Professional Documents

Culture Documents

36NiCrMo16 PDF

Uploaded by

Amy Griffin0 ratings0% found this document useful (0 votes)

220 views2 pagesThis document provides information on the material properties and specifications of 36NiCrMo16 steel. It includes the chemical composition limits, heat treatment processes and temperatures, mechanical properties at different sizes and conditions, hardness values after tempering, and experience with a forged round sample. The steel is specified in European, Italian, German, French, and other standards for use in applications that require high strength and toughness.

Original Description:

Original Title

36NiCrMo16.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides information on the material properties and specifications of 36NiCrMo16 steel. It includes the chemical composition limits, heat treatment processes and temperatures, mechanical properties at different sizes and conditions, hardness values after tempering, and experience with a forged round sample. The steel is specified in European, Italian, German, French, and other standards for use in applications that require high strength and toughness.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

220 views2 pages36NiCrMo16 PDF

Uploaded by

Amy GriffinThis document provides information on the material properties and specifications of 36NiCrMo16 steel. It includes the chemical composition limits, heat treatment processes and temperatures, mechanical properties at different sizes and conditions, hardness values after tempering, and experience with a forged round sample. The steel is specified in European, Italian, German, French, and other standards for use in applications that require high strength and toughness.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

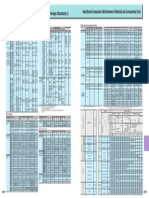

Quality 36NiCrMo16

According to standards EN 10083-3: 2006 Lucefin Group

Number 1.6773

Chemical composition

C% Si% Mn% P% S% Cr% Mo% Ni%

max max max

0,32-0,39 0,40 0,50-0,80 0,025 0,025 1,60-2,00 0,25-0,45 3,60-4,10 Permissible deviations

± 0.02 + 0.03 ± 0.04 + 0.005 + 0.005 ± 0.05 ± 0.04 ± 0.07 on the product

Temperature °C

Hot forming Normalizing Quenching Quenching Tempering Stress relieving

1100-900 850 880 830-860 550-650 50 under the temperature

air air oil, polymer, air of

water or s.b. (500) tempering

Soft Isothermal Full End quench Preheating Stress relieving

annealing annealing annealing hardenability test welding after welding

650 790 825 250 550 furnace cooling

air furnace cooling water AC1 AC3 MS Mf

(HB max 269) (HB max 275) 700 760 240 30

Mechanical and physical properties

Hot formed – hot rolled - rod mechan. properties for quenched and tempered condition EN 10083-3:2006

size d / t Testing at room temperature (longitudinal)

mm R Rp 0.2 A% C% Kv HB

over to N/mm2 N/mm2 min. min. min. J min. for information

16/8 1250-1450 1050 9 40 -- 370-415

16/8 40/20 1250-1450 1050 9 40 30 370-415

40/20 100/60 1100-1300 900 10 45 35 331-380

100/60 160/100 1000-1200 800 11 50 45 298-359

160/100 250/160 1000-1200 800 11 50 45 298-359

d = diameter t = thickness

Table of tempering values at room temperature for round Ø 10 mm after quenching at 850 °C in oil

HB 518 496 468 448 432 409 385 357 327 301

HRC 52.5 51 49 47.5 46 44 41.5 38.5 35 32

R N/mm2 1900 1820 1720 1610 1520 1420 1320 1200 1090 1000

Rp 0.2 N/mm2 1550 1500 1430 1360 1290 1200 1100 990 900 870

A % 7.0 8.0 8.6 9.2 9.6 10.0 11.0 12.4 14.0 14.0

C % 23 24 25 27 27 28 32 38 48 50

Kv J 28 28 27 26 26 26 28 38 64 64

Tempering at °C 200 250 300 350 400 450 500 550 600 650

36NiCrMo16 Lucefin Group

Hot rolled quenched and tempered after Cold drawn +QT +C

size Testing at room temperature (longitudinal)

mm R Rp 0.2 A% HB

over to N/mm2 N/mm2 min min

No indications are shown in the reference standards

Cold drawn quenched and tempered Cold drawn Cold drawn annealing

size Testing at room temperature (longitudinal) size obtained from otherwise annealing +

