Professional Documents

Culture Documents

Grating

Uploaded by

Ray GongCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Grating

Uploaded by

Ray GongCopyright:

Available Formats

bar grating

USA: Fisher & Ludlow, Inc. Canada: Fisher & Ludlow

introduction

Quality People Delivering Quality Products and Services

Today’s construction projects demand the highest quality With our strategic network of well-stocked warehouses

standards and at Nucor Grating, we deliver. Nucor Grating and fabrication facilities, our products are always readily

is proud to be your first choice in the North American available. The friendly and knowledgeable staff in our sales,

grating market. engineering, and drafting departments can take your

requirements from structural drawings to detailed grating

Our reputation for superior quality and service has rewarded drawings and on to completely fabricated, ready-to-install

us with the privilege of being specified on many of North grating. As we are both a manufacturer and fabricator,

America’s largest capital projects. Our products may be we offer our customers complete “One Source” responsibility

found around the world in industrial sectors such as oil for all their grating needs.

and gas production, mining, water and wastewater

treatment, power generation, as well as a wide variety Whether supplying trench grating covers, stair treads,

of architectural applications. elevated platforms or catwalks, from the floor up, you can

count on Nucor Grating to supply durable and reliable

We lead the industry with a commitment to continuous products. We thank you for your continued support in making

improvement in our safety and quality standards. We are Nucor Grating your #1 choice for grating.

ISO 9001:2008 certified and our steel grating products

count towards credits under the Leadership in Energy

and Environmental Design (LEED) green building program.

Paramount to all of our product designs is safety. At Nucor

Grating we believe that safety is not just a goal, but a

lifestyle. By promoting healthy and safe living beyond the

workplace, our successful team takes pride in achieving

outstanding safety track records both on and off the job.

This pride is apparent in the products we create and services

we offer our customers.

2 NUCOR GRATING > 1-800-334-2047 (USA) • 1-800-268-6277 (Canada) • www.nucorgrating.com

our complete product line

bar grating

tru-weld® steel and stainless steel fisholow® aluminum rectangular

bar grating bar grating

tru-weld® heavy duty bar grating fisholow® aluminum i-bar grating

fiberglass reinforced plastic (FRP) grating

molded frp grating pultruded frp grating

Warranty

We warrant all goods of our manufacture to be free from defects caused by faulty material or poor

workmanship and will at our option repair or replace, without charge, or allow credit for any such

goods found on examination by us to be defective under normal use and service within one year

from date of shipment to the buyer, provided we are promptly notified in writing upon discovery

of such defects. Goods shall not be returned to us without our consent in writing.

This warranty does not cover damage caused by improper installation, overloading, accident, neglect

or harmful alterations, or repairs made by others. The buyer’s remedies with respect to defective

goods shall be exclusively limited as above provided.

www.nucorgrating.com • 1-800-268-6277 (Canada) • 1-800-334-2047 (USA) < NUCOR GRATING 3

contents

5 bar grating

6 Tru-Weld® Standard Mesh Bar Grating

6 Bar Grating Anatomy

7 Steel Bar Grating

8 Custom Fabrication

9 How to Order

10 Manufacturing Tolerances

11 Steel Stair Treads

12 Standard Mesh Load Tables

14 Stainless Steel Bar Grating

15 Special Mesh Bar Grating

16 Special Mesh (Metric)

17 Special Mesh

18 Theoretical Weights and Open Areas

19 Heavy Duty Bar Grating

20 Heavy Duty Load Tables

22 Heavy Duty Special Mesh (Metric)

23 Heavy Duty Special Mesh

24 Fisholow® Aluminum Standard Mesh Bar Grating

25 Aluminum Stair Treads

26 Aluminum Load Tables

28 Aluminum Special Mesh

29 fiberglass reinforced plastic (FRP) grating

30 Molded FRP

31 Pultruded FRP

33 grating fastening methods

4 NUCOR GRATING > 1-800-334-2047 (USA) • 1-800-268-6277 (Canada) • www.nucorgrating.com

bar grating

steel, stainless steel, and aluminum

www.nucorgrating.com • 1-800-268-6277 (Canada) • 1-800-334-2047 (USA) < NUCOR GRATING 5

standard mesh bar grating

bar grating anatomy

Tru-Weld® Bar Grating

Tru-Weld bar grating is forge-welded, a system in which What does “Type 19-4” Mean?

Nucor Grating was a pioneer. In this process the bearing

bars and cross rods are permanently forged together by heat

and pressure into a single unit construction, resulting in greater

strength per pound than mechanical assembly methods.

Standard Mesh

The twisted cross rods provide a non-slip walking surface.

For applications where extremely slippery conditions prevail,

Serrated Tru-Weld offers a superior grip surface to the load

bearing bars.

Bar grating

Bar grating types are specified by bearing bar spacing

followed by cross rod spacing.

In imperial measurements, bearing bar spacing is described

in sixteenths of an inch. Therefore, Type 19 has bearing bar

centers at 19/16 of an inch (or 1 3/16”). Type 15 has bearing

plain surface bar centers at 15/16”. Type 11 is at 11/16” etc. The second

number after the dash in the Type designation refers to

the cross rod spacing. Cross rods are available in either 4”

(standard) or 2” (special) spacings.

All bar grating Types may also be described in metric units.

Again, the first number represents the bearing bar spacing

on centers and the second number represents the cross

rod spacing, both units measured in millimeters. Therefore,

Type 30-102 Metric equals bearing bars at 30mm centers

and cross rods at 102mm centers. This is the metric equivalent

of Type 19-4.

Note: Although the special 2” (50mm) cross rod spacing does

allow for less open space on the grating surface, it does not

affect the load rating of the grating. The most economical

and readily available choice for bar grating selection is

serrated surface Type 19-4 (Type 30-102 Metric).

6 NUCOR GRATING > 1-800-334-2047 (USA) • 1-800-268-6277 (Canada) • www.nucorgrating.com

standard mesh bar grating

Steel Bar Grating

Tru-Weld steel bar grating is the most popular product

manufactured by Nucor Grating. Nearly all sizes in Standard

Mesh Type 19-4 (Type 30-102 metric) are readily available in

our warehouses or stocked on the shelves of our distributors.

Simplicity in design is surpassed by its versatility in usage.

Standard Mesh

From mezzanines, platforms, catwalks, and stairs to fences,

benches, racking shelves, and ventilation covers, Tru-Weld

Steel Bar Grating is by no means limited to the industrial

applications for which it was originally designed.

Available in bare steel, shop primed, or hot dip galvanized.

bar grating

www.nucorgrating.com • 1-800-268-6277 (Canada) • 1-800-334-2047 (USA) < NUCOR GRATING 7

standard mesh bar grating

custom fabrication

Nucor Grating is a full service grating supplier. All of our

products are available in either stock panels, or fully

fabricated to suit your individual requirements. Examples of

fabrication include:

• Cutting to size

• Providing cutouts for penetrations in grating panels

• Welding banding, kick plate, or nosings to grating

Standard Mesh

• Fabricating stair treads

• Custom additions such as checker plate, lifting handles,

and hinges

• Circular layouts and radial platforms

Our Sales, Engineering, Drafting, and Fabrication departments

can take your requirements from structural drawings to

detailed grating drawings and on to completely fabricated

ready-to-install grating. Armed with the latest technology

in computer aided design and 3-D software applications,

Bar grating

Nucor Grating is dedicated to continuous improvement

and maximizing efficiencies in the detailing process.

Many of today’s projects demand just-in-time delivery.

Our experienced project managers can effectively coordinate

your multi-release schedules to ensure your job site receives

the grating they need, when they need it. Grating panels are

piece marked and clearly identified on our supplied grating

drawings for accurate field installation.

As we are both a manufacturer and fabricator of grating we

can offer our customers complete “One Source” responsibility

for all their grating needs.

8 NUCOR GRATING > 1-800-334-2047 (USA) • 1-800-268-6277 (Canada) • www.nucorgrating.com

standard mesh bar grating

how to order

Tru-Weld Bar Grating standard clearances

When ordering or specifying Tru-Weld Bar Grating,

please confirm:

• The Type of grating.

Type 19-4 (Type 30-102 Metric) is Standard.

• Bar Size

Standard Mesh

• Grating surface – serrated or plain top

• Finish – unpainted, shop primer, or hot dip galvanized

• Style and quantity of fasteners, if required.

Example: Nucor Grating Tru-Weld bar grating Type 19-4,

1 1/4 x 3/16 serrated, galvanized.

If purchasing fabricated grating, please also confirm:

• Span Direction (Direction of bearing bars)

bar grating

• Area to be covered and method of support

• Dimensions – indicate whether your dimensions

take clearances into account

• Indicate any banding, kick plate, or nosing requirements

• Shipping and tagging instructions

Standard Practices

Standard quantity measurements for invoicing

Invoicing area or net area for grating ordered to specific

dimensions without drawings will be based on length

by width of each panel, with no deductions for cutouts. load table information

For grating supplied from a drawing, the invoicing area The load table calculations used throughout this catalogue are

shall be on the basis of gross floor area measured out based on “single span” condition. The dimensions shown are

to out of grating, with no deductions for clearances. for a clear, unsupported span.

Any detailing and/or fabrication of grating by Nucor Grating

will conform to the ANSI/N.A.A.M.M. Standards.

Field measurement

The Seller shall not be responsible for the actual dimensions

of construction work in the field, but shall be responsible for

the accurate fabrication of grating and treads in accordance

with plans and specifications, if applicable.

*All weights will increase by 5% when galvanized.

www.nucorgrating.com • 1-800-268-6277 (Canada) • 1-800-334-2047 (USA) < NUCOR GRATING 9

standard mesh bar grating

manufacturing tolerances

Standard Mesh

Bar grating

Stair tread

Note: Length of tread is distance

between outer faces of carrier plates

or back to back of carrier angles.

10 NUCOR GRATING > 1-800-334-2047 (USA) • 1-800-268-6277 (Canada) • www.nucorgrating.com

standard mesh bar grating

steel stair treads

standard tread detail Tread with checker plate nosing

(Standard)

Tru-Weld standard treads with checker plate nosings are

cost effective, durable and self-cleaning. The checker plate

nosing insures maximum visibility and underfoot safety where

needed most.

