Professional Documents

Culture Documents

Carbon Nanotubes For Nanorobotics: Lixin Dong, Arunkumar Subramanian, and Bradley J. Nelson

Uploaded by

NavamaniSpOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Carbon Nanotubes For Nanorobotics: Lixin Dong, Arunkumar Subramanian, and Bradley J. Nelson

Uploaded by

NavamaniSpCopyright:

Available Formats

Carbon nanotubes for

nanorobotics

The well-defined geometry, exceptional mechanical properties, and

extraordinary electrical characteristics of carbon nanotubes qualify them

for structuring nanoelectronic circuits, nanoelectromechanical systems,

and nanorobotic systems. Relative displacements between the atomically

smooth, nested shells in multiwalled carbon nanotubes can be used as

robust nanoscale motion enabling mechanisms for applications such as

bearings, switches, gigahertz oscillators, shuttles, memories, syringes,

and actuators. The hollow structures of carbon nanotubes can serve

as containers, conduits, pipettes, and coaxial cables for storing mass

and charge, or for transport. Not only can nanotubes serve as building

blocks for more complex structures, tools, sensors, and actuators,

but they can also be used as fundamental components for future

nanorobots. We review the technological progress on carbon nanotubes

related to nanorobotics.

Lixin Dong, Arunkumar Subramanian, and Bradley J. Nelson*

Institute of Robotics and Intelligent Systems, ETH Zurich, CH-8092 Zurich, Switzerland

*E-mail: bnelson@ethz.ch

Nanorobotics is the emerging field of robotics at the nanometer construction of structures, tools, sensors, actuators, and systems

scale. It includes robots that are nanoscale in size, i.e. nanorobots smaller than 100 nm that will extend our ability to explore

(that have yet to be realized), and large robots capable of the nanoworld from perception, cognition, and manipulation

manipulating objects that have nanoscale dimensions with perspectives.

nanometer resolution, i.e. nanorobotic manipulators. Although Shrinking device size to nanoscale dimensions presents many

visionaries have foreseen a nanorobotic future of molecular fascinating opportunities, such as manipulating nano-objects with

manufacturing1–3 and nanomedicine4,5, the form nanorobots will nanotools, measuring mass in femtogram ranges, sensing forces at

take and what tasks they will actually perform remain unclear. piconewton scales, and inducing gigahertz motion, among other

However, it is clear that nanotechnology is progressing toward the possibilities waiting to be discovered. While we still understand little

12 DECEMBER 2007 | VOLUME 2 | NUMBER 6 ISSN:1748 0132 © Elsevier Ltd 2007

NT0206p12_21.indd 12 06/11/2007 14:30:00

Carbon nanotubes for nanorobotics REVIEW

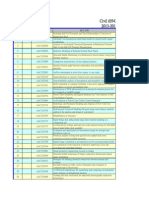

Table 1 Properties of CNTs.

Property Item Data Potential applications in nanorobotics

Layers Single/multiple

Aspect ratio 10–1000

Geometrical Diameter ~0.4 nm to >3 nm (SWNTs)

~1.4 nm to >100 nm (MWNTs)

Structures, probes, grippers/tweezers, scissors

Length Several micrometers (rope up to centimeters)

Young’s modulus ~1 TPa (steel: 0.2 TPa)

Tensile strength 45 GPa (steel: 2 GPa)

Mechanical

Density ~1.33–1.4 g/cm3 (Al: 2.7 g/cm3)

Interlayer friction Ultrasmall Actuators, bearings, syringes, switches, memories

Conductivity Metallic/semiconducting Diodes, transistors, switches, logic gates

Electronic Current carrying capacity ~1 TA/cm3 (Cu: 1 GA/cm3) Wires/cables

Field emission Activate phosphorus at ~1–3 V Proximity/position sensors

Electromechanical Piezoresistivity Positive/negative Deformation/displacement sensors

Thermal Heat transmission >3 kW/mK (Diamond: 2 kW/mK) Circuits, sensors, thermal actuators

about how to implement ‘advanced features’, such as intelligence, systems (NEMS), and nanorobotic systems. For nanorobotics, some

replication, and atom-by-atom mechanochemical synthesis at the of the most important characteristics of nanotubes include their

nanometer scale, early developments that have founded the field of nanometer diameter7,9, large aspect ratio (10–1000), terapascal-

nanorobotics include the invention of new tools such as scanning scale Young’s modulus10–17, excellent elasticity18,19, ultrasmall

tunneling microscopes (STMs)6 and the synthesis of atomically well- interlayer friction20–22, excellent field-emission properties23,24, various

defined new nanomaterials such as carbon nanotubes (CNTs)7. electric conductivities25–27, high thermal conductivity28–30, high

current carrying capability with essentially no heating, sensitivity of

CNT-based building blocks for nanorobotic conductance to various physical or chemical changes31–33, and charge-

systems induced bond-length change34. CNTs can serve in nanorobotic systems

The well-defined geometry, exceptional mechanical properties, and as structural elements, tools, sensors, and actuators. As shown in Fig. 1,

extraordinary electric characteristics, among other outstanding starting from as-grown CNTs, nanotubes can be assembled into more

physical properties of CNTs7 (see Table 1) qualify them for potential complex structures using bottom-up approaches or engineered to

applications8 in nanoelectronic circuits, nanoelectromechanical achieve secondary building blocks using top-down approaches.

(b) (c) (d)

(e) (a) (f)

(g) (h) (i)

Fig. 1 CNT-based building blocks. Starting from (a) as-grown CNTs, nanostructures can be created by the bottom-up approaches of (b–d) assembling, (e) filling, or

(f) decorating them, or in a top-down fashion by (g–i) engineering their shells/caps.