mm R Rp 0.2 A% HB mm hot rolled Peeled Reeled,

over to N/mm2 N/mm2 min min annealing HB max

No indications are shown in the reference standards

Forged quenched and tempered UNI EN 10250-3: 2001

size d / t Testing at room temperature

mm R Rp 0.2 A% L A% T A% Q Kv L Kv T Kv Q HB

over to N/mm2 min N/mm2 min min min min J min J min J min min

250/160 1000 800 11 8 -- 45 22 -- 298

250/160 500/330 1000 800 11 8 -- 45 22 -- 298

500/330 990/660 1000 800 11 8 -- 45 22 -- 298

L = longitudinal T = tangential Q = radial

d = diameter t = thickness

EN 10083-3: 2006 Jominy test HRC grain size 5 min.

distance in mm from quenched end

1.5 3 5 7 9 11 13 15 20 25 30 35 40 45 50 -- H

min 50 49 48 48 48 48 47 47 47 47 47 47 47 47 47 -- normal

max 57 56 56 56 56 56 55 55 55 55 55 55 55 55 55 --

Temperature Mod. of elasticity N/mm2 Rp 0.2 N/mm2 Thermal expansion

Testing at °C E long. G tang. Ǿ < 250 mm Ǿ 250-500 [(m/m●K) ●10-6 °C-1 ]

20 208000 79800 -- -- --

100 -- -- -- -- 11.5

200 -- -- -- -- 12.3

300 -- -- -- -- 12.8

400 -- -- -- -- 13.3

500 -- -- -- -- 13.7

600 -- -- -- -- 14.0

Specific heat capacity Density Thermal conductivity Specific electric resist. Conductivity

J/(Kg●K) Kg/dm3 W/(m●K) Ohm●mm2/m Siemens●m/mm2

460 7.84 33 0.30 3.33

Lucefin experience

Forged round 300 mm quenching 870 °C water, tempering 590 °C air

Depth from Longitudinal Testing

Heat Treatment R Rp 0.2 A% C% Kv +20°C Kv -20°C HB

surface N/mm 2 N/mm 2 J J

½ radius 1201 1110 12,8 55,0 90-98-90 62-58-60 371

Chemical composition %

C Si Mn P S Cr Mo Ni

0.34 0.25 0.50 0.012 0.005 1.68 0.40 3.70

EUROPE EN ITALY UNI CHINA GERMANY DIN FRANCE AFNOR U.K. B.S. RUSSIA USA AISI/SAE

36NiCrMo16 34NiCrMo16 -- 36NiCrMo16 35NCD16 835M30 -- --

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- 30 CR Ni Mo 8Document2 pages30 CR Ni Mo 8Amy GriffinNo ratings yet

- Handbook of Heating, Ventilating and Air ConditioningFrom EverandHandbook of Heating, Ventilating and Air ConditioningRating: 4 out of 5 stars4/5 (6)

- 40NiCrMo7 PDFDocument2 pages40NiCrMo7 PDFAmy GriffinNo ratings yet

- 34 CR Mo 4Document2 pages34 CR Mo 4Stefan GhNo ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- CR Mo 4Document2 pagesCR Mo 4Mohsen ParpinchiNo ratings yet

- Analytical Chemistry of Zirconium and Hafnium: International Series of Monographs in Analytical ChemistryFrom EverandAnalytical Chemistry of Zirconium and Hafnium: International Series of Monographs in Analytical ChemistryNo ratings yet

- 1 8550-34CrAlNi710Document2 pages1 8550-34CrAlNi710Michel PortalNo ratings yet

- 34 CR Ni Mo 6Document2 pages34 CR Ni Mo 6hp_vijaykNo ratings yet

- Newnes Circuit Calculations Pocket Book: with Computer ProgramsFrom EverandNewnes Circuit Calculations Pocket Book: with Computer ProgramsNo ratings yet

- 41Cr4 Chemical PDFDocument2 pages41Cr4 Chemical PDFGayathriRajasekaranNo ratings yet

- 34 CR Mo 4Document2 pages34 CR Mo 4ceca nikolicNo ratings yet

- Electric Arc Welding and Related Studies: Electric Arc Welding & Related StudiesFrom EverandElectric Arc Welding and Related Studies: Electric Arc Welding & Related StudiesNo ratings yet

