Professional Documents

Culture Documents

Characteristics of Fo Component

Uploaded by

pjblk0 ratings0% found this document useful (0 votes)

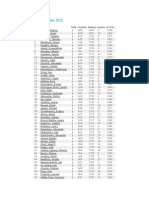

19 views3 pagesThe document provides information on the characteristics of different FO components including Coker LDO, Coker FO cut, Coker residue, and residue foots oil. It details properties such as density, distillation results, kinematic viscosity, flash point, pour point, total sulfur, conradson carbon residue, and drop set point. A second table provides the typical composition and properties of an HSD feedstock blend and FO blend that include these FO components.

Original Description:

doc

Original Title

Book1

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides information on the characteristics of different FO components including Coker LDO, Coker FO cut, Coker residue, and residue foots oil. It details properties such as density, distillation results, kinematic viscosity, flash point, pour point, total sulfur, conradson carbon residue, and drop set point. A second table provides the typical composition and properties of an HSD feedstock blend and FO blend that include these FO components.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

19 views3 pagesCharacteristics of Fo Component

Uploaded by

pjblkThe document provides information on the characteristics of different FO components including Coker LDO, Coker FO cut, Coker residue, and residue foots oil. It details properties such as density, distillation results, kinematic viscosity, flash point, pour point, total sulfur, conradson carbon residue, and drop set point. A second table provides the typical composition and properties of an HSD feedstock blend and FO blend that include these FO components.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 3

CHARACTERISTICS OF FO COMPONENT

Coker LDO Coker FO C/ Residue Foots Oil

1 Density at 15oC, Kg/m3 920.0 950.0 1020.0 915.0

Distillation under reduced pressure.

2 Distillation (Observed reading converted to AET)

Initial Boiling Point 0C 230 238 245 275

5% vol. rec. 0C 282 310 334 372

10% vol. rec. C 0

302 340 363 384

20% vol. rec. C 0

322 375 400 397

30% vol. rec. 0C 334 394 417 407

40% vol. rec. C 0

345 408 433 421

50% vol. rec. C 0

355 421 448 430

60% vol. rec. 0C 363 435 460 442

70% vol. rec. C 0

375 449 475 453

80% vol. rec. C 0

385 463 492 464

90% vol. rec. 0C 398 479 528 476

95% vol. rec. C 0

> 400 495 538 481

Final Boiling Point C0

> 400 515 > 538 495

3 (a) Kinematic Viscosity at 400C, cSt. 12.571 --- --- 95

3 (b) Kinematic Viscosity at 500C, cSt. --- 24 --- ---

3 (c) Kinematic Viscosity at 100 C, cSt.

0

--- --- 8 ---

4 Flash Point, C 0

95 120 >120 >120

5 Pour Point,0C 30 39 48 24

6 Total Sulphur, mg/Kg. 2600 3100 4700 2500

7 Conradson Carbon Residue, % by mass 0.02 0.15 7.5 0.016

8 Drop Set Point, 0C --- --- --- ---

ced pressure.

eading converted to AET)

HSD Feedstock Blend

Typical,% S (mg/kg) Cetane 95% Density

LK 3 73 39 290 0.809

COKER KERO 20 1750 41 290 0.84

LGO 22 1020 46 360 0.875

HGO 10 1500 48 370 0.88

HK 35 282 37 295 0.858

Coker LDO 10 2600 39 398 0.92

Total 100 1085.29 41.14 325.95 0.86507

FO Blend

Typical,% S (mg/kg) Visc @100 95% Density Pour point

Coker Residue 10 4700 8 538 1.02 48

CFO 55 3100 6 495 0.95 39

C LDO 25 2600 4 400 0.92 30

HK 10 282 0.5 295 0.858

LK 0 73 0.5 290 0.809

Foots Oil 0 2600 9.6 398 0.915 24

Total 100 1646.75 3.505 373.94 0.88345

You might also like

- GPM Calculation For NGL RecoveryDocument3 pagesGPM Calculation For NGL Recoverysanjay0% (1)

