Professional Documents

Culture Documents

Oznake Strugarskih Pločica

Uploaded by

Haris TrešnjoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Oznake Strugarskih Pločica

Uploaded by

Haris TrešnjoCopyright:

Available Formats

Insert Shape

S Triangular insert with a facet

H Hexagonal IC

(Secondary Cutting Edge)

O Octagonal

c Tolerance Class

P Pentagonal

Tolerance of Tolerance of Tolerance of Detail of M Class Insert Tolerance

S Square Nose Height Inscribed Circle Thickness Tolerance of Nose Height M (mm)

M (mm) IC (mm) S (mm)

T Triangular D.I.C. Square 80° 55° 35° Round

A e0.005 e0.025 e0.025

C Rhombic 80° 6.35 e0.08 e0.08 e0.08 e0.11 e0.16

F e0.005 e0.013 e0.025

9.525 e0.08 e0.08 e0.08 e0.11 e0.16

D Rhombic 55° C e0.013 e0.025 e0.025

12.70 e0.13 e0.13 e0.13 e0.15

E Rhombic 75° H e0.013 e0.013 e0.025

15.875 e0.15 e0.15 e0.15 e0.18

E e0.025 e0.025 e0.025

F Rhombic 50° 19.05 e0.15 e0.15 e0.15 e0.18

G e0.025 e0.025 e0.13

M Rhombic 86° 25.40 e0.18

J e0.005 e0.05 e0.15 e0.025

31.75 e0.20

V Rhombic 35° K * e0.013 e0.05 e0.15 e0.025

Tolerance of Inscribed Circle IC (mm)

W Trigon L * e0.025 e0.05 e0.15 e0.025

L Rectangular

M * e0.08 e0.18 e0.05 e0.15 e0.13 D.I.C. Square 80° 55° 35° Round

N * e0.08 e0.18 e0.05 e0.15 e0.025 6.35 e0.05 e0.05 e0.05 e0.05 e0.05

A Parallelogram 85° U * e0.13 e0.38 e0.08 e0.25 e0.13 9.525 e0.05 e0.05 e0.05 e0.05 e0.05 e0.05

12.70 e0.08 e0.08 e0.08 e0.08 e0.08

B

K

Parallelogram 82°

Parallelogram 55°

The surface of insert with

* mark is sintered. 15.875 e0.10 e0.10 e0.10 e0.10 e0.10

19.05 e0.10 e0.10 e0.10 e0.10 e0.10

R Round

25.40 e0.13 e0.13

X Special Design 31.75 e0.15 e0.15

z Insert Shape c Tolerance Class

z c

C N M G x v

x Normal Clearance v Fixing and/or for Chip Breaker

Normal Clearance Metric

Hole Chip Hole Chip

A 3° Hole

Breaker

Figure Hole

Breaker

Figure

B 5° W With Hole No A With Hole No

+

One Single

C 7° T With Hole

Sided

M With Hole

Sided

Double

D 15° Q With Hole No G With Hole

Sided

+

Double Without

E 20° U With Hole

Sided

N Hole

No

Without Single

F 25° B With Hole No R Hole Sided

+

One Without Double

G 30° H With Hole

Sided

F Hole Sided

N 0° C With Hole No X Special Design

+

Double

P 11° J With Hole

Sided

O Other Normal Clearance

Major Normal Clearance

Symbol

(mm)

02

L3 08

04

05

03

04

03

04

06

08 4.76

*Thickness is from the bottom of the insert

to the top of the cutting edge.

Symbol Thickness (mm)

03 09 06 05 05 09 5.56

06 6.00 S1

04 11 07 06 06 11 6.35 01

05 13 09 08 07 13 T0

08 8.00 02 2.38

09 06 16 11 09 09 16 T2 2.78

10 10.00

03 3.18

12 12.00

T3

12 08 22 15 12 12 22 12.70

04 4.76

15 10 19 16 15 27 15.875

06 6.35

16 16.00

19 13 23 19 19 33 07

20 20.00 09

27 22 22 38 22.225 n Insert Thickness

25 25.00

25 31 25 25 44 25.40

31 38 32 31 54 31.75

32 32.00

b Insert Size / Chip Breaker

LP MP RP

b n /

12 04 08 (E) (N) MP m , .

