Professional Documents

Culture Documents

Computer Aided Design

Uploaded by

Rushabh Patel0 ratings0% found this document useful (0 votes)

7 views2 pagesjhgjk

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentjhgjk

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views2 pagesComputer Aided Design

Uploaded by

Rushabh Pateljhgjk

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

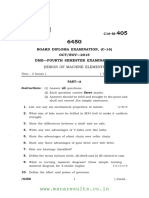

Seat No.: ________ Enrolment No.

___________

GUJARAT TECHNOLOGICAL UNIVERSITY

B.E. SEMESTER VIII(OLD) EXAMINATION – WINTER 2017

Subject Code: 181902 Date: 02-11-2017

Subject: Machine Design II

Time:02:30 pm to 05:00 pm Total Marks: 70

Instructions:

1. Attempt all questions.

2. Make suitable assumptions wherever necessary.

3. Figures to the right indicate full marks.

Q.1 (a) Answer the following: 06

1. State the advantages of steel wire ropes and explain the different types of

stresses induced in it.

2. Explain the belt conveyor with neat sketch.

(b) Design a drum and select a steel wire rope for an E.O.T. crane from the 08

following given data:

Lifting capacity = 55 kN Height of lift = 7 m

Weight lifting tackle = 1.2 kN Weight magnet = 20 kN

No of ropes = 4

Efficiency of pulley system = 93 % Factor of safety = 4

Q.2 (a) Explain the different methods used for increasing beam strength of a gear tooth. 04

(b) Design an eight speeds sliding gearbox for a drill press from the following data: 10

Minimum speed = 70 RPM Motor speed = 1440 RPM

Maximum speed = 1800 RPM Speed of input shaft = 900 RPM

Draw only the structural diagram and speed chart.

OR

(b) Explain the design procedure used for multi stage gear box design. 10

Q.3 (a) Explain the factors affecting the selection of gear materials in detail. 04

(b) Design the pair of 900 straight bevel gear is used to transmit 4 kW from the 10

motor running at 1440 r.p.m. from the given data:

No of teeth on pinion = 18 Pressure angle = 200 full depth

Service factor = 1.1 Speed reduction = 3 : 1

Stress concentration factor = 1.1 Ep = 2 x 105 N/mm2

Eg = 1.1 x 105 N/mm2 Factor of safety = 1.25

The value of deformation factor C is 115 N/mm. The other details are as below:

Material [σb ] MPa Hardness BHN

Pinion- steel 120 310 150

Gear – Castiron 80 290

OR

Q.3 (a) State the disadvantages of spur gears. List and explain the advantages of helical 04

gears. List the few applications of helical gears.

(b) A pair of spur gear is used in a speed reducer, driven by an electric motor. 10

Pinion transmits 5 kW at 500 r.p.m. The speed reduction is 3:1. Design the gear

pair assuming service factor of 1.5 for medium shock condition and continuous

operation. Lewis’s form factor Y = ∏ [0.154 - 0.912/Z] and σen = 600 MPa.

Total permissible error in tooth is 0.025 mm. Assume initially pitch line velocity

as 5 m/sec for module calculation and face width b = 10m. Take no of teeth on

pinion = 20. Use 200 FD involute tooth profile. The other details are as below:

Material [σb ] MPa Hardness BHN

Pinion- 40C8 200 225 150

Gear – FG300 100 180

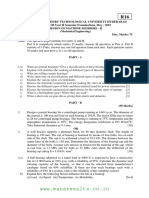

Q.4 (a) Explain the thermal consideration in Worm & Worm gear design in detail. 04

(b) Design a pair of helical gears having a transmission ratio of 3.33:1. The teeth are 10

20º full depth involute and the helix angle is 250. The pinion has 21 teeth and

transmits 10 kW at 1000 r.p.m. The face width is 10m . Service factor is 1.5 and

factor of safety is 2. Assume initially pitch line velocity as 5 m/sec for module

calculation. The value of deformation factor C in Buckingham’s equation is 114

N/mm. The other details are as below:

