Professional Documents

Culture Documents

ABB-Transformers-Site-Diagnosis-Paper - DMPT-2015-Slinger-Gomez-ENU PDF

Uploaded by

Jose Antonio Huamani ChuquirimayOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ABB-Transformers-Site-Diagnosis-Paper - DMPT-2015-Slinger-Gomez-ENU PDF

Uploaded by

Jose Antonio Huamani ChuquirimayCopyright:

Available Formats

Presentation 5.

Transformers Site Diagnosis

Robert Slinger / Johnny Sanchez Gomez, ABB TRES, UK

Introduction

The Power Transformer is the most expensive

plant/equipment in any electrical network. During

its whole life (transportation, installation or under

service operation), it is exposed to transient and

steady state stresses that can affect its condition

as well as its service life.

Therefore, a condition assessment should be

carried out on a frequent basis. This is crucial for

its successful operation and, as a consequence, Fig. 1 ABB Risk management approach to identify

for the reliability of the power system as a whole. transformers at risk

ABB proves the proper condition of the equipment,

giving accurate and reliable test results. Most of A definitive analysis of the subject of diagnostic

these tests are measured with the powerful tests on power transformers must take into account

solutions provided by OMICRON, and are that the majority of diagnostic indicators are

diagnosed and evaluated by ABB’s experts, who sensitive to all three fundamental stresses acting

have access to more than a century of knowledge on the transformer. Therefore, the general

in transformer manufacturing [2]. interpretations of the outputs are the diagnostic

indicators, localization of faults can be problematic

for a reliable evaluation of the risk of failure. The

Transformer Diagnosis experience and interpretation capabilities of

transformer experts are crucial for a successful

During installation or periodic maintenance, ABB’s

diagnosis.

Test Engineers have proven the versatility of each

of OMICRON’s solutions according to the Some of the required tests for a condition

requirements. This equipment, along with our assessment carried out by ABB are:

expertise to analyze the results, allows for a risk Frequency Response Analysis

management approach (see Fig. 1). Excitation Current

Essentially, this paper must consider three aspects Leakage Inductance Measurement

when determining the technical risk of the failure of Power Factor and Capacitance

a transformer [2]: Dielectric Frequency Response

Mechanical aspects: This involves the risk of Turns Ratio

short circuit failure, which is based on Bushings PF & Cap

assessment of the short circuit strength of the Dynamic Tap Changer Tests

windings and clamping structure, and the Windings Resistance

incidence including magnitude of short circuit

through fault events.

Thermal aspects: This involves the winding

OMICRON Highlights at ABB

thermal condition and is based on the

condition of the paper insulation. Aged, brittle Demagnetization

insulation is more likely to fail under the

mechanical stress conditions. Also, metal One of the main problems that can influence the

parts at high temperature could pose a risk to measurement of transformers is the residual

the transformer. magnetism, which can affect the results from FRA

Electric aspects: This involves the risk of or Exciting Current Measurements. By

dielectric failure and is based on the demagnetising with the CPC 100 + CP SB1, ABB

assessment of the dielectric withstand can ensure reliable results for both these

capability of the transformer insulation system measurements, coupled with a short

(oil, paper, etc.) and the electrical stress demagnetisation time. Further to this, removing the

imposed by the power system and naturally residual magnetism from the transformer helps to

occurring events. illuminate un-desirable protection operations due

to high inrush currents, or even internal damage

due to the mechanical forces.

© OMICRON 2015 – Diagnostic Measurements on Power Transformers Conference & Workshop

Presentation 5.2

FDS/DFR

The presence of moisture in a transformer

deteriorates the insulation by decreasing both the

electrical and mechanical strength. In general, the

mechanical life of non-upgraded Kraft paper

insulation is reduced by the presence of moisture.

OMICRON’s Dielectric Response Analyzer,

DIRANA, has been a powerful tool that has

reduced costs to ABB, and subsequently the

customer, during processes such as drying and

installation.

