Professional Documents

Culture Documents

PB3603 1 Raymond Mechanical Air Separator PDF

Uploaded by

miraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PB3603 1 Raymond Mechanical Air Separator PDF

Uploaded by

miraCopyright:

Available Formats

Raymond

Mechanical Air Separators

Air Preheater Company

Raymond Operation

®

Raymond Mechanical Air Separators

Produce Materials with High Uniform Fineness

The Raymond® Mechanical Air Sepa- Single Whizzer Air Separators Typical Applications

rator produces material with high uni- Single whizzer separators have only Cement - classify and dry raw

form fineness; operates in open or one bank of whizzer blades to set up mix, and to classify and cool finish

closed circuit; is excellent for de-dust- centrifugal action. This unit is ordi- cement.

ing; can provide drying and cooling; narily used for coarser separations up Limestone - produce limestone

and features the unique single or to approximately 10-15% R74 microns sand to meet the close specifications

double whizzer for faster separation (85 to 90% passing 200 mesh) which required for use in bituminous con-

of fines and more positive rejection of is excellent for de-dusting and raw mix crete, mortar, aggregate and many

oversize. cement operations. similar uses.

Flour Mixes - make fine, uniform

Operation Cycle Double Whizzer Air Separators cake mixes and for production of pro-

Material enters the hollow shaft or Double whizzer units have two rows tein-enriched grades of flour.

center feed pipe at the top of the sepa- or banks of whizzer blades. In normal Hydrated Lime - produce a high-

rator and drops upon the rotating dis- operations they can produce finished fineness, uniformly-classified hydrated

tributor plate below. This distributor materials up to 0.5-1% R44 microns lime for chemical and spray purposes.

place disperses the material into the (99 to 99.5% passing 325 mesh) and Food Products - classify various

upward sweep of circulating air devel- in finished cement circuits 2800 to food products including sugar, cocoa,

oped by the fan in the top chamber of 6000 Blaine or masonary cements. milk powder, food mixtures,corn

the drum. The whizzer blades set up starch, wheat starch and soybean

a centrifugal motion of the air and ma- Fineness Control meal.

terial. This concentrates the oversize Both the single and double whizzer Chemicals - make various grades

material along the surface of the up- units in 4 and 6 foot diameter sizes ranging from extremely fine to the

per inner cone, where gravity causes are equipped with vertical slide damp- granular, dust-free gradation, such as

it to flow into the lower inner cone and ers which allow external fineness ad- soda ash and sodium phosphate.

then out the coarse spout at the bot- justment while the unit is in operation. Talc and Clays - upgrade the qual-

tom. The airstream carrying the pow- For precise fineness control, all units ity of such materials as talc,

dered material of required fineness 8 foot diameter and larger are provided kaolin,clays and phospate rock by

moves through the fan and is delivered with special vertical swing dampers to removing such impurities as silica, flint

into the outer cone chamber where the increase their efficiency and versatil- and other foreign materials.

fines are discharged as finished prod- ity when separating in the minus 325 Metal and Metallurgical Powders

uct. After the fines are released in the mesh and subsieve size range. On - classify metal powders consisting of

outer cone, the air returns through the many materials, finished products with copper, bronze, iron and various al-

deflector ports to the inner cone, set- a high percentage passing 15 to 20 loys. De-dusting of sea-coal for

ting up a continuous circuit. microns can be obtained without diffi- foundry-facing in another typical ap-

culty. plication.

In addition to accomplishing faster

separation of the fines and more posi- Raymond® mechanical air separators

tive rejection of the oversize, the are built in eleven sizes ranging from The Air Preheater Company,

whizzer action is also useful in de- 4 feet to 24 feet in diameter, as well Raymond Operations continues in

as a 30 inch unit for small capacities its commitment of providing our

dusting operations-making granular

and test runs. Each size is available customers with the best products

products by removing objectionable

in a single or double whizzer construc- and service in the industry.

fines, for example-as well as produc-

ing microsize materials with maximum tion. A special 10 inch laboratory sepa-

For additional information, contact

surface area. rator completes the Raymond line and

your local Raymond Operations’

provides a useful machine for handling

sales office.

small lots of materials in experimen-

tal work.

