Professional Documents

Culture Documents

Clarke JU6H Specification Sheet

Uploaded by

abhayundaleCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Clarke JU6H Specification Sheet

Uploaded by

abhayundaleCopyright:

Available Formats

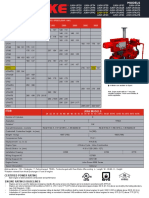

® MODELS

JU6H-UF32 JU6H-UFM2 JU6H-UF54 JU6H-UFKAQ8

JU6H-UFD0 JU6H-UF34 JU6H-UF58 JU6H-UF60 JU6H-UFKARG

FIRE PUMP ENGINES JU6H-UFD2 JU6H-UFM8 JU6H-UF50 JU6H-UF62 JU6H-UFKAS0

JU6H-UF30 JU6H-UFM0 JU6H-UF52 JU6H-UFKAPG JU6H-UF84

UK Purchased

FM-UL-cUL APPROVED RATINGS KW/BHP

JU6H RATED SPEED

MODEL 1470 1760 2100 2350 2600 2800 3000

UFD0 82 110 107 144 110 148

UFD2 110 148 110 148

UF30 70 94 104 140 119 160 119 160

UF32 119 160 119 160

UF34 119 160 119 160 119 160 131 175

UFM8 101 136 131 175

UFM0 131 175 154 207 149 200

UFM2 149 200 149 200

UF58 103 138 137 183

UF50 137 183 157 210 157 210

UF52 157 210 157 210

UF54 157 210 161 216 161 216 161 216

UF60 149 200 179 240 179 240

UF62 179 240 179 240

UFKAPG 164 220

UFKAQ8 169 227

Picture shown represents JU6H-TRWA engine model

UFKARG 188 252

UFKAS0 194 260

UF84 181 243 184 247 193 259 205 275

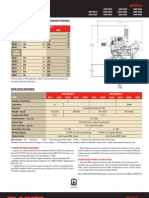

SPECIFICATIONS

JU6H MODELS

ITEM D0 D2 30 32 34 M8 M0 M2 58 50 52 54 60 62 KAPG/Q8/RG/S0 84

Number of Cylinders 6

Aspiration T TRWA

Rotation* CW

Overall Dimensions - mm (in.) 1178 (46.4) H x 1510 (59.4) L x 942 (37.1) W 1178 (46.4) H x 1510 (59.4) L x 944 (37.2) W

Crankshaft Centerline Height – mm (in.) 356 (14)

Weight – kg (lb) 750 (1657) 766 (1693)

Compression Ratio 17.0:1

Displacement – l (cu. in.) 6.8 (414)

Engine Type 4 Stroke Cycle – Inline Construction

Bore & Stroke – mm (in.) 4.19 x 5.00 (106 x 127)

Installation Drawing D538

Wiring Diagram AC C07651

Wiring Diagram DC C072145

Engine Series John Deere 6068 Series

Abbreviations: CW – Clockwise T – Turbocharged TRWA – Turbocharged with Raw Water Aftercooling L – Length W – Width H - Height

*Rotation viewed from Heat Exchanger / Front of engine

CERTIFIED POWER RATING ENGINE RATINGS BASELINES

• Each engine is factory tested to verify power and performance. • Engines are to be used for stationary emergency standby fire pump service only. Engines

are to be tested in accordance with NFPA 25.

• Although FM-UL ratings are shown at specific speeds, Clarke engines can be

applied at any intermediate speed. To determine the intermediate speed • Engines are rated at standard SAE conditions of 29.61 in. (752.1 mm) Hg barometer and

power; make a linear interpolation from the Clarke FM-UL power curve. 77°F (25°C) inlet air temperature [approximates 300 ft. (91.4 m) above sea level] by the

Contact Clarke or your Pump OEM Representative to obtain details. testing laboratory (see SAE Standard J 1349).

• A deduction of 3 percent from engine horsepower rating at standard SAE conditions shall

be made for diesel engines for each 1000 ft. (305 m) altitude above 300 ft. (91.4 m)

• A deduction of 1 percent from engine horsepower rating as corrected to standard SAE

conditions shall be made for diesel engines for every 10°F (5.6°C) above 77°F (25°C)

FM ambient temperature.