DECEMBER 2007 | VOLUME 2 | NUMBER 6 13

NT0206p12_21.indd 13 06/11/2007 14:30:16

REVIEW Carbon nanotubes for nanorobotics

As-grown CNTs can serve directly as functional elements of shell structure of MWNTs controllably to form intershell-motion-

nanodevices. The first example of such a device – a nanotube probe based devices in parallel is a significant challenge for their eventual

for an atomic force microscope (AFM) – was demonstrated by Dai et manufacturability and commercialization.

al.35 for improving the spatial resolution of an AFM and protecting With their hollow cores and large aspect ratios61,62, CNTs are

the tip from ‘tip crash’. In the device, a multiwalled CNT (MWNT) possible conduits for nanoscale amounts of various materials. A variety

was manually assembled onto a commercially available Si cantilever. of materials have been encapsulated by CNTs, such as metals and their

Further developments improved the construction technique through compounds63–65, water61, and fullerenes66. Applications of devices

direct chemical vapor deposition (CVD)36, controlled assembly16, and as templates67, thermometers68, and nano test tubes69 have been

picking up a tube from vertically aligned single-walled CNTs (SWNTs) presented. The possibility of delivering encapsulated materials from

grown from planar substrate surfaces37. Nanotube tweezers have been carbon shells70 is of great interest because of potential applications as

constructed with two nanotubes on a glass fiber and driven by the atomic sources for nanoprototyping, nanoassembly, and injection.

electrostatic interaction between them38.

By assembling as-grown CNTs, more complex structures can Nanoassembly of CNTs

be built. Nanotube intermolecular and intramolecular junctions Random spreading, direct growth71, fluidic self-assembly47, transfer

are basic elements for such structures. For nanoelectronics, pure printing72,73, and dielectrophoretic (DEP) assembly74 have been

nanotube circuits39–41 created by interconnecting nanotubes of used for positioning as-grown nanotubes or other nanostructures

different diameters and chirality may lead to the next generation of on electrodes for the construction of electronic devices, or NEMS

electronics42–46. Suspended junctions can function as electromechanical generally, in some type of regular array.

nonvolatile memory47. We have achieved controlled deposition of different nanoscale

Interlayer motion between individual carbon shells, which are forms of carbon on Si chips using DEP-driven, bottom-up assembly

cylindrically nested and suspended by van der Waals forces within techniques. This type of assembly is compatible with conventional

a MWNT, provide exceptional performance as linear and rotary top-down Si micro- and nanomachining techniques, and hence offers

nanobearings48 with an inherent position feedback capability20–22, and a powerful tool for batch manufacturing of next-generation NEMS.

potentially as gigahertz resonators/oscillators/shuttles49–51, tubular Specifically, we have demonstrated the suitability of this technique for

switches52–54, memories55,56, syringes, linear nano-servomotors with assembling MWNTs, double-walled CNTs (DWNTs), Cu-filled CNTs75,

integrated position sensing57, and rotational elements for use in and CNT coils (Fig. 2).

NEMS58,59. Apart from their favorable nanomechanical performance, The process used to build the nanostructure array is as follows.

the variation of CNT resistance with telescoping core motion60 First, the bottom nanoelectrode layer (15 nm Cr/45 nm Au) is defined

provides a unique electrical mechanism to sense and control their on a Si substrate, which is covered with a 500 nm insulating oxide.

operation. While prototype devices have proven some of the concepts The nanoelectrode layer is formed by defining patterns in a bilayer

previously, the capability to alter the as-synthesized closed-cap resist (poly(methyl methacrylate)/poly(methyl 2-acetamidoacrylate),

(a) (b) (c)

(d) (e) (f)

Fig. 2 Hybrid nanofabrication approach for realizing integrated nanosystems. (a) Nanoarray design. (b) MWNT nanosystem. Insets: schematic and lower

magnification scanning electron micrograph (SEM). (c) Direct assembly of sophisticated nanostructures. (d–f) Diverse nanomaterials such as DWNTs, Cu-filled

CNTs, and nanocoils.

14 DECEMBER 2007 | VOLUME 2 | NUMBER 6

NT0206p12_21.indd 14 06/11/2007 14:30:18

Carbon nanotubes for nanorobotics REVIEW

or PMMA/PMAA) using electron-beam lithography, followed by metal CNT junctions connected by EBID yield stronger junctions than

deposition and lift-off. The electrodes are 300 nm wide and are those connected through van der Waals forces, as shown in Figs. 3a

separated by 350 nm gaps. Next, carbon-based nanomaterials are and 3b. The development of conventional EBID has been limited by

deposited onto the electrodes by coupled ac-dc DEP76,77. For this step, the expensive electron filament used and low productivity. We have

the nanomaterials are suspended and sonicated in ethanol to insure demonstrated a parallel EBID system using CNTs as electron emitters.

homogeneity. The chip is then immersed in a reservoir containing the To construct stronger junctions without adding extra material,

suspension and a composite ac-dc electric field is applied with a high mechanochemical nanorobotic assembly is an important strategy.

frequency function generator. After about 100 s, the chip is removed This approach is based on solid-phase chemical reactions, or

from the reservoir and rinsed in clean ethanol. Finally, it is blown dry mechanosynthesis, which is defined as chemical synthesis controlled

with a nitrogen gun. by mechanical systems operating with atomic-scale precision. The

This assembly process realizes structures that aid in investigating technique enables direct positional selection of reaction sites3. By

and characterizing the electrical and mechanical properties of these picking up atoms with dangling bonds rather than stable atoms, it

novel nanomaterials. More importantly, the capability of assembling is easier to form primary bonds, which provides a simple but strong

disparate nanomaterials using the same technique would enable their connection. Destructive fabrication provides a way to form dangling

integration into complex nanostructures in realizing integrated NEMS bonds at the ends of broken tubes. Some of the dangling bonds may

and other nanosystems. then bond with neighboring atoms, but generally a few bonds will

Nanomanipulation is a promising approach for complex remain reactive. A nanotube with dangling bonds at its end will bind

nanoassembly78. Key techniques enable the control of the position more easily to another to form intramolecular junctions. Fig. 3c shows

and orientation of the building blocks with nanometer resolution such a junction78.

combined with their connection. Nanorobotic assembly allows for EBID involves high-energy electron beams and needs external

the construction of more complex structures into prototype NEMS. precursors for obtaining conductive deposits, which limits its

Nanotube intermolecular and intramolecular junctions are basic applications. Mechanochemical bonding is promising, but not yet

elements for such assemblies. Although some types of junctions have mature. Recently, we have developed a nanorobotic spot welding

been synthesized with chemical methods, there is no evidence yet that technique80 using Cu-filled CNTs for welding nanotubes. The solder is

a self-assembly-based approach can provide more complex structures. encapsulated inside the hollow cores of CNTs during their synthesis,

In Fig. 3, we show some examples of the nanorobotic assembly so no external precursors are needed. A bias of just a few volts can

of CNT junctions by emphasizing the connection methods. CNT induce the migration of the Cu, making it a cost-effective approach.

junctions have been created using van der Waals forces (Fig. 3a), Fig. 3d shows a junction welded using this technique. The quality of the

electron-beam-induced deposition (EBID)79 (Fig. 3b), bonding through weld is partly determined by the ability to control the mass flow rate

mechanochemistry (Fig. 3c), and spot welding via Cu encapsulated from the tube. An ultrahigh precision deposition of 120 ag/s, has been

inside CNTs (Fig. 3d). realized in our experiment based on electromigration.