ABB has used this tool during the past several

Fig. 3 CT testing with OMICRON CT Analyzer

years for analysis of transformers both in its

factories and in the field. The experience gained

from the tests and analyses has shown the Literature

potential of the DFR test for identifying not only

moisture problems, but also other defects in the [1] Guide for Diagnostic Field Testing of Electric

transformer insulation structure [2]. Power Apparatus—Part1: Oil Filled Power

Transformers, Regulators, and Reactors,

IEEE Std.62-1995, Aug. 1995.

[2] ABB TrafoServ Handbook LOW_Aug06

[3] Y. Du, M. Zahn, B.C. Lesieutre, A. V.

Mamishev and S. Lindgren, ”Moisture

Equilibrium in Transformer Paper-Oil

Systems”, IEEE Electrical Insulation

Magazine, Vol. 15, No. 1, pp. 11-20,

January/February 1999.

About the Authors

Robert Slinger born in

Lancaster, England in 1979,

progressed as a time served

Fig. 2 ABB Analysis tool for DFR measurements of

Industrial Electrician achieving

transformers

HNC in Electrical & Electronic

Engineering at Teeside

There are several conditions in a transformer that University. Robert developed

can lead to high or unusual measurement results. into Distribution and

Here are some of the causes that have been Transmission commissioning

diagnosed by ABB experts (see Fig. 2). gaining Senior Authorisations; he now works as

Moisture in the cellulose insulation Operations Manager at ABB transformer service

High oil conductivity due to ageing or following three years as field test Engineer.

overheating of the oil

Chemical contamination of cellulose Johnny Sanchez Gomez born

insulation in Pereira, Colombia in 1983.

Carbon tracking in cellulose He received the electrical

High resistance in the magnetic core steel engineering degree from

circuit Universidad Tecnologica de

Pereira in 2009. Since 2011 he

Current Transformer Tests has worked within ABB in

Colombia and the UK as field

CT testing has evolved since the OMICRON service specialist for the

CT Analyzer was created, and now tests which transformers divisions.

would normally take a couple of days are carried

out within just a couple of hours (see Fig. 3). With

the CT Analyzer, ABB has substantially reduced

the commissioning time of CT testing with

increased accuracy.

© OMICRON 2015 – Diagnostic Measurements on Power Transformers Conference & Workshop

You might also like

- Siemens WP Short CircuitDocument10 pagesSiemens WP Short CircuitJose Antonio Huamani ChuquirimayNo ratings yet

- Sync Check With Voltage Selection and VTs With Different Ratio enDocument8 pagesSync Check With Voltage Selection and VTs With Different Ratio enJose Antonio Huamani ChuquirimayNo ratings yet

- GHJDocument11 pagesGHJJose Antonio Huamani ChuquirimayNo ratings yet

- APS Booklet 2015Document252 pagesAPS Booklet 2015Jose Antonio Huamani ChuquirimayNo ratings yet

- IEEE Standard Definitions For Use in Reporting Electric Generating Unit Reliability Availability and ProductivityDocument78 pagesIEEE Standard Definitions For Use in Reporting Electric Generating Unit Reliability Availability and ProductivityDimas100% (1)

- Correccion Resistencia de Aislamiento1Document1 pageCorreccion Resistencia de Aislamiento1Jose Antonio Huamani ChuquirimayNo ratings yet

- Presentation Sgen2000p Zborovsky SiemensDocument22 pagesPresentation Sgen2000p Zborovsky SiemensJose Antonio Huamani ChuquirimayNo ratings yet

- Readme DIGSI 5 TEA-X-Plugin PDFDocument15 pagesReadme DIGSI 5 TEA-X-Plugin PDFJohan Laureano ApolinarioNo ratings yet

- Taikina-Aho Markku-2011-Redundant IEC 61850 Communication Protocols in Substation AutomationDocument134 pagesTaikina-Aho Markku-2011-Redundant IEC 61850 Communication Protocols in Substation AutomationJose Antonio Huamani ChuquirimayNo ratings yet

- Updoc - Tips Omicron Test UniversepdfDocument5 pagesUpdoc - Tips Omicron Test UniversepdfJose Antonio Huamani ChuquirimayNo ratings yet