Material [σb ] MPa Hardness BHN

Pinion- 55C8 240 360 150

Gear – 40C8 194 350

OR

Q.4 (a) Explain different types of gear tooth failures in detail. 04

(b) The following data refers to a worm & worm gear pair: 10

Worm – triple threaded Worm speed =1200 rpm

Power = 15 kW Teeth on worm gear = 36

Tooth profile - 20º full depth involute Coefficient of friction = 0.03

Axial pitch of worm = 30 mm Pitch diameter of worm = 60 mm

Calculate:

1.Helix angle of worm 2.Speed ratio 3.Centre distance 4.Efficiency of the drive

5. Apparent stress in worm gear teeth.

Q.5 (a) Explain the design of flywheel with a neat sketch. 04

(b) The cylinder of a four stroke diesel engine has the following specifications: 10

Brake power = 7.5 kW Speed = 1400 rpm

Maximum gas pressure = 3.5 MPa Mechanical efficiency = 80 %

Indicated mean effective pressure = 0.35 MPa;

The cylinder liner and head are made of grey cast iron (Sut = 260 MPa and μ =

0.25). The factor of safety for all parts is 6.

Calculate:

1. Bore and length of the cylinder liner

2. Thickness of the cylinder liner (Take, C= 3.2 mm)

3. Thickness of the cylinder head

OR

Q.5 (a) Explain the wet and dry cylinder liners used in an I.C engine with neat sketch. 04

(b) Design a cast iron piston for single acting four stroke engine for following 10

specification :

Cylinder Bore = 110 mm, Stroke = 130 mm,

Maximum gas pressure = 5 N/mm2 Brake mean effective pressure = 0.5 N/mm2

Fuel consumption = 0.2 kg/kw/hr Speed = 2000 rev/min.

HCV= 41870 KJ/kg Constant K for C.I. = 46.6 W/m/0C

For C.I piston, permissible tensile stress = 40 N/mm2

Permissible tensile stress or piston ring = 100 N/mm2

permissible tensile stress for pin = 150 N/mm2

*************

You might also like

- 181605-181902-MD - IiDocument3 pages181605-181902-MD - IiRushabh PatelNo ratings yet

- Gujarat Technological UniversityDocument3 pagesGujarat Technological Universityrajushamla9927No ratings yet

- MDDocument2 pagesMDAbhijeet PramanikNo ratings yet

- Machine Design IIDocument3 pagesMachine Design IIRushabh PatelNo ratings yet

- Machine Design IIDocument3 pagesMachine Design IIRushabh PatelNo ratings yet

- MD II Machine Design AssignmentsDocument5 pagesMD II Machine Design Assignmentsrishabhk28995No ratings yet

- 15A03602 Design of Machine Members - IIDocument2 pages15A03602 Design of Machine Members - IIJagannath CherkuNo ratings yet

- Machine Design Exam Questions on Gears, Bearings and Other Mechanical ComponentsDocument3 pagesMachine Design Exam Questions on Gears, Bearings and Other Mechanical ComponentsNILESH SUTHARNo ratings yet

- Design of Spur Gear Tutorial No: - DateDocument18 pagesDesign of Spur Gear Tutorial No: - DateAkhilesh NavikNo ratings yet

- 2020-11-10SupplementaryME402ME402-E - Ktu QbankDocument2 pages2020-11-10SupplementaryME402ME402-E - Ktu QbankbilalfocusNo ratings yet

- 181505-181902-MD - IiDocument2 pages181505-181902-MD - IiSiddharth PanchalNo ratings yet

- Be Winter 2022Document2 pagesBe Winter 2022shivamparmartechNo ratings yet

- Machine Design II Question PaperDocument8 pagesMachine Design II Question PaperProf. Avinash MahaleNo ratings yet

- 15A03602 Design of Machine Members - IIDocument2 pages15A03602 Design of Machine Members - IIJagannath CherkuNo ratings yet

- WWW Manaresults Co inDocument4 pagesWWW Manaresults Co inGod deva123No ratings yet