® MODELS

JU6H-UF32 JU6H-UFM2 JU6H-UF54 JU6H-UFKAQ8

JU6H-UFD0 JU6H-UF34 JU6H-UF58 JU6H-UF60 JU6H-UFKARG

FIRE PUMP ENGINES JU6H-UFD2 JU6H-UFM8 JU6H-UF50 JU6H-UF62 JU6H-UFKAS0

JU6H-UF30 JU6H-UFM0 JU6H-UF52 JU6H-UFKAPG JU6H-UF84

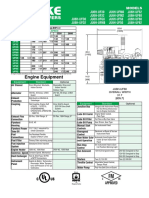

ENGINE EQUIPMENT

EQUIPMENT STANDARD OPTIONAL

Air Cleaner Direct Mounted, Washable, Indoor Service with Drip Shield Disposable, Drip Proof, Indoor Service Outdoor Type, Single or

Two Stage (Cyclonic)

Alarms Overspeed Alarm & Shutdown, Low Oil Pressure, Low & High Low Coolant Level, Low Oil Level, Oil Filter Differential Pressure,

Coolant Temperature, Low Raw Water Flow, High Raw Water Fuel Filter Differential Pressure, Air Filter Restriction

Temperature

Alternator 12V-DC, 42 Amps; with Poly-Vee Belt and Guard 24V-DC, 40 Amps; with Belt Guard

Coupling Bare Flywheel Listed Driveshaft and Guard, UFD0/D2/30/32/34 – CDS20-S1;

UFM8/M0/M2/58/50/52/54/60/62/84– CDS30-S1;

UFKAQ8/KAPG/RG/S0 – CDS50-SC

Engine Heater 230V-AC, 1360 Watt 115V-AC, 1360 Watt

Exhaust Flex Connection SS Flex, Clamped, 5” SS Flex, Clamped, 6”

Exhaust Protection Metal Guards on Manifolds and Turbocharger

Flywheel Housing SAE #3

Flywheel Power Take Off 11.5” SAE Industrial Flywheel Connection

Fuel Connections Fire Resistant, Flexible, USA Coast Guard Approved, Supply and

Return Lines

Fuel Filter Primary Filter with Priming Pump

Fuel Injection System Stanadyne, Direct Injection

Fuel Solenoid 12V-DC Energized to Stop (ETS) 12V-DC Energized to Run (ETR); 24V-DC Energized to Run (ETR);

24V-DC Energized to Stop (ETS)

Governor, Speed Constant Speed, Mechanical

Heat Exchanger Tube and Shell Type, 4 BAR (60 PSI), BSP(F) Connections Sea Water Compatible

Instrument Panel English and Metric, Tachometer, Hourmeter, Water Temperature,

Oil Pressure and Two (2) Voltmeters

Junction Box Integral with Instrument Panel; For DC Wiring Interconnection to

Engine Controller

Lube Oil Cooler Engine Water Cooled, Plate Type

Lube Oil Filter Full Flow with By-Pass Valve

Lube Oil Pump Gear Driven, Gear Type

Manual Start Control On Instrument Panel with Control Position Warning Light

Overspeed Control Electronic with Reset and Test on Instrument Panel

Raw Water Cooling Loop – Galvanized Seawater, All 316SS, High Pressure

w\Alarms

Raw Water Cooling Loop – Automatic from Fire Pump Controller and from Engine Instrument Not Supplied (for Vertical Turbine Fire Pump Applications)

Solenoid Operation Panel (for Horizontal Fire Pump Applications)

Run – Stop Control On Instrument Panel with Control Position Warning Light

Starters Two (2) 12V-DC Two (2) 24V-DC

Throttle Control Adjustable Speed Control, Tamper Proof

Water Pump Centrifugal Type, Poly-Vee Belt Drive with Guard

Abbreviations : DC – Direct Current, AC – Alternating Current, SAE – Society of Automotive Engineers, BSP(F) – British Standard Pipe Thread (Female), SS – Stainless Steel

UK, Ltd. Fire Protection Products, Inc.