- Rhe 10422315298 e 00113Document1 pageRhe 10422315298 e 00113Jose Antonio Huamani ChuquirimayNo ratings yet

- Dielectric Analysis of Power Transformers ENUDocument21 pagesDielectric Analysis of Power Transformers ENUJose Antonio Huamani Chuquirimay100% (1)

- PCBTransformers SPDocument65 pagesPCBTransformers SPJavier SalasNo ratings yet

- 0 WD490 VE460 00002 - RevF Seismic Calculation ReportDocument26 pages0 WD490 VE460 00002 - RevF Seismic Calculation ReportJose Antonio Huamani ChuquirimayNo ratings yet

- Testing Alpha Plane Characteristic Paper IPTS 2011 Munro ENUDocument21 pagesTesting Alpha Plane Characteristic Paper IPTS 2011 Munro ENUJose Antonio Huamani ChuquirimayNo ratings yet

- AComparativeStudyofIEC76andANSIC57 12ontransformersDocument1 pageAComparativeStudyofIEC76andANSIC57 12ontransformersJose Antonio Huamani ChuquirimayNo ratings yet

- Taikina-Aho Markku-2011-Redundant IEC 61850 Communication Protocols in Substation AutomationDocument134 pagesTaikina-Aho Markku-2011-Redundant IEC 61850 Communication Protocols in Substation AutomationJose Antonio Huamani ChuquirimayNo ratings yet

- Dielectric Analysis of Power Transformers ENUDocument21 pagesDielectric Analysis of Power Transformers ENUJose Antonio Huamani Chuquirimay100% (1)

- AcSELerator Quickset User ManualDocument12 pagesAcSELerator Quickset User ManualJose Antonio Huamani Chuquirimay100% (1)

- PCBTransformers SPDocument65 pagesPCBTransformers SPJavier SalasNo ratings yet

- High Voltage Testing GIS Paper ITMF 2010 Hulka ENUDocument16 pagesHigh Voltage Testing GIS Paper ITMF 2010 Hulka ENUJose Antonio Huamani ChuquirimayNo ratings yet

- SIPROTEC 5 V7 8 - en PDFDocument28 pagesSIPROTEC 5 V7 8 - en PDFJose Antonio Huamani ChuquirimayNo ratings yet

- CP TD1 Efficient On-Site Testing 2010 Issue1Document3 pagesCP TD1 Efficient On-Site Testing 2010 Issue1Oriel Boldrini ValdiviaNo ratings yet

- A Comparative Study of IEC 76 and ANSI C57.12 On TransformersDocument9 pagesA Comparative Study of IEC 76 and ANSI C57.12 On TransformersprasannamohandasNo ratings yet

- AcSELerator Quickset User ManualDocument14 pagesAcSELerator Quickset User ManualGustavoJanito100% (1)

- 21Y46166P1Document49 pages21Y46166P1Jorge Vasquez ChavarryNo ratings yet

- Siemens 7SA511 Numerical Distance Protection Relay Instruction ManualDocument326 pagesSiemens 7SA511 Numerical Distance Protection Relay Instruction ManualMiguel AngelNo ratings yet

- CPC 100 TESTRANO 600 AppNote Power Transformer Short Circuit Impedance 2017 ENUDocument52 pagesCPC 100 TESTRANO 600 AppNote Power Transformer Short Circuit Impedance 2017 ENUJose Antonio Huamani ChuquirimayNo ratings yet

- CT Failure Diagnostic Paper ITMF 2011 Junaidi ENU PDFDocument6 pagesCT Failure Diagnostic Paper ITMF 2011 Junaidi ENU PDFJose Antonio Huamani ChuquirimayNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Irjet V3i7136Document5 pagesIrjet V3i7136Rajesh SharmaNo ratings yet

- Multi Format Broadcast LCD Monitor: Operation Manual - v1.0Document36 pagesMulti Format Broadcast LCD Monitor: Operation Manual - v1.0Sergio MorenoNo ratings yet