Nanorobotic manipulation in three dimensions has opened a

new route for nanoassembly. However, nanomanipulation is still

(a) (b) performed in a serial manner with master-slave control, which is

certainly not a large-scale production technique. Nevertheless, with

advances in the exploration of mesoscopic physics, better control of

the material synthesis, more accurate actuators, and effective tools for

manipulation, high-speed, parallel, and automatic nanoassembly will be

possible.

Shell engineering of CNTs

(c) (d)

Open-ended CNTs have been created by removing the usually

capped ends of MWNTs with acid etching64, saturated current81,

electronic pulse48, or mechanical strain16,82, thus providing access

to the inner core of the nanotube cylinders. Acid etching is effective

for opening nanotube caps but does not expose the inner layers in

a controlled way. Controlled fabrication with saturated current is

Fig. 3 CNT junctions. (a) CNTs connected by van der Waals interactions.

(b) CNTs joined by EBID. (c) CNTs bonded by a mechanochemical reaction. potentially a large-scale manufacturing method, whereas electric pulse

(d) CNTs welded using Cu. and mechanical strain are convenient in situ processes. Mechanical

DECEMBER 2007 | VOLUME 2 | NUMBER 6 15

NT0206p12_21.indd 15 06/11/2007 14:30:20

REVIEW Carbon nanotubes for nanorobotics

pulling82 can be used to fabricate telescoping CNTs using nanorobotic if the nanotube is not fixed at the end but at the center of the

manipulation techniques78. Typical examples of bridged, cantilevered, cantilever, stress will occur only on a partial section. Fig. 4c shows a

and center-supported (with one open end) telescoping MWNTs are center-supported, telescoping MWNT being formed in this way. One

shown in Fig. 4. end remains capped, but can be opened if the process shown in Fig. 4b

Fig. 4a shows a bridged, telescoping MWNT with its left end fixed is repeated.

on a substrate and its right end fixed to an AFM cantilever. The thin The primary requirement for simultaneously engineering an array

neck of the bridged MWNT is formed by mechanical pulling, i.e. by of CNTs with control over length, location, and number of shells,

moving the cantilever to the right to break the outer layer(s) of the while applying a common electrical bias, is that the MWNT-based

MWNT and expose the inner ones, as shown in the inset. Fig. 4b nanostructures are created with nearly identical electrical circuit

shows a telescoping MWNT formed by a similar process but the resistance and heat-transport conditions. This causes uniform Joule

cantilever is moved until the core is left completely exposed. Similarly, heating across the array and etches all the nanotubes in parallel

to fabricate bearings. In addition, the nanostructure lends itself to

(a) shell-selective alteration of the MWNT geometry. A schematic of

such a nanostructure and the typical array design are shown in Figs.

5a and 5b. The nanostructure consists of a MWNT bridging two

nanoelectrodes at its distal ends while remaining fully suspended and

flat in the region between them. The CNT is sandwiched between

(b) (c) two layers of metal at each end to improve electrical contact. With

this architecture, the metallic contacts serve as heat sinks, and shell

removal as a result of thermal stress occurs in the suspended segment

(Fig. 5a). Also, the nature of contact with lithographically patterned

electrodes ensures that etching proceeds from the outermost shells

inwards.

Robust bearing operation with low friction requires that at least

5–10 outer shells are etched in each CNT in the array59. We find that

Fig. 4 (a) Bridged, (b) cantilevered, and (c) center-supported telescoping the threshold bias for removing these shells in an array is spread over a

MWNTs. 300–600 mV range (from VTH-low to VTH-high), which we refer to as the

(a) (b) (c) (d)

(e) (f) (g) (h)

Fig. 5 Electrically controlled shell engineering of MWNT arrays. (a) Schematic of the MWNT nanostructure. Insets: SEMs of the nanostructure at high and low

magnification. (b) Nanoelectrode array design. Inset: lower magnification image showing the entire array. (c) Illustration of an MWNT assembled by floating

electrode DEP. The electrode wiring scheme for parallel shell structuring is also shown. Inset: SEM of the fabricated array at a 40° tilt. Scale bar is 50 μm. (d) SEM

of a nanobearing shown at a 40° tilt. Inset: the degrees of freedom of the CNT shell structure. (e) MWNT assembled onto five metallic contacts and thinned in the

regions between the contacts. The electrode wiring scheme for current-driven engineering is also shown. Inset: array design. (f) Schematic of high-density MWNT

rotary motors and independent bearings that can be created by further nanomachining of this structure. (g) Telescoping segments formed with a 220 nm pitch and

separated by ~6–10 nm gaps. The arrows point to the intersegment gaps. Image taken at a 40° tilt. (h) Schematic of the core-shell mechanisms formed in (e) with

the intersegment gaps exaggerated to reveal the shell structure.

16 DECEMBER 2007 | VOLUME 2 | NUMBER 6

NT0206p12_21.indd 16 06/11/2007 14:30:21

Carbon nanotubes for nanorobotics REVIEW

‘array breakdown spectrum’. Two factors contribute to this spread in We are also able to realize piecewise and parallel modification of

threshold bias. Within a CNT, each shell has a characteristic breakdown shell structures at different segments along the length of an MWNT.

bias that increases from the outer to inner shells83. In addition, the This is a powerful tool for realizing bearings with more complex

breakdown bias varies from one nanotube to the other over a small architectures and for forming multiple devices on a single CNT, leading

range as a result of possible differences in contact conditions and CNT to ultrahigh-density NEMS. We achieve this with suitable electrode

properties such as diameter or chirality. designs for DEP assembly and current-driven shell etching steps.