Grange Works, Lomond Rd., Coatbridge, ML5-2NN 100 Progress Place, Cincinnati, Ohio 45246

United Kingdom United States of America

Tel +44-1236-429946 Fax +44-1236-427274 Tel +1-513-475-(FIRE)3473 Fax +1-513-771-8930

www.clarkefire.com www.clarkefire.com

C133434 revK Specifications and information contained in this brochure subject to change without notice. .

11APR17

You might also like

- Ficha Tecnica Motor DP6H-UFAA88Document9 pagesFicha Tecnica Motor DP6H-UFAA88SYA33% (3)

- Clarke EngineDocument9 pagesClarke EngineJust RysdanNo ratings yet

- Dq6h Ufka60 ProposalDocument10 pagesDq6h Ufka60 Proposaledward baskaraNo ratings yet

- ClarkeDocument11 pagesClarkeJuan Carlos100% (2)

- Parts Illustration - JU6 - Tier 3Document37 pagesParts Illustration - JU6 - Tier 3Franklin Gustavo Zagaceta Bautista100% (1)

- Manual Clarke NLDocument43 pagesManual Clarke NLAfriandhi100% (1)

- JU4H-UF34 ProposalDocument12 pagesJU4H-UF34 ProposalUmmeNo ratings yet

- Parts Illustration - IT4 - C135063Document27 pagesParts Illustration - IT4 - C135063Franklin Gustavo Zagaceta Bautista0% (1)

- Clarke INSTALLATION & OPERATION DATADocument12 pagesClarke INSTALLATION & OPERATION DATAInam Haq100% (1)

- Fire Pump Drivers: Engine EquipmentDocument8 pagesFire Pump Drivers: Engine EquipmentPedro OlivaresNo ratings yet

- L8FA / 08FA 08FH 12FT 12FH Part Name Part Number L6Fa / T6Fa / 06FA 06FHDocument1 pageL8FA / 08FA 08FH 12FT 12FH Part Name Part Number L6Fa / T6Fa / 06FA 06FHjasperzeus crisostomoNo ratings yet

- Aurora Diesel Pump - Performance CurveDocument116 pagesAurora Diesel Pump - Performance CurveHermantoro W. Pradana100% (1)

- Ju4h Uf14Document11 pagesJu4h Uf14Ahmed Salah Abd EL-WahedNo ratings yet

- CENTRIFUGAL FIRE PUMPS, SPLIT CASE - UL Product IqDocument11 pagesCENTRIFUGAL FIRE PUMPS, SPLIT CASE - UL Product IqTalha Nasir100% (1)

- Peerless Pump UL FM (1) Hai An-B - M 250Hp PDFDocument1 pagePeerless Pump UL FM (1) Hai An-B - M 250Hp PDFViệt Đặng XuânNo ratings yet

- 1000 GPM at 100 M - SCP 125 - 320 - JU4H - UF54 - 108 - UL+FM PDFDocument60 pages1000 GPM at 100 M - SCP 125 - 320 - JU4H - UF54 - 108 - UL+FM PDFNOMAN100% (2)

- Perkins 4012 46tag3a Briz MotorsDocument22 pagesPerkins 4012 46tag3a Briz MotorsmualiminNo ratings yet

- Clarke Mechanical Engine Controller Alarm Verification ProcedureDocument4 pagesClarke Mechanical Engine Controller Alarm Verification ProcedureChanat MeonsiNo ratings yet

- ClarkeDieselEngineJU4&6H NL v2Document2 pagesClarkeDieselEngineJU4&6H NL v2Faisol Rizal100% (2)

- Pitot Pressure Flow ChartDocument2 pagesPitot Pressure Flow ChartRyan GeisslerNo ratings yet

- Engine Manual - ClarkDocument65 pagesEngine Manual - ClarkMiguel100% (4)

- Manual de Compresor Ariel JGKDocument145 pagesManual de Compresor Ariel JGKDany Godinez100% (1)

- Valvula de Diluvio Watts 100d-bDocument2 pagesValvula de Diluvio Watts 100d-bLuis Carlos Figueroa Pinto100% (3)

- SPP Pumps - Mod. TD15F - Información TécnicaDocument7 pagesSPP Pumps - Mod. TD15F - Información TécnicaGabriel LopezNo ratings yet