Standard Mesh

Tread with aluminum abrasive nosing

(Special order)

bar grating

Cast aluminum abrasive nosings offer maximum slip resistance

on the leading edge of the tread.

End Plate Width and Hole Pattern Dimensions

# of TREAD WIDTH “A” dimension “B” dimension

Bars (Type 19-4 Only) (Outer Slot) (Inner Slot)

METRIC IMPERIAL METRIC IMPERIAL METRIC IMPERIAL

(mm) (inches) (mm) (inches) (mm) (inches)

5 157 6 3/16 64 2 1/2 n/a n/a

6 187 7 3/8 114 4 1/2 n/a n/a

7 217 8 9/16 114 4 1/2 n/a n/a

8 248 9 3/4 178 7 114 4 1/2 Note: Bolts for mounting to stringers are not included.

9 278 10 15/16 178 7 114 4 1/2

10 308 12 1/8 178 7 114 4 1/2

How to Order

For tread widths 9 3/4”, 10 15/16” & 12 1/8”, standard end

plate is complete with 2 slots. See “B” dimension in chart. When ordering or specifying Tru-Weld Bar Grating Treads,

please confirm:

End Plate Depth Dimensions

• Type, bar size, and surface of grating

grating depth “c” dimension “d” dimension • Type of nosing – checker plate is standard

METRIC IMPERIAL METRIC IMPERIAL METRIC IMPERIAL • Width of tread

(mm) (inches) (mm) (inches) (mm) (inches)

19 to 32 3/4 to 1 1/4 44 1 3/4 64 2 1/2 • Length of tread

38 and up 1 1/2 and up 57 2 1/4 76 3 • Finish – unpainted, shop primer, or hot dip galvanized

• Number of treads

• Shipping and tagging instructions

maximum recommended tread lengths

Example: Nucor Grating Tru-Weld bar grating treads,

bearing maximum lenth of tread

c/w 1 1/4” x 3/16” serrated grating, checker plate nosing

bar size (Type 19-4 Only)

and standard end plates, 12 1/8” wide x 36” long,

Plain Serrated

painted black, 150 pcs, tagged “Project ABC”.

METRIC IMPERIAL METRIC IMPERIAL METRIC IMPERIAL

(mm) (inches) (mm) (ft. & in.) (mm) (ft. & in.)

25 x 4.8 1 x 3/16 1040 3’ 5” 860 2’ 10”

32 x 4.8 1 1/4 x 3/16 1420 4’ 8” 1270 4’ 2”

38 x 4.8 1 1/2 x 3/16 1670 5’ 6” 1600 5’ 3” *All weights will increase by 5% when galvanized.

Note: 1/8” (3.2mm) bearing bar not recommended.

www.nucorgrating.com • 1-800-268-6277 (Canada) • 1-800-334-2047 (USA) < NUCOR GRATING 11

standard mesh bar grating

standard tru-weld – type 30 (Metric)

Bearing Bars: 30mm centers

type 30 metric

Stock panels: 915mm nominal width x 7315mm long

METRIC LEGEND

U = Safe Uniform Load (kPa)

Standard Mesh

C = Safe Concentrated Load (kN/metre of grating width)

D = Deflection (mm)

Loads and deflections given in this table are theoretical and are based on a maximum allowable fibre stress of 124.0 MPa.

All metric dimensions are based on a “soft” conversion.

bearing Approx. Load/ Span in millimetres (mm) SECtion

bar size Weight (kg/m2) Deflection modulus

(mm) TYPE TYPE PER 305mm

30-102 30-51 610 762 914 1067 1219 1372 1524 1676 1829 1981 2134 2286 2438 2591 2743 OF WIDTH

U 25.52 16.33 11.34 8.33 6.38 5.04

D 2.52 3.94 5.68 7.73 10.09 12.77 Spans and loads in the green shaded area

19 x 4.8 27.2 3000

C 7.78 6.22 5.18 4.44 3.89 3.46 exceed a deflection of 6mm for uniform loads

D 2.02 3.15 4.54 6.18 8.07 10.22 of 5kPa. Experience has shown that 6mm

Bar grating

U 30.24 19.32 13.44 9.87 7.56 5.97 4.84 4.00 3.36 deflection is the maximum deflection to give

D 1.89 2.96 4.26 5.79 7.57 9.58 11.82 14.31 17.03 pedestrian comfort, but can be exceeded

25 x 3.2 24.6 3540

C 9.22 7.37 6.14 5.27 4.61 4.10 3.69 3.35 3.07 for other types of loads at the discretion of

D 1.51 2.36 3.41 4.64 6.05 7.66 9.46 11.45 13.62 the engineer.

U 45.36 29.03 20.16 14.81 11.34 8.96 7.26 6.00 5.04

D 1.89 2.96 4.26 5.79 7.57 9.58 11.82 14.31 17.03 For serrated surface, increase depth by one size.

25 x 4.8 35.3 38.4 5330

C 13.83 11.06 9.22 7.90 6.91 6.14 5.53 5.03 4.61

D 1.51 2.36 3.41 4.64 6.05 7.66 9.46 11.45 13.62

U 47.25 30.24 21.00 15.43 11.81 9.33 7.56 6.25 5.25 4.47 3.86

D 1.51 2.36 3.41 4.64 6.05 7.66 9.46 11.45 13.62 15.99 18.54

32 x 3.2 29.9 33.0 5560

C 14.40 11.52 9.60 8.23 7.20 6.40 5.76 5.24 4.80 4.43 4.11

D 1.21 1.89 2.72 3.71 4.84 6.13 7.57 9.16 10.90 12.79 14.83

U 70.88 45.36 31.50 23.14 17.72 14.00 11.34 9.37 7.88 6.71 5.79

D 1.51 2.36 3.41 4.64 6.05 7.66 9.46 11.45 13.62 15.99 18.54

32 x 4.8 43.3 46.4 8310

C 21.60 17.28 14.40 12.34 10.80 9.60 8.64 7.86 7.20 6.65 6.17

D 1.21 1.89 2.72 3.71 4.84 6.13 7.57 9.16 10.90 12.79 14.83

U 68.04 43.55 30.24 22.22 17.01 13.44 10.89 9.00 7.56 6.44 5.55 4.84 4.25 3.77 3.36

D 1.26 1.97 2.84 3.86 5.04 6.39 7.88 9.54 11.35 13.32 15.45 17.74 20.18 22.78 25.54

38 x 3.2 35.3 38.4 8000

C 20.74 16.59 13.83 11.85 10.37 9.22 8.30 7.54 6.91 6.38 5.93 5.53 5.18 4.88 4.61

D 1.01 1.58 2.27 3.09 4.04 5.11 6.31 7.63 9.08 1.66 12.36 14.19 16.14 18.22 20.43

U 102.03 65.32 45.36 33.33 25.52 20.16 16.33 13.50 11.34 9.66 8.33 7.26 6.38 5.65 5.04

D 1.26 1.97 2.84 3.86 5.04 6.39 7.88 9.54 11.35 13.32 15.45 17.74 20.18 22.78 25.54

38 x 4.8 51.3 54.4 11960

C 31.11 24.89 20.74 17.78 15.55 13.83 12.44 11.31 10.37 9.57 8.89 8.30 7.78 7.32 6.91

D 1.01 1.58 2.27 3.09 4.04 5.11 6.31 7.63 9.08 10.66 12.36 14.19 16.14 18.22 20.43

U 138.92 88.91 61.74 45.36 34.73 27.44 22.23 18.37 15.44 13.15 11.34 9.88 8.68 7.69 6.86

D 1.08 1.69 2.43 3.31 4.32 5.47 6.76 8.18 9.73 11.42 13.24 15.20 17.63 19.53 21.89

45 x 4.8 59.4 62.5 16290

C 42.34 33.87 28.23 24.20 21.17 18.82 16.94 15.40 14.11 13.03 12.10 11.29 10.59 9.96 9.41

D 0.86 1.35 1.95 2.65 3.46 4.38 5.41 6.54 7.78 9.13 10.59 12.16 13.84 15.62 17.51

U 181.44 116.12 80.64 59.25 45.36 35.84 29.03 23.99 20.16 17.18 14.81 12.90 11.34 10.05 8.96

D 0.95 1.48 2.13 2.90 3.78 4.79 5.91 7.15 8.51 9.99 11.59 13.30 15.13 17.09 19.16

51 x 4.8 67.4 70.6 21290

C 55.30 44.24 36.87 31.60 27.65 24.58 22.12 20.11 18.43 17.02 15.80 14.75 13.83 13.01 12.29

D 0.76 1.18 1.70 2.32 3.03 3.83 4.73 5.72 6.81 7.99 9.27 10.64 12.11 13.67 15.32

U 229.64 146.97 102.06 74.98 57.41 45.36 36.74 30.37 25.52 21.74 18.75 16.33 14.35 12.71 11.34

D 0.84 1.31 1.89 2.58 3.36 4.26 5.26 6.36 7.57 8.88 10.30 11.82 13.45 15.19 17.03

57 x 4.8 75.4 78.6 26940

C 69.99 55.99 46.66 40.00 35.00 31.11 28.00 25.45 23.33 21.54 20.00 18.66 17.50 16.47 15.55

D 0.67 1.05 1.51 2.06 2.69 3.41 4.20 5.09 6.05 7.10 8.24 9.46 10.76 12.15 13.62

U 283.50 181.44 126.00 92.57 70.88 56.00 45.36 37.49 31.50 26.84 23.14 20.16 17.72 15.70 14.00

D 0.76 1.18 1.70 2.32 3.03 3.83 4.73 5.72 6.81 7.99 9.27 10.64 12.11 13.67 15.32

64 x 4.8 83.5 86.7 33250

C 86.41 69.13 57.61 49.38 43.21 38.41 34.56 31.42 28.80 26.59 24.69 23.04 21.60 20.33 19.20

D 0.61 0.95 1.36 1.85 2.42 3.06 3.78 4.58 5.45 6.39 7.42 8.51 9.69 10.93 12.26

Tru-Weld grating meets N.A.A.M.M. standards. *All weights will increase by 5% when galvanized.