Since applying a voltage that is much higher than the array A nanotube bridging three electrodes is shown in Fig. 5c, and a SEM

breakdown spectrum causes the destruction of all CNT shells in a single of the array is shown in the inset. By applying a common potential to

step, precise determination of the lowest voltage where breakdown the electrodes at distal ends and grounding the central metal contact

is initiated at one or more CNTs, VTH-low, is important. Some efforts (Fig. 5d), we can simultaneously drive currents through both suspended

have reported that shell breakdown in single CNTs occurs at the segments of the CNT and remove its outer walls. A nanotube

current saturation limit associated with backscattering by optical engineered using this technique has an architecture that is different

phonons. Hence, the threshold voltage has been determined by from those illustrated in Fig. 5a. One such CNT and its shell structure,

measuring the current-voltage, I-V, profile of the MWNT84. However, with possible degrees of freedom, is shown in Fig. 5d. We can realize

we have observed such saturation in only two cases in more than higher bearing densities by assembling CNTs onto a larger number of

25 experiments involving individual CNTs, CNT arrays, and parallel spatially separated electrodes with appropriate designs. Fig. 5e

transport through multiple segments of single CNTs. This absence shows independent CNT bearings with a 220 nm pitch created at

of saturation has also been reported previously85,86, where it was different locations along the length of a single MWNT bridging five

attributed to a shift in the saturation bias beyond the breakdown electrodes. Fig. 5f illustrates how the alternate metal contacts are held

threshold in CNTs with large diameters and short lengths. In arrays, it at the same potential to drive currents simultaneously through every

also cannot be ruled out that the onset of saturation in some CNTs is suspended segment and etch outer shells in parallel. The nanostructure

masked by others in the I-V plots. array is shown in the inset. If we break all shells in one step, instead of

In the absence of saturation, the only way to determine VTH-low partial thinning, we can create five telescoping segments with a

precisely involves starting with a very low bias (~1.5 V) and 220 nm pitch, separated by ~6–15 nm gaps (Fig. 5g). Each of these

progressively increasing the bias in successive cycles with small CNT segments is anchored to the metal by only its outer shells. Hence,

increments until breakdown is initiated. After the initiation of we now have bidirectional linear bearings with inner shells capable of

breakdown, the electric stress is repeatedly applied within the sliding inside the outer housing. A schematic of the nanostructure, with

breakdown spectrum to structure all the CNTs. With more than 20 the intersegment gaps exaggerated to reveal the shell architecture, is

biasing cycles typically required for structuring arrays, the duration shown in Fig. 5h.

and voltage profile used for each of these biasing cycles impacts on This is an interesting structure with a number of potential

process metrics such as yield and cycle time. We find that applying applications. With extremely small lengths (about 210 nm) for the

the breakdown voltages for short times, of the order of tens of three segments in the middle, these should exhibit lower friction forces

milliseconds, accelerates the shell structuring process without and faster response times during telescoping core movements than

compromising its controllability. This compares favorably with the previously reported53. With the core free to slide in either direction,

continuous application of the breakdown bias over longer cycle the segments can be used as oscillators where neighboring nanotube

durations85–87, where we find that the time intervals between shell segments electrically excite oscillations. We estimate the oscillation

removal are on the order of hundreds of seconds. frequency of the three telescoping segments in Fig. 5g to be 1.28 GHz

The voltage profile used within the short duration biasing cycles has by supposing an initial 5 nm extrusion using the model derived by

a direct influence on the process yield. A profile that sweeps voltages Zheng et al.50,88.

from 0 to Vmax provides higher yields than approaches that start with Because shell removal is driven by Joule heating, large structural

a high bias, such as constant bias pulses or sweeps from –Vmax to Vmax. defects such as kinks or holes86 can affect the location of shell removal.

This is demonstrated using results from two CNT arrays, labeled ‘A1’ However, current transport through MWNTs at length scales of the

and ‘A2’74. In array A1, electric stress is applied by sweeping voltages order of 100 nm is diffusive85,86, and shell removal is centered on the

from –Vmax to +Vmax in 10 mV increments and 100 μs time steps. The midpoint of suspended nanotubes when defects are only minor

biasing procedure for array A2 is identical to that of A1 except that (Fig. 5a).

voltage sweeps from 0 to Vmax are used. In array A1, 12 CNTs formed We find that we can controllably alter this midlength electric

structures suitable for controlled shell engineering. Of these nanotubes, breakdown in MWNTs and restrict it to occur predominantly over one

we were able to form eight bearings (67%). In array A2, eight of the half of the CNT by introducing additional, spatially separated metallic

nine nanotubes formed partly thinned bearings (89%). layers in contact with the current-carrying nanotube89. Fig. 6a

DECEMBER 2007 | VOLUME 2 | NUMBER 6 17

NT0206p12_21.indd 17 06/11/2007 14:30:24

REVIEW Carbon nanotubes for nanorobotics

illustrates a nanotube in contact with two additional metallic regions these images, substantial shell removal occurs in the region between

that are situated between the biasing electrodes. The additional the red arrowheads. It can be seen that the region of thinning is

metallic regions are held at a floating potential and serve as heat sinks confined to only the nanotube half that is in contact with the single-

to remove the Joule heat generated in CNTs. One of the heat sinks is layer heat sink. Finite-element simulations of the temperature

comprised of two layers of metal, which sandwich the nanotube, and distribution created in a current-carrying MWNT have confirmed this89.

has a contact area that is greater than at least half of the nanotube’s Electric breakdown can also cause the shrinkage of individual shells

surface area. The other heat sink has only one layer of metal at higher temperatures90,91, generating sharpened tips. Stretching

underneath the CNT and, because of the cylindrical CNT surface, makes CNTs under Joule heating and electron-beam radiation has revealed

only a line contact with the CNT on top of it. an even more interesting phenomenon. Huang et al. have observed

Since the thermal contact resistance and removal of Joule heat superplasticity in individual single-92, double-, and triple-walled CNTs93.

generated in the CNTs through these metallic contacts is dependant At temperatures above 2000ºC, tensile elongation of SWNTs and

on the contact area, we find that heat dissipation is higher at the MWNTs can reach up to 280% and 190% with diameter reductions

two-layer heat sink than the single-layer heat sink. This results in a of 15 times and 90%, respectively. Ding et al.94,95 describe these

nonuniform temperature profile along the CNT length, with higher observations of plastic relaxation in terms of dislocation theory and

temperatures in the CNT half that is in contact with the single-layer atomistic computer simulations. This phenomenon provides a self-

heat sink. A direct consequence of such a temperature distribution repairing mechanism to maintain tube perfection, which is particularly

is that the Joule-heating-induced electric breakdown occurs interesting for shell engineering.

predominantly in this half of the CNT. SEM images of nanotubes where

such location-controlled thinning occurs are shown in Figs. 6b–f. In Mass delivery from CNTs

Recently, novel CNTs filled with single-crystalline Cu nanoneedles have

been synthesized by a thermal CVD method using alkali-modified Cu

catalysts96. Because Cu is a good conductor of heat and electricity

and has a very low binding energy (0.1–0.144 eV/atom) when bound

to carbon, encapsulated Cu inside nanotubes is ideal for many

potential applications. We have investigated the controlled melting

and flow of single-crystalline Cu from CNTs assisted by nanorobotic

manipulation80.