- Technical Catalog JD c13965 PDFDocument473 pagesTechnical Catalog JD c13965 PDFOmar BecerraNo ratings yet

- DATA SHEET FIRE PEERLESS ELECTRICO 75HP-220V-MOD-4AEF10C (500 GPM at 150P...Document20 pagesDATA SHEET FIRE PEERLESS ELECTRICO 75HP-220V-MOD-4AEF10C (500 GPM at 150P...LUIS SOTELO50% (2)

- Solid Bore Discharge Formula & Flow Testing GuidelinesDocument1 pageSolid Bore Discharge Formula & Flow Testing GuidelinesDiego Francisco Ancajima CuevaNo ratings yet

- C0108031 O&M Manual y Curva Fabricante PDFDocument127 pagesC0108031 O&M Manual y Curva Fabricante PDFcesar100% (1)

- Parts Spare JU6H - UF60Document2 pagesParts Spare JU6H - UF60Dario Jaimes50% (2)

- CLARKE - Engine Oil and Fuel Filter Cross ReferenceDocument1 pageCLARKE - Engine Oil and Fuel Filter Cross ReferencecamiloayalaNo ratings yet

- TF20G 2000GPM DieselDocument1 pageTF20G 2000GPM DieselKarim Tarek100% (1)

- Tablas de Filtros Motores ClarkeDocument1 pageTablas de Filtros Motores ClarkeLeonardo Ramirez100% (1)

- Foam Agent Field ManualDocument11 pagesFoam Agent Field Manualnap_carino100% (1)

- 1 ProInert2 EquipmentDocument89 pages1 ProInert2 EquipmentfereszaNo ratings yet

- Operation and Maintenance Instructions Manual: DP/DQ/DR/DS/DT Model Engines Fire Pump ApplicationsDocument44 pagesOperation and Maintenance Instructions Manual: DP/DQ/DR/DS/DT Model Engines Fire Pump ApplicationsLwigy SaavedraNo ratings yet

- L7042GDocument2 pagesL7042GRose MarieNo ratings yet

- Waukesha V HP Series 4Document4 pagesWaukesha V HP Series 4rohizatNo ratings yet

- DP/DQ/DR/DS/DT Model EnginesDocument49 pagesDP/DQ/DR/DS/DT Model EnginesThanat Khemthong100% (1)

- 11b. DFP 2012 1013 Mechanical Manual PDFDocument167 pages11b. DFP 2012 1013 Mechanical Manual PDFWahyoe Damai100% (2)

- S-8B1 8B1TDocument6 pagesS-8B1 8B1TbryandownNo ratings yet

- John Deere 6081 GeneradorDocument2 pagesJohn Deere 6081 GeneradoremmanuelNo ratings yet

- Randolph Product CatalogueDocument22 pagesRandolph Product CatalogueIsrael Campos100% (2)

- Fairbanks Fire Pumps Standard Fire Pump Accessories3004005007501000125015002000250030003500400045005000Document23 pagesFairbanks Fire Pumps Standard Fire Pump Accessories3004005007501000125015002000250030003500400045005000Muhammad ArslanNo ratings yet

- Xp375wir SpecsDocument2 pagesXp375wir SpecsSpectrumRaijin50% (2)

- Fitflow Supplies 500GPM Pump DatasheetDocument2 pagesFitflow Supplies 500GPM Pump DatasheetRonni LBNo ratings yet

- Lta10-G1 SpecsDocument8 pagesLta10-G1 SpecsTrương Ngọc Thắng100% (1)

- Ansul 102Document145 pagesAnsul 102Kadiri OlanrewajuNo ratings yet

- Clarke Manual PLD C131042Document13 pagesClarke Manual PLD C131042zona amrullohNo ratings yet

- Ficha Técnica - ElectricaDocument8 pagesFicha Técnica - ElectricainspeccionestecnicasnfpaNo ratings yet

- Daniel Senior Orifice MeterDocument2 pagesDaniel Senior Orifice MeterTkeyah Phillips100% (1)

- Centrifugal Pump Repair Data Form: Performed By: DateDocument2 pagesCentrifugal Pump Repair Data Form: Performed By: DateGerardo Hg100% (2)

