Professional Documents

Culture Documents

Prorod Spec Sheet

Uploaded by

Bala SingamCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Prorod Spec Sheet

Uploaded by

Bala SingamCopyright:

Available Formats

PRO - ROD

COILED ROD SOLUTIONS

PRO - ROD

COILED ROD SOLUTIONS

COILED SUCKER ROD SELECTION GUIDE COILED SUCKER ROD SELECTION GUIDE

Specifications Specifications

Pro-Rod manufactures the following types of coiled rod to meet any Pro-Rod manufactures the following types of coiled rod to meet any

pumping condition. pumping condition.

Type 620C Grade D (Carbon) – AISI 1536M Carbon-Manganese Alloy Steel. Designed for medium to heavy loads at any depth in Type 620C Grade D (Carbon) – AISI 1536M Carbon-Manganese Alloy Steel. Designed for medium to heavy loads at any depth in

non-corrosive well fluids. This grade can be utilized in both reciprocating and Progressing Cavity Pump (PCP) applications. non-corrosive well fluids. This grade can be utilized in both reciprocating and Progressing Cavity Pump (PCP) applications.

Type 780M Grade D (Alloy) – AISI 4120M Chromium-Molybdenum Alloy Steel. Designed for heavy loads at any depth in mild to medium Type 780M Grade D (Alloy) – AISI 4120M Chromium-Molybdenum Alloy Steel. Designed for heavy loads at any depth in mild to medium

corrosive well fluids that are effectively inhibited against corrosion attack. This grade has been alloyed and effectively heat-treated to resist corrosive well fluids that are effectively inhibited against corrosion attack. This grade has been alloyed and effectively heat-treated to resist

corrosion and fatigue. Type 780M rods are recommended for both reciprocating and Progressing Cavity Pump (PCP) applications. corrosion and fatigue. Type 780M rods are recommended for both reciprocating and Progressing Cavity Pump (PCP) applications.

Type 750N Grade D (Special Alloy) – AISI 4320M Nickel-Chromium-Molybdenum Alloy Steel. Designed for heavy loads at any depth in Type 750N Grade D (Special Alloy) – AISI 4320M Nickel-Chromium-Molybdenum Alloy Steel. Designed for heavy loads at any depth in

corrosive well fluids that are effectively inhibited against corrosion attack. This grade had been alloyed and effectively heat-treated to corrosive well fluids that are effectively inhibited against corrosion attack. This grade had been alloyed and effectively heat-treated to

maximize its corrosion and fatigue resistance. Type 750N rods are recommended for both reciprocating and Progressing Cavity Pump maximize its corrosion and fatigue resistance. Type 750N rods are recommended for both reciprocating and Progressing Cavity Pump

(PCP) applications. (PCP) applications.

Type 960M Special High Strength Grade – AISI 4120M Chromium-Molybdenum Alloy Steel. Designed for extra heavy loads at any Type 960M Special High Strength Grade – AISI 4120M Chromium-Molybdenum Alloy Steel. Designed for extra heavy loads at any

depth in corrosive well fluids that are effectively inhibited against corrosion attack. This grade has been alloyed and effectively heat-treated depth in corrosive well fluids that are effectively inhibited against corrosion attack. This grade has been alloyed and effectively heat-treated

to resist corrosion and fatigue. Type 960M rods are recommended for both reciprocating and Progressing Cavity Pump (PCP) applications. to resist corrosion and fatigue. Type 960M rods are recommended for both reciprocating and Progressing Cavity Pump (PCP) applications.

Type 970N Special High Strength Grade – AISI 4330M Nickel-Chromium-Molybdenum Alloy Steel. Designed for extra heavy loads at Type 970N Special High Strength Grade – AISI 4330M Nickel-Chromium-Molybdenum Alloy Steel. Designed for extra heavy loads at

any depth in corrosive well fluids that are effectively inhibited against corrosion attack. This grade has been alloyed and effectively heat any depth in corrosive well fluids that are effectively inhibited against corrosion attack. This grade has been alloyed and effectively heat

treated to maximize its corrosion and fatigue resistance. Type 970N rods are recommended for both reciprocating and Progressing Cavity treated to maximize its corrosion and fatigue resistance. Type 970N rods are recommended for both reciprocating and Progressing Cavity

Pump (PCP) applications. Pump (PCP) applications.