12 NUCOR GRATING > 1-800-334-2047 (USA) • 1-800-268-6277 (Canada) • www.nucorgrating.com

standard mesh bar grating

standard tru-weld – type 19

Bearing Bars: 1 3/16“ centers

type 19

Stock panels: 3’ nominal width x 24’ long

IMPERIAL LEGEND

U = Safe Uniform Load (lbs./ft.2)

Standard Mesh

C = Safe Concentrated Load (lbs./foot of grating width)

D = Deflection (inches)

Loads and deflections given in this table are theoretical and are based on a maximum allowable fibre stress of 18,000 P.S.I.

bearing Approx. Load/ Span in Feet and inches SECtion

bar size Weight (lbs./ft.2) Deflection modulus

(inches) TYPE TYPE PER FOOT

19-4 19-2 2’ 0” 2’ 6” 3’ 0” 3’ 6” 4’ 0” 4’ 6” 5’ 0” 5’ 6” 6’ 0” 6’ 6” 7’ 0” 7’ 6” 8’ 0” 8’ 6” 9’ 0” OF WIDTH

U 533 341 237 174 133 105

D 0.099 0.155 0.223 0.304 0.397 0.503 Spans and loads in the green shaded area

3/4 x 3/16 5.58 0.183

C 533 426 355 305 266 237 Spans and loads in the pinkexceed

shadeda deflection

area exceedof 1/4” for uniform

a deflection loads

of 1/4”

D 0.079 0.124 0.179 0.243 0.318 0.402 of 100 ft.

for uniform loads of 100 lbs./sq. lbs/sq. ft. Experience

Experience has that

has shown shown that

1/4”

bar grating

U 632 404 281 206 158 125 101 84 70

deflection is the maximum1/4” deflection

deflection is the

to give maximumcomfort,

pedestrian deflection

but to

can

D 0.074 0.116 0.168 0.228 0.298 0.370 0.466 0.563 0.670 give pedestrian comfort, but can be exceeded

1 x 1/8 5.03 be exceeded for other types of loads at the discretion of the engineer. 0.216

C 632 505 421 361 316 281 253 230 211 for other types of loads at the discretion of

D 0.060 0.093 0.134 0.182 0.238 0.302 0.372 0.451surface,

For serrated 0.536increase depth by one size.

the engineer.

U 947 606 421 309 237 187 152 125 105

D 0.074 0.116 0.168 0.228 0.298 0.377 0.466 0.563 0.670 For serrated surface, increase depth by one size.

1 x 3/16 7.23 7.87 0.325

C 947 758 632 541 474 421 379 344 316

D 0.060 0.093 0.134 0.182 0.238 0.302 0.372 0.451 0.536

U 987 632 439 322 247 195 158 130 110 93 81

D 0.060 0.093 0.134 0.182 0.238 0.302 0.372 0.451 0.536 0.629 0.730

1 1/4 x 1/8 6.12 6.76 0.339

C 987 789 658 564 493 439 395 359 329 304 282

D 0.048 0.074 0.107 0.146 0.191 0.241 0.298 0.360 0.429 0.504 0.584

U 1480 947 658 483 370 292 237 196 164 140 121

D 0.060 0.093 0.134 0.182 0.238 0.302 0.372 0.451 0.536 0.629 0.730

1 1/4 x 3/16 8.87 9.51 0.507

C 1480 1184 987 846 740 658 592 538 493 455 423

D 0.048 0.074 0.107 0.146 0.191 0.241 0.298 0.360 0.429 0.504 0.584

U 1421 909 632 464 355 281 227 188 158 135 116 101 89 79 70

D 0.050 0.078 0.112 0.152 0.199 0.251 0.310 0.376 0.447 0.524 0.608 0.698 0.794 0.897 1.006

1 1/2 x 1/8 7.23 7.87 0.488

C 1421 1137 947 812 711 632 568 517 474 437 406 379 355 334 316

D 0.040 0.062 0.089 0.122 0.159 0.201 0.248 0.300 0.358 0.420 0.487 0.559 0.636 0.718 0.804

U 2132 1364 947 696 533 421 341 282 237 202 174 152 133 118 105

D 0.050 0.078 0.112 0.152 0.199 0.251 0.310 0.376 0.447 0.524 0.608 0.698 0.794 0.897 1.006

1 1/2 x 3/16 10.51 11.15 0.730

C 2132 1705 1421 1218 1066 947 853 775 711 656 609 568 533 502 474

D .0040 0.062 0.089 0.122 0.159 0.201 0.248 0.300 0.358 0.420 0.487 0.559 0.636 0.718 0.804

U 2901 1857 1289 947 725 573 464 384 322 275 237 206 181 161 143

D 0.043 0.067 0.096 0.130 0.170 0.215 0.266 0.322 0.383 0.450 0.521 0.599 0.681 0.769 0.862

1 3/4 x 3/16 12.17 12.81 0.994

C 2901 2321 1934 1658 1451 12859 1161 1055 967 893 829 774 725 683 645

D 0.034 0.053 0.077 0.104 0.136 0.172 0.273 0.257 0.306 0.360 0.417 0.479 0.545 0.615 0.689

U 3789 2425 1684 1237 947 749 606 501 421 359 309 269 237 210 187

D 0.037 0.058 0.084 0.114 0.149 0.189 0.233 0.282 0.335 0.393 0.456 0.524 0.596 0.673 0.754

2 x 3/16 13.81 14.45 1.299

C 3789 3032 2326 2165 1895 1684 1516 1378 1263 1166 1083 1011 947 892 842

D 0.030 0.047 0.067 0.091 0.119 0.151 0.186 0.225 0.268 0.315 0.365 0.419 0.477 0.538 0.603

U 4796 3069 2132 1566 1199 947 767 634 533 454 392 341 300 266 237

D 0.033 0.052 0.074 0.101 0.132 0.168 0.207 0.250 0.298 0.350 0.406 0.466 0.530 0.598 0.670

2 1/4 x 3/16 15.45 16.09 1.644

C 4796 3837 3197 2741 2398 2132 1918 1744 1599 1476 1370 1279 1199 1128 1066

D 0.026 0.041 0.060 0.081 0.106 0.134 0.166 0.200 0.238 0.280 0.324 0.372 0.424 0.478 0.536

U 5921 3789 2632 1933 1480 1170 947 783 658 561 483 421 370 328 292

D 0.030 0.047 0.067 0.091 0.119 0.151 0.186 0.225 0.268 0.315 0.365 0.419 0.477 0.538 0.603

2 1/2 x 3/16 17.11 17.75 2.029

C 5921 4737 3947 3383 2961 2632 2386 2153 1974 1822 1692 1579 1480 1393 1316

D 0.024 0.037 0.054 0.073 0.095 0.121 0.149 0.180 0.215 0.252 0.292 0.335 0.381 0.431 0.483

Tru-Weld grating meets N.A.A.M.M. standards. *All weights will increase by 5% when galvanized.

www.nucorgrating.com • 1-800-268-6277 (Canada) • 1-800-334-2047 (USA) < NUCOR GRATING 13

stainless steel bar grating

stainless steel information

tru-weld Stainless Steel Bar Grating

Tru-Weld Stainless Steel Bar Grating provides a long-term

durable grating solution for caustic atmospheres where

corrosion resistance and minimum carbide precipitation

are important considerations. Typical applications include

stairs and platforms within chemical production and storage,

food processing plants, and water and wastewater treatment

Stainless Steel

facilities. Your choice of 304, 304L, 316, or 316L Stainless

Steel grades are available.

Heat from the Electroforge welding process discolors the

surface of the stainless steel in the weld area. For this reason,

Tru-Weld Stainless Steel Bar Grating is best suited for

industrial uses where cosmetic appearance is not a factor.

Bar grating

stainless steel conversion factors

When considering load conditions for stainless steel bar

grating, please apply the calculations in the table below

to the values shown in the carbon steel load tables on

pages 12 and 13.

METRIC LEGEND IMPERIAL LEGEND

U = Safe Uniform Load (kPa) U = Safe Uniform Load (lbs./ft.2)

C = Safe Concentrated Load (kN/metre of grating width) C = Safe Concentrated Load (lbs./foot of grating width)

D = Deflection (mm) D = Deflection (inches)

Stainless Steel Grade Load/Deflection multiply carbon steel load tables by: BASED ON MAXIMUM ALLOWABLE FIBRE STRESS

U 1.111

304

C 1.111 20,000 P.S.I. (137.9 MPa)

Stainless Steel

D 1.151

U 0.917

304L

C 0.917 16,500 P.S.I. (113.8 MPa)

Stainless Steel

D 0.949

U 1.111

316

C 1.111 20,000 P.S.I. (137.9 MPa)

Stainless Steel

D 1.151

U 0.917

316L

C 0.917 16,500 P.S.I. (113.8 MPa)

Stainless Steel

D 0.949

14 NUCOR GRATING > 1-800-334-2047 (USA) • 1-800-268-6277 (Canada) • www.nucorgrating.com

special mesh bar grating

special mesh information

tru-weld Special Mesh Bar Grating

Tru-Weld Special Mesh Bar Grating offer a variety of close

or wide space mesh options to suit specific aesthetic or

functional bar spacing requirements.

As with Tru-Weld Standard Mesh Bar Grating, Special Mesh

Bar Grating may be ordered with either plain or serrated

bearing bars. Similarly, panels are manufactured with a

Special Mesh

standard 4” cross rod spacing but 2” cross rod spacing

is available.

Close Mesh

Advantages of the close mesh grating style include close mesh wide mesh

greatly increased load bearing capabilities and prevention

of fall through by dangerous objects such as heavy tools

or equipment accidentally dropped from above.

Wide Mesh

bar grating

Wide mesh grating options are designed for applications

requiring additional openness of bar grating to minimize

buildup of snow, ice, or other debris.

Available in most 1/8” and 3/16” Steel and Stainless Steel

bar sizes and select Heavy Duty bar sizes.

*Special Mesh Bar Grating is a non-stocked specialty item.

For the most cost effective and readily available bar grating

option, choose Standard Mesh Type 19-4 (Type 30-102 Metric).

