Professional Documents

Culture Documents

Karavia: SVC For Dynamic Voltage Control of A 220 KV Transmission System Fed by The Inga-Kolwesi HVDC Link

Uploaded by

Daniel ChristianOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Karavia: SVC For Dynamic Voltage Control of A 220 KV Transmission System Fed by The Inga-Kolwesi HVDC Link

Uploaded by

Daniel ChristianCopyright:

Available Formats

Karavia: SVC for dynamic voltage control of a 220 kV

transmission system fed by the Inga-Kolwesi HVDC link

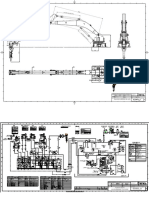

A Static Var Compensator (SVC) rated at 75 Mvar inductive Main circuit design

to 75 Mvar capacitive (-75/+75 Mvar) at 220 kV supplied by The SVC is connected to the 220 kV network via a three-

ABB came on line at the end of 2013 as a Turn-key installa- phase power transformer rated at 75 MVA. It consists of a

tion at the Karavia substation of the state utility SNEL (Société Thyristor Controlled Reactor (TCR) rated at 150 Mvar and two

Nationale d’Electricité) of the Democratic Republic of Congo. Harmonic Filters tuned close to the 5th and 7th harmonics and

Three MSC (Mechanically Switched Capacitors), each rated at rated at 50.3 Mvar and 24.7 Mvar respectively. The phase-

30 Mvar at 220 kV are part of the installation, as well. angle control of the TCR results in continuously variable reac-

tive power over the entire -75/+75 Mvar operating range of

The SVC is part of the rehabilitation of the 220 kV HVAC cor- the SVC.

ridor for power export into the mineral rich Katanga province

in the south, holding among other things some of the larg-

220 kV

est deposits of copper and cobalt in the world. The 220 kV

corridor receives large amounts of environmentally friendly

hydro power from the Inga Falls on the Congo river over the 75 MVA

1.700 km long Inga-Kolwezi HVDC link. The Karavia 220 kV

substation is located approximately 290 km from the Kolwezi

converter station at the receiving end of the HVDC link. MSC MSC MSC

30 Mvar 30 Mvar 30 Mvar

The SVC has the following tasks:

− Improve the voltage and angular stability of the 220 kV AC

network of Katanga;

− Compensate the deficit of reactive power of the grid,

otherwise to be imported from neighboring Zambia;

− Enhance the first swing stability by maintaining the system

voltage during large disturbances. TCR 5th 7th

150 Mvar 50,3 Mvar 24,7 Mvar

Single-line diagram, Karavia SVC

Control system Main technical data

The SVC is controlled by a microprocessor based control

system. The control system is based on the MACH 2 concept, Controlled voltage 220 kV

built around an industrial PC with add in circuit boards and SVC rating 75Mvar inductive to 75 Mvar

I/O racks connected via standard type field buses. Dedicated capacitive, continuously variable

voltage and current transformers provide the control system (-75/+75 Mvar)

with network variables employed in the SVC control. Control system Three-phase symmetrical voltage

control by means of a closed loop

The control system provides facilities for SVC control either voltage regulator

from the Operator Work Station (OWS) in the SVC control Thyristor valve PCT (Phase Control Thyristor) type,

Application Note 1JNS016412, 2013-12

room or remotely via a GWS to a conventional RTU/SCADA water cooled, indirect light firing

system.

The SVC control system is structured in the following modes:

−− Automatic Voltage Control

− − Manual Control

In Automatic Voltage Control, the control system is a closed

loop system with control of the positive-phase sequence volt-

age at the 220 kV bus. The voltage regulator is required to be

fast enough to counteract voltage variations and disturbances

but also retain an adequate stability margin. The voltage regu-

lator output is the SVC susceptance reference, BSVC, which is

used to determine the firing angles of the TCR.