Construction and Specifications

Standard construction of the

Raymond® mechanical air separator

includes cast, abrasion resistant Top Plate Door

Inner Drum Top Plate

whizzer cones and replaceable steel- Top Plate

Outer Drum

plate liners on the inner cone. Outer Drum Liners

Outer Fan Blade

The distributor plate is protected with Vertical Swing

Damper Assembly

Whizzer Blades

special liners along the outer edge

Whizzer Cones Inner Drum Liner

with a cone at the center to provide Inner Drum Inner Drum Door

Whizzer Plates

further protection and insure even flow

of the incoming material off the Inner Cone Liners

Outer Drum Door

disbributor plate at the start of classi-

fication.

Distribution Plate Assembly Deflector

Separators for handling abrasive ma- Lower Inner Cone

terials can be equipped with special

Vent Pipe Connection

abrasion resistant liners in all parts of

the machine. Upper Outer Cone

All mechanical air separators are pro-

vided with a vent connection in the

cone section as standard construc- Lower Outer Cone

tion for removing infiltrating air and

keeping the unit under negative pres-

sure for dust free operation.

Coarse Valve

Fines

The 4 and 6 foot diameter Raymond® (If required)

mechanical air separators are built on

the same principle as the larger units

but are arranged with a vertical motor

drive. This eliminates the need for a

gear and pinion.

Double Whizzer Separator

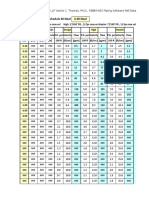

Approximate Weight H eight - H H eight - h D iameter - D h

Siz e

lb kg ft mm ft mm ft mm H

30" 950 400 5.2 1,500 1.5 400 3.2 900

4' 2,000 900 8.0 2,400 4.3 1,200 5.0 1,500

6' 4,000 1,800 11.0 3,300 5.8 1,700 7.1 2,100

8' 8,000 3,600 14.3 4,300 7.7 2,300 9.7 2,900

10' 11,500 5,200 16.8 5,100 8.5 2,500 11.7 3,500

12' 22,500 10,200 19.7 5,900 9.7 2,900 14.2 4,300

14' 28,500 12,900 22.1 6,700 10.3 3,100 16.0 4,800

16' 39,300 17,800 25.5 7,700 12.1 3,600 17.8 5,400

D

18' 44,800 20,300 27.1 8,200 11.9 3,600 20.8 6,300

21' 69,400 31,400 29.3 8,900 14.9 4,500 24.0 7,300

24' 90,000 40,800 37.3 11,300 17.2 5,200 27.0 8,200

Product Bulletin 3603-1

Applications

Closed Circuit Grinding The advantages of using a Raymond® Cooling in separators is also a wide-

When operated in closed circuit com- mechanical air separator in closed cir- spread practice in classifying finished

bination with a pulverizer, the separa- cuit with the grinding mill for produc- cement.

tor skims off the fines as fast as they ing closely sized finished products

are made so the mill works only on include: Both the single and double whizzer

fresh material without wasting power. units can be provided with cooling and

The tailings are discharged back to 1. Positive control of fineness or sur- drying auxiliaries which consist of up

the mill for further reduction. The face area and the elimination of over- to four inlet openings in the drum sec-

reground material is returned to the size particles. tion and two air outlets in the cone

separator with the feed, so that a con- 2. Convenient variation of product section. Water jackets can also be

stant circulating load is set up be- fineness-vertical dampers permit wide provided on the cone sections for use

tween the mill and the separator. range changes in fineness, externally in cooling finished cement on sizes

while the separator is in operation. 18’ through 24’ diameter.