Rod Ends – API and Drive Rod Ends are manufactured with Pro-Rod materials to API and ISO dimensions and tolerances. Rod Ends – API and Drive Rod Ends are manufactured with Pro-Rod materials to API and ISO dimensions and tolerances.

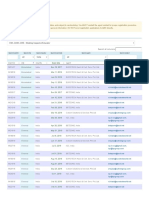

PROPERTIES PROPERTIES

Physical Properties - quenched & tempered Physical Properties - quenched & tempered

Pro-Rod Type 620C 780M 750N 960M 970N Pro-Rod Type 620C 780M 750N 960M 970N

Tensile, ksi (MPa) min. 120 (827) 120 (827) 125 (862) 140 (965) 140 (965) Tensile, ksi (MPa) min. 120 (827) 120 (827) 125 (862) 140 (965) 140 (965)

Yield, ksi (MPa) min. 85 (586) 100 (689) 100 (689) 115 (793) 115 (793) Yield, ksi (MPa) min. 85 (586) 100 (689) 100 (689) 115 (793) 115 (793)

Hardness, Rc 22 min 22 min 24 min 30 min 30 min Hardness, Rc 22 min 22 min 24 min 30 min 30 min

Dimensions & Weight Dimensions & Weight

Size Nominal O.D. lb/ft O.D. Tolerance Size Nominal O.D. lb/ft O.D. Tolerance

in. (mm) (kg/m) ± in. (± mm) in. (mm) (kg/m) ± in. (± mm)

13/16 (20.6) 1.76 (2.63) 0.02 (0.51) 13/16 (20.6) 1.76 (2.63) 0.02 (0.51)

7/8 (22.2) 2.04 (3.05) 0.02 (0.51) 7/8 (22.2) 2.04 (3.05) 0.02 (0.51)

1 (25.4) 2.67 (3.97) 0.02 (0.51) 1 (25.4) 2.67 (3.97) 0.02 (0.51)

1 1/8 (28.6) 3.38 (5.05) 0.02 (0.51) 1 1/8 (28.6) 3.38 (5.05) 0.02 (0.51)

MAXIMUM ALLOWABLE TORQUE MAXIMUM ALLOWABLE TORQUE

All Torque Values are ft-lbs (N-m) All Torque Values are ft-lbs (N-m)

Maximum Service Maximum Service

Grade D Grade D Grade D Special Service Special Service Grade D Grade D Grade D Special Service Special Service

Rod Size Carbon (620C) Alloy (780M) Special Alloy (750N) (960M) (970N) Rod Size Carbon (620C) Alloy (780M) Special Alloy (750N) (960M) (970N)

in. (mm) AISI 1536M AISI 4120M AISI 4320M AISI 4120M AISI 4330M in. (mm) AISI 1536M AISI 4120M AISI 4320M AISI 4120M AISI 4330M

13/16 (20.6) 540 (732) 565 (766) 580 (786) 725 (983) 725 (983) 13/16 (20.6) 540 (732) 565 (766) 580 (786) 725 (983) 725 (983)

7/8 (22.2) 680 (922) 735 (997) 750 (1,017) 900 (1,220) 900 (1,220) 7/8 (22.2) 680 (922) 735 (997) 750 (1,017) 900 (1,220) 900 (1,220)

1 (25.4) 1,015 (1,376) 1,100 (1,491) 1,110 (1,505) 1,350 (1,830) 1,350 (1,830) 1 (25.4) 1,015 (1,376) 1,100 (1,491) 1,110 (1,505) 1,350 (1,830) 1,350 (1,830)

1 1/8 (28.6 ) 1,445 (1,959) 1,535 (2,081) 1,550 (2,101) 1,900 (2,576) 1,900 (2,576) 1 1/8 (28.6 ) 1,445 (1,959) 1,535 (2,081) 1,550 (2,101) 1,900 (2,576) 1,900 (2,576)

* All values based on rod in like new condition. * All values based on rod in like new condition.

* To maximize rod fatigue life, Pro-Rod recommends using a 0.8 safety factor. * To maximize rod fatigue life, Pro-Rod recommends using a 0.8 safety factor.