In Manual Control mode, the SVC operates with open-loop

control. The desired reactive power output is obtained by

manually changing the SVC primary susceptance reference.

External bank control

There are three MSC at the Karavia substation, controlled by

the SVC control system. The primary purpose of this control

function is to manage the available reactive power sources to

maintain a steady voltage level and minimize the number of

circuit breaker operations while preserving the dynamic range

of the SVC.

Thyristor valve

The three-phase thyristor valve consists of three single-phase

units with PCTs (Phase Control Thyristor) stacked vertically

in two anti-parallel stacks per phase. Snubber circuits (series For more information please contact:

connected resistors and capacitors) are mounted in parallel

ABB AB

with each thyristor. The thyristors are electrically fired, with

FACTS

energy for firing taken from the snubber circuits. Thyristor

SE-721 64 Västerås, SWEDEN

firing orders are communicated via optical light guides from

Phone: +46 (0)21 32 50 00

the valve control unit located at ground potential (indirect light

Fax: +46 (0)21 32 48 10

firing). The thyristors are liquid cooled, with de-ionized, low

conductivity water as coolant. www.abb.com/FACTS

You might also like

- Some Power Electronics Case Studies Using Matlab Simpowersystem BlocksetFrom EverandSome Power Electronics Case Studies Using Matlab Simpowersystem BlocksetNo ratings yet

- SVC For Voltage Stability in The Saudi Arabian 380 KV Power Transmission GridDocument2 pagesSVC For Voltage Stability in The Saudi Arabian 380 KV Power Transmission GridEswar ChNo ratings yet

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetRating: 2 out of 5 stars2/5 (1)

- SVC ABB AustraliaDocument4 pagesSVC ABB AustraliaAKKI READERNo ratings yet

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetNo ratings yet

- Hardware Circuit ImplementationDocument4 pagesHardware Circuit ImplementationDungNo ratings yet

- SVC in Steel Manufacturing: An Indian Case: Single-Line Diagram of The SVC and EAFDocument2 pagesSVC in Steel Manufacturing: An Indian Case: Single-Line Diagram of The SVC and EAFshaikhsajid242No ratings yet

- SVC AbbDocument3 pagesSVC AbbAbhishek KukrejaNo ratings yet

- Analysis of Dynamic Power Factor Correction Using Flexible Ac Transmission SystemsDocument6 pagesAnalysis of Dynamic Power Factor Correction Using Flexible Ac Transmission SystemsAnikendu MaitraNo ratings yet

- Unit 2 - FACTSDocument64 pagesUnit 2 - FACTSUdaya KumarNo ratings yet

- The Static Var Compensator (SVC) Device in The Power Systems Using Matlab/SimpowersystemsDocument7 pagesThe Static Var Compensator (SVC) Device in The Power Systems Using Matlab/SimpowersystemsDonkena VinayNo ratings yet

- SVCDocument92 pagesSVCDiego MaldonadoNo ratings yet

- SVC Light Evaluation of First Installation at Hagfors, SwedenDocument6 pagesSVC Light Evaluation of First Installation at Hagfors, Swedenteektak1No ratings yet

- 250-kW Grid-Connected PV Array - MATLAB & SimulinkDocument2 pages250-kW Grid-Connected PV Array - MATLAB & SimulinkMuhammad Kamran MustafaNo ratings yet

- 3 Voltage Level Improving by Using Static VARDocument7 pages3 Voltage Level Improving by Using Static VAREngr Muhammad Imran KhanNo ratings yet

- Overload Control of A 220 KV Transmission Line by Means of An OLCDocument2 pagesOverload Control of A 220 KV Transmission Line by Means of An OLChanythekingNo ratings yet

- Static VAR CompensationDocument30 pagesStatic VAR Compensationsubbu2051100% (1)

- Static VAR Compensation (SVC)Document2 pagesStatic VAR Compensation (SVC)Vedant KulkarniNo ratings yet

