Professional Documents

Culture Documents

Mix Design - Flyash

Uploaded by

Ajay Mahale0 ratings0% found this document useful (0 votes)

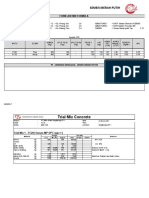

57 views1 pageThis document provides mix design details for concrete grades M10, M15, and M30 including ingredient types and suppliers, proportions, workability parameters, and notes. The key information includes:

- Cement, fly ash, mineral additions, aggregates and their suppliers and specific gravities used in the mixes.

- Mix designs listing cement, fly ash, aggregate proportions, water, admixture dosages, and expected fresh concrete densities for each grade.

- Notes about allowable variation in aggregates and admixtures, strength testing procedures, retention time, curing responsibilities, and yield checking processes.

Original Description:

concrete mix design

Original Title

Mix Design -Flyash (1)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides mix design details for concrete grades M10, M15, and M30 including ingredient types and suppliers, proportions, workability parameters, and notes. The key information includes:

- Cement, fly ash, mineral additions, aggregates and their suppliers and specific gravities used in the mixes.

- Mix designs listing cement, fly ash, aggregate proportions, water, admixture dosages, and expected fresh concrete densities for each grade.

- Notes about allowable variation in aggregates and admixtures, strength testing procedures, retention time, curing responsibilities, and yield checking processes.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

57 views1 pageMix Design - Flyash

Uploaded by

Ajay MahaleThis document provides mix design details for concrete grades M10, M15, and M30 including ingredient types and suppliers, proportions, workability parameters, and notes. The key information includes:

- Cement, fly ash, mineral additions, aggregates and their suppliers and specific gravities used in the mixes.

- Mix designs listing cement, fly ash, aggregate proportions, water, admixture dosages, and expected fresh concrete densities for each grade.

- Notes about allowable variation in aggregates and admixtures, strength testing procedures, retention time, curing responsibilities, and yield checking processes.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

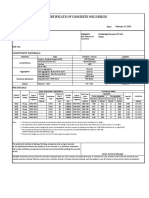

NUVOCO VISTAS CORP LTD

(Formally Lafarge India Ltd)

/ Plant: Thane 2 Date: 19/7/18 Ref No

Client: RRC Ventures Project: DKS,Thane

A . Ingredient Data

Ingredient Type Supplier Specific Gravity

Cement OPC 53 Ambuja/Bharati 3.15

Fly Ash Astech/adventure 2.23

Mineral Addition GGBS JSW 2.8

Ultraslag Ultra fine Product Pvt Ltd 2.9

20 mm Nuvoco Approved Supplier 2.86

Coarse Aggregate

10 mm Nuvoco Approved Supplier 2.83

Cr. Sand Nuvoco Approved Supplier 2.68

Fine Aggregate

Sand 2 Nuvoco Approved Supplier 2.7

Low PC Sika/chryso/CAC 1.05

Admixture Retarder Sika/chryso/CAC 1.2

High Pc Sika/chryso/CAC 1.09

B . Mix Design ( SSD )

Grade Slump /Flow Cement Flyash Add 10 mm 20 mm Cr. Sand Free Water Low PC Retarder Density

M 10 175+-25 150 100 0 510 540 980 175 3.75 1.50 2460

M 15 175+-25 180 90 0 550 520 950 170 4.05 1.62 2466

M 30 175+-25 320 110 0 520 530 820 165 6.45 2.58 2474

Notes

1. Aggrgeate proportion can by changed by + 5 % ,in case of change in Aggregate gradation

2. Admixture dosage can be vary by +- 0.3% as per the workability requirement and climate condition

3. Strength Criteria is on Cubes as per IS 456 with standard curing procedure as per IS 516

4. Retention time is 3:00 hr from batching

5. We will be only responsible for site cube casted by our person which will be casting & testing witness by

client Engg.

6.The Curing of the concrete is the responsibility of the customer and as such concrete should be properly

cured without any delay, before the concrete losses moisture on the finished surface to avoid any shrinkage

cracks.

