Professional Documents

Culture Documents

GTV Thrust Cakculatiohns

Uploaded by

Ratnakar Patil0 ratings0% found this document useful (0 votes)

12 views3 pagescalculatuions

Original Title

Gtv Thrust Cakculatiohns

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentcalculatuions

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views3 pagesGTV Thrust Cakculatiohns

Uploaded by

Ratnakar Patilcalculatuions

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 3

Gtv thrust cakculatiohns

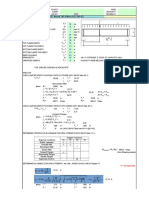

STEM THRUST AND TORQUE

Rt

Lead Angle

INPUTS : d stem

dstem 1.625in Stem diameter in inches

P 325psi Internal Pressure (Refer calculation sheet no. 1)

TPI 4in

1

Threads per inch

Lp

1

4

in Stem thread lead

μ 0.15 coefficient of friction (Dry )

Valve Factor= 0.3 for wedge gates,

1.1 for globe, underseat flow

Fv 0.30

TPI SL DL TL

10 1/10

8 1/8 1/4 3/8

7 1/7 2/7 3/7

6 1/6 1/3 1/2

5 1/5 2/5 3/5

4 1/4 1/2 3/4

3 1/2 2/7 4/7

3 1/3 2/3 1

2 1/2 2/5 4/5

D 13.25in STEM THREAD LEAD (Lp) Seat / Inside Diameter

θ 14.50deg Acme thread flank angle

Packing friction factor

Fp 600

lbf

in

Stem Material : ASTM A 182 CL2

Yield Strength : 55000 psi

σallowable : 30000 psi

τallow : 18333.5 psi

Factor of Safety : 1.5

CALCULATIONS :

Rt 0.5 dstem

0.5

TPI

Thread pitch radius

Rt 0.75in

cos(θrad) 0.968

α atan

Lp

2π Rt

0.053rad Thread helix angle

Crane Energy Flow Solutions 1-3 02.STEM THRUST & TORQUEGATE_0.xmcd

Calculation sheet No.: 02 17-12-2012

Le

Sacme

Nacme

dpacme

STEM FACTOR :

SF Rt tan(α)cos(θrad) μ

cos(θrad) μtan(α)

SF 0.1573in

SF 0.0131ft

STEM THRUST :

Fstem FvP

π

4

D

2

Fp dstem P

π

4

dstem

2

Fstem 15092.962lbf

STEM TORQUE :

Tstem FstemSF

Tstem 198lbf ft

ACTUATOR SPECIFICATION :

μ 0.15

Ttoruqe Tstem μ Tstem 227.495lbf ft

Tact 250 lbf ft Max Toruqe of Actuator (ref Diamond Gears)

Fact

Tact

SF

19074lbf

STEM STRESS AREA (Sa1) @ 1 5/8 - 4 ACME :

dpacme 1.4672in Minimum pitch dia

dmacme 1.3210in Minimum Minor dia

Sacme

dpacme dmacme

4

2

π ( ACME calculation sheet )

Sacme 1.526 in

2

STEM STRESS @ 1 5/8 - 4 ACME

σtacme

Fstem

Sacme

σtacme 9887.733psi

Crane Energy Flow Solutions 2-3 02.STEM THRUST & TORQUEGATE_0.xmcd

Calculation sheet No.: 02 17-12-2012

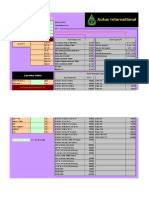

MIN NUMBER OF THREADS IN ENGAGEMENT TO WITHSTAND IN SHEAR :

t

1

TPI

2

τallow 18333.5psi

nacme

Fstem

π dmacme t τallow

1.587

MIN NUMBER OF THREADS IN ENGAGEMENT TO WITHSTAND IN BEARING PRESSURE :

σbrg 2133.501psi ( Allowable bearing pressure between steel & cast iron) CMTI page no. 174

nacmebrg

Fstem

π

4

dstem

2

dmacme

2

σbrg

10.057

MIN LENGTH OF THREAD ENGAGEMENT :

as nacmebrg > nacme

Le nacmebrg

You might also like

- Data SheetDocument2 pagesData SheetyiuhimluiNo ratings yet

- 1 Goulds Pumps 3196 1.5x3-8STXDocument7 pages1 Goulds Pumps 3196 1.5x3-8STXPaola moreno100% (1)

- VP3455DDocument11 pagesVP3455DSteni MoaiNo ratings yet

- Torque SheetDocument12 pagesTorque Sheetyash1239No ratings yet

- Tsa 2Document6 pagesTsa 2Amit SurtiNo ratings yet

- MC Quay Daikin Midea: Split Duct Split Wall Split Duct Split Wall Split Duct Split WallDocument3 pagesMC Quay Daikin Midea: Split Duct Split Wall Split Duct Split Wall Split Duct Split WallsatriapNo ratings yet