- ABB Study ReportDocument2 pagesABB Study ReportdhananjayNo ratings yet

- Plant Single Line DiagramDocument3 pagesPlant Single Line DiagramvijayNo ratings yet

- Asynchronous Back-To-Back HVDC Link With Voltage Source ConvertersDocument7 pagesAsynchronous Back-To-Back HVDC Link With Voltage Source ConvertersShashi PandeyNo ratings yet

- Static Var Compensator: Rongxin Power Electronic Co., LTDDocument17 pagesStatic Var Compensator: Rongxin Power Electronic Co., LTDSteven Leif EsselNo ratings yet

- SVC For Voltage Stabilization and Harmonic Suppression in Rolling MillDocument2 pagesSVC For Voltage Stabilization and Harmonic Suppression in Rolling MilldeciohNo ratings yet

- 3.problems SVC - Static Var or SolvedDocument19 pages3.problems SVC - Static Var or Solvedgonfree100% (1)

- 220 KV Algarrobal SubstationDocument10 pages220 KV Algarrobal Substationcesar pozoNo ratings yet

- Voltage Control of Transmission System Using Static Var CompensatorDocument3 pagesVoltage Control of Transmission System Using Static Var CompensatormssmsNo ratings yet

- HVDC Transmission Using Voltage Source Converters (VSC) : M.KISHAN (07EK1AO219)Document7 pagesHVDC Transmission Using Voltage Source Converters (VSC) : M.KISHAN (07EK1AO219)RaviKiran AvulaNo ratings yet

- SVC To Increase The Transmission Capacity and Stability of The Mexican 400 KV SystemDocument2 pagesSVC To Increase The Transmission Capacity and Stability of The Mexican 400 KV SystemRobert J Blandín MNo ratings yet

- Main ProjectDocument15 pagesMain ProjectChandana K R 4UB20EE010No ratings yet

- Engineering Journal Modeling, Control and Steady State Analysis of Back To Back VSC HVDC SystemDocument6 pagesEngineering Journal Modeling, Control and Steady State Analysis of Back To Back VSC HVDC SystemEngineering JournalNo ratings yet

- First Generation of FACTSDocument22 pagesFirst Generation of FACTSmhd986100% (1)

- Adaptive VAR CompensatorDocument8 pagesAdaptive VAR CompensatorHillary McgowanNo ratings yet

- 400 KV Swyd FOR DOJDocument49 pages400 KV Swyd FOR DOJSam0% (1)

- Reactive Power High-Voltage Electricity Transmission (1) (2) Flexible AC Transmission SystemDocument11 pagesReactive Power High-Voltage Electricity Transmission (1) (2) Flexible AC Transmission SystemsirishaNo ratings yet

- Description: Static VAR CompensatorDocument2 pagesDescription: Static VAR CompensatorPrem KumarNo ratings yet

- Voltage Stability Improvement Using Static Var Compensator in Power SystemsDocument6 pagesVoltage Stability Improvement Using Static Var Compensator in Power SystemsKiran Kumar BsNo ratings yet

- BSTP en HVDC Psse Training, Day 1 - TheoryDocument107 pagesBSTP en HVDC Psse Training, Day 1 - TheoryEngr Mohsin Saleem100% (1)

- Iraq Network 400kV, 50Hz Interconnect With Iran, Turkey and Syria Inter-Area Oscillation Damping and Voltage Regulation by Using SVCDocument6 pagesIraq Network 400kV, 50Hz Interconnect With Iran, Turkey and Syria Inter-Area Oscillation Damping and Voltage Regulation by Using SVCMuhammad ZahidNo ratings yet

- Optimum Location of Static Var Compensator (SVC) in Over Head Transmission Lines C. Dinakaran G. BalasundaramDocument5 pagesOptimum Location of Static Var Compensator (SVC) in Over Head Transmission Lines C. Dinakaran G. BalasundaramM Yudi NugrohoNo ratings yet