*All weights will increase by 5% when galvanized.

www.nucorgrating.com • 1-800-268-6277 (Canada) • 1-800-334-2047 (USA) < NUCOR GRATING 15

special mesh bar grating

special mesh (metric)

special close mesh

(metric)

Deflections as per table on page 12. metric Panel width in millimetres

(For 4.8mm bearing bars)

X

Type 18 Metric # of close mesh standard wide mesh

ADA Compatible with 4.8mm bars Bars mesh

TYPE 18 TYPE 24 TYPE 30 TYPE 41 TYPE 48 TYPE 60

Multiply load values by 1.72 as per METRIC METRIC METRIC METRIC METRIC METRIC

table on page 12. 2 22 28 35 46 52 65

Special Mesh

3 40 52 65 87 100 125

4 57 76 95 129 148 186

5 75 100 125 170 195 246

6 92 124 156 211 243 306

Type 24 Metric 7 110 148 186 252 291 367

Multiply load values by 1.25 as per 8 127 171 216 294 338 427

9 144 195 246 335 386 487

table on page 12. 10 162 219 276 381 433 548

11 179 243 306 418 481 608

12 197 267 337 459 529 668

13 214 291 367 500 576 729

Bar grating

special wide mesh 14 232 314 397 541 624 789

15 249 338 427 583 683 849

(metric) 16 267 362 457 624 719 910

Deflections as per table on page 12. 17 284 386 487 665 767

18 302 410 518 706 814

Type 41 Metric 19 319 433 548 748 862

Multiply load values by 0.73 as per 20 337 457 578 789 910

21 354 481 608 830

table on page 12. 22 371 505 638 872

23 389 529 668 913

24 406 552 698

25 424 576 729

26 441 600 759

27 459 624 789

28 476 648 819

Type 48 Metric 29 494 672 849

Multiply load values by 0.63 as per 30 511 695 879

table on page 12. 31 529 719 910

32 546 743

33 564 767

34 581 790

35 598 814

36 615 838

37 862

38 886

Type 60 Metric 39 910

Multiply load values by 0.50 as per 40

table on page 12. 41

Dimensions shown are out to out of bearing bars.

For 3.2mm bearing bars, deduct 1.6mm from panel width.

All metric dimensions are based on a “soft” conversion.

*All weights will increase by 5% when galvanized.

16 NUCOR GRATING > 1-800-334-2047 (USA) • 1-800-268-6277 (Canada) • www.nucorgrating.com

special mesh bar grating

special mesh

special close mesh

Deflections as per table

on page 13. IMPERIAL Panel width in INCHES

X

(For 3/16” bearing bars)

Type 11 # of close mesh standard wide mesh

ADA Compatible with 3/16” bars Bars mesh

TYPE TYPE TYPE TYPE TYPE TYPE

Multiply load values by 1.72 as per 11 15 19 26 30 38

table on page 13. 2 7/8 1 1/8 1 3/8 1 27/32 2 1/16 2 9/16

Special Mesh

3 1 9/16 2 1/16 2 9/16 3 15/32 3 15/16 4 15/16

4 2 1/4 3 3 3/4 5 3/32 5 13/16 7 5/16

5 2 15/16 3 15/16 4 15/16 6 23/32 7 11/16 9 11/16

6 3 5/8 4 7/8 6 1/8 8 11/32 9 9/16 12 1/16

Type 15 7 4 5/16 5 13/16 7 5/16 9 31/32 11 7/16 14 7/16

Multiply load values by 1.25 as per 8 5 6 3/4 8 1/2 11 19/32 13 5/16 16 13/16

9 5 11/16 7 11/16 9 11/16 13 7/32 15 3/16 19 3/16

table on page 13. 10 6 3/8 8 5/8 10 7/8 14 27/32 17 1/16 21 9/16

11 7 1/16 9 9/16 12 1/16 16 15/32 18 15/16 23 15/16

12 7 3/4 10 1/2 13 1/4 18 3/32 20 13/16 26 5/16

13 8 7/16 11 7/16 14 7/16 19 23/32 22 11/16 28 11/16

bar grating

special wide mesh 14 9 1/8 12 3/8 15 5/8 21 11/32 24 9/16 31 1/16

15 9 13/16 13 5/16 16 13/16 22 31/32 26 7/8 33 7/16

Deflections as per table 16 10 1/2 14 1/4 18 24 19/32 28 5/16 35 13/16

on page 13. 17 11 3/16 15 3/16 19 3/16 26 7/32 30 3/16

18 11 7/8 16 1/8 20 3/8 27 27/32 32 1/16

Type 26 19 12 9/16 17 1/16 21 9/16 29 15/32 33 15/16

Multiply load values by 0.73 as per 20 13 1/4 18 22 3/4 31 3/32 35 13/16

21 13 15/16 18 15/16 23 15/16 32 23/32

table on page 13.

22 14 5/8 19 7/8 25 1/8 34 11/32

23 15 5/16 20 13/16 26 5/16 35 31/32

24 16 21 3/4 27 1/2

25 16 11/16 22 11/16 28 11/16

26 17 3/8 23 5/8 29 7/8

27 18 1/16 24 9/16 31 1/16

28 18 3/4 25 1/2 32 1/4

Type 30 29 19 7/16 26 7/16 33 7/16

Multiply load values by 0.63 as per 30 20 1/8 27 3/8 34 5/8

table on page 13. 31 20 13/16 28 5/16 35 13/16

32 21 1/2 29 1/4

33 22 3/16 30 3/16

34 22 7/8 31 1/8

35 23 9/16 32 1/16

36 24 1/4 33

37 33 15/16

38 34 7/8

Type 38 39 35 13/16

Multiply load values by 0.50 as per 40

table on page 13. 41

Dimensions shown are out to out of bearing bars.

For 1/8” bearing bars, deduct 1/16” from panel width.

*All weights will increase by 5% when galvanized.

www.nucorgrating.com • 1-800-268-6277 (Canada) • 1-800-334-2047 (USA) < NUCOR GRATING 17

special mesh bar grating

theoretical weights and open areas

All metric dimensions are based on a “soft” conversion.

metric weights (kg/m2)

bearing Bar special close mesh standard mesh special wide mesh

size (mm) TYPE TYPE TYPE TYPE TYPE TYPE TYPE TYPE TYPE TYPE TYPE TYPE TYPE

15-51 18-102 18-51 24-102 24-51 30-102 30-51 41-102 41-51 48-102 48-61 60-102 60-51

19 x 4.8 54.39 44.67 47.80 33.49 36.42 27.24 30.37 n/a n/a 18.02 20.51 15.33 17.77

25 x 3.2 49.07 40.09 43.16 30.12 33.10 24.56 27.68 19.19 n/a 16.26 18.75 13.87 16.31

25 x 4.8 70.55 58.64 61.71 42.72 46.68 35.30 38.43 27.49 n/a 23.19 25.68 19.58 22.02

32 x 3.2 59.76 49.31 52.39 36.91 39.89 29.88 33.01 23.34 n/a 19.73 22.17 16.70 19.14

Special Mesh

32 x 4.8 86.62 72.46 75.53 53.80 56.78 43.31 46.43 33.74 n/a 28.37 30.86 23.83 26.32

38 x 3.2 70.55 58.64 61.71 43.75 46.73 35.30 38.43 27.49 n/a 23.19 25.68 19.58 22.02

38 x 4.8 102.63 86.27 89.40 65.62 70.21 51.31 54.44 39.94 n/a 34.23 37.35 28.81 31.93

44 x 4.8 119.18 100.58 103.65 76.07 80.66 59.42 62.54 46.14 n/a 40.67 44.87 34.27 38.52

51 x 4.8 135.34 114.49 117.57 86.27 90.86 67.43 70.55 52.34 n/a 45.90 50.09 38.57 42.82

57 x 4.8 150.48 127.53 130.65 95.84 100.43 75.43 78.56 58.59 n/a 50.78 54.98 42.62 46.82

64 x 4.8 166.64 141.49 144.57 106.05 110.64 83.54 86.66 64.74 n/a 55.95 60.20 46.92 51.12

imperial weights (lbs/ft2)

bearing Bar special close mesh standard mesh special wide mesh

Bar grating

size (inches) TYPE 9.5-2 TYPE 11-4 TYPE 11-2 TYPE 15-4 TYPE 15-2 TYPE 19-4 TYPE 19-2 TYPE 26-4 TYPE 26-2 TYPE 30-4 TYPE 30-2 TYPE 38-4 TYPE 38-2

3/4 x 3/16 11.14 9.15 9.79 6.86 7.46 5.58 6.22 n/a n/a 3.69 4.20 3.14 3.64

1 x 1/8 10.05 8.21 8.84 6.17 6.78 5.03 5.67 3.93 n/a 3.33 3.84 2.84 3.34

1 x 3/16 14.45 12.01 12.64 8.75 9.56 7.23 7.87 5.63 n/a 4.75 5.26 4.01 4.51

1 1/4 x 1/8 12.24 10.10 10.73 7.56 8.17 6.12 6.76 4.78 n/a 4.04 4.54 3.42 3.92

1 1/4 x 3/16 17.74 14.84 15.47 11.02 11.63 8.87 9.51 6.91 n/a 5.81 6.32 4.88 5.39

1 1/2 x 1/8 14.45 12.01 12.64 8.96 9.57 7.23 7.87 5.63 n/a 4.75 5.26 4.01 4.51

1 1/2 x 3/16 21.02 17.67 18.31 13.44 14.38 10.51 11.15 8.18 n/a 7.01 7.65 5.90 6.54

1 3/4 x 3/16 24.41 20.60 21.23 15.58 16.52 12.17 12.81 9.45 n/a 8.33 9.19 7.02 7.89

2 x 3/16 27.72 23.45 24.08 17.67 18.61 13.81 14.45 10.72 n/a 9.40 10.26 7.90 8.77

2 1/4 x 3/16 30.82 26.12 26.76 19.63 20.57 15.45 16.09 12.00 n/a 10.40 11.26 8.73 9.59

2 1/2 x 3/16 34.13 28.98 29.61 21.72 22.66 17.11 17.75 13.26 n/a 11.46 12.33 9.61 10.47

metric open area imperial open area

bearing Bar special standard mesh special wide mesh bearing Bar special standard mesh special wide mesh

size (mm) close mesh size (inches) close mesh

TYPE 18 TYPE 24 TYPE 30 TYPE 41 TYPE 48 TYPE 60 TYPE 11 TYPE 15 TYPE 19 TYPE 26 TYPE 30 TYPE 38

51mm cross rods 2” cross rods

3.2mm 74% 77% 79% 81% 82% 83% 1/8 74% 77% 78% 81% 82% 83%

4.8mm 64% 70% 74% 78% 79% 81% 3/16 64% 70% 74% 78% 79% 81%

102mm cross rods 4” cross rods

3.2mm 78% 82% 84% 87% 88% 89% 1/8 78% 82% 84% 87% 88% 89%

4.8mm 68% 75% 79% 83% 84% 86% 3/16 68% 75% 79% 83% 84% 86%

RailROAD Grating

Tru-Weld Steel Railroad Grating is special wide mesh Type 26-4

(Type 41-102 Metric) with bearing bars supplied serrated for

additional safety. It was originally designed specifically for

use as brake steps, running boards, walkways, and platforms

on railcars and locomotives. Railroad Grating is supplied as

standard AAR (Association of American Railroads) approved

welded bar grating with bar spacing at 1 5/8” centers and

cross rods at 4” centers.

