/B/C, 93C86A/B/CJesús GutiérrezNo ratings yet

- Ds Irg 4000 Baur En-GbDocument3 pagesDs Irg 4000 Baur En-Gbrupesh kumarNo ratings yet

- 9788131526361Document1 page9788131526361Rashmi AnandNo ratings yet

- Unit1 ResourcesDocument41 pagesUnit1 ResourcesNadia Abigail DowneyNo ratings yet

- Python 3 Cheat SheetDocument16 pagesPython 3 Cheat SheetFredrik Johansson71% (7)

- News From Vietnam Chemical DatabaseDocument3 pagesNews From Vietnam Chemical DatabasequýNo ratings yet

- Tech Diff Between 11i and R12 - Multi OrgDocument8 pagesTech Diff Between 11i and R12 - Multi OrgRAj PoliteNo ratings yet

- Translation Look Aside BufferDocument17 pagesTranslation Look Aside BufferMeghanaNo ratings yet

- Traxmaker ManualDocument220 pagesTraxmaker ManualcharlesNo ratings yet

- Computer Network - Leaky Bucket AlgorithmDocument5 pagesComputer Network - Leaky Bucket AlgorithmakttripathiNo ratings yet

- PROG102 - GCS200708 - NguyenXuanNam - Assignment 1Document41 pagesPROG102 - GCS200708 - NguyenXuanNam - Assignment 1Nam Nguyen50% (2)

- Stock Management ProgrammingDocument9 pagesStock Management ProgrammingSayak JanaNo ratings yet

- The Engineering Design Revolution - CAD History - 13 IBM, Lockheed and DassaultDocument44 pagesThe Engineering Design Revolution - CAD History - 13 IBM, Lockheed and DassaultphamduyprojectNo ratings yet

- Rani DatabaseDocument31 pagesRani DatabaseMichaelNo ratings yet

- GCDAI Curriculum Sept 2019Document20 pagesGCDAI Curriculum Sept 2019vinodkumarNo ratings yet

- Pcu BackupDocument88 pagesPcu BackupD37667No ratings yet

- 8051 Design by Nitesh PDFDocument27 pages8051 Design by Nitesh PDFniteshg11No ratings yet

- Using Word To Create Great-Looking Reports: Abstract: This Article Gives Step-By-Step Instructions OnDocument3 pagesUsing Word To Create Great-Looking Reports: Abstract: This Article Gives Step-By-Step Instructions OnBusiness Expert PressNo ratings yet

- BT Home Hub Recovery Instructions WindowsDocument5 pagesBT Home Hub Recovery Instructions WindowsranknameNo ratings yet

- Globe at Home Plan 1299 LTE Go BigDocument3 pagesGlobe at Home Plan 1299 LTE Go BigAu Pangan-MartilloNo ratings yet

- How To Recover Windows LoaderDocument15 pagesHow To Recover Windows LoaderThea Marie SantarinNo ratings yet

- 2019 Essay Questions: Ssay UestionDocument2 pages2019 Essay Questions: Ssay UestionSunday OkekeNo ratings yet

- Inputaccel 5.3: Capture For Documentum Quick Start GuideDocument22 pagesInputaccel 5.3: Capture For Documentum Quick Start GuideLiju ThomasNo ratings yet

- Altium FPGA To PCBDocument234 pagesAltium FPGA To PCBElectrical-Engineer100% (1)

- Elmod 6 Quick StartDocument55 pagesElmod 6 Quick StartDoug Weir100% (3)

- DSA Lab ManualDocument13 pagesDSA Lab ManualMuhammad AhsanNo ratings yet

- BRKACI-2006 Intergration of Hypervisors and L4-7 Service Into ACI PDFDocument83 pagesBRKACI-2006 Intergration of Hypervisors and L4-7 Service Into ACI PDFDat PhamNo ratings yet

- Computer Program - Part 1Document5 pagesComputer Program - Part 1kulNo ratings yet

- 3D Geo Modelling - ArcsceneDocument12 pages3D Geo Modelling - ArcsceneHaroonNo ratings yet