- Material Balance in Froth Flotation (Excel File Additional Document)Document4 pagesMaterial Balance in Froth Flotation (Excel File Additional Document)joseph kafumbila100% (1)

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- Drilling Fluids Processing HandbookFrom EverandDrilling Fluids Processing HandbookRating: 4.5 out of 5 stars4.5/5 (4)

- Component Units 1 2 3 4 5 6: F G F GDocument6 pagesComponent Units 1 2 3 4 5 6: F G F Gbighead3158No ratings yet

- Ten Blend 2019Document4 pagesTen Blend 2019Para DiseNo ratings yet

- 01 Belt Con ZTB2 WDocument2 pages01 Belt Con ZTB2 WBùi Hắc HảiNo ratings yet

- Limestone Limestone Clinker Mixed Mat. Mixed Mat. ClayDocument2 pagesLimestone Limestone Clinker Mixed Mat. Mixed Mat. ClayBùi Hắc HảiNo ratings yet

- EKI Quiz 1Document7 pagesEKI Quiz 1Nandach Benci DisakitiNo ratings yet

- Consumption Statement (Upto IX R/Bill) : Sl. No. Item Quantity Unit Grit Sand Grit SandDocument10 pagesConsumption Statement (Upto IX R/Bill) : Sl. No. Item Quantity Unit Grit Sand Grit Sandsandeeep mauryaNo ratings yet

- Combustion Gas T1 298 T2 1873 H 298 T 1 T 2 T - 1 T 3 Entalpi T1 Entalpi T2 Delta H Mol Entalpi CO2 94440 44.140 0.005Document3 pagesCombustion Gas T1 298 T2 1873 H 298 T 1 T 2 T - 1 T 3 Entalpi T1 Entalpi T2 Delta H Mol Entalpi CO2 94440 44.140 0.005Ridho QuluqNo ratings yet

- Scci - Irr PT Bukit Asam - Maret 2021Document9 pagesScci - Irr PT Bukit Asam - Maret 2021wahyusetyawanNo ratings yet

- 3 Zuata 16Document1 page3 Zuata 16Miguel BetancourtNo ratings yet

- Tugas - 2: Surface FacilitiesDocument5 pagesTugas - 2: Surface FacilitiesStephanie VirganaNo ratings yet

- Perhitungan Huidifikasi Edit - 2Document8 pagesPerhitungan Huidifikasi Edit - 2Aria MandalikaNo ratings yet

- Perhitungan Package Boiler 2007 UA (ALHAMDULILLAHFIX)Document23 pagesPerhitungan Package Boiler 2007 UA (ALHAMDULILLAHFIX)Fakhri FachrezaNo ratings yet

- Aashto T 193Document3 pagesAashto T 193faisa BajwaNo ratings yet

- Design ConditionDocument1 pageDesign ConditionPHAM THANH TUNo ratings yet

- PGSU Molar CalculatorDocument7 pagesPGSU Molar CalculatorJp JandayanNo ratings yet

- Compo SetDocument1 pageCompo SetabdorleNo ratings yet

- Compressed HP Steam BFW T (C) 25 250 P (Bar) 6 40 Ref Towler TowlerDocument12 pagesCompressed HP Steam BFW T (C) 25 250 P (Bar) 6 40 Ref Towler TowlerDanielle BarkerNo ratings yet

- VRM C SimulatorDocument19 pagesVRM C SimulatorIrshad HussainNo ratings yet

- #3 Tranf MasaDocument4 pages#3 Tranf MasaDaniela Alejandra Gutierrez CuadrosNo ratings yet

- M.Novriyanto M1B118028 - UTS SIMKOMDocument10 pagesM.Novriyanto M1B118028 - UTS SIMKOMDave N7RNo ratings yet

- C1 C2 C3 C4 TC (K) TR: Feed Into ColumnDocument4 pagesC1 C2 C3 C4 TC (K) TR: Feed Into ColumnKarthik RajeshNo ratings yet