- Machine Design Model PaperDocument2 pagesMachine Design Model Paperlalamramesh78No ratings yet

- rr321401 Principles of Machine DesignDocument8 pagesrr321401 Principles of Machine DesignSRINIVASA RAO GANTANo ratings yet

- rr312404 Design of Machine ElementsDocument8 pagesrr312404 Design of Machine ElementsSRINIVASA RAO GANTANo ratings yet

- r05320305 Design of Machine Members IIDocument9 pagesr05320305 Design of Machine Members IISRINIVASA RAO GANTANo ratings yet

- WWW - Manaresults.Co - In: (Common To Ame, Me)Document3 pagesWWW - Manaresults.Co - In: (Common To Ame, Me)Vikranth DeepakNo ratings yet

- nr321401 Principles of Machine DesignDocument2 pagesnr321401 Principles of Machine DesignSRINIVASA RAO GANTANo ratings yet

- Machine Design - LDocument2 pagesMachine Design - LNilesh Mistry (Nilesh Sharma)No ratings yet

- r05312401 Design of Machine ElementsDocument8 pagesr05312401 Design of Machine ElementsSrinivasa Rao GNo ratings yet

- Supp Nov 2009Document10 pagesSupp Nov 2009prk74No ratings yet

- Makalah GTWDocument8 pagesMakalah GTWfaisalNo ratings yet

- Machine Elements Exam QuestionsDocument3 pagesMachine Elements Exam QuestionsKalpesh JadhavNo ratings yet

- 2018sme 7 Sem Design of Mechanical Drives Summer 2018Document2 pages2018sme 7 Sem Design of Mechanical Drives Summer 2018Komal HingeNo ratings yet

- WWW - Manaresults.co - In: (Mechanical Engineering)Document2 pagesWWW - Manaresults.co - In: (Mechanical Engineering)Mohammed SohailNo ratings yet

- r05320305 Design of Machine Members IIDocument11 pagesr05320305 Design of Machine Members IISrinivasa Rao G100% (4)

- R5310305-Design of Machine Members - IDocument4 pagesR5310305-Design of Machine Members - IsivabharathamurthyNo ratings yet

- Me 7 Sem Subject Design of Mechanical Drives Jun 2017Document2 pagesMe 7 Sem Subject Design of Mechanical Drives Jun 2017djniksthehearteditorNo ratings yet

- 21751-6838-Principles of Machine DesignDocument8 pages21751-6838-Principles of Machine DesignMacasaet Al-awnNo ratings yet

- WWW - Manaresults.Co - In: (Common To ME, AME)Document3 pagesWWW - Manaresults.Co - In: (Common To ME, AME)Your ChoiceNo ratings yet

- rr320305 Design of Machine Members IIDocument8 pagesrr320305 Design of Machine Members IISrinivasa Rao GNo ratings yet

- Design of Machine Elements-II Exam QuestionsDocument9 pagesDesign of Machine Elements-II Exam QuestionsPrasinNo ratings yet

- WWW Manaresults Co inDocument3 pagesWWW Manaresults Co inGod deva123No ratings yet

- 15A03602 Design of Machine Members - IIDocument2 pages15A03602 Design of Machine Members - IIJagannath CherkuNo ratings yet

- 4363 111 Machine Design IDocument6 pages4363 111 Machine Design Iyogesh_b_k100% (2)

- Machine Design-II Question BankDocument32 pagesMachine Design-II Question BankAbhishek SakatNo ratings yet

- Design of Machine Members-II Feb 2022Document3 pagesDesign of Machine Members-II Feb 2022Anand KedhariNo ratings yet

- Be Winter 2021Document2 pagesBe Winter 2021Nikesh rampariyaNo ratings yet

- B.Tech Degree S8 (S, FE) / S6 (PT) (S, FE) Examination June 2023 (2015 Scheme)Document3 pagesB.Tech Degree S8 (S, FE) / S6 (PT) (S, FE) Examination June 2023 (2015 Scheme)Venkitaraj K PNo ratings yet