- 42 CR Mo 4Document2 pages42 CR Mo 4ElMacheteDelHuesoNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Tempering Conditions For 30CrNiMo8Document2 pagesTempering Conditions For 30CrNiMo8madyeNo ratings yet

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNo ratings yet

- 16 Ni CR 11Document2 pages16 Ni CR 11ceca nikolicNo ratings yet

- Electronics – From Theory Into Practice: Applied Electricity and Electronics DivisionFrom EverandElectronics – From Theory Into Practice: Applied Electricity and Electronics DivisionRating: 5 out of 5 stars5/5 (1)

- 41 CR 4Document2 pages41 CR 4Jhon ChitNo ratings yet

- Welding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesFrom EverandWelding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesNo ratings yet

- Quality X20Cr13: Lucefin GroupDocument2 pagesQuality X20Cr13: Lucefin GroupRajeev ChandelNo ratings yet

- Quality 39nicrmo3: Lucefin GroupDocument2 pagesQuality 39nicrmo3: Lucefin Groupmarko9292No ratings yet

- C53 Technical CardDocument1 pageC53 Technical CardAnonymous umabEI6No ratings yet

- Quality 1.4021 Chemical Composition: Lucefin GroupDocument2 pagesQuality 1.4021 Chemical Composition: Lucefin GroupSonNguyenNo ratings yet

- Astm A350 LF2Document1 pageAstm A350 LF2anjangandak2932100% (1)

- 40NiCrMo3 PDFDocument1 page40NiCrMo3 PDFAmy GriffinNo ratings yet

- 39nicrmo3 en 10083-3: 2006: End Quench Hardenability Test TemperingDocument1 page39nicrmo3 en 10083-3: 2006: End Quench Hardenability Test Temperingvo thanh lamNo ratings yet

- 42CrMo4 Datos Tecnicos PDFDocument2 pages42CrMo4 Datos Tecnicos PDFjlplazaolaNo ratings yet

- 102 CR 6Document2 pages102 CR 6ceca nikolicNo ratings yet

- Astm A350 LF2 PDFDocument1 pageAstm A350 LF2 PDFAna Raquel SantosNo ratings yet

- Quality 102Cr6: Lucefin GroupDocument1 pageQuality 102Cr6: Lucefin GroupPaulo ZechinNo ratings yet

- 39NiCrMo3 PDFDocument2 pages39NiCrMo3 PDFAmy GriffinNo ratings yet

- SAE 1018 - Data Sheet PDFDocument1 pageSAE 1018 - Data Sheet PDFHari SuthanNo ratings yet

- 02 Asae 101892Document1 page02 Asae 101892raviteja036No ratings yet

- 1.4305 Sae303 DatasheetDocument2 pages1.4305 Sae303 Datasheetehudingram6535No ratings yet

- Quality 1.4362 Chemical Composition: Technical CardDocument2 pagesQuality 1.4362 Chemical Composition: Technical CardTeodor EzaruNo ratings yet

- 1.3505 100cr6 PDFDocument1 page1.3505 100cr6 PDFmcNo ratings yet

- XC 38 H 1Document1 pageXC 38 H 1smith willNo ratings yet

- Technical Card Ck45 Mechanical PropertiesDocument3 pagesTechnical Card Ck45 Mechanical PropertiesNuno Miguel TorcatoNo ratings yet

- 90 MN CR V8Document1 page90 MN CR V8arunajay724No ratings yet

- 1 8159-51CrV4Document2 pages1 8159-51CrV4black_absynthNo ratings yet

- Quality C10E: Lucefin GroupDocument3 pagesQuality C10E: Lucefin Grouptuananh638No ratings yet

- Quality C10E: Lucefin GroupDocument3 pagesQuality C10E: Lucefin Grouptuananh638No ratings yet

- Quality 42crmo4: Lucefin GroupDocument1 pageQuality 42crmo4: Lucefin GroupAnonymous Gbers2ENo ratings yet

- Quality 16Mncr5: Lucefin GroupDocument2 pagesQuality 16Mncr5: Lucefin GroupPrasadNo ratings yet

- 1816 Nicr 4Document2 pages1816 Nicr 4Rebekah WilsonNo ratings yet

- Quality 40nicrmov16 Ku: Lucefin GroupDocument1 pageQuality 40nicrmov16 Ku: Lucefin Groupkbwoniu123No ratings yet