* Correct rod end makeup connection is critical to the operation of a Progressing Cavity Pump installation. * Correct rod end makeup connection is critical to the operation of a Progressing Cavity Pump installation.

Care and Handling Care and Handling

Maximum Recommended Weight Indicator Pull on a Coiled Sucker Rod String Maximum Recommended Weight Indicator Pull on a Coiled Sucker Rod String

The following calculates the maximum rig weight indicator pull on a stuck rod string. The calculations are based on 90% of the minimum The following calculates the maximum rig weight indicator pull on a stuck rod string. The calculations are based on 90% of the minimum

yield strength, for a rod string in “like new” condition. The maximum load should be reached by a straight, steady pull and not a shock load. yield strength, for a rod string in “like new” condition. The maximum load should be reached by a straight, steady pull and not a shock load.

For a tapered string, calculate the total weight in pounds of all rods above the bottom section. Add to this weight the values in the table For a tapered string, calculate the total weight in pounds of all rods above the bottom section. Add to this weight the values in the table

below for the rod type and size of the bottom section. This is the maximum load that should be pulled on a rod string. For a straight rod below for the rod type and size of the bottom section. This is the maximum load that should be pulled on a rod string. For a straight rod

string, the table values are the maximum pull. string, the table values are the maximum pull.

MAXIMUM RECOMMENDED WEIGHT INDICATOR PULL MAXIMUM RECOMMENDED WEIGHT INDICATOR PULL

Load in Load in Load in Load in

Rod Type Size - in. (mm) Pounds (daN) Rod Type Size - in. (mm) Pounds (daN) Rod Type Size - in. (mm) Pounds (daN) Rod Type Size - in. (mm) Pounds (daN)

13/16 (20.6) 44,330 (19,718) 13/16 (20.6) 53,660 (23,869) 13/16 (20.6) 44,330 (19,718) 13/16 (20.6) 53,660 (23,869)

Type 620C & 7/8 (22.2) 51,410 (22,868) Type 960M 7/8 (22.2) 62,240 (27,683) Type 620C & 7/8 (22.2) 51,410 (22,868) Type 960M 7/8 (22.2) 62,240 (27,683)

780M 780M

1 (25.4) 67,150 (29,869) 1 (25.4) 81,290 (36,157) 1 (25.4) 67,150 (29,869) 1 (25.4) 81,290 (36,157)

1 1/8 (28.6) 84,990 (37,803) 1 1/8 (28.6) 102,880 (45,762) 1 1/8 (28.6) 84,990 (37,803) 1 1/8 (28.6) 102,880 (45,762)

13/16 (20.6) 46,665 (20,756) 13/16 (20.6) 56,000 (24,907) 13/16 (20.6) 46,665 (20,756) 13/16 (20.6) 56,000 (24,907)

Type 750N 7/8 (22.2) 54,120 (24,072) Type 970N 7/8 (22.2) 64,940 (28,887) Type 750N 7/8 (22.2) 54,120 (24,072) Type 970N 7/8 (22.2) 64,940 (28,887)

1 (25.4) 70,685 (31,441) 1 (25.4) 84,820 (37,729) 1 (25.4) 70,685 (31,441) 1 (25.4) 84,820 (37,729)

1 1/8 (28.6) 89,460 (39,793) 1 1/8 (28.6) 107,355 (47,751) 1 1/8 (28.6) 89,460 (39,793) 1 1/8 (28.6) 107,355 (47,751)

CANADIAN MANUFACTURING SERVICE & DISPATCH CALGARY SALES OFFICE FOR MORE INFO CONTACT CANADIAN MANUFACTURING SERVICE & DISPATCH CALGARY SALES OFFICE FOR MORE INFO CONTACT

FACILITY & HEAD OFFICE P.O. Box 12279 #1540, Bantrel Tower prorodinfo@doverals.com FACILITY & HEAD OFFICE P.O. Box 12279 #1540, Bantrel Tower prorodinfo@doverals.com

3201 - 84th Ave. Lloydminster, Alberta T9V 3C5 700 – 6th Avenue SW www.doverals.com 3201 - 84th Ave. Lloydminster, Alberta T9V 3C5 700 – 6th Avenue SW www.doverals.com