- 14 ACAD-R-45 - Unit Test QPDocument9 pages14 ACAD-R-45 - Unit Test QPsomnath swamiNo ratings yet

- rr320305 Design of Machine Members IIDocument8 pagesrr320305 Design of Machine Members IISRINIVASA RAO GANTANo ratings yet

- 05-04 Machine Design & Cad-II (Me)Document2 pages05-04 Machine Design & Cad-II (Me)Abdul AhadNo ratings yet

- Mechatronics exam with questions on control systems and PLC applicationsDocument62 pagesMechatronics exam with questions on control systems and PLC applicationshaptooorNo ratings yet

- 5051 Apr 20Document3 pages5051 Apr 20Rithik Raj RanjuNo ratings yet

- Dts Model Que Type B 2018-19Document2 pagesDts Model Que Type B 2018-19rammit2007No ratings yet

- GTU BE-SEMESTER-VII Machine Design Exam QuestionsDocument2 pagesGTU BE-SEMESTER-VII Machine Design Exam QuestionsNILESH SUTHARNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityTNo ratings yet

- Dme - II Mid - I QP Set-1,2 (16bt50301)Document2 pagesDme - II Mid - I QP Set-1,2 (16bt50301)Gangaraju MoopuriNo ratings yet

- Design of Machine ElementsDocument4 pagesDesign of Machine ElementsChandani KannakeNo ratings yet

- DMM Ii (2015)Document35 pagesDMM Ii (2015)gorijalaNo ratings yet

- Design of Transmission SystemsDocument3 pagesDesign of Transmission SystemsSaravanan KumarNo ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- High Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsFrom EverandHigh Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsNo ratings yet

- Machine Design Elements and AssembliesFrom EverandMachine Design Elements and AssembliesRating: 3.5 out of 5 stars3.5/5 (2)

- Friction Stir Welding of High Strength 7XXX Aluminum AlloysFrom EverandFriction Stir Welding of High Strength 7XXX Aluminum AlloysNo ratings yet

- Advanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkFrom EverandAdvanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkNo ratings yet

- ) ZT Dcfguz5Fl, SF: Smjl0V!) V/Tu"T LCZF Ahfzg (RF,) ZFBJF V/U (GL Dfu"Nlx"Sf Q LgidmDocument5 pages) ZT Dcfguz5Fl, SF: Smjl0V!) V/Tu"T LCZF Ahfzg (RF,) ZFBJF V/U (GL Dfu"Nlx"Sf Q LgidmRushabh PatelNo ratings yet

- Recommendations to Improve COVID-19 ManagementDocument5 pagesRecommendations to Improve COVID-19 ManagementRushabh PatelNo ratings yet

- Guidelines of Textile MarketDocument4 pagesGuidelines of Textile MarketRushabh PatelNo ratings yet

- Shoulder Stretching and Strengthening: IMG Physical TherapyDocument8 pagesShoulder Stretching and Strengthening: IMG Physical TherapyRushabh PatelNo ratings yet

- Ebaco Indoor Rubber Flooring Technical Specs & BenefitsDocument3 pagesEbaco Indoor Rubber Flooring Technical Specs & BenefitsRushabh PatelNo ratings yet

- Recommendations to Improve COVID-19 ManagementDocument5 pagesRecommendations to Improve COVID-19 ManagementRushabh PatelNo ratings yet

- Guidelines of Textile MarketDocument4 pagesGuidelines of Textile MarketRushabh PatelNo ratings yet

- Guidelines of Textile MarketDocument4 pagesGuidelines of Textile MarketRushabh PatelNo ratings yet

- GTU Revised Academic Calendar for 2016-17 Even TermDocument2 pagesGTU Revised Academic Calendar for 2016-17 Even TermRushabh PatelNo ratings yet

- Ebaco Indoor Rubber Flooring Technical Specs & BenefitsDocument3 pagesEbaco Indoor Rubber Flooring Technical Specs & BenefitsRushabh PatelNo ratings yet