(a) (b) Fig. 7a is a series of time-resolved transmission electron

micrographs (TEMs) taken from video frames showing the flow process.

The Cu core starts to flow inside the carbon shell from the bottom to

the tip of the first bamboo section as the bias voltage reaches 2.5 V.

The entire process continues for about 70 s. The flow rate is 11.6 nm/s

according to the apparent change of length of the Cu core (Fig. 7b).

Accordingly, we have calculated the mass change as shown in Fig. 7c,

(c) (d) and the mass flow rate is determined by fitting the data to the curve.

This yields ~120 ag/s, which is strikingly slow and controllable, and

allows precise delivery of mass at the attogram scale since time-based

(e) control can readily reach sub-second precision.

Fig. 7d shows time-resolved current versus voltage characteristics

under a constant positive bias of 2.5 V. The current density under 2.5 V

bias when flow occurs is calculated according to the cross-sectional

(f) (g) area as 2.60 × 106–3.07 × 106 A/cm2. This is comparable to the

Fig. 6 Shell engineering. (a) Illustration of an MWNT nanostructure with observed value for electromigration of Fe in CNTs (~7 × 106 A/cm2)70.

two additional heat sinks and its electrode wiring scheme. (b–d) SEMs of The difference may be a result of the lower binding energy of Cu

nanostructures, of the type shown in panel (c), after electric breakdown.

Thinning is predominantly confined to the CNT half on the side containing the (0.1–0.144 eV/atom) than that of Fe to carbon shells (0.3 eV/atom)97.

single-layer heat sink. Images taken at a stage tilt of 40°. Insets in (b),(c): top The high current densities employed here will lead to resistive

view of the nanostructures. Inset in (d): top view of the heat-sink region at heating. Temperatures as high as 2000–3000°C have been estimated

a higher magnification clearly showing the changes in CNT diameter. (e),(f)

SEMs of CNTs showing localized thinning. (g) Typical nanoelectrode array according to the change in lattice spacing in electric breakdown

design. experiments on nonfilled MWNTs86 at a slightly higher bias (3 V)

18 DECEMBER 2007 | VOLUME 2 | NUMBER 6

NT0206p12_21.indd 18 06/11/2007 14:30:25

Carbon nanotubes for nanorobotics REVIEW

(a)

(b) (c)

(d) (e)

Fig. 7 Attogram-precision mass delivery for nanorobotic spot welding. (a) Time-resolved TEMs from video frames showing the flow process. The Cu core starts to

flow inside the carbon shells from the root to the tip as the bias voltage reaches up to 2.5 V. The process continues for about 70 s. (b) The flow rate is 11.6 nm/s

according to the apparent change of length of the Cu core. The W probe is positively biased. (c) Plot of mass change versus time. The mass flow rate from the fitted

curve is ~0.12 fg/s. (d) Plot of time-resolved current against voltage characteristics under a constant bias of 2.5 V. The current density under 2.5 V bias as flow

occurs is ~2.60 × 106–3.07 × 106 A/cm2. (e) Correlation of the current density, J, and the mass flow rate, dm/dt.

than those used here. We have then correlated the current density, J, Compared with other mass-delivery processes previously

and the mass flow rate, dm/dt, as shown in Fig. 7e. The relation investigated, electrically driven delivery has several interesting aspects:

dm/dt =0.3J2 – 1.6J + 2.1 suggests that a real positive value of dm/dt 1. A very low current can induce melting and drive the flow, which is

(≥43 ag/s) can only be given when the current density J surpasses much more efficient than irradiation-based techniques involving

2.6 × 106 A/cm2. The existence of this threshold also implies the flow high-energy electron beams79,98–100, focused ion beams (FIBs)101,

mechanism is likely to be electromigration70. Under a negative bias, or lasers62. Combined with DEP assembly, it is possible to solder the

i.e. when the W probe serves as a cathode, we observe flow in the tubes onto electrodes for batch fabrication of NEMS.

opposite direction. 2. The melting occurs rapidly (at least at the millisecond level), which

Other possible mechanisms for flow can be excluded. Capillary force is several orders of magnitude faster than using a high-intensity

can induce filling/flowing, but the direction should be opposite to the electron beam or FIB (generally on the order of a minute79,98–101).

observed flow, i.e. from the tip to the bottom of the carbon shells. 3. Because both the rate and direction of mass transport depends

Thermal expansion can enable flow, but the flow should be isotropic on the external electrical drive, precise control of ultrasmall mass

heading toward both the tip and the bottom of the carbon shells. delivery is possible. Time-based control will allow the delivery of

A recent investigation has shown that the irradiation of MWNTs can attograms of mass102.

cause a large pressure buildup within the nanotube core, which can 4. Cu is compatible with conventional semiconductor processing. Our

plastically deform, extrude, and break encapsulated solid material98. In experiments show that it will also play an important role for scaled-

our experiments, however, no contraction of the carbon shells has been down systems. Carbon shells provide an effective barrier against

observed. oxidation and consequently ensure long-term stability of the Cu

DECEMBER 2007 | VOLUME 2 | NUMBER 6 19

NT0206p12_21.indd 19 06/11/2007 14:30:27

REVIEW Carbon nanotubes for nanorobotics

core, which also facilitates conservation of the material unlike retracted position because of the small intershell sliding resistance

conveying mass on the external surface of nanotubes102. force. The oscillation frequency can be in the gigahertz range50,88.