- WOODWARD SPEED SW. ESSE-2 OnlyDocument24 pagesWOODWARD SPEED SW. ESSE-2 OnlyAnkit RedkarNo ratings yet

- Ziegler - Fire Pumps - FPN 10-6000-2 HDocument55 pagesZiegler - Fire Pumps - FPN 10-6000-2 HSecu09No ratings yet

- 31050862Document11 pages31050862farukNo ratings yet

- Ficha T. Motor JU6H-UFD0Document9 pagesFicha T. Motor JU6H-UFD0Nelson IglesiasNo ratings yet

- Proposal - JU6H-UF30 - 160 HP at 2350 RPMDocument11 pagesProposal - JU6H-UF30 - 160 HP at 2350 RPMMaurilio Batista de Lima100% (1)

- GeneratePDF (1) - Proposal JU6H-UFDO - 144 HP@ 2100 RPMDocument11 pagesGeneratePDF (1) - Proposal JU6H-UFDO - 144 HP@ 2100 RPMMaurilio Batista de LimaNo ratings yet

- Spec Sheet Jw6h-Ufaa-Ad c133422Document4 pagesSpec Sheet Jw6h-Ufaa-Ad c133422janter edward marpaung100% (1)

- jw6h Ufaam8 UsaDocument8 pagesjw6h Ufaam8 UsaRoronoa ZorroNo ratings yet

- GeM Bidding 4690676Document4 pagesGeM Bidding 4690676abhayundaleNo ratings yet

- National Rubber Policy 2019 PDFDocument25 pagesNational Rubber Policy 2019 PDFratneshNo ratings yet

- GeM Bidding 5006827Document11 pagesGeM Bidding 5006827abhayundaleNo ratings yet

- Requirement - 4Document9 pagesRequirement - 4abhayundaleNo ratings yet

- National Rubber Policy 2019 PDFDocument25 pagesNational Rubber Policy 2019 PDFratneshNo ratings yet

- Agricultural Pumping Efficiency in India: Role of StandardsDocument17 pagesAgricultural Pumping Efficiency in India: Role of StandardsabhayundaleNo ratings yet

- Tenders For Supply of Printing, Prescription Pad, A and D Book, Check List For Med BD, Paper A4, Envelope A4Document6 pagesTenders For Supply of Printing, Prescription Pad, A and D Book, Check List For Med BD, Paper A4, Envelope A4Hussain ShaikhNo ratings yet

- GeM Bidding 4764677Document4 pagesGeM Bidding 4764677SANJU RANINo ratings yet

- JP Industrial Pump Product Overview USDocument8 pagesJP Industrial Pump Product Overview USMatsumura SokonNo ratings yet

- National Rubber Policy 2019 PDFDocument25 pagesNational Rubber Policy 2019 PDFratneshNo ratings yet

- TEXTILES AND GARMENTS - Make in India PDFDocument4 pagesTEXTILES AND GARMENTS - Make in India PDFabhayundaleNo ratings yet

- Design of VFD Drive For AC MotorDocument8 pagesDesign of VFD Drive For AC MotorralphholingsheadNo ratings yet

- National Rubber Policy 2019 PDFDocument25 pagesNational Rubber Policy 2019 PDFratneshNo ratings yet

- PDF 44201231009PMSHM-SHVTDocument53 pagesPDF 44201231009PMSHM-SHVTabhayundale100% (1)

- Instructions For Filling of Passport Application Form and Supplementary FormDocument20 pagesInstructions For Filling of Passport Application Form and Supplementary FormabhayundaleNo ratings yet

- White Paper CDocument27 pagesWhite Paper CTrần Quang ThắngNo ratings yet

- A History of Fire PumpsDocument1 pageA History of Fire PumpsabhayundaleNo ratings yet

- Caustic Soda: Safe Handling ofDocument29 pagesCaustic Soda: Safe Handling ofYamin MohdNo ratings yet

- New Microsoft Office Word DocumentDocument3 pagesNew Microsoft Office Word DocumentabhayundaleNo ratings yet