Edmonton, Alberta T6P 1K1 P: (780) 871-0783 Calgary, Alberta T2P 0T8 www.prorod.com Edmonton, Alberta T6P 1K1 P: (780) 871-0783 Calgary, Alberta T2P 0T8 www.prorod.com

P: (780) 449-7101 (24Hrs) P: (780) 449-7101 (24Hrs) P: (403) 269-5116 P: (780) 449-7101 (24Hrs) P: (780) 449-7101 (24Hrs) P: (403) 269-5116

F: (780) 416-5240 F: (403) 263-4768 F: (780) 416-5240 F: (403) 263-4768

You might also like

- K-71TM K-71TLF KX-200H: Tubular Wires Mild SteelDocument1 pageK-71TM K-71TLF KX-200H: Tubular Wires Mild SteelIrinaNo ratings yet

- Bonnie Forge Couple DimensionsDocument14 pagesBonnie Forge Couple DimensionsTodd AlexanderNo ratings yet

- Synergy CatalogueDocument8 pagesSynergy CatalogueTino JuNo ratings yet

- Filler Wire For Gtaw PDFDocument27 pagesFiller Wire For Gtaw PDFrezaNo ratings yet

- Vibratory Compactors: S S L M T L C T L C W LDocument4 pagesVibratory Compactors: S S L M T L C T L C W LPAUL FRANKLIN ANGULO CABANILLASNo ratings yet

- Reinforcement Steel WorksDocument28 pagesReinforcement Steel WorksPooja PawarNo ratings yet

- Steel Plate For Boilers and Pressure Vessels: S.No. Steel Grade Executive StandardDocument7 pagesSteel Plate For Boilers and Pressure Vessels: S.No. Steel Grade Executive StandardHarish SivakumarNo ratings yet

- Emp Dry ProcessDocument6 pagesEmp Dry ProcessKucing GemukNo ratings yet

- Covered Electrodes: Mild Steel High Tensile Steel Low Hydrogen Steel Stainless SteelDocument42 pagesCovered Electrodes: Mild Steel High Tensile Steel Low Hydrogen Steel Stainless SteelChainarong ArunchaiwatNo ratings yet

- Basics of Grinding 1Document21 pagesBasics of Grinding 1maulikgadara100% (1)

- NOR Steel Sucker Rods and Pony Rods BR 062122Document8 pagesNOR Steel Sucker Rods and Pony Rods BR 062122Pedro GilNo ratings yet

- NOR - Steel Sucker Rods and Pony Rods - V2Document8 pagesNOR - Steel Sucker Rods and Pony Rods - V2Cosersum Int C ANo ratings yet

- Series Description: Universal Product Line: Steel Externals - Jacketed PumpsDocument9 pagesSeries Description: Universal Product Line: Steel Externals - Jacketed PumpsAnonymous uCYIu1No ratings yet

- AISI 4130 Alloy Steel (UNS G41300) : Chemical CompositionDocument2 pagesAISI 4130 Alloy Steel (UNS G41300) : Chemical CompositionALEX MURPHYNo ratings yet

- Home About Us Products & Market Media Contact: Minimum Standard RequirementsDocument4 pagesHome About Us Products & Market Media Contact: Minimum Standard RequirementsMohamed AlkharashyNo ratings yet

- Home About Us Products & Market Media Contact: Minimum Standard RequirementsDocument4 pagesHome About Us Products & Market Media Contact: Minimum Standard RequirementsAtiqur RahmanNo ratings yet

- BLOOMFOSS BT-Hydraulic-ActuatorDocument27 pagesBLOOMFOSS BT-Hydraulic-Actuatorpedro100% (1)

- Catalogue Seal Oil CoolerDocument28 pagesCatalogue Seal Oil CoolerSharad KokateNo ratings yet

- Low Alloy13Document5 pagesLow Alloy13Branko FerenčakNo ratings yet

- GRADE 302: Element Content (%)Document3 pagesGRADE 302: Element Content (%)Shashank Saxena100% (1)

- Metal Seated Ball ValveDocument24 pagesMetal Seated Ball Valvehiep nguyenNo ratings yet