The system configuration for a telescoping nanotube with field-

NEMS emission position feedback is shown in Fig. 8e. An opened MWNT

The next step along the road to fabricating nanorobots is to fabricate is fixed onto an AFM cantilever (acting as the cathode) by EBID on

simpler NEMS. NEMS make it possible to manipulate nanosized objects the right-hand end of the structure. The tube is placed against a

with nanosized tools, measure mass in femtogram ranges, sense force substrate serving as an anode, where G is the interelectrode distance

at piconewton scales, and induce gigahertz motion. between the substrate and the AFM cantilever. The protruding length

As examples, configurations and mechanical models of linear of the nanotube, l, will change by Δl from its initial length, l0, as the

nanomotors based on bridged, cantilevered, and centrally supported electrostatic force between the core and the counter-electrode exceeds

telescoping MWNTs, and laterally actuated MWNTs are shown in the sum of the interlayer friction and van der Waals forces between the

Fig. 8. Electrostatic force, van der Waals interaction, and the total core and the cathode. Hence, the gap between the nanotube tip and

intershell sliding resistance force are denoted by Fe, FvdW, and Fr, the anode, g, will change whereas G remains constant. Field emission

respectively. is measured using the configuration shown in Fig. 8e. Fig. 8f shows a

The motion of the core section can be controlled by the typical I-V curve of a telescoping nanotube (see the inset micrograph

electrostatic force. Atomic-scale mechanisms, such as interatomic of Fig. 8f) when G = 1000 nm. Each point represents an average of 100

locking, provide resistance to sliding of the core in the outer tube, samples within a 9 s interval. The inset shows the change of emission

but experiments indicate that the intershell-sliding resistance force current with time at a constant bias of 120 V. An obvious feature of

between two neighboring shells of perfect, or nearly perfect, molecular this I-V curve that differs from conventional ones is the ‘kink’ observed

structure is substantially smaller than the van der Waals restoring between 115 V and 135 V. Based on the parallel shell engineering, it is

force. The retraction of an extruded core of a MWNT into the outer possible to batch fabricate such devices.

shells has been observed experimentally20. The restoring force resulting

from excess van der Waals interaction energies from core extrusion, it Summary

has been realized, drives the core to oscillate with respect to its fully We have reviewed technological progress on CNTs related to

nanorobotics. The assembly of large arrays of carbon nanomaterials,

such as MWNTs, DWNTs, Cu-filled CNTs, and CNT coils, onto

nanoelectrodes using DEP of individual nanotubes has been

described. Nanorobotic assembly has been shown to be effective for

interconnecting CNTs. Mechanical strain and electric breakdown have

been demonstrated in shell engineering of CNTs. Site-selective shell

(a) (b)

engineering has been realized using electric breakdown with heat-

dissipation modulation using nanomachined heat sinks. Controlled mass

delivery of Cu inside nanotube shells has been realized by applying a

low bias voltage. The mass flow rate has been determined to be

120 ag/s. Nanoscale linear servomotors with integrated position

(c) (d) sensing and other NEMS have been investigated. Whereas these

structures and devices can individually serve as building blocks for

structures, tools, sensors, and actuators, many of them may also be

fundamental components for building nanorobots in the future.

As an emerging field, nanorobotics faces many challenges because

of the extreme scaling effects that must be considered. Problems we

now see, such as how to build more complex systems with smaller

building blocks, calibrate ultrasensitive sensors, and control actuators

(e) (e) with dynamics far faster than the rate of control feedback, are just

Fig. 8 Interlayer-motion-based nanodevices. (a) Bridged MWNT prismatic the beginning. While the future remains unclear, we can be certain

nanomotor. (b) Cantilevered MWNT prismatic nanomotor. (c) Centrally that nanorobotics is steadily progressing toward the construction

supported MWNT linear nanomotor. (d) Laterally actuated linear nanomotor. of structures, tools, sensors, actuators, and systems that will extend

(e) Prismatic nanomotor with integrated field-emission position sensing.

(f) Typical I-V curve of a telescoping nanotube where the interelectrode gap G our ability to explore the nanoworld from perception, cognition, and

is 1000 nm. Inset: change of emission current with time at 120 V. manipulation perspectives.

20 DECEMBER 2007 | VOLUME 2 | NUMBER 6

NT0206p12_21.indd 20 06/11/2007 14:30:30

Carbon nanotubes for nanorobotics REVIEW

REFERENCES

1. Feynman, R. P., Caltech. Eng. Sci. (1960) 23, 22 53. Deshpande, V. V., et al., Nano Lett. (2006) 6, 1092

2. Crichton, M., Prey, Avon Books, New York, (2002) 54. Yan, Q. M., et al., Appl. Phys. Lett. (2006) 88, 173107

3. Drexler, K., Nanosystems: Molecular Machinery, Manufacturing and 55. Maslov, L., Nanotechnology (2006) 17, 2475

Computation, Wiley, New York, (1992) 56. Kang, J. W., et al., Nanotechnology (2007) 18, 095705

4. Freitas, Jr., R. A., Nanomedicine, Vol. I: Basic Capabilities, Landes Bioscience, 57. Dong, L. X., et al., IEEE Trans. Autom. Sci. Eng. (2006) 3, 228

Austin, (1999)