- Sistema de Lubricacion Pump HorizontalesDocument16 pagesSistema de Lubricacion Pump HorizontalesRodríguez EdwardNo ratings yet

- Ficha Tecnica Cd3450-InfopacketDocument11 pagesFicha Tecnica Cd3450-InfopacketmisaelmoralescNo ratings yet

- Product Information Packet: 20HP, 1765RPM, 3PH, 60HZ, 256T, 0952M, TEFC, F1Document10 pagesProduct Information Packet: 20HP, 1765RPM, 3PH, 60HZ, 256T, 0952M, TEFC, F1pavanreguNo ratings yet

- Min1244a12 - Tag 130-Pu-029Document7 pagesMin1244a12 - Tag 130-Pu-029Monty MathewsNo ratings yet

- Data Sheet Tag 180-Pu-011eDocument8 pagesData Sheet Tag 180-Pu-011eSarah PerezNo ratings yet

- e-XC 18x20x15.5 VFD Pump Curve 8-12-19Document3 pagese-XC 18x20x15.5 VFD Pump Curve 8-12-19Federico PerottiNo ratings yet

- Homelite String Trimmer Parts Manual SX135 String Trimmer UT 20601 CDocument12 pagesHomelite String Trimmer Parts Manual SX135 String Trimmer UT 20601 CTomas StrNo ratings yet

- FRCLM PDFDocument3 pagesFRCLM PDFMohan ShanmugamNo ratings yet

- Pressure Vessel THCK CalcDocument8 pagesPressure Vessel THCK Calcmkchy12100% (1)

- Plate Girder Design Based On AISC Manual 13th Edition (AISC 360-05)Document15 pagesPlate Girder Design Based On AISC Manual 13th Edition (AISC 360-05)Anisha MayaNo ratings yet

- Toshiba 0604SDSR41A Motor 60HPDocument6 pagesToshiba 0604SDSR41A Motor 60HPSoluPoliNo ratings yet

- 3119-Gear Box Data Sheet Rev.01Document4 pages3119-Gear Box Data Sheet Rev.01SAHTEESHKUMARNo ratings yet

- 7.voltage DropDocument33 pages7.voltage Droprajpre1213No ratings yet

- Data SheetDocument2 pagesData SheetBrijesh SharmaNo ratings yet

- Hydraulic ProgramDocument2 pagesHydraulic ProgramDaniel NavarroNo ratings yet

- Saddle Support Calculation PD 5500,2000 Annex.G)Document26 pagesSaddle Support Calculation PD 5500,2000 Annex.G)Neeraj Kumar33% (3)

- EM7054T-I: Product Information PacketDocument11 pagesEM7054T-I: Product Information PacketCikalong YardNo ratings yet

- Agitated Nutsche FilterDocument1 pageAgitated Nutsche FilterHaseeb KhanNo ratings yet

- Triplex Duplex Triplex Four Three Duplex: 11 11 10 10 0.34 SQ - inDocument39 pagesTriplex Duplex Triplex Four Three Duplex: 11 11 10 10 0.34 SQ - inYawn D ArtistNo ratings yet

- Specification of Helical Compression Spring EN 15800:2010 Designed To EN 13906-1: 2002 Part No: 001 Issue No: 001Document1 pageSpecification of Helical Compression Spring EN 15800:2010 Designed To EN 13906-1: 2002 Part No: 001 Issue No: 001Rafael TellezNo ratings yet

- UG-37 F FactorDocument7 pagesUG-37 F FactorjamesNo ratings yet

- Using The ASME VIII-1 Nozzle F Factor (UG-37)Document8 pagesUsing The ASME VIII-1 Nozzle F Factor (UG-37)Liu YangtzeNo ratings yet

- Homelite Chain Saw Parts Manual For LX30 Bandit Chain Saw UT 10705 E PDFDocument10 pagesHomelite Chain Saw Parts Manual For LX30 Bandit Chain Saw UT 10705 E PDFPanos RousetisNo ratings yet

- Bolts Torque CalculatorDocument2 pagesBolts Torque CalculatorsopapilasNo ratings yet

- Bolts Torque CalculatorDocument2 pagesBolts Torque Calculatorabs0001No ratings yet

- Plate GirderDocument22 pagesPlate GirdertitlesaengNo ratings yet

- Specs of Ducted UnitsDocument2 pagesSpecs of Ducted UnitsAdil MohdNo ratings yet

- 09 12 GEI Service ManualDocument70 pages09 12 GEI Service ManualToni TalevskiNo ratings yet

- VTN80G B.M. Thuot Nodal Design v0.1Document15 pagesVTN80G B.M. Thuot Nodal Design v0.1Đoàn SơnNo ratings yet

- ASV PT30 Parts ManualDocument23 pagesASV PT30 Parts ManualTrevorNo ratings yet

- Homelite String Trimmer Parts Manual d725cd String Trimmer UT 20739Document12 pagesHomelite String Trimmer Parts Manual d725cd String Trimmer UT 20739Walter CitoNo ratings yet