- Of VSC HVDC: Study Protection Strategy For Based SystemDocument6 pagesOf VSC HVDC: Study Protection Strategy For Based SystemMani AshouriNo ratings yet

- SVC A02-0100Document16 pagesSVC A02-0100Christian NgalaNo ratings yet

- Power Synchronization Control of VSC-HVDC Transmission For Weak Ac SystemDocument5 pagesPower Synchronization Control of VSC-HVDC Transmission For Weak Ac SystemGuru MishraNo ratings yet

- CA Vcontact VSC (En) I 1vcp000165 1002Document42 pagesCA Vcontact VSC (En) I 1vcp000165 1002ayalmalikiNo ratings yet

- A Linear Quadratic Tracking Based Voltage Controller For VSI MVDC Shipboard Power System ApplicationDocument5 pagesA Linear Quadratic Tracking Based Voltage Controller For VSI MVDC Shipboard Power System ApplicationJose Luis SarmientoNo ratings yet

- 18 11KV VCBs PDFDocument37 pages18 11KV VCBs PDFSharafat AliNo ratings yet

- SVC Abb Case StudyDocument2 pagesSVC Abb Case StudybhsujanNo ratings yet

- Progect 2Document12 pagesProgect 2ali hussainNo ratings yet

- HVDC Transmission Using Voltage Source Converters (VSC)Document9 pagesHVDC Transmission Using Voltage Source Converters (VSC)oeric2kNo ratings yet

- Aredes2001 Article MultipulseConvertersAndControlDocument9 pagesAredes2001 Article MultipulseConvertersAndControlAbhay KotnalaNo ratings yet

- Introduction To FACTS: Alternating Current Transmission System (FACTS) Devices in Power Grids. FACTS AllowDocument4 pagesIntroduction To FACTS: Alternating Current Transmission System (FACTS) Devices in Power Grids. FACTS AllowsameekshaNo ratings yet

- Design and Assessment of Static VAR Compensator On Railways Power Grid Operation Under Normal and Contingencies ConditionsDocument6 pagesDesign and Assessment of Static VAR Compensator On Railways Power Grid Operation Under Normal and Contingencies ConditionsSUMAN ChandrashekharNo ratings yet

- Transient Stability of A Two-Machine Transmission System With Power System Stabilizers (PSS) and Static Var Compensator (SVC) NewDocument26 pagesTransient Stability of A Two-Machine Transmission System With Power System Stabilizers (PSS) and Static Var Compensator (SVC) Newkrishnendu maitraNo ratings yet

- Flexible Ac Transmission Systems (Facts) : Prof. M.V. Aware Electrical Engg. Dept. Vnit, NagpurDocument33 pagesFlexible Ac Transmission Systems (Facts) : Prof. M.V. Aware Electrical Engg. Dept. Vnit, NagpurAmit KeshriNo ratings yet

- Flexible Ac Transmission Systems (Facts) : Prof. M.V. Aware Electrical Engg. Dept. Vnit, NagpurDocument33 pagesFlexible Ac Transmission Systems (Facts) : Prof. M.V. Aware Electrical Engg. Dept. Vnit, NagpurJeevan KumarNo ratings yet

- HVDC Transmission Using Voltage Source Converters: AbstractDocument8 pagesHVDC Transmission Using Voltage Source Converters: AbstractVelu SamyNo ratings yet

- Detailed Model of A 100-kW Grid-Connected PV Array - MATLAB & SimulinkDocument3 pagesDetailed Model of A 100-kW Grid-Connected PV Array - MATLAB & SimulinkMuhammad Kamran Mustafa100% (1)

- SVC Voltage ControlDocument61 pagesSVC Voltage Controlrakla111No ratings yet

- Comparison Between LCC and VSCDocument5 pagesComparison Between LCC and VSCijsretNo ratings yet