*All weights will increase by 5% when galvanized.

18 NUCOR GRATING > 1-800-334-2047 (USA) • 1-800-268-6277 (Canada) • www.nucorgrating.com

heavy duty bar grating

heavy duty information

Heavy-Duty Steel Bar Grating

Steel Bar Grating with bearing bars thicker than 3/16” is

considered to be “Heavy Duty” and carries the designation

prefix “Type HD”. Available bar thicknesses are 1/4” and

3/8” in either a plain or serrated surface. Standard depths

range from 1” up to 4”, although larger sizes are available

upon request.

Heavy Duty

Tru-Weld Heavy Duty Steel Bar Grating is commonly used for

floor trench and sump covers exposed to heavy equipment

traffic. It is used extensively throughout mining, power

generation, highways, airfields, and on truck terminal loading

docks and ramps. It is suitable for large single span conditions

or where grating must support extreme loads.

*All weights will increase by 5% when galvanized.

*For serrated surface, the load carrying capacity

bar grating

would be minimized.

www.nucorgrating.com • 1-800-268-6277 (Canada) • 1-800-334-2047 (USA) < NUCOR GRATING 19

heavy duty bar grating

heavy duty tru-weld – type HD-30 (Metric)

Bearing Bars: 30mm centers

type hd-30 metric

Panel Sizes: 914mm nomimal width x 6096mm long for 6.4mm only

610mm nomimal width x 6096mm long for 9.5mm

METRIC LEGEND

U = Safe Uniform Load (kPa)

C = Safe Concentrated Load (kN/metre of grating width)

Heavy Duty

Loads and deflections given in this table are theoretical and are based on a maximum allowable fibre stress of 137.9 MPa.

All metric dimensions are based on a “soft” conversion.

bearing Approx. Load/ Span in millimetres (mm) SECtion

bar size Weight (kg/m2) Deflection modulus

(mm) TYPE TYPE PER 305mm

30-102 30-51 305 457 610 762 914 1067 1219 1372 1524 1676 1829 1981 2134 2286 2438 OF WIDTH

U 268 120 67 43 30 22 17 13 11 9 7 6 5 5 4

25 x 6.4 47.0 51.3 6900

C 41 27 20 16 14 12 10 9 8 7 7 6 6 5 5

U 403 179 101 65 45 33 25 20 16 13 11 10 8 7 6

25 x 9.5 68.0 72.7 10350

C 61 41 31 25 20 18 15 14 12 11 10 9 9 8 8

Bar grating

U 419 187 105 67 47 34 26 21 17 14 12 10 9 7 7

32 x 6.4 58.0 62.0 10780

C 64 43 32 26 21 18 16 14 13 12 11 10 9 9 8

U 629 280 157 101 70 51 39 31 25 21 17 15 13 11 10

32 x 9.5 84.0 88.9 16170

C 96 64 48 38 32 27 24 21 19 17 16 15 14 13 12

U 604 269 151 97 67 49 38 30 24 20 17 14 12 11 9

38 x 6.4 68.0 72.7 15520

C 92 61 46 37 31 26 23 20 18 17 15 14 13 12 12

U 906 404 227 145 101 74 57 45 36 30 25 21 19 16 14

38 x 9.5 100.0 105.0 23300

C 138 92 69 55 46 39 35 31 28 25 23 21 20 18 17

U 822 366 206 132 92 67 51 41 33 27 23 19 17 15 13

44 x 6.4 79.0 83.5 21100

C 125 84 63 50 42 36 31 28 25 23 21 19 18 17 16

U 1233 549 308 198 137 101 77 61 49 41 34 29 25 22 19

44 x 9.5 116.0 121.1 31700

C 188 126 94 75 63 54 47 42 38 34 31 29 27 25 24

U 1074 478 268 172 120 88 67 53 43 36 30 25 22 19 17

51 x 6.4 89.0 94.7 27600

C 164 109 82 66 55 47 41 36 33 30 27 25 23 22 20

U 1611 717 403 258 179 132 101 80 65 53 45 38 33 29 25

51 x 9.5 131.0 137.2 41400

C 246 164 123 98 82 70 61 55 49 45 41 38 35 33 31

U 1359 605 340 218 151 111 85 67 54 45 38 32 28 24 21

57 x 6.4 100.0 116.2 34900

C 207 138 104 83 69 59 52 46 41 38 35 32 30 28 26

U 2039 908 510 327 227 167 128 101 82 68 57 48 42 36 32

57 x 9.5 147.0 169.4 52400

C 311 207 155 124 104 89 78 69 62 57 52 48 44 41 39

U 1678 747 419 269 187 137 105 83 67 56 47 40 34 30 26

64 x 6.4 110.0 116.2 43100

C 256 171 128 102 85 73 64 57 51 47 43 39 37 34 32

U 2517 1121 629 403 280 206 158 124 101 83 70 60 51 45 39

64 x 9.5 163.0 169.4 64700

C 384 256 192 154 128 110 96 85 77 70 64 59 55 51 48

U 2416 1076 604 387 269 197 151 119 97 80 67 57 49 43 38

76 x 6.4 131.0 137.7 62100

C 368 246 184 147 123 105 92 82 74 67 61 57 53 49 46

U 3624 1614 906 581 404 296 227 179 145 120 101 86 74 65 57

76 x 9.5 194.0 201.1 93100

C 553 369 276 221 184 158 138 123 111 101 92 85 79 74 69

U 3289 1465 822 527 366 269 206 163 132 109 91 78 67 59 51

89 x 6.4 152.0 159.2 84500

C 502 335 251 201 167 143 125 111 100 91 84 77 72 67 63

U 4933 2197 1233 790 549 403 309 244 198 163 137 117 101 88 77

89 x 9.5 226.0 233.4 126800

C 752 502 376 301 251 215 188 167 151 137 125 116 108 100 94

U 4295 1913 1074 688 478 351 269 212 172 142 119 102 88 76 67

102 x 6.4 173.0 193.8 110400

C 655 437 328 262 219 187 164 146 131 119 109 101 94 87 82

U 6443 2870 1611 1032 717 526 403 318 258 213 179 153 132 115 101

102 x 9.5 257.0 279.3 165600

C 983 656 491 393 328 281 246 218 197 179 164 151 140 131 123

Tru-Weld grating meets N.A.A.M.M. standards. *All weights will increase by 5% when galvanized.

20 NUCOR GRATING > 1-800-334-2047 (USA) • 1-800-268-6277 (Canada) • www.nucorgrating.com

heavy duty bar grating

heavy duty tru-weld – type HD-19

Bearing Bars: 1 3/16“ centers

type hd-19

Panel Sizes: 3’ 0” nomimal width x 20’ for 1/4” only

2’ 0” nomimal width x 20’ for 3/8” only

IMPERIAL LEGEND

U = Safe Uniform Load (lbs./ft.2)

C = Safe Concentrated Load (lbs./foot of grating width)

Heavy Duty

Loads and deflections given in this table are theoretical and are based on a maximum allowable fibre stress of 20,000 P.S.I.