58. Fennimore, A. M., et al., Nature (2003) 424, 408

5. Asimov, I., Fantastic Voyage, Bantam, New York, (1966)

59. Bourlon, B., et al., Nano Lett. (2004) 4, 709

6. Binnig, G., et al., Phys. Rev. Lett. (1982) 49, 57

60. Cumings, J., et al., Phys. Rev. Lett. (2004) 93, 086801

7. Iijima, S., Nature (1991) 354, 56

61. Supple, S., et al., Phys. Rev. Lett. (2003) 90, 214501

8. Baughman, R. H., et al., Science (2002) 297, 787

62. Kral, P., et al., Phys. Rev. Lett. (1999) 82, 5373

9. Wang, N., et al., Nature (2000) 408, 50

63. Ajayan, P. M., et al., Nature (1993) 361, 333

10. Yu, M. F., et al., Phys. Rev. Lett. (2000) 84, 5552

64. Tsang, S. C., et al., Nature (1994) 372, 159

11. Treacy, M. M. J., et al., Nature (1996) 381, 678

65. Ajayan, P. M., et al., Phys. Rev. Lett. (1994) 72, 1722

12. Yakobson, B. I., et al., Am. Scientist (1997) 85, 324

66. Smith, B. W., et al., Nature (1998) 396, 323

13. Wong, E. W., et al., Science (1997) 277, 1971

67. Ajayan, P. M., et al., Nature (1995) 375, 564

14. Krishnan, A., et al., Phys. Rev. B (1998) 58, 14013

68. Gao, Y. H., et al., Nature (2002) 415, 599

15. Poncharal, P., et al., Science (1999) 283, 1513

69. Ugarte, D., et al., Science (1996) 274, 1897

16. Yu, M. F., et al., Science (2000) 287, 637

70. Svensson, K., et al., Phys. Rev. Lett. (2004) 93, 145901

17. Salvetat, J. P., et al., Phys. Rev. Lett. (1999) 82, 944

71. Zhang, Y. G., et al., Appl. Phys. Lett. (2001) 79, 3155

18. Yakobson, B. I., et al., Phys. Rev. Lett. (1996) 76, 2511

72. Ahn, J. H., et al., Science (2006) 314, 1754

19. Walters, D. A., et al., Appl. Phys. Lett. (1999) 74, 3803

73. Liu, X. L., et al., Nano Lett. (2006) 6, 34

20. Cumings, J., et al., Science (2000) 289, 602

74. Subramanian, A., et al., Nanotechnology (2007) 18, 075703

21. Kolmogorov, A. N., et al., Phys. Rev. Lett. (2000) 85, 4727

75. Tao, X. Y., et al., Nanotechnology (2006) 17, 224

22. Kis, A., et al., Phys. Rev. Lett. (2006) 97, 025501

76. Chung, J. Y., et al., Langmuir (2004) 20, 3011

23. Rinzler, A. G., et al., Science (1995) 269, 1550

77. Subramanian, A., et al., Micro and Nanorobotic Assembly Using

24. De Heer, W. A., et al., Science (1995) 270, 1179 Dielectrophoresis. In: Robotics: Science and Systems I, edited by Thrun, S., et al.,

25. Saito, R., et al., Phys. Rev. B (1992) 46, 1804 (eds.), MIT Press, Cambridge, (2005), 327

26. Ebbesen, T. W., et al., Nature (1996) 382, 54 78. Fukuda, T., et al., Proc. IEEE (2003) 91, 1803

27. Dai, H. J., et al., Science (1996) 272, 523 79. Dong, L. X., et al., Appl. Phys. Lett. (2002) 81, 1919

28. Liang, W. J., et al., Nature (2001) 411, 665 80. Dong, L. X., et al., Nano Lett. (2007) 7, 58

29. Frank, S., et al., Science (1998) 280, 1744 81. Collins, P. C., et al., Science (2001) 292, 706

30. Kim, P., et al., Phys. Rev. Lett. (2001) 87, 215502 82. Dong, L. X., et al., IEEE/ASME Trans. Mechatron. (2004) 9, 350

31. Tombler, T. W., et al., Nature (2000) 405, 769 83. Bourlon, B., et al., Phys. Rev. Lett. (2004) 92, 026804

32. Kong, J., et al., Science (2000) 287, 622 84. Collins, P. G., et al., Phys. Rev. Lett. (2001) 86, 3128

33. Zhou, C. W., et al., Science (2000) 290, 1552 85. Lee, Y. H., et al., Appl. Phys. Lett. (2006) 89, 073109

34. Li, C. Y., et al., Nanotechnology (2006) 17, 4624 86. Huang, J. Y., et al., Phys. Rev. Lett. (2005) 94, 236802

35. Dai, H. J., et al., Nature (1996) 384, 147 87. Molhave, K., et al., Nano Lett. (2006) 6, 1663

36. Hafner, J. H., et al., Nature (1999) 398, 761 88. Zheng, Q. S., et al., Phys. Rev. B (2002) 65, 245409

37. Hafner, J. H., et al., J. Phys. Chem. B (2001) 105, 743 89. Subramanian, A., et al., Appl. Phys. A (2007) 89, 133

38. Kim, P., et al., Science (1999) 286, 2148 90. Dong, L. X., et al., Engineering Multi-Walled Carbon Nanotube Shells by Electric

Breakdown. In: Proceedings of European Nano Systems 2006 (ENS2006), Paris,

39. Saito, R., et al., Phys. Rev. B (1996) 53, 2044

France, (2006), 25

40. Chico, L., et al., Phys. Rev. Lett. (1996) 76, 971

91. Yuzvinsky, T. D., et al., Nano Lett. (2006) 6, 2718

41. Menon, M., et al., Phys. Rev. Lett. (1997) 79, 4453

92. Huang, J. Y., et al., Nature (2006) 439, 281

42. Tans, S. J., et al., Nature (1998) 393, 49

93. Huang, J. Y., et al., Phys. Rev. Lett. (2007) 98, 185501

43. Bachtold, A., et al., Science (2001) 294, 1317

94. Ding, F., et al., Nano Lett. (2007) 7, 681

44. Yao, Z., et al., Nature (1999) 402, 273

95. Ding, F., et al., Phys. Rev. Lett. (2007) 98, 075503

45. Postma, H. W. C., et al., Science (2001) 293, 76

96. Tao, X. Y., et al., Diamond Relat. Mater. (2006) 15, 1271

46. Fuhrer, M. S., et al., Science (2000) 288, 494

97. Weissmann, M., et al., Phys. Rev. B (2006) 73, 125435

47. Rueckes, T., et al., Science (2000) 289, 94

98. Sun, L., et al., Science (2006) 312, 1199

48. Cumings, J., et al., Nature (2000) 406, 586

99. Xu, S. Y., et al., Small (2005) 1, 1221

49. Zheng, Q. S., et al., Phys. Rev. B (2002) 65, 245409

100. Yokota, T., et al., Phys. Rev. Lett. (2003) 91, 265504

50. Zheng, Q. S., et al., Phys. Rev. Lett. (2002) 88, 045503

101. Matsui, S., et al., J. Vac. Sci. Technol. B (2000) 18, 3181

51. Jensen, K., et al., Phys. Rev. Lett. (2006) 96, 215503

102. Regan, B. C., et al., Nature (2004) 428, 924

52. Forro, L., Science (2000) 289, 560

DECEMBER 2007 | VOLUME 2 | NUMBER 6 21

NT0206p12_21.indd 21 06/11/2007 14:30:31

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- ASME P-Numbers 1Document2 pagesASME P-Numbers 1SH1961No ratings yet

- Sandvik Metal Cutting Technology Training HandbookDocument364 pagesSandvik Metal Cutting Technology Training HandbookITL200_U95% (21)