- LH SeriesDocument4 pagesLH Seriesge_bdNo ratings yet

- Static Var Compensators: by Prof. C. RadhakrishnaDocument30 pagesStatic Var Compensators: by Prof. C. RadhakrishnaathbeljoeNo ratings yet

- PM-7200 Module Series: Gigabit and Fast Ethernet Modules For PT Series Rackmount Ethernet SwitchesDocument5 pagesPM-7200 Module Series: Gigabit and Fast Ethernet Modules For PT Series Rackmount Ethernet SwitchesDaniel ChristianNo ratings yet

- FOX615 Installation 1KHW002461Document98 pagesFOX615 Installation 1KHW002461Daniel ChristianNo ratings yet

- Online Surge Arrester Monitor - EXCOUNT-III: Remote Real-Time Monitoring, Diagnostics and AnalysisDocument2 pagesOnline Surge Arrester Monitor - EXCOUNT-III: Remote Real-Time Monitoring, Diagnostics and AnalysisDaniel ChristianNo ratings yet

- ABB Sage T 75 1250 Circuit BreakerDocument3 pagesABB Sage T 75 1250 Circuit BreakerMatt RudyNo ratings yet

- RXSF Flag Relay - UnlockedDocument20 pagesRXSF Flag Relay - UnlockedDaniel ChristianNo ratings yet

- Proven-LF - SA Catalogue - 2Document2 pagesProven-LF - SA Catalogue - 2Daniel ChristianNo ratings yet

- Induction Motor Starting Analysis and Start Aided Device Comparison Using ETAPDocument7 pagesInduction Motor Starting Analysis and Start Aided Device Comparison Using ETAPDaniel ChristianNo ratings yet

- Catalogue-CABTEK-CW and A2Document2 pagesCatalogue-CABTEK-CW and A2Daniel ChristianNo ratings yet

- M1173-L Socket Outlet: General InformationDocument2 pagesM1173-L Socket Outlet: General InformationDaniel ChristianNo ratings yet

- Manual Operating NSD570 PDFDocument350 pagesManual Operating NSD570 PDFDaniel Christian100% (3)

- TPS-NU - Analogue Digital Protection Equipment PDFDocument4 pagesTPS-NU - Analogue Digital Protection Equipment PDFDaniel ChristianNo ratings yet

- Route - Map JR Bus KanazawaDocument3 pagesRoute - Map JR Bus KanazawaDaniel ChristianNo ratings yet

- Manual FOX505Document48 pagesManual FOX505Daniel Christian100% (1)

- ITP Arrester SulselbarruDocument14 pagesITP Arrester SulselbarruDaniel ChristianNo ratings yet

- 1MRK 505 340-BEN A Busbar Protection REB670 2.1 IEC Product Version: 2.1Document1 page1MRK 505 340-BEN A Busbar Protection REB670 2.1 IEC Product Version: 2.1Daniel ChristianNo ratings yet

- Insulation Level and Clearances For 230 KV Air Insulated SubstationDocument6 pagesInsulation Level and Clearances For 230 KV Air Insulated SubstationDaniel ChristianNo ratings yet

- HV Catalog LS Vina PDFDocument28 pagesHV Catalog LS Vina PDFDaniel ChristianNo ratings yet

- Reference HV Cable LS-Vina Copper 400sqmmDocument1 pageReference HV Cable LS-Vina Copper 400sqmmDaniel ChristianNo ratings yet

- Line Trap and Line Matching Unit: All Rights ReservedDocument26 pagesLine Trap and Line Matching Unit: All Rights ReservedDaniel ChristianNo ratings yet

- 1MRK006516 AD Transformer ProtectionDocument2 pages1MRK006516 AD Transformer ProtectionDaniel ChristianNo ratings yet

- Network TopologyDocument36 pagesNetwork TopologykanagalasasankNo ratings yet

- (Task Specific Risk Assessment) : No Name Signature Position Date N Name Signature Position DateDocument5 pages(Task Specific Risk Assessment) : No Name Signature Position Date N Name Signature Position DateRavi Shankar TurlapatiNo ratings yet