bearing Approx. Weight Load/ Span in feet and inches SECtion

bar size (lbs./ft2) Deflection modulus

(inches) TYPE TYPE PER FOOT

19-4 19-2 1’ 0” 1’ 6” 2’ 0” 2’ 6” 3’ 0” 3’ 6” 4’ 0” 4’ 6” 5’ 0” 5’ 6” 6’ 0” 6’ 6” 7’ 0” 7’ 6” 8’ 0” OF WIDTH

U 5613 2495 1403 898 624 458 351 277 225 186 156 133 115 100 88

1 x 1/4 9.4 10.5 0.432

C 2807 1871 1403 1123 936 802 702 624 561 510 468 432 401 374 351

U 8427 3745 2107 1348 936 688 527 416 337 279 234 199 172 150 132

1 x 3/8 13.8 14.9 0.646

C 4213 2809 2107 1685 1404 1204 1053 936 843 766 702 648 602 562 527

bar grating

U 8773 3899 2193 1404 975 716 548 433 351 290 244 208 179 156 137

1 1/4 x 1/4 11.6 12.7 0.675

C 4387 2924 2193 1755 1462 1253 1097 975 877 798 731 675 627 585 548

U 13160 5849 3290 2106 1462 1074 823 650 526 435 366 311 269 234 206

1 1/4 x 3/8 17.1 18.2 1.009

C 6580 4387 3290 2632 2193 1880 1645 1462 1316 1196 1097 1012 940 877 823

U 12627 5612 3157 2020 1403 1031 789 624 505 417 351 299 258 224 197

1 1/2 x 1/4 13.8 14.9 0.972

C 6313 4209 3157 2525 2104 1804 1578 1403 1263 1148 1052 971 902 842 789

U 18947 8421 4737 3031 2105 1547 1184 936 758 626 526 448 387 337 296

1 1/2 x 3/8 20.4 21.5 1.453

C 9473 6316 4737 3789 3158 2707 2368 2105 1895 1722 1579 1457 1353 1263 1184

U 17187 7639 4297 2750 1910 1403 1074 849 687 568 477 407 351 306 269

1 3/4 x 1/4 16.0 17.1 1.323

C 8593 5729 4297 3437 2864 2455 2148 1910 1719 1562 1432 1322 1228 1146 1074

U 25787 11461 6447 4126 2865 2105 1612 1273 1031 852 716 610 526 458 403

1 3/4 x 3/8 23.7 24.8 1.978

C 12893 8596 6447 5157 4298 3684 3223 2865 2579 2344 2149 1984 1842 1719 1612

U 22453 9979 5613 3593 2495 1833 1403 1109 898 742 624 531 458 399 351

2 x 1/4 18.3 19.4 1.728

C 11227 7484 5613 4491 3742 3208 2807 2495 2245 2041 1871 1727 1604 1497 1403

U 33680 14969 8420 5389 3742 2749 2105 1663 1347 1113 936 797 687 599 526

2 x 3/8 27.0 28.1 2.583

C 16840 11227 8420 6736 5613 4811 4210 3742 3368 3062 2807 2591 2406 2245 2105

U 28427 12634 7107 4548 3159 2321 1777 1404 1137 940 790 673 580 505 444

2 1/4 x 1/4 20.5 21.6 2.700

C 14213 9476 7107 5685 4738 4061 3553 3159 2843 2584 2369 2187 2030 1895 1777

U 42627 18945 10657 6820 4736 3480 2664 2105 1705 1409 1184 1009 870 758 666

2 1/4 x 3/8 30.1 31.3 4.036

C 21313 14209 10657 8525 7104 6090 5328 4736 4263 3875 3552 3279 3045 2842 2664

U 35093 15597 8773 5615 3899 2865 2193 1733 1404 1160 975 831 716 624 548

2 1/2 x 1/4 22.7 23.8 2.700

C 17547 11698 8773 7019 5849 5013 4387 3899 359 3190 2924 2699 2507 2340 2193

U 52627 23390 13157 8420 5847 4296 3289 2599 2105 1740 1462 1246 1074 936 822

2 1/2 x 3/8 33.6 34.7 4.036

C 26313 17542 13157 10525 8771 7518 6578 5847 5263 4784 4386 4048 3759 3508 3289

U 50520 22453 12630 8083 5613 4124 3158 2495 2021 1670 1403 1196 1031 898 789

3 x 1/4 27.1 28.2 3.889

C 25260 16840 12630 10104 8420 7217 6315 5613 5052 4593 4210 3886 3609 3368 3158

U 75787 33683 18947 12126 8421 6187 4737 3743 3031 2505 2105 1794 1547 1347 1184

3 x 3/8 40.1 41.2 5.813

C 37893 25262 18947 15157 12631 10827 9473 8421 7579 6890 6316 5830 5413 5052 4737

U 68773 30566 17193 11004 7641 5614 4298 3396 2751 2273 1910 1628 1404 1223 1075

3 1/2 x 1/4 31.5 32.6 5.293

C 34387 22924 17193 13755 11462 9825 8597 7641 6877 6252 5731 5290 4912 4585 4298

U 103160 45849 25790 16506 11462 8421 6448 5094 4126 3410 2866 2442 2105 1834 1612

3 1/2 x 3/8 46.7 47.8 7.911

C 51580 34387 25790 20632 17193 14737 12895 11462 10316 9378 8597 7935 7369 6877 6448

U 89827 39923 22457 14372 9981 7333 5614 4436 3593 2969 2495 2126 1833 1597 1404

4 x 1/4 38.6 39.7 7.000

C 44913 29942 22457 17965 14971 12832 11228 9981 8983 8166 7486 6910 6416 5988 5614

U 134733 59881 33683 21557 14970 10999 8421 6653 5389 4454 3743 3189 2750 2395 2105

4 x 3/8 56.1 57.2 10.446

C 67367 44911 33683 26947 22456 19248 16842 14970 13473 12248 11228 10364 9624 8982 8421

Tru-Weld grating meets N.A.A.M.M. standards. *All weights will increase by 5% when galvanized.

www.nucorgrating.com • 1-800-268-6277 (Canada) • 1-800-334-2047 (USA) < NUCOR GRATING 21

heavy duty bar grating

heavy duty special mesh (metric)

heavy duty close mesh (metric)

Type HD-24 Metric

Multiply load values by 1.25 as per table on page 20.

*All weights will increase by 5% when galvanized.

Heavy Duty

Deflections as per table on page 20. Dimensions shown are out to out of bearing bars. All metric dimensions are based on a “soft” conversion.

metric Panel width in millimetres

# of close mesh standard mesh wide mesh wide mesh wide mesh

Bars Type HD-24 Metric Type HD-30 Metric Type HD-35 Metric Type HD-48 Metric Type HD-60 Metric

6mm 9.5mm 6mm 9.5mm 6mm 9.5mm 6mm 9.5mm 6mm 9.5mm

BAR BAR BAR BAR BAR BAR BAR BAR BAR BAR

2 30 n/a 37 40 41 44 54 57 67 70

3 54 n/a 67 70 76 79 102 105 127 130

4 78 n/a 97 100 111 114 149 152 187 191

5 102 n/a 127 130 146 149 197 200 248 251

Bar grating

6 125 n/a 157 160 181 184 244 248 308 311

7 149 n/a 187 191 216 219 292 295 368 371

8 173 n/a 217 221 251 254 340 343 429 432

9 197 n/a 248 251 286 289 387 391 489 492

10 221 n/a 278 281 321 324 435 438 549 552

11 244 n/a 308 311 356 359 482 486 610 613

12 268 n/a 338 341 391 394 530 533 670

13 292 n/a 368 371 425 429 578 581 730

14 316 n/a 398 402 460 464 625 629 791

15 340 n/a 429 432 495 499 673 851

16 364 n/a 459 462 530 534 721 911

17 387 n/a 489 492 565 569 768

18 411 n/a 519 522 600 604 816

19 435 n/a 549 552 635 864

20 458 n/a 579 582 670 911

21 483 n/a 610 613 705

22 506 n/a 640 740

23 530 n/a 670 775

24 554 n/a 700 810

25 578 n/a 730 845

26 602 n/a 760 879

27 791 914

28 821

29 851

30 881

31 911

heavy duty wide mesh (metric)

Type HD-35 Metric Type HD-48 Metric Type HD-60 Metric

Multiply load values by 0.86 as per table Multiply load values by 0.63 as per table Multiply load values by 0.50 as per table

on page 20. on page 20. on page 20.

22 NUCOR GRATING > 1-800-334-2047 (USA) • 1-800-268-6277 (Canada) • www.nucorgrating.com

heavy duty bar grating

heavy duty special mesh

heavy duty close mesh

Type HD-15

Multiply load values by 1.25 as per table on page 21.

*All weights will increase by 5% when galvanized.

Heavy Duty

Deflections as per table on page 21. Dimensions shown are out to out of bearing bars.

imperial Panel width in inches

# of close mesh standard mesh wide mesh wide mesh wide mesh

Bars Type HD-15 Type HD-19 Type HD-22 Type HD-30 Type HD-38

1/4 3/8 1/4 3/8 1/4 3/8 1/4 3/8 1/4 3/8

BAR BAR BAR BAR BAR BAR BAR BAR BAR BAR

2 1 3/16 n/a 1 7/16 1 9/16 1 5/8 1 3/4 2 1/8 2 1/4 2 5/8 2 3/4

3 2 1/8 n/a 2 5/8 2 3/4 3 3 1/8 4 4 1/8 5 5 1/8

4 3 1/16 n/a 3 13/16 3 15/16 4 3/8 4 1/2 5 7/8 6 7 3/8 7 1/2

5 4 n/a 5 5 1/8 5 3/4 5 7/8 7 3/4 7 7/8 9 3/4 9 7/8

bar grating

6 4 15/16 n/a 6 3/16 6 5/16 7 1/8 7 1/4 9 5/8 9 3/4 12 1/8 12 1/4

7 5 7/8 n/a 7 3/8 7 1/2 8 1/2 8 5/8 11 1/2 11 5/8 14 1/2 14 5/8

8 6 13/16 n/a 8 9/16 8 11/16 9 7/8 10 13 3/8 13 1/2 16 7/8 17

9 7 3/4 n/a 9 3/4 9 7/8 11 1/4 11 3/8 15 1/4 15 3/8 19 1/4 19 3/8

10 8 11/16 n/a 10 15/16 11 1/16 12 5/8 12 3/4 17 1/8 17 1/4 21 5/8 21 3/4

11 9 5/8 n/a 12 1/8 12 1/4 14 14 1/8 19 19 1/8 24 24 1/8

12 10 9/16 n/a 13 5/16 13 7/16 15 3/8 15 1/2 20 7/8 21 26 3/8

13 11 1/2 n/a 14 1/2 14 5/8 16 3/4 16 7/8 22 3/4 22 7/8 28 3/4

14 12 7/16 n/a 15 11/16 15 13/16 18 1/8 18 1/4 24 5/8 24 3/4 31 1/8

15 13 3/8 n/a 16 7/8 17 19 1/2 19 5/8 26 1/2 33 1/2

16 14 5/16 n/a 18 1/16 18 3/16 20 7/8 21 28 3/8 35 7/8

17 15 1/4 n/a 19 1/4 19 3/8 22 1/4 22 3/8 30 1/4

18 16 3/16 n/a 20 7/16 20 9/16 23 5/8 23 3/4 32 1/8

19 17 1/8 n/a 21 5/8 21 3/4 25 34

20 18 1/16 n/a 22 13/16 22 15/16 26 3/8 35 7/8

21 19 n/a 24 24 1/8 27 3/4

22 19 15/16 n/a 25 3/16 29 1/8

23 20 7/8 n/a 26 3/8 30 1/2

24 21 13/16 n/a 27 9/16 31 7/8

25 22 3/4 n/a 28 3/4 33 1/4

26 23 11/16 n/a 29 15/16 34 5/8

27 31 1/8 36

28 32 5/16

29 33 1/2

30 34 11/16

31 35 7/8

heavy duty wide mesh

Type HD-22 Type HD-30 Type HD-38

Multiply load values by 0.86 as per table Multiply load values by 0.63 as per table Multiply load values by 0.50 as per table

on page 21. on page 21. on page 21.

www.nucorgrating.com • 1-800-268-6277 (Canada) • 1-800-334-2047 (USA) < NUCOR GRATING 23

aluminum standard mesh bar grating

aluminum information

Fisholow® Rectangular

and I-Bar Grating

Aluminum Standard Mesh

Fisholow Aluminum Bar Gratings employ a unique interlocking

system that joins the bearing bars and cross rods together

in panels of exceptional rigidity and strength. Lightweight,

corrosion-resistant, non-sparking alloys are ideal for pedestrian

platforms in chemical, petroleum, and food processing plants.