7.For quantity or yield check-client will be to do weighment of TM at any weighbride as per client requirement

Mr. Kalpesh

( QC Incharge)

You might also like

- Concrete Materials: Properties, Specifications, and TestingFrom EverandConcrete Materials: Properties, Specifications, and TestingRating: 4.5 out of 5 stars4.5/5 (5)

- Test Report: Shree Siddhivinayak ConstructionDocument2 pagesTest Report: Shree Siddhivinayak ConstructionrahulNo ratings yet

- M-25 OPC Cement Without AdmixtureDocument5 pagesM-25 OPC Cement Without Admixturesnigdha.0613No ratings yet

- Material Submittal For Al Sarh Trading & Cont. (C20 &C25 Screed) PDFDocument117 pagesMaterial Submittal For Al Sarh Trading & Cont. (C20 &C25 Screed) PDFBikasNo ratings yet

- FT-MA-C-BD-004 Rev. 00 - MA For Concrete Mix Design - Bina-Pile Concrete (Approved)Document4 pagesFT-MA-C-BD-004 Rev. 00 - MA For Concrete Mix Design - Bina-Pile Concrete (Approved)Muhammad ShahzryNo ratings yet

- Certificate of Concrete Mix Design: Strength - Performance - PassionDocument1 pageCertificate of Concrete Mix Design: Strength - Performance - PassionRamesh F SinghNo ratings yet

- Nuvoco TRDocument2 pagesNuvoco TRTricon Fortis noida projectNo ratings yet

- 9686-6130-FQ-000-0007 Cement Content Higher Than 400Kg Per Cubic MetreDocument13 pages9686-6130-FQ-000-0007 Cement Content Higher Than 400Kg Per Cubic MetreANIL PLAMOOTTILNo ratings yet

- Workshop PT Sinar Anugerah Mitra Abadi-SINAR ANUGERAH MITRA ABADI fc'40 6+-2 - SD Water Ratio 4 DigitDocument1 pageWorkshop PT Sinar Anugerah Mitra Abadi-SINAR ANUGERAH MITRA ABADI fc'40 6+-2 - SD Water Ratio 4 Digitdeny susantoNo ratings yet

- Design Mix M-30 (Result Change)Document6 pagesDesign Mix M-30 (Result Change)sunil prajapatiNo ratings yet

- M20 PileDocument2 pagesM20 PileSudarsanan KNo ratings yet

- M 35 PS Basf UltDocument2 pagesM 35 PS Basf UltSudarsanan KNo ratings yet

- Elongation Test Bs. 812 Part (1) : Client: Ministry of Public Work and HousingDocument5 pagesElongation Test Bs. 812 Part (1) : Client: Ministry of Public Work and Housingm8877223No ratings yet

- Admore Gas (PVT) LTD: Bulk Oil Installation Depot at DaulatpurDocument12 pagesAdmore Gas (PVT) LTD: Bulk Oil Installation Depot at DaulatpurBilal Mustafa SiddiquiNo ratings yet

- 9686-6130-FQ-000-0007 Cement Content Higher Than 400Kg Per Cubic Metre 2..Document11 pages9686-6130-FQ-000-0007 Cement Content Higher Than 400Kg Per Cubic Metre 2..ANIL PLAMOOTTILNo ratings yet

- M 30 SFRSDocument2 pagesM 30 SFRSSudarsanan KNo ratings yet

- Daily MCBC Mar 2024Document1 pageDaily MCBC Mar 2024Shoubhik MukherjeeNo ratings yet

- Cement Circular 2023-4Document13 pagesCement Circular 2023-4Sammy ChanNo ratings yet

- BRFL Textiles PVT LTD: Sample DescriptionDocument1 pageBRFL Textiles PVT LTD: Sample DescriptionNarendraSinghNo ratings yet

- Delivery OrderDocument2 pagesDelivery OrderGayan IndunilNo ratings yet

- BHCP1-JEL-RFI-C00-Z0094-Compressive Strength Testing at Koboi Bente & PU Mataram LaboratoryDocument3 pagesBHCP1-JEL-RFI-C00-Z0094-Compressive Strength Testing at Koboi Bente & PU Mataram LaboratoryyohanesfernandoNo ratings yet

- Daily Drilling Fluid Report A4 Size (030A) - EnglishDocument1 pageDaily Drilling Fluid Report A4 Size (030A) - EnglishMuhammad SaqibNo ratings yet

- Mar of GegcDocument2 pagesMar of GegcNithin Sunny ChackoNo ratings yet

- SCC Class A G40 Concrete MixDocument1 pageSCC Class A G40 Concrete MixWunNaNo ratings yet

- 16.2ppg Tail 7inch LIner Jindal StarDocument2 pages16.2ppg Tail 7inch LIner Jindal StarMohamed El-SawahNo ratings yet

- RDC - M25 Mix Design With Flyash.Document1 pageRDC - M25 Mix Design With Flyash.Naresh CharyNo ratings yet

- BRFL Textiles PVT LTD: Sample DescriptionDocument1 pageBRFL Textiles PVT LTD: Sample DescriptionNarendraSinghNo ratings yet

- Material Submittal No. 0003 r.01 For Mdpe Pipes & Fittings, Sdr-11 (Naffco Flow Control, U.a.e.)Document136 pagesMaterial Submittal No. 0003 r.01 For Mdpe Pipes & Fittings, Sdr-11 (Naffco Flow Control, U.a.e.)rheynavarro24No ratings yet