- Ayuanda Putri - Assigment 2 PMBDocument7 pagesAyuanda Putri - Assigment 2 PMBAyuanda PutriNo ratings yet

- Lab Phy CapacitorDocument5 pagesLab Phy CapacitorCarl StromoNo ratings yet

- SANLAU1 Mong Coc Thanh UyDocument20 pagesSANLAU1 Mong Coc Thanh Uylam phuNo ratings yet

- Erosional Flow Rate Vs Flowing PressureDocument1 pageErosional Flow Rate Vs Flowing PressureJay SadNo ratings yet

- Erosional Velocity CalcDocument1 pageErosional Velocity CalcJay SadNo ratings yet

- h= b= A= ε t =: Parametrii sectiuniiDocument22 pagesh= b= A= ε t =: Parametrii sectiuniiOana Alexandra IagărNo ratings yet

- Erosional Velocity CalcDocument1 pageErosional Velocity CalcmusNo ratings yet

- Hagedorn Brown CorrelationDocument28 pagesHagedorn Brown Correlationberkah haniNo ratings yet

- Taller de TermodinamicaDocument10 pagesTaller de Termodinamicasara perezNo ratings yet

- Group 3 Spectrometry DPARDocument9 pagesGroup 3 Spectrometry DPARKim Rohn AbrilNo ratings yet

- OLGA Simulation ResultsDocument8 pagesOLGA Simulation ResultsSabrina Rahmi AdiyarNo ratings yet

- Flow Assurance Management and BenchmarkiDocument13 pagesFlow Assurance Management and BenchmarkiAttalh Djaafar AttalhNo ratings yet

- EclipssssssDocument6 pagesEclipssssssRestyanti YunseNo ratings yet

- Vessel'S Midnight Ullage ReportDocument31 pagesVessel'S Midnight Ullage ReportnawhiNo ratings yet

- Vessel'S Midnight Ullage ReportDocument31 pagesVessel'S Midnight Ullage ReportnawhiNo ratings yet

- Erosional Velocity CalcDocument1 pageErosional Velocity CalcthevendNo ratings yet

- HW GasDocument5 pagesHW GastauqeerNo ratings yet

- Acetaldehyde Production From Ethanol by Eco-Friendly Non-Chromium Catalysts Consisting of Copper and Calcium SilicateDocument6 pagesAcetaldehyde Production From Ethanol by Eco-Friendly Non-Chromium Catalysts Consisting of Copper and Calcium SilicateSARATH BALANo ratings yet

- Kuwaiti Gas & Oil Company: Bakr North South Amer Al Hamed Flow Rate Temp PressureDocument2 pagesKuwaiti Gas & Oil Company: Bakr North South Amer Al Hamed Flow Rate Temp PressureOmar WardehNo ratings yet

- DHT - CI CheckDocument1 pageDHT - CI CheckSudarshan GopalNo ratings yet

- 1 Hamaca MejoradoDocument2 pages1 Hamaca MejoradoMiguel BetancourtNo ratings yet

- OUT TSP RW1 RW2 RW3 RW4 RW5 RW6 RW7 RW8 CW1 CW2 CW3 CW4 CW5Document5 pagesOUT TSP RW1 RW2 RW3 RW4 RW5 RW6 RW7 RW8 CW1 CW2 CW3 CW4 CW5Ricardo Andres AristizabalNo ratings yet

- NM MantappisanDocument224 pagesNM MantappisanRisky Andi0% (1)

- Beer-Lambert Law GraphsDocument2 pagesBeer-Lambert Law GraphsNona NanoNo ratings yet

- HT Xlpe PDFDocument3 pagesHT Xlpe PDFrengaramanujanNo ratings yet

- Physical Chemistry Assignment 2Document5 pagesPhysical Chemistry Assignment 2Dick HardwoodNo ratings yet

- Diagrama de InteraccionDocument10 pagesDiagrama de InteraccionErick Mamani ZuñigaNo ratings yet