LM MM RM

LK MK RK

m , .

Symbol Figure Cutting Edge Figure

00 Sharp Nose

Sharp

V3 0.03 F R LS MS RS

Cutting Edges

V5 0.05

01 0.1 Round Left L

E

Cutting Edges

02 0.2

FP LP MP

04 0.4

Chamfered N

08 0.8 T

Cutting Edges

12 1.2

16 1.6 Chamfered

and Rounded S MA SW MW

20 2.0

Cutting Edges

24 2.4

28 2.8 Mitsubishi Materials omit

the honing symbol.

32 3.2 HZ HX HV

00 : Inch

Round Insert

M0 : Metric

( )

You might also like

- Qdoc - Tips Masinski Elementi Tablice I Grafikoni 2016 17pdfDocument124 pagesQdoc - Tips Masinski Elementi Tablice I Grafikoni 2016 17pdfBarney StinsonNo ratings yet

- Kvaliteta U Zavarivanju - I. Samardžić PDFDocument34 pagesKvaliteta U Zavarivanju - I. Samardžić PDFMiaNo ratings yet

- VratilaDocument14 pagesVratilaNihadNo ratings yet

- Vjezba 1 - StrukturiranjeDocument16 pagesVjezba 1 - StrukturiranjeMarkoNo ratings yet

- Ležišta Pojam Osobine 4T5 23.10Document38 pagesLežišta Pojam Osobine 4T5 23.10Anonymous 4nfv9lQxyDNo ratings yet

- Difuziono ZavarivanjeDocument12 pagesDifuziono ZavarivanjeNedret BajramovicNo ratings yet

- 9 Zupcanici ZahvatDocument7 pages9 Zupcanici ZahvatMario FridlNo ratings yet

- Alati I Pribori Za RezanjeDocument6 pagesAlati I Pribori Za RezanjeElvis OmanovićNo ratings yet

- Me Tolerancije FolijeDocument11 pagesMe Tolerancije FolijeBranko LazicNo ratings yet

- 4 Postupci OOC I DioDocument45 pages4 Postupci OOC I DioHakuna MatataNo ratings yet

- Mašinski Elementi I-TolerancijeDocument10 pagesMašinski Elementi I-TolerancijeJelena MarkovićNo ratings yet

- Skripta - Tehnicko CrtanjeDocument25 pagesSkripta - Tehnicko CrtanjeMarijanNo ratings yet

- VIII - Grafički Rad - Tehnička Dokumentacija PDFDocument2 pagesVIII - Grafički Rad - Tehnička Dokumentacija PDFEnvera ŠarićNo ratings yet

- Alati Za OdsjecanjeDocument4 pagesAlati Za OdsjecanjeFilip KrsnikNo ratings yet

- Osnove KonstruiranjaDocument82 pagesOsnove KonstruiranjacicibankkNo ratings yet

- ElektropneumatikaDocument36 pagesElektropneumatikaПётр ПоповичNo ratings yet

- Obrada Na GlodaliciDocument32 pagesObrada Na GlodalicibbijelacNo ratings yet

- LjevarstvoDocument13 pagesLjevarstvodarkkashya100% (1)

- Konstrukcija AlataDocument6 pagesKonstrukcija AlataAzraaaNo ratings yet

- Program Lančani PrijenosDocument6 pagesProgram Lančani Prijenospromet103No ratings yet

- 08 KlinoviDocument49 pages08 KlinoviAdnan MustafićNo ratings yet

- РЕНДИСАЉКАDocument30 pagesРЕНДИСАЉКАDragana VicentijevicNo ratings yet

- 2 1 Odstupanje U Procesu ObradeDocument22 pages2 1 Odstupanje U Procesu ObradeAidaNo ratings yet