The separator may be used in combi- 3. Increase in the output capacity of

nation with ball mills, tube mills and the grinding mill. Experience has Open Circuit

compartment mills. Its function is to shown increases from 25 to 75% or In some cases, it is convenient to in-

maintain a constant fineness in more. stall the separator independently from

deliverying the finished product. 4. Lowering the temperature of the the mill to make both a fine and coarse

mill and product. product simultaneously.

It saves power in the overall operation 5. Improvement in grind efficiency,

Feed

and increases the capacity of the com- as in the case of ball mills where ball

plete unit. coating with fine material can reduce

grinding ball effectiveness.

Circulating Load Separator

Internal Air Flow System for

Drying and Cooling

Separator Effective drying within the separator

Raw Feed is normally limited to those installa- Coarse

tions where the separator is used in

Coarse closed circuit with a grinding unit. The Fines

Grinding Mill

oversize particles with entrained mois-

Fines ture, rejected in the first pass as Raymond® Mechanical Separator in

Open Circuit System

coarse, are further reduced in the

Raymond® Mechanical Separator in

Closed Circuit System

grinding mill to permit efficient drying

in the second pass through the sys-

tem.

ALSTOM Power, Inc., Air Preheater Co., Raymond Operations, 4525 Weaver Pkwy., Warrenville, IL 60555 USA

Toll Free: 877.661.5509 - Tel: 630.393.1000 - Fax: 630.393.1001

E-mail: info@airpreheatercompany.com - Website: www.airpreheatercompany.com

You might also like

- FLS Ok Mill Common Platform WEB PDFDocument12 pagesFLS Ok Mill Common Platform WEB PDFVerananda AriyantoNo ratings yet

- Bucket ElevatorsDocument11 pagesBucket ElevatorsMehmet CNo ratings yet

- 03mill SlidesDocument21 pages03mill SlidesNael El SayyadNo ratings yet

- SeparatorsDocument6 pagesSeparatorsKADİR durmaz100% (1)

- Raw Meal BeneficiationDocument41 pagesRaw Meal Beneficiationdina safiri100% (1)

- Shree Project FinalDocument20 pagesShree Project FinalMostafa KordyNo ratings yet

- 31 MER VRM Inspections - Rev JSJ 120507Document45 pages31 MER VRM Inspections - Rev JSJ 120507Camilo CamposNo ratings yet

- Kinds of Conveyor Belts Pipe Conveyor Belt Conveyo 5ad270867f8b9acc4a8b4583Document19 pagesKinds of Conveyor Belts Pipe Conveyor Belt Conveyo 5ad270867f8b9acc4a8b4583nicolasNo ratings yet

- Duo Dan MillDocument4 pagesDuo Dan Millnhungocbk92_22841857No ratings yet

- Jaypee Cement Project ReportDocument29 pagesJaypee Cement Project ReportPurnendu MishraNo ratings yet

- Helical Gearbox InstallationDocument8 pagesHelical Gearbox InstallationKUNALJAYNo ratings yet

- Chapter 1Document56 pagesChapter 1Surbhi JainNo ratings yet

- 06 Mill Body Upper HousingDocument15 pages06 Mill Body Upper HousingDavid Vilca MamaniNo ratings yet

- Collaboration Cuts Costs and Increases Capacity by 35%: CASE: India Cements Limited, ChilamkurDocument4 pagesCollaboration Cuts Costs and Increases Capacity by 35%: CASE: India Cements Limited, ChilamkurjmpbarrosNo ratings yet

- Shutdown Maintenance Activites at Mechanical Clinker (Line-1)Document4 pagesShutdown Maintenance Activites at Mechanical Clinker (Line-1)salman saleemNo ratings yet

- Ball Mill OptimiztionDocument8 pagesBall Mill OptimiztionShakil AhmadNo ratings yet

