Professional Documents

Culture Documents

Pivoted Weight Screw

Uploaded by

John SmithOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pivoted Weight Screw

Uploaded by

John SmithCopyright:

Available Formats

Pivoted Weigh Screw

Feeders & Conveyors

Best Solution for Dusty or Hazardous Products

Featuring compact design and a totally enclosed product

stream, Active Weighing Solutions Pivoted Weigh Screw

Feeders and Conveyors are particularly suited to dusty and

Malt outloading hazardous product applications where accuracy is

into container at 100tph

important.

Engineered for Accuracy Applications

Design is critical to achieving the desired accuracy for • Monitoring

each application. Screw diameter and speed are • Flow Rate Control

engineered to provide the correct material loading for • Bulk Out Loading

the greatest accuracy. Achievable accuracy in each

situation depends upon the characteristics of the Features

product and the application.

• Low Profile

The design approach uses a constant weight model to

• Fully Enclosed Product

ensure the highest possible accuracy over the com- Stream

plete operating range.

Pivoted Weigh Screw Conveyor- Cement application

Key design parameters:

• Flow Rate Diagnostic Capability

• Speed

• Bulk Density The controller has an diagnostic out-

put that can be used to capture data

Balanced with the physical screw parameters:

directly into laptop to allow analysis of

• Diameter data.

• Pitch

• Fill Capacity

Typical Accuracy Typical Weight Distribution

Free Flowing Products - typically less than ±1% The graph shows a constant weight

e.g. Canola & Malt* distribution in the screw indicating

consistent feed Pivoted Weigh Screw Feeder- Hydrated Lime

* Note: Malt out loading has been tested and application

proved at better than ±0.5%

Non Free Flowing Products typically ±1 to 2%

e.g. Flour (powdery products)

Difficult Products - typically ±2 to 3%

e.g. Cement

Note: Cement is difficult to feed, however if

good flow control is established ±1% can be

achieved

Screw Conveyor Display Screw Feeder Display

MD1 with MW95A P Module MD1 with MW96A P Module

Typical Totalisation Curve Pivoted Weigh Screw Conveyor- Malt Bulk Outloading

application

The graph shows uniform product

delivery.

Pivoted Weigh Screw Controller Typical Flow Rates

Controller Spec: Each application is designed to meet

MD1 Display customer requirements.

MW95A P Module (Screw Conveyor - Monitor only) e.g.

MW96A P Module (Screw Feed - Rate control) Malt 100tph

MT6F Transmitter

Controllers standard features Hydrated Lime 6 tph

• Pulse Output Cement 25tph

• 4-20mA Flow Rate Retransmission

• Fully Automatic Zeroing

• Programmable Limit Outputs

FO R SPECIFIC APPLICATIO NS CO NTACT ACTIVE WEIG HING SO LUTIO NS O R O UR REPRESENTATIVE.

Active Weighing Solutions is continually improving the design of its products and reserves the right to make alterations without prior notification.

Active Weighing Solutions Telephone: +61 3 9873 7677

Unit 2, 41-49 Norcal Road Facsimile: +61 3 9873 7655

Nunawading, Victoria 3131

Email: enquiries@activeweighing.com.au

P.O. Box 338, Box Hill

Victoria 3128 Australia Website: www.activeweighing.com.au

You might also like

- FH344 GBDocument20 pagesFH344 GBSamehibrahem100% (1)

- MULTIDOS WeighfeederDocument4 pagesMULTIDOS Weighfeedershadi22No ratings yet

- Strategic Planning ModelDocument55 pagesStrategic Planning ModelShamkant KomarpantNo ratings yet

- DKMU - Introduction To The DKMUDocument30 pagesDKMU - Introduction To The DKMUjefry100% (2)

- Applied Thermodynamics IIDocument124 pagesApplied Thermodynamics IIHimanshu1712100% (2)

- SAP CRM Technical CourseDocument8 pagesSAP CRM Technical CoursesupreethNo ratings yet

- Product Sheet Load CellsDocument2 pagesProduct Sheet Load CellssakarisoNo ratings yet

- WS 30/60 KG B/BL Weighing Systems: Product Profile OptionsDocument4 pagesWS 30/60 KG B/BL Weighing Systems: Product Profile Optionsابو بيلسانNo ratings yet

- En DIN Standards in Pipeline ConstructionDocument2 pagesEn DIN Standards in Pipeline ConstructionJohn Smith67% (3)

- FT E003 - Elevator Head Design - STIF Eng PDFDocument1 pageFT E003 - Elevator Head Design - STIF Eng PDFTriết Lãm NgôNo ratings yet

- MULTIDOS MTD-E® Conveyor Belt Scraper Operating Manual Supplement - bvh2350gbDocument20 pagesMULTIDOS MTD-E® Conveyor Belt Scraper Operating Manual Supplement - bvh2350gbSoehartono HsNo ratings yet