- EN19 Alloy Steel - EN19 Forging - EN19 Flat - Saaj Steel CorporationDocument5 pagesEN19 Alloy Steel - EN19 Forging - EN19 Flat - Saaj Steel CorporationNaiduNo ratings yet

- 2012 Jjtools Catalogue PDFDocument180 pages2012 Jjtools Catalogue PDFAnonymous aZKer3gNo ratings yet

- Ancon Stainless Steel Reinforcement Round Bars Australia EditionDocument12 pagesAncon Stainless Steel Reinforcement Round Bars Australia EditionBrad MannNo ratings yet

- S&P Overview - VGSP1014 - R0Document6 pagesS&P Overview - VGSP1014 - R0nicolasgonzNo ratings yet

- AWS - Welding Journal - 2004 - 02Document117 pagesAWS - Welding Journal - 2004 - 02arnoldbatista55No ratings yet

- A Mefi MC001 E1Document16 pagesA Mefi MC001 E1aptureincNo ratings yet

- Endurance Carbide CatalogDocument4 pagesEndurance Carbide CatalogAmy SalaskeNo ratings yet

- Aisi O1: Cold Work Tool SteelDocument7 pagesAisi O1: Cold Work Tool Steeltewiinaba777No ratings yet

- CI5000ENGDocument7 pagesCI5000ENGKaliya PerumalNo ratings yet

- British Steel Product Range BrochureDocument128 pagesBritish Steel Product Range BrochureHari PrasadNo ratings yet

- Inconel-Alloy 622 625Document1 pageInconel-Alloy 622 625meNo ratings yet

- Brosur Baja Gunung Raja Paksi Wire RodDocument1 pageBrosur Baja Gunung Raja Paksi Wire RodRobbi Shobri RakhmanNo ratings yet

- Ab-Ss: Keeping The World FlowingDocument4 pagesAb-Ss: Keeping The World FlowingGourav SharmaNo ratings yet

- Datasheet-Sandvik-Saf-32760-En-V2020-12-10 07 - 47 Version 1Document7 pagesDatasheet-Sandvik-Saf-32760-En-V2020-12-10 07 - 47 Version 1Weipeng LvNo ratings yet

- Sullivan & Sons Type H Control Valve PDFDocument4 pagesSullivan & Sons Type H Control Valve PDFAntonella EspinozaNo ratings yet

- Crosby Eye Hooks: On Pages 122 - 123Document1 pageCrosby Eye Hooks: On Pages 122 - 123Yudha J MalmsteenNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Martin DuarteNo ratings yet

- SB Drill Collar PDFDocument51 pagesSB Drill Collar PDFSiva GanaNo ratings yet

- Product Flyer 320 525 01 2023Document2 pagesProduct Flyer 320 525 01 2023Beltazor HellboyNo ratings yet

- L14015 Cam Clutch Trifold 1016smallDocument6 pagesL14015 Cam Clutch Trifold 1016smalloliver huangNo ratings yet

- Refrateck SolutionsDocument8 pagesRefrateck SolutionsMagesh Kumar0% (1)

- Industrial Diaphragm Valves: SaundersDocument14 pagesIndustrial Diaphragm Valves: SaundersscribdkhatnNo ratings yet

- Product Specification BS-4449Document2 pagesProduct Specification BS-4449Cyprian Cypu100% (2)

- York Compressor - CCIservice ManualDocument23 pagesYork Compressor - CCIservice ManualRubiToo100% (1)

- Jindal Saw LTD - SeamlessDocument30 pagesJindal Saw LTD - SeamlessRajat Chhabra0% (1)

- Stainless Steel 420 Material Chemical CompositionDocument3 pagesStainless Steel 420 Material Chemical Compositionr arumugamNo ratings yet

- Catalogo ISCDocument6 pagesCatalogo ISCAdolfo AriasNo ratings yet

- Norris Polished Rods (P004-V02-072208) - 1Document5 pagesNorris Polished Rods (P004-V02-072208) - 1Rodrigo RuizNo ratings yet

- B10M Dry Powder Fire ExtinguisherDocument2 pagesB10M Dry Powder Fire ExtinguisherMajaz AhmedNo ratings yet