- Roller MillDocument41 pagesRoller MillrecaiNo ratings yet

- ResumeDocument3 pagesResumeHari Prathap ReddyNo ratings yet

- Polguide Final PalDocument15 pagesPolguide Final Paldeepak kumarNo ratings yet

- 00 Introduction Polysius-HistoryDocument17 pages00 Introduction Polysius-HistoryEnrique BandaNo ratings yet

- 3 Cooleftrr - PpsDocument19 pages3 Cooleftrr - PpsAli HüthütNo ratings yet

- 24 00 RP and BM Operation EDocument9 pages24 00 RP and BM Operation EDiego AlejandroNo ratings yet

- Nelson Machinery Int'l Equipment Highlights 2019-04Document64 pagesNelson Machinery Int'l Equipment Highlights 2019-04Andy GNo ratings yet

- 04 General Frames Pedestals Lower HousingDocument13 pages04 General Frames Pedestals Lower HousingDavid Vilca MamaniNo ratings yet

- MAMMUT Single-Shaft Hammer Crusher: HilfsvorrichtungenDocument1 pageMAMMUT Single-Shaft Hammer Crusher: HilfsvorrichtungenpeymanNo ratings yet

- Department of Chemical EngineeringDocument19 pagesDepartment of Chemical EngineeringPandia RajanNo ratings yet

- FivesFCB Brochure Horomill GBDocument6 pagesFivesFCB Brochure Horomill GBpeymanNo ratings yet

- Ball Mill Internals: GRINDING I - Training SessionDocument31 pagesBall Mill Internals: GRINDING I - Training SessionFran jimenezNo ratings yet

- Ido Tank CilDocument40 pagesIdo Tank CilSafrin SangiaNo ratings yet

- Per Banding An Desain Fls Pfister FeederDocument5 pagesPer Banding An Desain Fls Pfister Feederde_chemenx2540No ratings yet

- Bijur Delimon KatalogDocument24 pagesBijur Delimon Katalogdamian_k19No ratings yet

- Grinding Mills Optimisation: Magotteaux / Slegten / Sturtevant SolutionsDocument44 pagesGrinding Mills Optimisation: Magotteaux / Slegten / Sturtevant Solutionsshani5573100% (1)

- V SK VSK: Focus On EfficiencyDocument8 pagesV SK VSK: Focus On EfficiencyGerman Gabriel Anaya VegaNo ratings yet

- Loesche Seminar VCM Study Dec03Document132 pagesLoesche Seminar VCM Study Dec03stelios nikoladosNo ratings yet

- Ball MillDocument2 pagesBall Millpadma26327No ratings yet

- Pneumatic TransportDocument9 pagesPneumatic TransportMehmet CNo ratings yet

- 154 Loesche Mills For Cement Raw Material E 2016Document28 pages154 Loesche Mills For Cement Raw Material E 2016faheemqcNo ratings yet

- Polytrack Clinker Cooler.: PolysiusDocument3 pagesPolytrack Clinker Cooler.: PolysiushathamphanNo ratings yet

- FullerKinyonKompactPumps PDFDocument4 pagesFullerKinyonKompactPumps PDFAnoop Tiwari0% (1)

- Coal Mill InstallationDocument24 pagesCoal Mill InstallationCristian David MurielNo ratings yet

- Introduction To Vertical Roller MillDocument35 pagesIntroduction To Vertical Roller MillrecaiNo ratings yet

- aTS Conveyors PDFDocument20 pagesaTS Conveyors PDFbulentbulutNo ratings yet

- Loesche Overview EN PDFDocument34 pagesLoesche Overview EN PDFNguyễn Quang Hưng100% (1)

- Training PODFA: Overview of The Pyroprocessing ComponentsDocument50 pagesTraining PODFA: Overview of The Pyroprocessing ComponentsДен СтаднікNo ratings yet

- CFI Controlled Flow Inverted Cone SiloDocument4 pagesCFI Controlled Flow Inverted Cone SiloTùng CCIDNo ratings yet