- R2B-P3-206-02-P-HD-00205 - DATASHEETS FOR CONTROL VALVE, SLIDE, U-21000 - Rev.1Document21 pagesR2B-P3-206-02-P-HD-00205 - DATASHEETS FOR CONTROL VALVE, SLIDE, U-21000 - Rev.1Diana Paula Echartea MolinaNo ratings yet

- Brief Analysis of Waste Paper Pulp ProcessingDocument12 pagesBrief Analysis of Waste Paper Pulp ProcessingtisaNo ratings yet

- Cost Analysis in Injection Moulded Plastic Parts DesigningDocument9 pagesCost Analysis in Injection Moulded Plastic Parts DesigningNavamaniSpNo ratings yet

- Maunuscript Ventilator Jiayuu Clean RevisedDocument15 pagesMaunuscript Ventilator Jiayuu Clean RevisedNavamaniSpNo ratings yet

- Din 3961 PDFDocument12 pagesDin 3961 PDFNavamaniSpNo ratings yet

- Mellor. AC & DC Motors & Geared Motors. The Motor Gear People. T - +44 (0) 1254 53854 WWW - Mellorelectrics.co - Uk PDFDocument20 pagesMellor. AC & DC Motors & Geared Motors. The Motor Gear People. T - +44 (0) 1254 53854 WWW - Mellorelectrics.co - Uk PDFNavamaniSpNo ratings yet

- Mellor. AC & DC Motors & Geared Motors. The Motor Gear People. T - +44 (0) 1254 53854 WWW - Mellorelectrics.co - Uk PDFDocument20 pagesMellor. AC & DC Motors & Geared Motors. The Motor Gear People. T - +44 (0) 1254 53854 WWW - Mellorelectrics.co - Uk PDFNavamaniSpNo ratings yet

- Slewing Bearing Catalogue - 06115 2 en TCM 12-182061Document14 pagesSlewing Bearing Catalogue - 06115 2 en TCM 12-182061NavamaniSpNo ratings yet

- Hussain SajidDocument175 pagesHussain SajidNavamaniSpNo ratings yet

- A NBM Based On P-N Relationship For DFIG Wind Turbine Fault DetectionDocument6 pagesA NBM Based On P-N Relationship For DFIG Wind Turbine Fault DetectionNavamaniSpNo ratings yet

- Influence of Aging On Microstructure and Toughness of Die-Casting Die SteelsDocument13 pagesInfluence of Aging On Microstructure and Toughness of Die-Casting Die SteelsNavamaniSpNo ratings yet

- 03main 06 06Document52 pages03main 06 06emregnesNo ratings yet

- Performance of RC Frame Structure With Various Beam To Column Flexural Capacity Ratio - A Case Study Sudip KaranjitDocument7 pagesPerformance of RC Frame Structure With Various Beam To Column Flexural Capacity Ratio - A Case Study Sudip KaranjitBinod ManandharNo ratings yet

- Detalle de Caja Da RegistroDocument2 pagesDetalle de Caja Da RegistroCarlos VasquezNo ratings yet

- COOL - 006 Advances in Liquid Coolant Technologies For Electronics Cooling 2005Document7 pagesCOOL - 006 Advances in Liquid Coolant Technologies For Electronics Cooling 2005Leslie Diaz JalaffNo ratings yet

- The Synthesis of Doped Manganese Cobalt Ferrites by Autocombustion TehniqueDocument4 pagesThe Synthesis of Doped Manganese Cobalt Ferrites by Autocombustion TehniqueAlin DrucNo ratings yet

- Elastomeric Fibres - Fibres With Elastic CapabilityDocument5 pagesElastomeric Fibres - Fibres With Elastic Capability9043785763No ratings yet

- CalorimetroDocument7 pagesCalorimetroYaraNo ratings yet

- Crank Shaft, Deflection and Bearing AdjustmentsDocument16 pagesCrank Shaft, Deflection and Bearing AdjustmentsAnandan GunasekaranNo ratings yet

- NALCOOL 2000 - Automobile Coolant Corrosion InhibitorDocument2 pagesNALCOOL 2000 - Automobile Coolant Corrosion InhibitorChemEqualNo ratings yet

- D D Khedkar Evaluation of Suitability of Ambanala Water, Amravati, For IrrigationDocument4 pagesD D Khedkar Evaluation of Suitability of Ambanala Water, Amravati, For IrrigationDr. Dinesh D KhedkarNo ratings yet

- IsoplatonDocument1 pageIsoplatonikahashimNo ratings yet

- Tips & Techniques NOVA-8 Rev00Document10 pagesTips & Techniques NOVA-8 Rev00AntWonxxxNo ratings yet

- Mechanical BookDocument93 pagesMechanical BookShiba Narayan SahuNo ratings yet

- Machinedesign 3389 Fundamentals of Annular Snap Fit JointsDocument6 pagesMachinedesign 3389 Fundamentals of Annular Snap Fit JointsGonzalo J. Amaolo L.No ratings yet

- Product Information Flyer: CIMTECH® 285Document2 pagesProduct Information Flyer: CIMTECH® 285sobheysaidNo ratings yet

- Asce 41Document102 pagesAsce 41Ahmed AlyNo ratings yet

- 3 PDF TestsDocument3 pages3 PDF Testssaif aliNo ratings yet

- Engineering-Civil (0543)Document48 pagesEngineering-Civil (0543)myusuf_engineerNo ratings yet

- Eurocode 2 Faqs: 2 Min CdevDocument5 pagesEurocode 2 Faqs: 2 Min CdevkrishnakumarNo ratings yet

- Assignment - Tension MembersDocument3 pagesAssignment - Tension MembersUlasi IfeanyiNo ratings yet

- DSC OverviewDocument6 pagesDSC Overviewprabhat singhNo ratings yet

- Rock Blasting For MiningDocument24 pagesRock Blasting For MiningSantha Raman R RNo ratings yet

- The Oolitization Rate Determination of Bentonite Moulding MixturesDocument4 pagesThe Oolitization Rate Determination of Bentonite Moulding Mixturesvivek1312No ratings yet

- Boiler Efficiency R K JainDocument28 pagesBoiler Efficiency R K JainPriyesh KumarNo ratings yet

- SartoriusDocument12 pagesSartoriusSarto RosNo ratings yet

- PracDocument31 pagesPracapi-3737745100% (1)