- 1 2714Document1 page1 2714K Mohana PraneshNo ratings yet

- Astm A1Document1 pageAstm A1shahid khanNo ratings yet

- C55EDocument2 pagesC55EniranjanbmazireNo ratings yet

- Quality 1.2080 Chemical Composition: Lucefin GroupDocument1 pageQuality 1.2080 Chemical Composition: Lucefin GroupMSc Kostic MilosNo ratings yet

- S235JR Sau OL 37Document1 pageS235JR Sau OL 37Pișta GonzalesNo ratings yet

- AISI304Document2 pagesAISI304tony_abNo ratings yet

- Sae 1045Document1 pageSae 1045Martin UrrizaNo ratings yet

- 20 MN CR 5Document2 pages20 MN CR 5sansmgNo ratings yet

- Catalogo MITUTOYO INGLÊSDocument1 pageCatalogo MITUTOYO INGLÊSAmy GriffinNo ratings yet

- Perkins 1104cDocument140 pagesPerkins 1104cGilvan Junior82% (11)

- Material ComparisonDocument1 pageMaterial ComparisonNoir HamannNo ratings yet

- QuickFlex DMG Mori Seiki - enDocument24 pagesQuickFlex DMG Mori Seiki - enAmy GriffinNo ratings yet

- Cincom Evolution Line: Sliding Headstock Type Automatic CNC LatheDocument8 pagesCincom Evolution Line: Sliding Headstock Type Automatic CNC LatheAmy GriffinNo ratings yet

- Material ComparisonDocument1 pageMaterial ComparisonNoir HamannNo ratings yet

- Milk - Run Volkswagen PDFDocument34 pagesMilk - Run Volkswagen PDFAmy GriffinNo ratings yet

- Prog Eia-Iso MP 6200y PDFDocument356 pagesProg Eia-Iso MP 6200y PDFAmy GriffinNo ratings yet

- Perkins 1104cDocument140 pagesPerkins 1104cGilvan Junior82% (11)

- A6-A6M 02b Rolled Steel PDFDocument64 pagesA6-A6M 02b Rolled Steel PDFJoflNo ratings yet

- AÇOS VILLARES VF800-AT - InglesDocument2 pagesAÇOS VILLARES VF800-AT - InglesAmy Griffin100% (1)

- Rockwell Hardness of Metallic Materials: Standard Test Methods ForDocument38 pagesRockwell Hardness of Metallic Materials: Standard Test Methods ForochableNo ratings yet

- Mazak Programing Class BookDocument510 pagesMazak Programing Class BookBriciu Teofil Mihail100% (7)

- 39NiCrMo3 PDFDocument2 pages39NiCrMo3 PDFAmy GriffinNo ratings yet

- 34 CR Ni Mo 6Document2 pages34 CR Ni Mo 6hp_vijaykNo ratings yet

- Astm A350 LF2Document1 pageAstm A350 LF2anjangandak2932100% (1)

- 40NiCrMo3 PDFDocument1 page40NiCrMo3 PDFAmy GriffinNo ratings yet

- Astma105 PDFDocument1 pageAstma105 PDFAmy GriffinNo ratings yet

- AutoCAD 2013Document264 pagesAutoCAD 2013panosscribd100% (1)

- Manual Fresa Dora Ha AsDocument143 pagesManual Fresa Dora Ha AsAmy GriffinNo ratings yet

- Parker Fluid Power Seal Design Guide 5370Document300 pagesParker Fluid Power Seal Design Guide 5370edwardsheridan0% (1)

- 2800 Series: 2806C-E16TAG2Document2 pages2800 Series: 2806C-E16TAG2Tony LiNo ratings yet

- Advanced Technologies Resolved ESP Monitoring Problems PDFDocument2 pagesAdvanced Technologies Resolved ESP Monitoring Problems PDFAdri Coca SuaznabarNo ratings yet

- Owner's Manual & Safety InstructionsDocument8 pagesOwner's Manual & Safety InstructionsRenato GodoyNo ratings yet

- Physical Chemistry 2nd Edition Ball Solution ManualDocument17 pagesPhysical Chemistry 2nd Edition Ball Solution Manualrobyn96% (27)