- Mastic-Mix DesignDocument10 pagesMastic-Mix DesignVaasu KotyadaNo ratings yet

- Concrete Mix Design C40/20-400 KG MSRC: Combined GradingDocument1 pageConcrete Mix Design C40/20-400 KG MSRC: Combined GradingkamakshiNo ratings yet

- Concrete Mix Design: VaryDocument1 pageConcrete Mix Design: VaryAdnoc AlmeraikhiNo ratings yet

- Concrete Moisture Correction SheetDocument7 pagesConcrete Moisture Correction SheetAmit MaityNo ratings yet

- M35 Bhole ConstructionDocument6 pagesM35 Bhole ConstructionBIPL REPORT100% (1)

- M-25 Mix DesignDocument2 pagesM-25 Mix DesignSharath RMNo ratings yet

- 5071 e Mec Oth DM G V 003 - r5 - Gad & Tds For Butterfly Valves - Cat IDocument7 pages5071 e Mec Oth DM G V 003 - r5 - Gad & Tds For Butterfly Valves - Cat IvaibhavNo ratings yet

- Strucmax Ii MMS Ii Qap Ii 2023-24 Ii R0Document2 pagesStrucmax Ii MMS Ii Qap Ii 2023-24 Ii R0Prince MittalNo ratings yet

- M-15 UltratechDocument29 pagesM-15 Ultratechshivshankar kushwahaNo ratings yet

- Concrete Compression Test Report: 150X150X150 150X150X150 150X150X150 150X150X150 150X150X150 150X150X150Document3 pagesConcrete Compression Test Report: 150X150X150 150X150X150 150X150X150 150X150X150 150X150X150 150X150X150Okello StevenNo ratings yet

- DLC Degin GulbaxaniDocument6 pagesDLC Degin GulbaxaniImran KhanNo ratings yet

- Grout MixDocument2 pagesGrout MixAhmed MassadehNo ratings yet

- Concrete Compression Test: Cementitious Content Type of CementDocument4 pagesConcrete Compression Test: Cementitious Content Type of Cementmohammed alebiedNo ratings yet

- All Terrain Tire All Road Conditions: THE For Use ONDocument3 pagesAll Terrain Tire All Road Conditions: THE For Use ONdionisio emilio reyes jimenezNo ratings yet

- 2022 Equipment Purchase Price (List B) Pahang: Page 1/5Document5 pages2022 Equipment Purchase Price (List B) Pahang: Page 1/5mcyiesNo ratings yet

- Mix Design Report For M-30 Grade of Concrete: M/s Aegis Logistics LTDDocument5 pagesMix Design Report For M-30 Grade of Concrete: M/s Aegis Logistics LTD123shripadNo ratings yet

- MAS SheetDocument2 pagesMAS SheetnithinNo ratings yet

- Flexible Pavement Design - KalmboliDocument10 pagesFlexible Pavement Design - KalmboliDevendra DandotiyaNo ratings yet

- M30Pile Mix Design & Trial SheetDocument3 pagesM30Pile Mix Design & Trial Sheetabir senguptaNo ratings yet

- Proposal PT Mutiara Indah ConstructionDocument38 pagesProposal PT Mutiara Indah ConstructionI Wayan PartamaNo ratings yet

- Suhaimi: Summary of Field - TestDocument4 pagesSuhaimi: Summary of Field - Testhammad21No ratings yet

- Starworth 1Document1 pageStarworth 1KIRAN GNo ratings yet

- M25 Mix Design & Trial SheetDocument3 pagesM25 Mix Design & Trial Sheetabir senguptaNo ratings yet

- DM SSSDocument5 pagesDM SSSiitmpdNo ratings yet

- PreviewDocument1 pagePreviewJohn Cyril MusniNo ratings yet

- Semen Merah Putih: Form Job Mix FormulaDocument21 pagesSemen Merah Putih: Form Job Mix FormulaMochamad Abdul Mu'thiNo ratings yet

- UntitledDocument22 pagesUntitledshivshankar kushwahaNo ratings yet

- Client National Highways Authority of India Authority Engineer Epc ContractorDocument10 pagesClient National Highways Authority of India Authority Engineer Epc ContractorDeepakNo ratings yet

- ConcreteDocument21 pagesConcretekmandar99No ratings yet

- Test Report: Pavement Quality Concrete Mix Design of M-45 GradeDocument20 pagesTest Report: Pavement Quality Concrete Mix Design of M-45 GradeImran Khan100% (1)

- Test Report: Consulting Engineers Group LTDDocument9 pagesTest Report: Consulting Engineers Group LTDImran Khan100% (1)