- Gluten-Free Diets and Exercise Performance: A Nutritionist 'S ViewDocument2 pagesGluten-Free Diets and Exercise Performance: A Nutritionist 'S ViewRushabh PatelNo ratings yet

- Recommendations to Improve COVID-19 ManagementDocument5 pagesRecommendations to Improve COVID-19 ManagementRushabh PatelNo ratings yet

- Shoulder Stretching and Strengthening: IMG Physical TherapyDocument8 pagesShoulder Stretching and Strengthening: IMG Physical TherapyRushabh PatelNo ratings yet

- Recommendations to Improve COVID-19 ManagementDocument5 pagesRecommendations to Improve COVID-19 ManagementRushabh PatelNo ratings yet

- Guidelines of Textile MarketDocument4 pagesGuidelines of Textile MarketRushabh PatelNo ratings yet

- Current Concepts in Sport NutritionDocument56 pagesCurrent Concepts in Sport NutritionJulioNo ratings yet

- Gluten-Free Diets and Exercise Performance: A Nutritionist 'S ViewDocument2 pagesGluten-Free Diets and Exercise Performance: A Nutritionist 'S ViewRushabh PatelNo ratings yet

- Mauro Di Pasquale - Anabolic - SynergismDocument5 pagesMauro Di Pasquale - Anabolic - SynergismBobNo ratings yet

- Experiment - 5: AIM: Study and Calculate The Efficiency of Fin in Natural and Forced ConvectionDocument17 pagesExperiment - 5: AIM: Study and Calculate The Efficiency of Fin in Natural and Forced ConvectionRushabh PatelNo ratings yet

- Btech First Year Syllabus FinalDocument39 pagesBtech First Year Syllabus FinalvenkithebossNo ratings yet

- High Intensity Circuit Training Using Body WeightDocument6 pagesHigh Intensity Circuit Training Using Body Weightenrico.talpoNo ratings yet

- Experiment - 2: Heat Loss by Natural Convection From Ice PlateDocument7 pagesExperiment - 2: Heat Loss by Natural Convection From Ice PlateRushabh PatelNo ratings yet

- Post-Graduate Research Centre For Industrial Design: B.E. Semester IV: Design Engineering - 1BDocument12 pagesPost-Graduate Research Centre For Industrial Design: B.E. Semester IV: Design Engineering - 1BRushabh PatelNo ratings yet

- New Doc 170119 - 1 - Full Time Project AssociateDocument1 pageNew Doc 170119 - 1 - Full Time Project AssociateRushabh PatelNo ratings yet

- Application Form Advt DT 29-03-2018 Teaching StaffDocument5 pagesApplication Form Advt DT 29-03-2018 Teaching Staffbhushan tavdeNo ratings yet

- Ebaco Indoor Rubber Flooring Technical Specs & BenefitsDocument3 pagesEbaco Indoor Rubber Flooring Technical Specs & BenefitsRushabh PatelNo ratings yet

- MSM Manual 02072016 035354AMDocument177 pagesMSM Manual 02072016 035354AMPraveen SinghNo ratings yet

- Composite WallDocument6 pagesComposite WallRushabh PatelNo ratings yet

- Experiment - 4: AIM: To Measure The Emissivity of Test PlateDocument8 pagesExperiment - 4: AIM: To Measure The Emissivity of Test PlateRushabh PatelNo ratings yet

- Heat Transfer: Lab ManualDocument3 pagesHeat Transfer: Lab ManualRushabh PatelNo ratings yet

- Serial Number AutoCAD 2014Document5 pagesSerial Number AutoCAD 2014Punith Ky67% (9)

- PSAB Product ManualDocument4 pagesPSAB Product ManualArnold StevenNo ratings yet

- Module 4Document24 pagesModule 4MARIE ANN DIAMANo ratings yet

- GD-1884 Manual PDFDocument10 pagesGD-1884 Manual PDFAnonymous srwHCpANo ratings yet