- Hegel Catalogue 2010Document11 pagesHegel Catalogue 2010LukaszNo ratings yet

- Information and Communication Technology (s.07)Document13 pagesInformation and Communication Technology (s.07)Atirah HaisNo ratings yet

- Costas Receiver and QAM DemodulationDocument10 pagesCostas Receiver and QAM DemodulationRohan JainNo ratings yet

- Toshiba VRF MMS Service ManualDocument216 pagesToshiba VRF MMS Service ManualThếSơnNguyễn100% (3)

- Reset Forgotten BIOS PasswordDocument5 pagesReset Forgotten BIOS Passwordtweety874No ratings yet

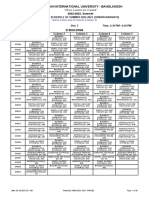

- Day 3 Slot 3 Mid Sm23 SummerDocument32 pagesDay 3 Slot 3 Mid Sm23 SummerNayeem SarkarNo ratings yet

- 3.5 To 30 MHZ Automatic Antenna Impedance Matching SystemDocument100 pages3.5 To 30 MHZ Automatic Antenna Impedance Matching SystemAlexandru MaiorNo ratings yet

- Delta Wye ReportDocument5 pagesDelta Wye ReportAhmad Hariez FuzeinNo ratings yet

- John Keel - How To Make Your Own UFO DetectorDocument2 pagesJohn Keel - How To Make Your Own UFO Detectorfatherazhara100% (1)

- OKS Clamp-On Buffer Ultrasonic Flow TransducersDocument18 pagesOKS Clamp-On Buffer Ultrasonic Flow Transducerssmit6954No ratings yet

- Sheet 5Document1 pageSheet 5محمود موافيNo ratings yet

- Flowmeter MT WDocument36 pagesFlowmeter MT WRangga K NegaraNo ratings yet

- ES2 0 3180 MT6750 - Android - ScatterDocument15 pagesES2 0 3180 MT6750 - Android - ScatterHosein HaidariNo ratings yet

- 4.1 - 6.3 - 1720E Turbidity SensorDocument4 pages4.1 - 6.3 - 1720E Turbidity Sensorcuongnv_19No ratings yet

- Electronics and Instrumentation - 2020Document28 pagesElectronics and Instrumentation - 2020RahulNo ratings yet

- Qatar Transmission System Expansion - Phase 10 Substations Package S5 & S8 CONTRACT No. GTC/371C/2010Document20 pagesQatar Transmission System Expansion - Phase 10 Substations Package S5 & S8 CONTRACT No. GTC/371C/2010Vijai PrasathNo ratings yet

- CT Whitepaper Stellar DetectorDocument8 pagesCT Whitepaper Stellar DetectorsitalekshmiNo ratings yet

- Fiber Optic ConnectorsDocument36 pagesFiber Optic ConnectorsVikaskumar ReddyNo ratings yet

- Topcon RL-H5A - EDocument2 pagesTopcon RL-H5A - EAudityaNo ratings yet

- Manual Usuario Balanza healtOMeter 500KLDocument16 pagesManual Usuario Balanza healtOMeter 500KLararmijosNo ratings yet

- TCH Availability Assignment Success RateDocument6 pagesTCH Availability Assignment Success RateMohamad SupriogiNo ratings yet

- FET Terminal Functions and JFET Biasing CharacteristicsDocument7 pagesFET Terminal Functions and JFET Biasing CharacteristicsDiana Jane Terez LazaroNo ratings yet

- HVR M10Document317 pagesHVR M10bzrmiltosNo ratings yet

- HBXX 6516DS VTMDocument2 pagesHBXX 6516DS VTMajobudiNo ratings yet

- AM and FMDocument11 pagesAM and FMritaempalmadoNo ratings yet

- RF Sealing TheoryDocument3 pagesRF Sealing Theorykirandasi123No ratings yet

- 30gx PDFDocument36 pages30gx PDFVinod NairNo ratings yet

- Ground Fault ProtectionDocument60 pagesGround Fault ProtectiondallabragNo ratings yet