- FrictionDocument4 pagesFrictionMuzafar ahmadNo ratings yet

- Print PDFDocument11 pagesPrint PDFFe CasarolliNo ratings yet

- Automobile Manufacturing Process (17403) : Chapter 1. ForgingDocument87 pagesAutomobile Manufacturing Process (17403) : Chapter 1. ForgingPramod DhaigudeNo ratings yet

- Ansi Asabe S261.7 Feb1989 (R2011)Document5 pagesAnsi Asabe S261.7 Feb1989 (R2011)StephanNo ratings yet

- Fastshapes - Sprocket: Typical ApplicationsDocument23 pagesFastshapes - Sprocket: Typical ApplicationsJimmy MyNo ratings yet

- SJS Cementing-Equipment ENGDocument44 pagesSJS Cementing-Equipment ENGMustafa Asgerov100% (1)

- DavonDocument1,601 pagesDavonPalyyNo ratings yet

- SmartBright LED Downlight G3Document11 pagesSmartBright LED Downlight G3Puji SnNo ratings yet

- Minimal Requirements: Solaris InstallationDocument74 pagesMinimal Requirements: Solaris InstallationsrinivasNo ratings yet

- List of Sanitary and Plumbing ItemsDocument4 pagesList of Sanitary and Plumbing ItemssumalathaNo ratings yet

- HQ Accessoriescatalogue 20142015 LRDocument28 pagesHQ Accessoriescatalogue 20142015 LRapi-36492444No ratings yet

- 2018 2019 - Seafirst CatalogDocument40 pages2018 2019 - Seafirst CatalogЯрослав БогдановNo ratings yet

- Web UI Norox Neu PDFDocument8 pagesWeb UI Norox Neu PDFGovardhan RaviNo ratings yet

- Building Applied Natural Language GenerationDocument32 pagesBuilding Applied Natural Language Generationrat86No ratings yet

- SHEET #1 Title Sheet Site Safety Logistic Plan ForDocument5 pagesSHEET #1 Title Sheet Site Safety Logistic Plan ForRadha BuildtechNo ratings yet

- Technical Catalogue eSV-SpecialVersion 50-60HzDocument264 pagesTechnical Catalogue eSV-SpecialVersion 50-60HzRichard Marco Antonio Obando LopezNo ratings yet

- 023 POL902.00 CB1Q3934en 01 ModBusDocument4 pages023 POL902.00 CB1Q3934en 01 ModBusEvandroRodriguesNo ratings yet

- PTWDocument3 pagesPTWAngel Silva VicenteNo ratings yet

- Difference Between Dictionary Managed Tablespace (DMT) and Locally Managed Tablespace (LMT)Document2 pagesDifference Between Dictionary Managed Tablespace (DMT) and Locally Managed Tablespace (LMT)Rose MaNo ratings yet

- Block PlanDocument1 pageBlock PlanJade Atkinson PhellaineNo ratings yet

- Business Plan: Syeda Zurriat & Aimen RabbaniDocument11 pagesBusiness Plan: Syeda Zurriat & Aimen RabbanizaraaNo ratings yet

- M3 Hull Plate Nesting - SP1Document50 pagesM3 Hull Plate Nesting - SP1Bùi Công Lộc100% (1)

- ELEG 270 Electronics: Dr. Ali BostaniDocument25 pagesELEG 270 Electronics: Dr. Ali BostanigigiNo ratings yet

- CFRD 05 - BayardoDocument23 pagesCFRD 05 - BayardodiegofernandodiazsepNo ratings yet

- Co Linear Antenna DesignDocument2 pagesCo Linear Antenna DesignAhmed JafarNo ratings yet