- Flyer Symap-Bc, BCG, X, XG, yDocument11 pagesFlyer Symap-Bc, BCG, X, XG, yanon_123213442No ratings yet

- q22 001 Fat Procedure Mt1 SK 4910 B ADocument18 pagesq22 001 Fat Procedure Mt1 SK 4910 B APham Thai Tuyen100% (1)

- Ambuja Cement - Sustainable Development Report 2013Document59 pagesAmbuja Cement - Sustainable Development Report 2013dazzlerofallNo ratings yet

- Water Electrolysis For Hydrogen Production (Pasquale Cavaliere) (Z-Library)Document852 pagesWater Electrolysis For Hydrogen Production (Pasquale Cavaliere) (Z-Library)irisqu2No ratings yet

- Development of Web Based Power Quality Monitoring SystemDocument8 pagesDevelopment of Web Based Power Quality Monitoring SystemsudhakarcjNo ratings yet

- Unit 4 Pump: Suction, Delivery, Static and Accelerating HeadDocument11 pagesUnit 4 Pump: Suction, Delivery, Static and Accelerating HeadSurya PalNo ratings yet

- Reading Material ATEX ProcessDocument14 pagesReading Material ATEX ProcessABHISHEK DOLLENo ratings yet

- Physics Full Book TestDocument3 pagesPhysics Full Book TestLearnEnglish WithAriNo ratings yet

- 2102 - Vol - 2BDocument7 pages2102 - Vol - 2BSoumen KarNo ratings yet

- IOTDocument6 pagesIOTKaze KazeNo ratings yet

- CDM - English - Formato Traducci N PblicaDocument93 pagesCDM - English - Formato Traducci N PblicaGustavo PreciadoNo ratings yet

- Power-Xformer Upto 420 KV-CM List Updated On 22.02.2017Document11 pagesPower-Xformer Upto 420 KV-CM List Updated On 22.02.2017KeshavNo ratings yet

- 30-12-18 - Sr. ICON ALL - Jee-Main - GTM-7 - QP - Code-B PDFDocument28 pages30-12-18 - Sr. ICON ALL - Jee-Main - GTM-7 - QP - Code-B PDFM jhansiNo ratings yet

- OiLibya Lubricants Guide InteractiveDocument10 pagesOiLibya Lubricants Guide Interactivehoussem houssem100% (1)

- Re561416-En 1 10Document73 pagesRe561416-En 1 10Edciel EbuenNo ratings yet

- Numerical PicDocument7 pagesNumerical PicchintanpNo ratings yet

- Cell Emf Under Nonstandard Conditions Lecture 3Document3 pagesCell Emf Under Nonstandard Conditions Lecture 3Lyra GurimbaoNo ratings yet

- Automatic Drainage Cleaning Machine Run Through Solar PowerDocument8 pagesAutomatic Drainage Cleaning Machine Run Through Solar Powervikalpsharma96No ratings yet

- PID-signs and Symbols - Rev2Document1 pagePID-signs and Symbols - Rev2Vũ QuangNo ratings yet

- Half LifeDocument3 pagesHalf LifeJames Tan Zi JieNo ratings yet

- Corn Stover To Ethanol Model PDFDocument32 pagesCorn Stover To Ethanol Model PDFGraciaVelitarioNo ratings yet

- PDS - GulfSea Synth Compressor Oil 46 68Document2 pagesPDS - GulfSea Synth Compressor Oil 46 68Md.Obydur RahmanNo ratings yet

- 1420-2R1 Lube Oil Logic Enhancement PDFDocument4 pages1420-2R1 Lube Oil Logic Enhancement PDFManuel L LombarderoNo ratings yet

- DCC ChecklistDocument1 pageDCC Checklistluci_camNo ratings yet

- Boiler Tube FailureDocument4 pagesBoiler Tube FailurenileshNo ratings yet

- Substation/Switch Yard: Presented by Ankit Kumar REG - NO-11907132 ROLL - NO-07 Section-K19By Group - 1Document38 pagesSubstation/Switch Yard: Presented by Ankit Kumar REG - NO-11907132 ROLL - NO-07 Section-K19By Group - 1Ankit Kumar100% (1)