- Research Methods in PsychologyDocument2 pagesResearch Methods in PsychologyHillaryNo ratings yet

- CSC4212 Lecture 3 - 3D Viewing - Projection TransformationDocument31 pagesCSC4212 Lecture 3 - 3D Viewing - Projection TransformationAhmad AbbaNo ratings yet

- ES Q2 Mod8Document26 pagesES Q2 Mod8maacovsNo ratings yet

- Fluid Mechanics Chapter on Mechanical Energy and EfficiencyDocument43 pagesFluid Mechanics Chapter on Mechanical Energy and EfficiencyShazrel IzlanNo ratings yet

- RENAULT Quality PlanningDocument20 pagesRENAULT Quality PlanningEhsan ArbabtaftiNo ratings yet

- Hkts 210 Sub/Hkts 200 Sub: SubwooferDocument6 pagesHkts 210 Sub/Hkts 200 Sub: SubwooferDan PopNo ratings yet

- Faculty of Engineering Mechanical Engineering Program: Vibration Engineering Lab: KM31401: LAB IVDocument7 pagesFaculty of Engineering Mechanical Engineering Program: Vibration Engineering Lab: KM31401: LAB IVhasmikaNo ratings yet

- Player PrefsDocument1 pagePlayer PrefsHafiz AbdulwahabNo ratings yet

- Mechanical Properties ExplainedDocument38 pagesMechanical Properties ExplainedJamaica VelascoNo ratings yet

- Chapter 2 - Exercises - Econometrics2Document2 pagesChapter 2 - Exercises - Econometrics2Mai AnhNo ratings yet

- Essay #1 - Second DraftDocument6 pagesEssay #1 - Second DraftHayden NganNo ratings yet

- Airy stress function enables determination of stress components in pure beam bendingDocument19 pagesAiry stress function enables determination of stress components in pure beam bendingmaran.suguNo ratings yet

- Pending Exception RDocument17 pagesPending Exception Rsyafri maryonoNo ratings yet

- DPWH Design Assessment ChecklistDocument18 pagesDPWH Design Assessment ChecklistGeovanni DumpasanNo ratings yet

- Word Processing and Desktop Publishing SoftwareDocument24 pagesWord Processing and Desktop Publishing SoftwareMubarak KashiNo ratings yet

- Faculty of Engineering and Computing Sciences: Annexure-IDocument2 pagesFaculty of Engineering and Computing Sciences: Annexure-IAkshay MehtaNo ratings yet

- Maths EnglishDocument26 pagesMaths EnglishmeenasarathaNo ratings yet

- A Short Guide To Arrows in ChemistryDocument1 pageA Short Guide To Arrows in ChemistryJefferson RibeiroNo ratings yet

- ASME Fatigue Life CurvesDocument3 pagesASME Fatigue Life CurvesnamasralNo ratings yet

- XML JavascriptDocument62 pagesXML Javascriptanon-506495No ratings yet

- Problem 13.3Document2 pagesProblem 13.3kannyNo ratings yet

- Timetable Saturday 31 Dec 2022Document1 pageTimetable Saturday 31 Dec 2022Khan AadiNo ratings yet

- Recent Updates For The Heat Transfer Solver in Ls Dyna R With Focus On Computational Welding MechanicsDocument14 pagesRecent Updates For The Heat Transfer Solver in Ls Dyna R With Focus On Computational Welding MechanicsamitkmrjNo ratings yet

- ELEN3017A Project Brief 2022 Rev2Document3 pagesELEN3017A Project Brief 2022 Rev2Dick MabhidaNo ratings yet

- RWM61 Data SheetDocument3 pagesRWM61 Data SheetBarth XaosNo ratings yet

- Materials and Techniques Used For The "Vienna Moamin": Multianalytical Investigation of A Book About Hunting With Falcons From The Thirteenth CenturyDocument17 pagesMaterials and Techniques Used For The "Vienna Moamin": Multianalytical Investigation of A Book About Hunting With Falcons From The Thirteenth CenturyAirish FNo ratings yet