- Melwa (Western Provice) 2018-03-22Document89 pagesMelwa (Western Provice) 2018-03-22Lakshan FonsekaNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Hareth MRAIDINo ratings yet

- Adhesive and Sealant 11Document3 pagesAdhesive and Sealant 11AsrinNo ratings yet

- Reasoned Document IRS T-45Document20 pagesReasoned Document IRS T-45Sec-II BGPLNo ratings yet

- Galleria Q Parc (U Channel Work Cost Comparison)Document1 pageGalleria Q Parc (U Channel Work Cost Comparison)Yogesh GilgileNo ratings yet

- This Domain Is Registered at NamecheapDocument3 pagesThis Domain Is Registered at NamecheapBala SingamNo ratings yet

- Dumond Smart Strip SdsDocument7 pagesDumond Smart Strip SdsBala SingamNo ratings yet

- Calibration Block - BIGPROBEDocument19 pagesCalibration Block - BIGPROBEBala SingamNo ratings yet

- Hha Brochure Pmi Master SmartDocument5 pagesHha Brochure Pmi Master SmartBala SingamNo ratings yet

- 1 Indeed Public ViewDocument4 pages1 Indeed Public ViewBala SingamNo ratings yet

- Vickers 30kg ManualDocument12 pagesVickers 30kg ManualBala SingamNo ratings yet

- Muffle FurnaceDocument2 pagesMuffle FurnaceBala SingamNo ratings yet

- AI-702M/704M/706M High Performance Intelligent Multi-Channel IndicatorsDocument15 pagesAI-702M/704M/706M High Performance Intelligent Multi-Channel IndicatorsBala SingamNo ratings yet

- ThiruvarutpaDocument19 pagesThiruvarutpaBala SingamNo ratings yet

- Canadian DRIP List - Canadian DRIP PrimerDocument6 pagesCanadian DRIP List - Canadian DRIP PrimerBala SingamNo ratings yet

- Session 5-Thermal Spray Coatings For Corrosion Protection-What You Need To KnowDocument48 pagesSession 5-Thermal Spray Coatings For Corrosion Protection-What You Need To KnowBala SingamNo ratings yet

- Industrial Building For Sale/Lease: Asking Price: $4,650,000Document3 pagesIndustrial Building For Sale/Lease: Asking Price: $4,650,000Bala SingamNo ratings yet

- AC Coupon TM GuideDocument4 pagesAC Coupon TM GuideBala SingamNo ratings yet

- Multi Channel IndicatorDocument1 pageMulti Channel IndicatorBala SingamNo ratings yet

- AI-702M/704M/706M High Performance Intelligent Multi-Channel IndicatorsDocument15 pagesAI-702M/704M/706M High Performance Intelligent Multi-Channel IndicatorsBala SingamNo ratings yet

- Choose Event Type To View Schedules: CWI, CAWI, CWE - Welding Inspector/EducatorDocument2 pagesChoose Event Type To View Schedules: CWI, CAWI, CWE - Welding Inspector/EducatorBala SingamNo ratings yet

- Proth Psgs Manual PDFDocument106 pagesProth Psgs Manual PDFBala SingamNo ratings yet

- Hardness Test TrainingDocument18 pagesHardness Test TrainingBala SingamNo ratings yet

- X-Ray Pipeline CrawlerDocument4 pagesX-Ray Pipeline CrawlerBala SingamNo ratings yet

- Replica Metallography and Penetrant TestingDocument14 pagesReplica Metallography and Penetrant TestingBala Singam100% (1)

- Supervisor: Job/Location: Date: Work To Be Done: Task LocationDocument1 pageSupervisor: Job/Location: Date: Work To Be Done: Task LocationBala SingamNo ratings yet

- PDF Catalogue PDFDocument42 pagesPDF Catalogue PDFBala SingamNo ratings yet

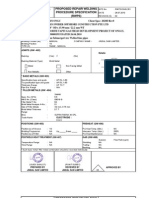

- P45 To P45 PQR CertifiedDocument7 pagesP45 To P45 PQR CertifiedBala SingamNo ratings yet

- Altair's Student Guides - CAE For Simulation of Metal FormingDocument60 pagesAltair's Student Guides - CAE For Simulation of Metal FormingKFourMetrics100% (26)