Fisholow gratings is recommended in most water and waste

water treatment facilities and is becoming increasingly popular

for use in architectural building designs.

Fisholow Aluminum Bar Grating is available in two bar profiles:

Rectangular Bar and I-bar. Similar to Tru-Weld Steel Bar rectangular bar

Grating, Fisholow Rectangular Bar Grating is offered with

a plain or serrated surface. Fisholow I-Bar Grating produces

exceptional load ratings at a fraction of the weight of its

rectangular counterpart, and is designed with a slip resistant

Bar grating

corrugated surface on the top of each I-bar.

Both Rectangular Bar and I-Bar styles are available in special

mesh options.

i-bar

24 NUCOR GRATING > 1-800-334-2047 (USA) • 1-800-268-6277 (Canada) • www.nucorgrating.com

aluminum standard mesh bar grating

aluminum stair treads

standard tread detail Aluminum Tread with corrugated

angle nosing (Standard)

Aluminum Standard Mesh

Fisholow treads with standard corrugated angle nosing are

strong, lightweight, and self-cleaning. They are ideal for

applications requiring corrosion resistance, non-sparking,

and rust proof grating. The corrugated angle nosing insures

maximum visibility and underfoot safety where needed most.

bar grating

aluminum Tread with aluminum

abrasive nosing (Special order)

The optional cast aluminum abrasive nosing offers a superior

slip resistance on the leading edge of the tread.

End Plate Width and Hole Pattern Dimensions

# of TREAD WIDTH “A” dimension “B” dimension

Bars (Type 19-4 Only) (Outer Slot) (Inner Slot)

METRIC IMPERIAL METRIC IMPERIAL METRIC IMPERIAL

(mm) (inches) (mm) (inches) (mm) (inches)

5 157 6 3/16 64 2 1/2 n/a n/a

6 187 7 3/8 114 4 1/2 n/a n/a

7 217 8 9/16 114 4 1/2 n/a n/a

8 248 9 3/4 178 7 114 4 1/2

9 278 10 15/16 178 7 114 4 1/2

10 308 12 1/8 178 7 114 4 1/2 Note: Bolts for mounting to stringers are not included.

For tread widths 9 3/4”, 10 15/16” & 12 1/8”, standard end

plate is complete with 2 slots. See “B” dimension in chart. How to Order

When ordering or specifying Fisholow treads, please confirm:

maximum recommended tread lengths • Type, bar size, and surface of grating

• Type of nosing – corrugated angle nosing is standard

bearing maximum lenth of tread • Width of tread

bar size (Type 19-4 Only)

• Length of tread

Plain Serrated

• Number of treads

METRIC IMPERIAL METRIC IMPERIAL METRIC IMPERIAL

(mm) (inches) (mm) (ft. & in.) (mm) (ft. & in.)

• Shipping and tagging instructions

25 x 4.8 1 x 3/16 710 2’ 4” – –

32 x 4.8 1 1/4 x 3/16 860 2’ 10” 790 2’ 7” Example: Nucor Grating Fisholow treads, c/w 1 1/4” x 3/16”

38 x 4.8 1 1/2 x 3/16 1070 3’ 6” 970 3’ 2” serrated rectangular-bar aluminum bar grating, corrugated

44 x 4.8 1 3/4 x 3/16 1300 4’ 3” 1170 3’ 10”

angle nosing and standard end plates, 12 1/8” wide x 30” long,

Note: 1/8” (3.2mm) bearing bar not recommended. 150 pcs, tagged “Project ABC”.

www.nucorgrating.com • 1-800-268-6277 (Canada) • 1-800-334-2047 (USA) < NUCOR GRATING 25

aluminum standard mesh bar grating

standard fisholow – type 30 (Metric)

Bearing Bars: 30mm centers, 6063T6

aluminum type 30

Cross Bars: 6063T5

Stock panels: 915mm nominal width x 7315mm long metric

Aluminum Standard Mesh

METRIC LEGEND

U = Safe Uniform Load (kPa)

C = Safe Concentrated Load (kN/metre of grating width)

D = Deflection (mm)

Loads and deflections given in this table are theoretical and are based on a maximum allowable fibre stress of 82.82 MPa.

All metric dimensions are based on a “soft” conversion. For Fisholow I-bar loading, use the equivalent depth 4.8mm bar size values in this load table.

bearing Approx. Load/ Span in millimetres (mm) SECtion

bar size Weight (kg/m2) Deflection modulus

(mm) PER 305mm

610 762 914 1067 1219 1372 1524 1676 1829 1981 2134 2286 2438 2591 2743 OF WIDTH

U 20.16 12.90 8.96 6.58 5.04 3.98

D 3.66 5.72 8.23 11.20 14.63 18.52 Spans and loads in the pink shaded area exceed a deflection of 6mm for

25 x 3.2 9.37 3.54

C 6.14 4.92 4.10 3.51 3.07 2.73 uniform loads of 5kPa. Experience has shown that 6mm deflection is the

D 2.93 4.57 6.58 8.96 11.70 14.81 maximum deflection to give pedestrian comfort, but can be exceeded for

Bar grating

U 30.24 19.35 13.44 9.87 7.56 5.97 other types of loads at the discretion of the engineer.

D 3.66 5.72 8.23 11.20 14.63 18.52

25 x 4.8 13.28 For serrated surface, increase depth by one size. 5.33

C 9.22 7.37 6.14 5.27 4.61 4.10

D 2.93 4.57 6.58 8.96 11.70 14.81

U 31.50 20.16 14.00 10.29 7.88 6.22 5.04 4.17 3.50

D 2.93 4.57 6.58 8.96 11.70 14.81 18.29 22.13 26.33

32 x 3.2 11.28 5.55

C 9.60 7.68 6.40 5.49 4.80 4.27 3.84 3.49 3.20

D 2.34 3.66 5.27 7.17 9.36 11.85 14.63 17.70 21.07

U 47.25 30.24 21.00 15.43 11.81 9.33 7.56 6.25 5.25 4.47 3.86

D 2.93 4.57 6.58 8.96 11.70 14.81 18.29 22.13 26.33 30.91 35.84

32 x 4.8 16.16 8.31

C 14.40 11.52 9.60 8.23 7.20 6.40 7.68 65.24 4.80 4.43 4.11

D 2.34 3.66 5.27 7.17 9.36 11.85 14.63 17.70 21.07 24.73 28.68

U 45.36 29.03 20.16 14.81 11.34 8.96 7.26 6.00 5.04 4.29 3.70 3.23 2.84 2.51 22.24

D 2.44 3.81 5.49 7.47 9.75 12.34 15.24 18.44 21.95 25.76 29.87 34.29 39.01 44.04 49.38

38 x 3.2 13.28 8.00

C 13.83 11.06 9.22 7.90 6.91 6.14 5.53 5.03 4.61 4.25 3.95 3.69 3.46 3.25 3.07

D 1.95 3.05 4.39 5.97 7.80 9.88 12.19 14.75 17.56 20.60 23.90 27.43 31.21 35.23 39.50

U 68.04 43.55 30.24 22.22 17.01 13.44 10.89 9.00 7.56 6.44 5.55 4.84 4.25 3.77 3.36

D 2.44 3.81 5.49 7.47 9.75 12.34 15.24 18.44 21.95 25.76 29.87 34.29 39.01 44.04 49.38

38 x 4.8 18.99 11.96

C 20.74 16.59 13.83 11.85 10.37 9.22 8.30 5.03 6.91 6.38 5.93 5.53 5.18 4.88 4.61

D 1.95 3.05 4.39 5.97 7.80 9.88 12.19 14.75 17.56 20.60 23.90 27.43 31.21 35.23 39.50

U 92.61 59.27 41.16 30.24 23.15 18.29 14.82 12.25 10.29 8.77 7.56 6.59 5.79 5.13 4.57

D 2.09 3.27 4.70 6.40 8.36 10.58 13.06 15.81 18.81 22.08 25.60 29.39 33.44 37.75 42.32

45 x 4.8 21.87 16.29

C 28.23 22.58 18.82 16.13 14.11 12.55 11.29 10.26 9.41 8.69 8.07 7.53 7.06 6.64 6.27

D 1.67 2.61 3.76 5.12 6.69 8.46 10.45 12.64 15.05 17.56 20.48 23.51 26.75 30.20 33.86

U 120.96 77.41 53.76 39.50 30.24 23.89 19.35 15.99 13.44 11.45 9.87 8.60 7.56 6.70 5.97

D 1.83 2.86 4.11 5.60 7.32 9.26 11.43 13.83 16.46 19.32 22.40 25.72 29.26 33.03 37.03

51 x 4.8 24.80 21.29

C 36.87 29.50 24.58 21.07 18.43 16.39 14.75 13.41 12.29 11.34 10.53 9.83 9.22 8.68 8.19

D 1.46 2.29 3.29 4.48 5.85 7.41 9.14 11.06 13.17 15.45 17.92 20.57 23.41 26.43 29.63

U 153.09 97.98 68.04 49.99 38.27 30.24 24.49 20.24 17.01 14.49 12.50 10.89 9.57 8.48 7.56

D 1.63 2.54 3.66 4.98 6.50 8.23 10.16 12.29 14.63 17.17 19.91 22.86 26.01 29.36 32.92

57 x 4.8 27.73 26.94

C 46.66 37.33 31.11 26.66 23.33 20.74 18.66 16.97 15.55 14.36 13.33 12.44 11.67 10.98 10.37

D 1.30 2.03 2.93 3.98 5.20 6.58 8.13 9.83 11.70 13.74 15.93 18.29 20.81 23.49 26.33

U 189.00 120.96 84.00 61.71 47.25 37.33 30.24 24.99 21.00 17.89 15.43 13.44 11.81 10.46 9.33

D 1.46 2.29 3.29 4.48 5.85 7.41 9.14 11.06 13.17 15.45 17.92 20.57 23.41 26.43 29.63

64 x 4.8 30.61 33.25

C 57.61 46.09 38.41 32.92 28.80 25.60 23.04 20.95 25.60 17.73 16.46 15.36 14.40 13.55 12.80

D 1.17 1.83 2.63 3.58 4.68 5.93 7.32 8.85 10.53 12.36 14.34 16.46 18.73 21.14 23.70

I-Bar weights (metric) Fisholow grating meets N.A.A.M.M. standards.