- Postupci Obrade Odvajanjem Čestica Alatom Bez OštriceDocument30 pagesPostupci Obrade Odvajanjem Čestica Alatom Bez Oštriceemiliobrnadic1867No ratings yet

- MASINSKI - ELEMENTI-Tablice I Grafikoni-2018-19 PDFDocument124 pagesMASINSKI - ELEMENTI-Tablice I Grafikoni-2018-19 PDFRamo TursunovićNo ratings yet

- Rezimi Obrade PDFDocument3 pagesRezimi Obrade PDFDanijel KnezevicNo ratings yet

- SolidWorks - Vjezba 0r7Document8 pagesSolidWorks - Vjezba 0r7Nejra DedajićNo ratings yet

- Teorijske Osnove Obrade RezanjemDocument14 pagesTeorijske Osnove Obrade Rezanjemjdv1234No ratings yet

- Koludrovic 1 PDFDocument10 pagesKoludrovic 1 PDFacairalexNo ratings yet

- Kuka Broj 8Document1 pageKuka Broj 8Samsung IphoneNo ratings yet

- Veze Klinovima I CivijamaDocument10 pagesVeze Klinovima I CivijamaasNo ratings yet

- Programiranje CNC Strojeva Sinumerik 840dDocument216 pagesProgramiranje CNC Strojeva Sinumerik 840dMurat BeyNo ratings yet

- Sremic 2017 DiplomskiDocument104 pagesSremic 2017 DiplomskiElmedin Alisa FazlićNo ratings yet

- AdadDocument12 pagesAdadNermin RedžićNo ratings yet

- Z Horvat Vratilo PDFDocument23 pagesZ Horvat Vratilo PDFRadovan BačaninNo ratings yet

- Tarni Prijenos EKII 2017 WEB PDFDocument48 pagesTarni Prijenos EKII 2017 WEB PDFVanja100% (1)

- 57 Obrada TesterisanjemDocument6 pages57 Obrada TesterisanjemSmetell MinecraftNo ratings yet

- Šta Predstavlja Proces Obrade Prosijecanjem?Document7 pagesŠta Predstavlja Proces Obrade Prosijecanjem?Mirza DurakovicNo ratings yet

- REDUKTORI Upustvo Za ProracunDocument48 pagesREDUKTORI Upustvo Za ProracunMilenko MaksimovicNo ratings yet

- Valjanje WDocument18 pagesValjanje WHaris DžaferovićNo ratings yet

- Toplinska Obrada Alatnih ČelikaDocument23 pagesToplinska Obrada Alatnih Čelikapetrus erectusNo ratings yet

- Rezne PločiceDocument8 pagesRezne PločiceIvana Šutalo DujmenovićNo ratings yet

- NavarivanjeDocument7 pagesNavarivanjeIvica MilosevskiNo ratings yet

- Kritična Brzina VrtnjeDocument6 pagesKritična Brzina VrtnjeEdin OsmančevićNo ratings yet

- 1 1 Posluzivanje CNC StrojevaDocument6 pages1 1 Posluzivanje CNC StrojevaDubravko KernNo ratings yet

- 05 - Nerazdvojive Veze - Zakovicni SpojeviDocument45 pages05 - Nerazdvojive Veze - Zakovicni SpojeviBelyNo ratings yet

- SolidWorks Projektovanje Pomoću Računara 2Document275 pagesSolidWorks Projektovanje Pomoću Računara 2qwertz_mNo ratings yet

- Probijanje ProsijecanjeDocument21 pagesProbijanje Prosijecanjemirzakovac3077No ratings yet

- GlodanjeDocument27 pagesGlodanjemara2proletaNo ratings yet

- Skripta CNC Osnove Primjeri S Programima PDFDocument50 pagesSkripta CNC Osnove Primjeri S Programima PDFdjuka65No ratings yet