- ASTM A 967 Standard Specification For Chemical Passivation Treatments For Stainless SteelDocument6 pagesASTM A 967 Standard Specification For Chemical Passivation Treatments For Stainless SteelsuriyaNo ratings yet

- Aluminium Sheet Grade 65032 SuppliersDocument17 pagesAluminium Sheet Grade 65032 Supplierssanghvi overseas incNo ratings yet

- Gear Manufacturing Process With QuestionsDocument60 pagesGear Manufacturing Process With QuestionsUjwala Sonawane100% (1)

- Chloride Stress Corrosion Cracking - SSINADocument4 pagesChloride Stress Corrosion Cracking - SSINADaniel WilliamsNo ratings yet

- The Activation of Aluminium by Mercury Ions in Non Aggressive Media 2006 Corrosion ScienceDocument14 pagesThe Activation of Aluminium by Mercury Ions in Non Aggressive Media 2006 Corrosion SciencehortalemosNo ratings yet

- 3 Iron Carbon DiaDocument21 pages3 Iron Carbon DiaChhavi SharmaNo ratings yet

- CON-03!03!22 Temper Bead Welding ProcedureDocument6 pagesCON-03!03!22 Temper Bead Welding ProceduresusanwebNo ratings yet

- Saej 524 V 002Document5 pagesSaej 524 V 002Marcos Verissimo Juca de PaulaNo ratings yet

- Electrode CalculationDocument2 pagesElectrode CalculationRanjan Kumar100% (1)

- FAIDocument14 pagesFAIalejandroruiz020697No ratings yet

- Arandela Nord-LockDocument4 pagesArandela Nord-LockAsmecon s.a.s. IngenieriaNo ratings yet

- NAS517 - Genuine Aircraft HardwareDocument1 pageNAS517 - Genuine Aircraft HardwareNancy RodriguezNo ratings yet

- BusbarDocument119 pagesBusbarGabriel IrimiaNo ratings yet

- Wurth Abrasives PDFDocument7 pagesWurth Abrasives PDFQaiser MehmoodNo ratings yet

- A Brief Review On Micromachining of MaterialsDocument6 pagesA Brief Review On Micromachining of Materialsprasanth kNo ratings yet

- SEFCOR Quick Reference Catalog 2011Document301 pagesSEFCOR Quick Reference Catalog 2011samirparida81No ratings yet

- Alloy Steel ASTM A217 GRADE WC6Document2 pagesAlloy Steel ASTM A217 GRADE WC6Dika Wahyu WijayaNo ratings yet

- Metric DIN 125 Spec PDFDocument4 pagesMetric DIN 125 Spec PDFSandro CNo ratings yet

- ISO 630-6-2014 - Technical Delivery Conditions For Seismic-Improved Structural Steels For BuildingDocument22 pagesISO 630-6-2014 - Technical Delivery Conditions For Seismic-Improved Structural Steels For BuildingMohanrajMJNo ratings yet

- Rusting and Corrosion: Conditions For Iron To RustDocument3 pagesRusting and Corrosion: Conditions For Iron To Rusthussein hajiNo ratings yet

- Catalogue IndustriesDocument8 pagesCatalogue IndustriesAlber MoelNo ratings yet

- Setup For Centerless Grinders 320Document25 pagesSetup For Centerless Grinders 320arvinupNo ratings yet

- GATEMSM CompressedDocument13 pagesGATEMSM CompressedChaitanya Kishore ChitikenaNo ratings yet

- Iso - Iso Standards - Ics 25.220Document8 pagesIso - Iso Standards - Ics 25.220Harish Kumar Kannepalli0% (1)

- Chapter 3Document47 pagesChapter 3eiman bataNo ratings yet

- Astm A519Document14 pagesAstm A519PrakashNo ratings yet

- Casting, Welding, Machine Tools, Material SC PDFDocument240 pagesCasting, Welding, Machine Tools, Material SC PDFSanjay Kajal0% (1)

- Casting Basis-Rev 2Document27 pagesCasting Basis-Rev 2Vasudev DevNo ratings yet

- Rev 2 - Proposed Repair WPSDocument2 pagesRev 2 - Proposed Repair WPSRakesh Patel75% (4)