- EDP Product Service Guide 2020 A5 Booklet Compressed Compressed Compressed 1Document72 pagesEDP Product Service Guide 2020 A5 Booklet Compressed Compressed Compressed 1Guillermo SoteloNo ratings yet

- Grading & Batching: Gain More Give Away LessDocument8 pagesGrading & Batching: Gain More Give Away LessАндрейNo ratings yet

- Belt and Bucket Elevator - LBEB - Data Sheet - ENDocument2 pagesBelt and Bucket Elevator - LBEB - Data Sheet - ENsalih khattabNo ratings yet

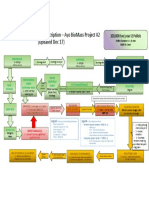

- Process Flow & Equipment Description - Ayo Biomass Project #2 (Updated Dec 17)Document1 pageProcess Flow & Equipment Description - Ayo Biomass Project #2 (Updated Dec 17)Nguyên Võ TriệuNo ratings yet

- Weighing and Feeding Guide SolutionsDocument20 pagesWeighing and Feeding Guide SolutionsalisuseNo ratings yet

- Single Idler Belt Scale: Instruction Manual PL-319 January 2001Document21 pagesSingle Idler Belt Scale: Instruction Manual PL-319 January 2001Julisa LombardoNo ratings yet

- Auto Combination WeigherDocument8 pagesAuto Combination WeigherSEHATI TEKNOLOGINo ratings yet

- Belt Scale Handbook 180629070959 PDFDocument28 pagesBelt Scale Handbook 180629070959 PDFrbounaNo ratings yet

- Disocont Tersus bvd2398gb PDFDocument4 pagesDisocont Tersus bvd2398gb PDFSuandi AnasNo ratings yet

- CM1000L Spareparts EN Rev.01.02Document26 pagesCM1000L Spareparts EN Rev.01.02Elton Luiz Trinchette de SantanaNo ratings yet

- General Belt Scale Brochure 4-8-10Document10 pagesGeneral Belt Scale Brochure 4-8-10cristobalmono100% (1)

- Loma CW3 Checkweigher DatasheetDocument2 pagesLoma CW3 Checkweigher DatasheetTomasNo ratings yet

- BVD 2462 GBDocument2 pagesBVD 2462 GBAnonymous P18XRitOPPNo ratings yet

- Combination MD and Checkweigher SystemsDocument2 pagesCombination MD and Checkweigher SystemsChandra NurikoNo ratings yet

- Checkweigher RFQ FormDocument2 pagesCheckweigher RFQ Formwasim KhokharNo ratings yet

- 7ML19985DK03 PDFDocument154 pages7ML19985DK03 PDFrabt1No ratings yet

- Compact, Accurate, Flexible: CWA Dynamic CheckweigherDocument2 pagesCompact, Accurate, Flexible: CWA Dynamic CheckweigherSanta KimNo ratings yet

- CW WP Dynamic Weigh Cell TechnologyDocument20 pagesCW WP Dynamic Weigh Cell Technologymario gultomNo ratings yet

- 7MH7163 Siemens Test Chain Storage ReelsDocument1 page7MH7163 Siemens Test Chain Storage ReelsEong Huat Corporation Sdn BhdNo ratings yet

- Milltronics: Instruction Manual July 2003Document77 pagesMilltronics: Instruction Manual July 2003Dan Hidalgo QuintoNo ratings yet

- 7MH7161 Siemens Milltronics Test ChainsDocument1 page7MH7161 Siemens Milltronics Test ChainsEong Huat Corporation Sdn BhdNo ratings yet

- Veg20650 2Document4 pagesVeg20650 2Numan Munawar0% (1)

- BVD 2407 GBDocument5 pagesBVD 2407 GBSaeed Ahmad ChandioNo ratings yet

- BVD2273GB TersusDocument4 pagesBVD2273GB TersusMohamed ElfawalNo ratings yet

- Platform Load Cell, PWS Type 10 ... 700 KGDocument4 pagesPlatform Load Cell, PWS Type 10 ... 700 KGSohail AhmedNo ratings yet

- E-Catalog - Operator Less Continues Vertical Conveyor From Impel Intralogistic - IndiaDocument6 pagesE-Catalog - Operator Less Continues Vertical Conveyor From Impel Intralogistic - IndiaImpel IntralogisticsNo ratings yet

- Ishida Checkweigher Scotraco PDFDocument6 pagesIshida Checkweigher Scotraco PDFchrissNo ratings yet

- FB WeighingDocument8 pagesFB Weighingdeden rahardyansyahNo ratings yet

- Global Cement ArticleDocument3 pagesGlobal Cement Articleskb25No ratings yet

- CDW150 Coriolis Flow MeterDocument14 pagesCDW150 Coriolis Flow MeterVali PopescuNo ratings yet