- Tema-1 Ljevanje-Osnove Tehnologije-Jednokratne FormeDocument30 pagesTema-1 Ljevanje-Osnove Tehnologije-Jednokratne FormeTamaraNo ratings yet

- EDMDocument20 pagesEDMArmin KotoricNo ratings yet

- Betonska UporistaDocument14 pagesBetonska UporistamiskoNo ratings yet

- Čelik Razred ADocument15 pagesČelik Razred AmiskoNo ratings yet

- Fitocenoloska Tabela Marina MandicDocument6 pagesFitocenoloska Tabela Marina MandicNikola MarjanovicNo ratings yet

- Trigonometrija pravok.trokuta-matureDocument3 pagesTrigonometrija pravok.trokuta-maturetanja.cvijanovic-stipicNo ratings yet

- Disipacija Toplote Rebra RadijatoraDocument4 pagesDisipacija Toplote Rebra RadijatorakonticvNo ratings yet

- Numerički Proračun-Izvedeno StanjeDocument6 pagesNumerički Proračun-Izvedeno StanjeSafet MušovićNo ratings yet

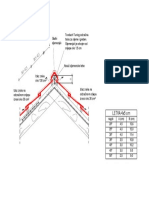

- LETVA 4x5 CM: Zračni Prostor Kontra LetveDocument1 pageLETVA 4x5 CM: Zračni Prostor Kontra LetveHamza MuratovicNo ratings yet

- Tondach SaturnDocument1 pageTondach SaturnPredrag NikolicNo ratings yet

- Rješenja Zadataka Prvog Kolokvijuma B-PopravniDocument3 pagesRješenja Zadataka Prvog Kolokvijuma B-PopravniDado CengaNo ratings yet

- Marketing Marketing I 2011 04 06Document130 pagesMarketing Marketing I 2011 04 06Haris TrešnjoNo ratings yet

- TezisteDocument15 pagesTezisteAdnan Đozo100% (1)

- Proračun Koničnog ZupčanikaDocument7 pagesProračun Koničnog ZupčanikaHaris TrešnjoNo ratings yet

- ADI Proracun 1Document11 pagesADI Proracun 1Haris TrešnjoNo ratings yet

- sLeLi Ljukovac HericDocument17 pagessLeLi Ljukovac HericHaris TrešnjoNo ratings yet

- Proračun Koničnog ZupčanikaDocument7 pagesProračun Koničnog ZupčanikaHaris TrešnjoNo ratings yet

- Trgovačka Roba Računovodstveno Praćenje SeminarskiDocument20 pagesTrgovačka Roba Računovodstveno Praćenje SeminarskiHaris TrešnjoNo ratings yet

- Template Zadavanja Projektnog Zadatka I Ocjenjivanje 2014 15Document1 pageTemplate Zadavanja Projektnog Zadatka I Ocjenjivanje 2014 15Haris TrešnjoNo ratings yet

- Email PDFDocument1 pageEmail PDFHaris TrešnjoNo ratings yet

- Template Zadavanja Projektnog Zadatka I Ocjenjivanje 2014 15Document1 pageTemplate Zadavanja Projektnog Zadatka I Ocjenjivanje 2014 15Haris TrešnjoNo ratings yet

- uVIJET TECENJADocument23 pagesuVIJET TECENJAEsmer AahilNo ratings yet

- Predloška Za Izradu Projektnog Zadatka Iz PPR-ADocument3 pagesPredloška Za Izradu Projektnog Zadatka Iz PPR-AHaris TrešnjoNo ratings yet

- TIG Zav1Document22 pagesTIG Zav1Anonymous OLaAJ553uNo ratings yet

- Dodatak Za PDF FajloveDocument1 pageDodatak Za PDF FajloveHaris TrešnjoNo ratings yet

- Zadaca Primjer RjesenjaDocument7 pagesZadaca Primjer RjesenjaHaris TrešnjoNo ratings yet