- Int. J. Miner. Process.: Emin Cafer CilekDocument10 pagesInt. J. Miner. Process.: Emin Cafer CilekJose Patricio VelardeNo ratings yet

- CMM 23-70-04 CVR Fa2100 L3Document334 pagesCMM 23-70-04 CVR Fa2100 L3Romain ANGUELU100% (1)

- RF Engineer - Small Cell Design (Ibwave) - Job DescriptionDocument2 pagesRF Engineer - Small Cell Design (Ibwave) - Job Descriptionmansoor 31 shaikhNo ratings yet

- Well Integrity for Workovers and RecompletionsFrom EverandWell Integrity for Workovers and RecompletionsRating: 5 out of 5 stars5/5 (3)

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionFrom EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionRating: 4.5 out of 5 stars4.5/5 (543)

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tFrom EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tRating: 4.5 out of 5 stars4.5/5 (27)

- The Journeyman Electrician Exam Study Guide: Proven Methods for Successfully Passing the Journeyman Electrician Exam with ConfidenceFrom EverandThe Journeyman Electrician Exam Study Guide: Proven Methods for Successfully Passing the Journeyman Electrician Exam with ConfidenceNo ratings yet

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Programming the Raspberry Pi, Third Edition: Getting Started with PythonFrom EverandProgramming the Raspberry Pi, Third Edition: Getting Started with PythonRating: 5 out of 5 stars5/5 (2)

- 2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersFrom Everand2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersRating: 5 out of 5 stars5/5 (1)

- Conquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeFrom EverandConquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeRating: 4.5 out of 5 stars4.5/5 (10)

- A Mind at Play: How Claude Shannon Invented the Information AgeFrom EverandA Mind at Play: How Claude Shannon Invented the Information AgeRating: 4 out of 5 stars4/5 (53)

- Hacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsFrom EverandHacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsRating: 3.5 out of 5 stars3.5/5 (2)

- Power System Control and ProtectionFrom EverandPower System Control and ProtectionB. Don RussellRating: 4 out of 5 stars4/5 (11)

- Guide to the IET Wiring Regulations: IET Wiring Regulations (BS 7671:2008 incorporating Amendment No 1:2011)From EverandGuide to the IET Wiring Regulations: IET Wiring Regulations (BS 7671:2008 incorporating Amendment No 1:2011)Rating: 4 out of 5 stars4/5 (2)

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionFrom EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionRating: 4 out of 5 stars4/5 (331)

- Practical Electrical Wiring: Residential, Farm, Commercial, and IndustrialFrom EverandPractical Electrical Wiring: Residential, Farm, Commercial, and IndustrialRating: 3.5 out of 5 stars3.5/5 (3)

- The Fast Track to Your Extra Class Ham Radio License: Covers All FCC Amateur Extra Class Exam Questions July 1, 2020 Through June 30, 2024From EverandThe Fast Track to Your Extra Class Ham Radio License: Covers All FCC Amateur Extra Class Exam Questions July 1, 2020 Through June 30, 2024No ratings yet

- Beginner's Guide to Reading Schematics, Fourth EditionFrom EverandBeginner's Guide to Reading Schematics, Fourth EditionRating: 3.5 out of 5 stars3.5/5 (10)

- Retro Gaming with Raspberry Pi: Nearly 200 Pages of Video Game ProjectsFrom EverandRetro Gaming with Raspberry Pi: Nearly 200 Pages of Video Game ProjectsNo ratings yet

- Multiplexed Networks for Embedded Systems: CAN, LIN, FlexRay, Safe-by-Wire...From EverandMultiplexed Networks for Embedded Systems: CAN, LIN, FlexRay, Safe-by-Wire...No ratings yet

- DIY Drones for the Evil Genius: Design, Build, and Customize Your Own DronesFrom EverandDIY Drones for the Evil Genius: Design, Build, and Customize Your Own DronesRating: 3.5 out of 5 stars3.5/5 (3)