- Instruction Manual For CheckweigherDocument54 pagesInstruction Manual For Checkweigheralesia delgadoNo ratings yet

- Discharger: Operating InstructionsDocument18 pagesDischarger: Operating InstructionsWaleed MouhammedNo ratings yet

- Weigh Feeders: AcrisonDocument12 pagesWeigh Feeders: AcrisonneoegoNo ratings yet

- MCT460 User Guide Manual (First Edition) Rev1.2Document60 pagesMCT460 User Guide Manual (First Edition) Rev1.2Dwi April Yanto100% (1)

- 2016 Thayer Belt Scale Handbook 4 2016 ADocument14 pages2016 Thayer Belt Scale Handbook 4 2016 Ausebio64No ratings yet

- TDTG Bucket ElevatorDocument20 pagesTDTG Bucket ElevatorVictor Julio Torres Daza0% (1)

- Premium and Atrium Using Unity Pro: Weighing Module User ManualDocument162 pagesPremium and Atrium Using Unity Pro: Weighing Module User ManualSonixAraunaNo ratings yet

- Load Cell ActuatorsDocument2 pagesLoad Cell Actuatorssandeep100% (1)

- Brochure Weighing-Feeding 2013 enDocument36 pagesBrochure Weighing-Feeding 2013 enAudi TresnawanNo ratings yet

- As 1855-2008 Methods For The Determination of Transverse Tensile Properties of Round Steel PipeDocument7 pagesAs 1855-2008 Methods For The Determination of Transverse Tensile Properties of Round Steel PipeSAI Global - APACNo ratings yet

- GCC Scales - Weighing Indicator WH7510Document1 pageGCC Scales - Weighing Indicator WH7510kevinNo ratings yet

- Sansui Digital Weighbridge DetailsDocument11 pagesSansui Digital Weighbridge DetailsShreepad ChandolkarNo ratings yet

- Smartfill: Do You Already Have Enough Information On Your Grinding Process?Document2 pagesSmartfill: Do You Already Have Enough Information On Your Grinding Process?youssef tabetNo ratings yet

- HollySys-Scada PDFDocument2 pagesHollySys-Scada PDFCarlos MajanoNo ratings yet

- Guidance Note: Installation and Set-Up of Coriolis Mass Flow MetersDocument4 pagesGuidance Note: Installation and Set-Up of Coriolis Mass Flow MetersRawlinsonNo ratings yet

- JT95A JT95A JT95A JT95A: Jestronic 400 & Jestronic 500Document9 pagesJT95A JT95A JT95A JT95A: Jestronic 400 & Jestronic 500Mamadou djibril BaNo ratings yet

- PRSP Checkweigher GBDocument5 pagesPRSP Checkweigher GBChandra NurikoNo ratings yet

- Dacs-Wn Series PDFDocument6 pagesDacs-Wn Series PDFJames IzquierdoNo ratings yet

- Metler Toledo Ind560 PLC enDocument149 pagesMetler Toledo Ind560 PLC enAndres RodriguezNo ratings yet

- K - Tron ProductDocument12 pagesK - Tron Productkresimir.mikoc9765No ratings yet

- Brochure of Container Module Batching PlantDocument2 pagesBrochure of Container Module Batching PlantJefry eastonNo ratings yet

- Doseur A Vis Pesee enDocument2 pagesDoseur A Vis Pesee enمحمد الأمير الحازميNo ratings yet

- Checkpoint SeriesDocument2 pagesCheckpoint SeriesGuillermo SoteloNo ratings yet

- Case Histories of Incidents in Heated Bitumen Storage TanksDocument5 pagesCase Histories of Incidents in Heated Bitumen Storage TanksJohn SmithNo ratings yet

- Safety When Moving Bitumen Product Between Tanks: BulletinDocument2 pagesSafety When Moving Bitumen Product Between Tanks: BulletinJohn SmithNo ratings yet

- C Albert Eden Local Board Light Rail INPUT APPENDIXDocument151 pagesC Albert Eden Local Board Light Rail INPUT APPENDIXJohn SmithNo ratings yet

- SIHI LEH600 Performance CurvesDocument1 pageSIHI LEH600 Performance CurvesJohn SmithNo ratings yet

- Product Data Sheet Figure 969 Hopper Knife Gate Valves Keystone en en 5196836Document4 pagesProduct Data Sheet Figure 969 Hopper Knife Gate Valves Keystone en en 5196836John SmithNo ratings yet

- Health and Safety in Employment Pressure Equipment Cranes and Passenger Ropeways Regulations 1999Document38 pagesHealth and Safety in Employment Pressure Equipment Cranes and Passenger Ropeways Regulations 1999John SmithNo ratings yet