- Long Filter BagDocument1 pageLong Filter BagAlbar BudimanNo ratings yet

- Vertical Roller MillDocument2 pagesVertical Roller MillAhmed Younis0% (2)

- KHD Pyroclon EnglDocument4 pagesKHD Pyroclon Englkresimir.mikoc9765100% (1)

- Gas Cooling Tower LowDocument4 pagesGas Cooling Tower Lowpalto1No ratings yet

- FLSmidth SF Cooler UpgradeDocument2 pagesFLSmidth SF Cooler UpgradeMohammed AbdoNo ratings yet

- Slegten Opticontrol PDFDocument4 pagesSlegten Opticontrol PDFjorge1947100% (1)

- Air Slide Working ManualDocument20 pagesAir Slide Working ManualKrishnadas Gopalakrishnan100% (3)

- Assiut Cement PlantDocument17 pagesAssiut Cement PlantMahmoud RashadNo ratings yet

- Bulletin 9 - CFD Analysis and Flow Smoothening in PH Down Comer Duct To Reduce Pressure DropDocument2 pagesBulletin 9 - CFD Analysis and Flow Smoothening in PH Down Comer Duct To Reduce Pressure DropSivaram KrishnamoorthyNo ratings yet

- Raw MealDocument48 pagesRaw Mealrashmiranjan1110No ratings yet

- Ultra Tech Cement TadipatriDocument18 pagesUltra Tech Cement TadipatriAshutosh SinghNo ratings yet

- JEMAJOE Company PofileDocument28 pagesJEMAJOE Company PofilearthegaNo ratings yet

- Dorr-Oliver Vacuum Drum FilterDocument4 pagesDorr-Oliver Vacuum Drum FilterFrancois HamiauxNo ratings yet

- FLS OK Cement Mill WEBDocument8 pagesFLS OK Cement Mill WEBjinendraNo ratings yet

- Demisters & Tower Packings CatalogueDocument28 pagesDemisters & Tower Packings CatalogueVioleta ArabadzhievaNo ratings yet

- Alarm PDFDocument1 pageAlarm PDFmiraNo ratings yet

- 1FN19100AA000AA0 Datasheet en PDFDocument1 page1FN19100AA000AA0 Datasheet en PDFmiraNo ratings yet

- Chapter 4 PLC Programming PDFDocument100 pagesChapter 4 PLC Programming PDFmiraNo ratings yet

- BCH Electronic Motor Protection RelayDocument12 pagesBCH Electronic Motor Protection RelayMahasweta MitraNo ratings yet

- NSK Linear Guides Catalogue PDFDocument61 pagesNSK Linear Guides Catalogue PDFmiraNo ratings yet

- TRANE Steam Driven Absorption ChillersDocument41 pagesTRANE Steam Driven Absorption ChillersMarian Vančo100% (1)

- MCM3320 Application Training Switchgear Engineer Training 083006 Rev4 New Cummins Template PDFDocument215 pagesMCM3320 Application Training Switchgear Engineer Training 083006 Rev4 New Cummins Template PDFmira100% (4)

- 03 0 Industrial Refrigeration PDFDocument36 pages03 0 Industrial Refrigeration PDFmiraNo ratings yet

- Tds Nexbase 3060Document2 pagesTds Nexbase 3060RMascilNo ratings yet

- Air Entraining CementDocument14 pagesAir Entraining CementBashairu WaseemNo ratings yet

- Ficha Técnica Stemgrass 50mm - Chile PastosDocument1 pageFicha Técnica Stemgrass 50mm - Chile PastosCarlosAlfonsoVasconcelloPeñaNo ratings yet

- Ginansilyo Ni Marya Galaxy WarsDocument21 pagesGinansilyo Ni Marya Galaxy WarsLibélula Ramírez100% (1)

- Section - 1-1 Section - 2-2 (Showing R/F Det.) : Rajasthan State Gas LimitedDocument1 pageSection - 1-1 Section - 2-2 (Showing R/F Det.) : Rajasthan State Gas Limitedsumit kumarNo ratings yet