- Motor ClasstyDocument128 pagesMotor Classtywatep_08No ratings yet

- 12 Terminologies Used For Power of The Ship's Marine Propulsion EngineDocument9 pages12 Terminologies Used For Power of The Ship's Marine Propulsion EngineGerald HandersonNo ratings yet

- 350DLC Excavator PIN 1FF350DX D805001 IntroductionDocument5 pages350DLC Excavator PIN 1FF350DX D805001 IntroductionWillian Ticlia RuizNo ratings yet

- Preliminary: Underground Mining LoaderDocument20 pagesPreliminary: Underground Mining Loaderwilfredo escobar gutierrezNo ratings yet

- Engine Power Measurements PDFDocument6 pagesEngine Power Measurements PDFAbdaljaleelAlqazeeNo ratings yet

- PowerROC T45 - Brochure - English PDFDocument5 pagesPowerROC T45 - Brochure - English PDFFelipe Contreras OrellanaNo ratings yet

- Cat 772g BRDocument28 pagesCat 772g BR111No ratings yet

- Crane ControlDocument81 pagesCrane ControlKnjigescribdNo ratings yet

- SET D MachineDocument8 pagesSET D Machinelance galorportNo ratings yet

- Tiguan OverviewDocument44 pagesTiguan OverviewBadoiu LiviuNo ratings yet

- Pump Efficiency and Irrigation System PerformanceDocument7 pagesPump Efficiency and Irrigation System PerformancePatrizaNo ratings yet

- Kubota LowBoy II Diesel Generator GL7000 GL11000 GL Series - Service ManualDocument154 pagesKubota LowBoy II Diesel Generator GL7000 GL11000 GL Series - Service ManualHasan Rauf100% (1)

- Letter Code NEMA PDFDocument1 pageLetter Code NEMA PDFdabs_orangejuiceNo ratings yet

- 60ZVDocument8 pages60ZVBarongNo ratings yet

- 06.1 Exh I - App I - Vessel Spec 150 MT (Final) - HD29-submitDocument21 pages06.1 Exh I - App I - Vessel Spec 150 MT (Final) - HD29-submitThanh Anh MaiNo ratings yet

- How to Size Generators for Motors and AppliancesDocument5 pagesHow to Size Generators for Motors and AppliancesJeremiah GilbolingaNo ratings yet

- Pc200 8 KomatsuDocument12 pagesPc200 8 KomatsuWachid Ramadani100% (6)

- Mr647632en 2019-01Document206 pagesMr647632en 2019-01Dmytro Manzyk100% (3)

- Genset DataDocument12 pagesGenset DatagebreNo ratings yet

- DX800LC PDFDocument29 pagesDX800LC PDFblas castillo100% (2)

- LVM Catalog 2013 Electric MotorDocument228 pagesLVM Catalog 2013 Electric MotorvikzefgNo ratings yet

- KTA38-G2A, Hoja de DatosDocument4 pagesKTA38-G2A, Hoja de DatosCarlos MisanoNo ratings yet

- Basic Electrical FormulasDocument2 pagesBasic Electrical FormulasronniedakingpouNo ratings yet

- CauhoiontapDocument7 pagesCauhoiontapÁNH NGỌC NGUYỄN THỊNo ratings yet

- MotoriDocument68 pagesMotorizio.jean01No ratings yet

- Design of A 33-Knot Aluminum Catamaran FerryDocument13 pagesDesign of A 33-Knot Aluminum Catamaran FerrygksahaNo ratings yet

- Vibro Compactador Cs 54Document16 pagesVibro Compactador Cs 54ricsnikNo ratings yet

- NEMA, ANSI, NETA, NECA Codes and Standards ReviewerDocument25 pagesNEMA, ANSI, NETA, NECA Codes and Standards ReviewerStanley Vette LaubingerNo ratings yet

- Mahindra 8000 9500 4WD Series Brochure Web PDFDocument6 pagesMahindra 8000 9500 4WD Series Brochure Web PDFParamesh Siva100% (1)

- Service Genie Z135Document295 pagesService Genie Z135Taz Juan G100% (1)

- Oil Coolers: Mobile Air CooledDocument5 pagesOil Coolers: Mobile Air CooledErdincNo ratings yet