- Vendor Manual Soliphant FTM50 TI00392FEN - 1313 PDFDocument36 pagesVendor Manual Soliphant FTM50 TI00392FEN - 1313 PDFJohn SmithNo ratings yet

- ISO Starline Pump Curves and DataDocument99 pagesISO Starline Pump Curves and DataJohn SmithNo ratings yet

- Foamglas Underground-Brochure PDFDocument12 pagesFoamglas Underground-Brochure PDFJohn SmithNo ratings yet

- HASH House Harriers Song Sheet Book Update4Document27 pagesHASH House Harriers Song Sheet Book Update4John SmithNo ratings yet

- Wilkerson 2" Lubricator SpecificationsDocument2 pagesWilkerson 2" Lubricator SpecificationsJohn SmithNo ratings yet

- Action Research: Repeated Reading To Improve Students' Reading FluencyDocument4 pagesAction Research: Repeated Reading To Improve Students' Reading FluencyIylia NatasyaNo ratings yet

- Lesson 2.5 Reading Strategies - Narrative TextsDocument34 pagesLesson 2.5 Reading Strategies - Narrative Textsjannica yzabelNo ratings yet

- Circular QueueDocument10 pagesCircular QueuesalembalkiNo ratings yet

- Atex Flow ChartDocument1 pageAtex Flow ChartMohammad KurdiaNo ratings yet

- Allen BradleyDocument10 pagesAllen BradleyenggomarpuNo ratings yet

- NRB Bank ReportDocument49 pagesNRB Bank ReportTanvirBariNo ratings yet

- Ps1 GeneralDocument2 pagesPs1 Generalkulin123456No ratings yet

- Hot Runner KEBA2580 220VDocument19 pagesHot Runner KEBA2580 220VAarón DíazNo ratings yet

- EstratehiyaDocument2 pagesEstratehiyaMikaella AlvarezaNo ratings yet

- Cobol Batch To Groovy ScriptDocument34 pagesCobol Batch To Groovy ScriptDavid BermudezNo ratings yet

- Understanding Work Conditioning and Work Hardening Programs For A Successful RTW 3 13 2014 NovaCare PDFDocument37 pagesUnderstanding Work Conditioning and Work Hardening Programs For A Successful RTW 3 13 2014 NovaCare PDFSitiSarah0% (1)

- Personal Details:: User ID Candidate's NameDocument9 pagesPersonal Details:: User ID Candidate's NameAnkur SharmaNo ratings yet

- Fordyce MW 1983Document46 pagesFordyce MW 1983garbagepatchNo ratings yet

- Full Download Strategic Management Text and Cases 9th Edition Dess Test BankDocument35 pagesFull Download Strategic Management Text and Cases 9th Edition Dess Test Banksaumvirgen2375812100% (28)

- Listening Was Defined by Julian Treasure A2Document2 pagesListening Was Defined by Julian Treasure A2kim olimbaNo ratings yet

- STAT1008 Cheat SheetDocument1 pageSTAT1008 Cheat SheetynottripNo ratings yet

- Life Saving Rules FAQsDocument7 pagesLife Saving Rules FAQsArulboy123100% (1)

- Caillau, Guillon. S. Ephræm. Opera Omnia. 1832. Volume 7.Document540 pagesCaillau, Guillon. S. Ephræm. Opera Omnia. 1832. Volume 7.Patrologia Latina, Graeca et OrientalisNo ratings yet

- CSSMasterclassBook PDFDocument168 pagesCSSMasterclassBook PDFyankeeNo ratings yet

- Sustainable Architecture WikiDocument9 pagesSustainable Architecture WikisiddiqueaquibNo ratings yet

- Chapter 1: History, Definition and Benefits of ReadingDocument12 pagesChapter 1: History, Definition and Benefits of ReadingKreshia KC IledanNo ratings yet

- Information Current As of October 2008 Requirements Correspond To 2009-2010 CatalogDocument24 pagesInformation Current As of October 2008 Requirements Correspond To 2009-2010 Catalogpiqueen314No ratings yet

- DOA 19 Leaflet Framini 2p en-GB-ID High-ResDocument2 pagesDOA 19 Leaflet Framini 2p en-GB-ID High-ResHeri SiswantoNo ratings yet

- Chebyshevs Inequality - ProblemspdfDocument6 pagesChebyshevs Inequality - ProblemspdfamreenNo ratings yet

- Breaking Into The Movies: Public Pedagogy and The Politics of FilmDocument10 pagesBreaking Into The Movies: Public Pedagogy and The Politics of FilmDouglasNo ratings yet

- CV - Nhan - EnglishDocument4 pagesCV - Nhan - EnglishnhanpcNo ratings yet