- Epilux 155 SFDocument2 pagesEpilux 155 SFMohamed NasifNo ratings yet

- TBN 1Document11 pagesTBN 1Ben Karthiben NathanNo ratings yet

- Lecture 6 (CERAMIC INDUSTRY)Document50 pagesLecture 6 (CERAMIC INDUSTRY)Aqsa chNo ratings yet

- Sample Electrical PlanDocument1 pageSample Electrical PlanMaeka Loraine GalvezNo ratings yet

- Acids Bases & Salts Class 10TH ScienceDocument4 pagesAcids Bases & Salts Class 10TH ScienceLavanya Priya SathyanNo ratings yet

- Eco Stone Stone Veneer PricelistDocument2 pagesEco Stone Stone Veneer PricelistOctonioNo ratings yet

- Foaming of Friction Stir Processed Al /mgco3 Precursor Via Ame HeatingDocument27 pagesFoaming of Friction Stir Processed Al /mgco3 Precursor Via Ame HeatingArshad SiddiqueeNo ratings yet

- Pipe Sizing Data.Document50 pagesPipe Sizing Data.haqjmiNo ratings yet

- TDS-Tembutil IF GBDocument2 pagesTDS-Tembutil IF GBHung Mai VanNo ratings yet

- Cleat WiringDocument10 pagesCleat WiringBhaswati PandaNo ratings yet

- WO2013132439A1Document72 pagesWO2013132439A1I Love MusicNo ratings yet

- State of The Art Electrical Discharge Machining (EDM)Document14 pagesState of The Art Electrical Discharge Machining (EDM)varun.119100% (1)

- Unit 6B CORROSIONDocument19 pagesUnit 6B CORROSIONMeghana SNo ratings yet

- Profile-SamSad InteriorDocument16 pagesProfile-SamSad InteriorMd Farid AhmedNo ratings yet

- Polyethylene - Aluminium Roof (Tetra Pak)Document6 pagesPolyethylene - Aluminium Roof (Tetra Pak)Soumendra Roy50% (2)

- Modification of Dielectric Properties, After Barium Titanate Nanoparticles Sintering, From A Thermoplastic Polymer MatrixDocument6 pagesModification of Dielectric Properties, After Barium Titanate Nanoparticles Sintering, From A Thermoplastic Polymer MatrixScarlatache VladNo ratings yet

- DEMO-ASME Filler Metals DatabaseDocument6 pagesDEMO-ASME Filler Metals DatabaseadammzjinNo ratings yet

- Lab Report Part A Cod FullDocument8 pagesLab Report Part A Cod Fullnor atiqah100% (1)

- Concrete Construction Article PDF - Aluminum in Concrete PDFDocument2 pagesConcrete Construction Article PDF - Aluminum in Concrete PDFLucasNo ratings yet

- Micro Precision Grinding OperationDocument29 pagesMicro Precision Grinding OperationAzmi MustafaNo ratings yet

- Evaluation of AISI 4140 Steel Repair Without Post-Weld Heat TreatmentDocument9 pagesEvaluation of AISI 4140 Steel Repair Without Post-Weld Heat TreatmentAek JayNo ratings yet

- Flotation of MineralsDocument3 pagesFlotation of MineralsgabrielNo ratings yet

- Madanapalle Institue of Technology & Science Madanapalle: A Study On Abrasive Jet MachiningDocument20 pagesMadanapalle Institue of Technology & Science Madanapalle: A Study On Abrasive Jet MachiningYashwanth ReddyNo ratings yet

- Chemical Plants and Its EquipmentsDocument15 pagesChemical Plants and Its EquipmentsjeffyNo ratings yet

- 364.9T-03 (11) Cracks in A Repair (TechNote)Document3 pages364.9T-03 (11) Cracks in A Repair (TechNote)YaserNo ratings yet