- Diarab RoadDocument6 pagesDiarab RoadHishmat EzzelarabNo ratings yet

- Ancient and Modern Paper CharacterizatioDocument20 pagesAncient and Modern Paper CharacterizatioVornicu NicoletaNo ratings yet

- Fuels and Combustion: - Calorific Value - Significance and Comparison Between LCV andDocument44 pagesFuels and Combustion: - Calorific Value - Significance and Comparison Between LCV andanurag prernaNo ratings yet

- Stability of PVDF Hollow Fibre Membranes in Sodium Hydroxide Aqueous SolutionDocument11 pagesStability of PVDF Hollow Fibre Membranes in Sodium Hydroxide Aqueous SolutionrameshNo ratings yet

- Physical Properties of Group 18, Group 1 and Group 17 ElementsDocument2 pagesPhysical Properties of Group 18, Group 1 and Group 17 ElementsJames Chua Hong KhengNo ratings yet

- (Donald Mackay) Multimedia Environmental ModelsDocument273 pages(Donald Mackay) Multimedia Environmental ModelsKim HiềnNo ratings yet

- Satyam Bhuyan Wear 2010Document6 pagesSatyam Bhuyan Wear 2010satyambhuyan_5338070No ratings yet

- Purigo 5s - PDSDocument2 pagesPurigo 5s - PDSShelveen BhanNo ratings yet

- Mechanical Properties of MaterialsDocument24 pagesMechanical Properties of MaterialsMohannad sehwailNo ratings yet

- Geographical Organisation: Marketing ManagerDocument10 pagesGeographical Organisation: Marketing ManagerVinod MalkarNo ratings yet

- TN H01-Hand Book For Design of Steel StructuresDocument210 pagesTN H01-Hand Book For Design of Steel StructuresEdward van Martino88% (8)

- Material Price ListDocument43 pagesMaterial Price ListSathish RagavanNo ratings yet

- Stock Per 17 Okt 20 HargaDocument13 pagesStock Per 17 Okt 20 HargaLutfi QamariNo ratings yet

- Color of Underground Warning TapeDocument1 pageColor of Underground Warning TapeA.K.A. HajiNo ratings yet

- Igat6 D PL Me SPC 0007 01 Spec For Barred TeeDocument9 pagesIgat6 D PL Me SPC 0007 01 Spec For Barred Teeamini_mohi100% (1)

- Open Test Series - Paper-1 - (21-09-2021)Document31 pagesOpen Test Series - Paper-1 - (21-09-2021)Yogesh KhatriNo ratings yet

- Hofim: Hermetically-Sealed Motor-Compressor SystemDocument6 pagesHofim: Hermetically-Sealed Motor-Compressor Systemdvcher78No ratings yet

- The Human Genome ProjectDocument19 pagesThe Human Genome ProjectSuraj Bhattarai100% (3)

- Assignment 1 - Chapter 3 AnswerDocument9 pagesAssignment 1 - Chapter 3 AnswerHarryzam MartelNo ratings yet

- GD-1884 Manual PDFDocument10 pagesGD-1884 Manual PDFAnonymous srwHCpANo ratings yet

- Concrete Mix DesignDocument12 pagesConcrete Mix DesignWilliam ProvidoNo ratings yet

- Amino Acid ChartDocument6 pagesAmino Acid ChartCleveland BrownNo ratings yet

- SD - Cupric Tartrate TS, Alkaline (Fehling's Solution) (B) (USP204) (EU)Document7 pagesSD - Cupric Tartrate TS, Alkaline (Fehling's Solution) (B) (USP204) (EU)atikah razakNo ratings yet

- Quiz Name OxidationDocument3 pagesQuiz Name OxidationAnony MousNo ratings yet

- South West Museums Libraries and Archives Council Signposts To Collections Care Factsheet 4 Preventive Conservation March 2006Document5 pagesSouth West Museums Libraries and Archives Council Signposts To Collections Care Factsheet 4 Preventive Conservation March 2006Willi De Barros GonçalvesNo ratings yet

- Engineering ChemistryDocument60 pagesEngineering ChemistryAditya ShindeNo ratings yet

- Safety Data Sheet PropanDocument9 pagesSafety Data Sheet PropanFahri SofianNo ratings yet

- Aeg Lav72800 PDFDocument36 pagesAeg Lav72800 PDFGerardoNo ratings yet

- Aphron Invasion Control System (ICS)Document8 pagesAphron Invasion Control System (ICS)LoganBohannonNo ratings yet

- Heating Catalogue 2019Document44 pagesHeating Catalogue 2019Zoran SimanicNo ratings yet

- CorrosionDocument9 pagesCorrosionhesampirNo ratings yet