- Product Information Packet: 250HP, 3570RPM, 3PH, 60HZ, 449TS, 18104M, TEFCDocument9 pagesProduct Information Packet: 250HP, 3570RPM, 3PH, 60HZ, 449TS, 18104M, TEFCJosé Isaac Chávez HuamánNo ratings yet

- SPEC1Document273 pagesSPEC1Chandra KumarNo ratings yet

- Durco Mark2and3 50Hz60Hz CurvesDocument60 pagesDurco Mark2and3 50Hz60Hz Curvesfagb1978100% (1)

- En - 5 - 3 - 460 - Super - X 03040402Document22 pagesEn - 5 - 3 - 460 - Super - X 03040402Alessandro FontesNo ratings yet

- EXAMPLE Nozzle Calculations Using ASME VIII Div 2 Appendix 1-10Document16 pagesEXAMPLE Nozzle Calculations Using ASME VIII Div 2 Appendix 1-10jtai1983No ratings yet

- 625245-A-S990-01 ChassisDocument687 pages625245-A-S990-01 Chassisdavidmaciasv007No ratings yet

- Baldor M7047T-HBB48Document10 pagesBaldor M7047T-HBB48tsonjayaNo ratings yet

- Cu-Alloy ISI Globe Valves.359144603Document1 pageCu-Alloy ISI Globe Valves.359144603Kishore KumarNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Precision Equipments (Chennai) Pvt. Ltd. Plot No.B-70/1, Sipcot Industrial Park, Irrungattukottai, Chennai - 602105. Mechanical Data SheetDocument1 pagePrecision Equipments (Chennai) Pvt. Ltd. Plot No.B-70/1, Sipcot Industrial Park, Irrungattukottai, Chennai - 602105. Mechanical Data SheetAnonymous AyDvqgNo ratings yet

- SPAN Approval 2018 - Sludge Pump (Lampiran A)Document9 pagesSPAN Approval 2018 - Sludge Pump (Lampiran A)Syed IhyaNo ratings yet

- Wimd32 ParamsDocument86 pagesWimd32 ParamsvishiwizardNo ratings yet

- 2.1 Template Kit - Part Number (Admin Unit)Document212 pages2.1 Template Kit - Part Number (Admin Unit)Hijrah Saputro RaharjoNo ratings yet

- U-Match GOOD R410A SpecificationsDocument20 pagesU-Match GOOD R410A SpecificationsmiguelNo ratings yet

- Completion Program For YRNS-009-10.14Document20 pagesCompletion Program For YRNS-009-10.14hoss mosafaNo ratings yet

- Ac Brake Dat Series PetheDocument1 pageAc Brake Dat Series Pethekinner3No ratings yet

- TechniSolve Software - C1Document4 pagesTechniSolve Software - C1Dennis Jose DionisioNo ratings yet

- VWDL3514Document10 pagesVWDL3514ing.cdpadillaNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileFrom EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileNo ratings yet

- Part Logic1Document2 pagesPart Logic1Ratnakar PatilNo ratings yet

- Weir Oil Gas BrochureDocument33 pagesWeir Oil Gas BrochureRatnakar Patil100% (1)

- Wellhead Dual Tubing Hanger RequirementsDocument1 pageWellhead Dual Tubing Hanger RequirementsRatnakar PatilNo ratings yet

- Parveen Well Head PDFDocument25 pagesParveen Well Head PDFRatnakar PatilNo ratings yet

- Common Valve Casting Materials MetallurgyDocument4 pagesCommon Valve Casting Materials MetallurgyRatnakar PatilNo ratings yet

- ViN Trunn Mounted BVDocument8 pagesViN Trunn Mounted BVRatnakar PatilNo ratings yet

- Wellhead Products Catalog vFEB2015 PDFDocument20 pagesWellhead Products Catalog vFEB2015 PDFRatnakar PatilNo ratings yet

- Enquiry Form DataDocument3 pagesEnquiry Form DataRatnakar PatilNo ratings yet

- Universal Company Profile StainlessDocument7 pagesUniversal Company Profile StainlessRatnakar PatilNo ratings yet

- Company Profile en TORNOSDocument14 pagesCompany Profile en TORNOSRatnakar PatilNo ratings yet

- Control Valve Eng. TipsDocument3 pagesControl Valve Eng. TipsRatnakar PatilNo ratings yet

- Ball Joint DesignDocument8 pagesBall Joint DesignRatnakar PatilNo ratings yet

- Reverse Flow Cyclones For Tea DustDocument11 pagesReverse Flow Cyclones For Tea DustRatnakar PatilNo ratings yet

- Student's Holiday - Vi 19619Document1 pageStudent's Holiday - Vi 19619Ratnakar PatilNo ratings yet

- Study Successful CalculationDocument58 pagesStudy Successful CalculationRatnakar PatilNo ratings yet

- Machine Hours RateDocument15 pagesMachine Hours RateRatnakar PatilNo ratings yet