- Bitumen Merey Api 16 FOB Any Caribbean Port: Calle Maestro Noguerol Nº24, 1-A, 18193, Granada, Kingdom of SpainDocument3 pagesBitumen Merey Api 16 FOB Any Caribbean Port: Calle Maestro Noguerol Nº24, 1-A, 18193, Granada, Kingdom of SpainRoberticoZeaNo ratings yet

- Rodrigo Rodriguez Hoyos CartagenaDocument7 pagesRodrigo Rodriguez Hoyos CartagenaDj Roddo El MixologoNo ratings yet

- Sokol15F: 3225 Gallows Road, 4B0418 Fairfax, Virginia 22037-0001Document1 pageSokol15F: 3225 Gallows Road, 4B0418 Fairfax, Virginia 22037-0001asad razaNo ratings yet

- Hitungan Steel 1Document1 pageHitungan Steel 1lutfiNo ratings yet

- Bonny Light TBP Nigeria Distillation: AssayDocument1 pageBonny Light TBP Nigeria Distillation: AssayHaris ShahidNo ratings yet

- Insulating Firebrick Data SheetDocument1 pageInsulating Firebrick Data SheetJackNo ratings yet

- Columna C-1Document53 pagesColumna C-1pedroNo ratings yet

- Balance Metalurgico de La Mina FresnilloDocument8 pagesBalance Metalurgico de La Mina FresnilloPerez GilNo ratings yet

- Corey HouseDocument14 pagesCorey Housepjblk100% (1)

- Engel, A. Fischer Adolf Fischer. "He Expected and Desired To Lose His Life in The ProtestDocument3 pagesEngel, A. Fischer Adolf Fischer. "He Expected and Desired To Lose His Life in The ProtestpjblkNo ratings yet

- Karaoke Catalog: 1000 Most Popular SongsDocument11 pagesKaraoke Catalog: 1000 Most Popular SongspjblkNo ratings yet

- A Question For The Genius, The One Who Shall Solve The Problem Will Write His/her Name in The Attached FileDocument1 pageA Question For The Genius, The One Who Shall Solve The Problem Will Write His/her Name in The Attached FilepjblkNo ratings yet

- The Church of The Holy WisdomDocument143 pagesThe Church of The Holy Wisdompjblk100% (1)

- Captain WelshDocument5 pagesCaptain Welshpjblk100% (2)

- Top 100 Players October 2012Document2 pagesTop 100 Players October 2012pjblkNo ratings yet

- Gas Dynamics in Clusters of GalaxiesDocument30 pagesGas Dynamics in Clusters of GalaxiespjblkNo ratings yet

- Cosmology With Clusters of GalaxiesDocument48 pagesCosmology With Clusters of GalaxiespjblkNo ratings yet

- Fire Is The Rapid: Oxidation Combustion Heat Light Products Rusting DigestionDocument56 pagesFire Is The Rapid: Oxidation Combustion Heat Light Products Rusting DigestionpjblkNo ratings yet

- Clusters of Galaxies in The Radio: Relativistic Plasma and ICM/Radio Galaxy Interaction ProcessesDocument34 pagesClusters of Galaxies in The Radio: Relativistic Plasma and ICM/Radio Galaxy Interaction ProcessespjblkNo ratings yet

- Woman Muslim LeadersDocument195 pagesWoman Muslim LeaderspjblkNo ratings yet

- The Sunyaev-Zel'dovich Effect in Cosmology and Cluster PhysicsDocument31 pagesThe Sunyaev-Zel'dovich Effect in Cosmology and Cluster PhysicspjblkNo ratings yet

- Metal Content and Production in Clusters of GalaxiesDocument35 pagesMetal Content and Production in Clusters of GalaxiespjblkNo ratings yet

- Gravitational Lensing by Clusters of GalaxiesDocument41 pagesGravitational Lensing by Clusters of GalaxiespjblkNo ratings yet

- Optical Detection of Clusters of GalaxiesDocument24 pagesOptical Detection of Clusters of GalaxiespjblkNo ratings yet