bearing bar weights (kg/m ) 2

size (mm) TYPE 18-102 TYPE 24-102 TYPE 30-102 TYPE 48-102 TYPE 60-102

25 x 6 n/a 11.47 9.03 5.96 4.98

32 x 6 n/a 13.96 11.18 7.37 6.15

38 x 6 n/a 16.11 12.84 8.59 7.18

45 x 6 n/a 18.21 14.50 9.86 8.54

51 x 6 n/a 20.26 16.11 11.91 9.18

57 x 6 n/a 22.80 18.99 12.74 10.64

64 x 6 n/a 23.29 19.48 13.04 10.89

26 NUCOR GRATING > 1-800-334-2047 (USA) • 1-800-268-6277 (Canada) • www.nucorgrating.com

aluminum standard mesh bar grating

standard fisholow – type 19

Bearing Bars: 1 3/16“ centers, 6063T6

aluminum type 19

Cross Bars: 6063T5

Stock panels: 3’ nominal width x 24’ long

Aluminum Standard Mesh

IMPERIAL LEGEND

U = Safe Uniform Load (lbs./ft.2)

C = Safe Concentrated Load (lbs./foot of grating width)

D = Deflection (inches)

Loads and deflections given in this table are theoretical and are based on a maximum allowable fibre stress of 12,000 P.S.I.

For Fisholow I-bar loading, use the equivalent depth 3/16” bar size values in this load table.

bearing Approx. Load/ Span in Feet and inches SECtion

bar size Weight Deflection modulus

(inches) (lbs./ft.2) PER FOOT

2’ 0” 2’ 6” 3’ 0” 3’ 6” 4’ 0” 4’ 6” 5’ 0” 5’ 6” 6’ 0” 6’ 6” 7’ 0” 7’ 6” 8’ 0” 8’ 6” 9’ 0” OF WIDTH

U 421 269 187 137 105 83

D 0.114 0.225 0.324 0.441 0.576 0.729 Spans and loads in the pink shaded area exceed a deflection of 1/4”

1 x 1/8 1.92 0.216

C 421 337 281 241 211 187 for uniform loads of 100 lbs/sq. ft. Experience has shown that 1/4”

D 0.115 0.18 0.259 0.353 0.461 0.583 deflection is the maximum deflection to give pedestrian comfort, but can

bar grating

U 632 404 281 206 158 125 be exceeded for other types of loads at the discretion of the engineer.

D 0.144 0.225 0.324 0.441 0.576 0.729

1 x 3/16 2.72 For serrated surface, increase depth by one size. 0.325

C 632 505 421 361 316 281

D 0.115 0.18 0.259 0.353 0.461 0.583

U 658 421 292 215 164 130 105 87 73

D 0.115 0.18 0.259 0.353 0.461 0.583 0.720 0.871 1.037

1 1/4 x 1/8 2.31 0.339

C 658 526 439 376 329 292 263 239 219

D 0.092 0.144 0.207 0.282 0.369 0.467 0.576 0.697 0.829

U 987 632 439 322 247 195 158 130 110 93 81

D 0.115 0.18 0.259 0.353 0.461 0.583 0.720 0.871 1.037 1.217 1.411

1 1/4 x 3/16 3.31 0.507

C 987 789 658 564 493 439 395 359 329 304 282

D 0.092 0.144 0.207 0.282 0.369 0.467 0.576 0.697 0.829 0.973 1.129

U 947 606 421 309 237 187 152 125 105 90 77 67 59 52 47

D 0.096 0.150 0.216 0.294 0.384 0.486 0.600 0.726 0.864 1.014 1.176 1.35 1.536 1.734 1.944

1 1/2 x 1/8 2.72 0.488

C 947 758 632 541 474 421 379 344 316 291 271 253 237 223 211

D 0.077 0.120 0.173 0.235 0.307 0.389 0.480 0.581 0.691 0.811 0.941 1.08 1.229 1.387 1.555

U 1421 909 632 464 355 281 227 188 158 135 116 101 89 79 70

D 0.096 0.15 0.216 0.294 0.384 0.486 0.6 0.726 0.864 1.014 1.176 1.35 1.536 1.734 1.944

1 1/2 x 3/16 3.89 0.730

C 1421 1137 947 812 711 632 568 517 474 437 406 379 355 334 316

D 0.077 0.12 0.173 0.235 0.307 0.389 0.48 0.581 0.691 0.811 0.941 1.08 1.229 1.387 1.555

U 1934 1238 860 632 484 382 309 256 215 183 158 138 121 107 96

D 0.082 0.129 0.185 0.252 0.329 0.417 0.514 0.622 0.741 0.869 1.008 1.157 1.317 1.486 1.666

1 3/4 x 3/16 4.48 0.994

C 1934 1547 1289 1105 967 860 774 703 645 595 553 516 484 455 430

D 0.066 0.103 0.148 0.202 0.263 0.333 0.411 0.498 0.592 0.695 0.806 0.926 1.053 1.189 1.333

U 2526 1617 1123 825 632 499 404 334 281 239 206 180 158 140 125

D 0.072 0.113 0.162 0.221 0.288 0.365 0.45 0.545 0.648 0.761 0.882 1.013 1.152 1.301 1.458

2 x 3/16 5.08 1.299

C 2526 2021 1684 1444 1263 1123 1011 919 842 777 962 674 632 594 561

D 0.058 0.09 0.13 0.176 0.263 0.292 0.36 0.436 0.518 0.608 0.706 0.81 0.922 1.04 1.166

U 3197 2046 1421 1044 799 632 512 423 355 303 261 227 200 177 158

D 0.064 0.100 0.144 0.196 0.256 0.324 0.400 0.484 0.576 0.676 0.784 0.900 1.024 1.156 1.296

2 1/4 x 3/16 5.68 1.644

C 3197 2558 2132 1827 1599 1421 1279 1163 1066 984 1218 1137 799 752 711

D 0.051 0.080 0.115 0.157 0.205 0.259 0.320 0.387 0.461 0.541 0.627 0.720 0.819 0.925 1.037

U 3947 2526 1754 1289 987 780 632 522 439 374 322 281 247 219 195

D 0.058 0.090 0.130 0.176 0.230 0.292 0.360 0.436 0.518 0.608 0.706 0.81 0.922 1.04 1.166

2 1/2 x 3/16 6.28 2.029

C 3947 3158 2632 2256 1974 1754 1579 1435 1316 1215 1128 1053 987 929 877

D 0.046 0.072 0.104 0.141 0.184 0.233 0.288 0.348 0.415 0.487 0.564 0.648 0.737 0.832 0.933

I-Bar weights (imperial) Fisholow grating meets N.A.A.M.M. standards.

bearing bar weights (lbs./ft )

2

size (inches) TYPE 11-4 TYPE 15-4 TYPE 19-4 TYPE 30-4 TYPE 38-4

1 x 1/4 n/a 2.35 1.85 1.22 1.02

1 1/4 x 1/4 n/a 2.86 2.29 1.51 1.26

1 1/2 x 1/4 n/a 3.30 2.63 1.76 1.47

1 3/4 x 1/4 n/a 3.73 2.97 2.02 1.75

2 x 1/4 n/a 4.15 3.30 2.24 1.88

2 1/4 x 1/4 n/a 4.67 3.89 2.61 2.18

2 1/2 x 1/4 n/a 4.77 3.99 2.67 2.23

www.nucorgrating.com • 1-800-268-6277 (Canada) • 1-800-334-2047 (USA) < NUCOR GRATING 27

aluminum special mesh bar grating

aluminum special mesh

Aluminum Special Mesh Bar Grating is a non-stocked specialty item. For the most cost effective and readily available aluminum

bar grating option, choose Standard Fisholow Type 19-4 (Type 30-102 Metric).

Aluminum Special Mesh

special close mesh

(metric) special close mesh

Deflections as per table on page 26. Deflections as per table on page 27.

Type 18 Metric Type 11

Multiply load values by 1.72 as per Multiply load values by 1.72 as per

table on page 26. table on page 27.

Type 18 Metric is not available Type 11 is not available in I-bar

in I-bar style bearing bars. style bearing bars.

Type 24 Type 15

Multiply load values by 1.25 as per Multiply load values by 1.25 as per

table on page 26. table on page 27.

Bar grating

special wide mesh

(metric) special wide mesh

Deflections as per table on page 26. Deflections as per table on page 27.

Type 48 Metric Type 30

Multiply load values by 0.63 as per Multiply load values by 0.63 as per

table on page 26. table on page 27.

Type 60 Metric Type 38

Multiply load values by 0.50 as per Multiply load values by 0.50 as per

table on page 26. table on page 27.

For panel widths, see steel panel width charts located on pages 16 and 17. All types of aluminum bar grating available up to

3 feet (915mm) nominal width.

28 NUCOR GRATING > 1-800-334-2047 (USA) • 1-800-268-6277 (Canada) • www.nucorgrating.com

fiberglass reinforced plastic (frp) grating

www.nucorgrating.com • 1-800-268-6277 (Canada) • 1-800-334-2047 (USA) < NUCOR GRATING 29

molded frp grating

molded frp information

molded Fibreglass reinforced plastic

(FRP) grating

Molded Fiberglass Reinforced Plastic (FRP) Grating is

manufactured in an open, heated mold. Continuous E-glass

fibers are interwoven in alternating layers while being

completely wetted out with thermosetting resin systems.

This continuous process produces an integral, one piece

construction which provides resilience and bi-directional

Molded FRP

strength. Although the concave profile of standard plain

surface Molded FRP Grating provides excellent anti-skid

properties, an integral grit surface can be supplied for

additional slip resistance. Other benefits include:

• Corrosion Resistant How to Order Molded FRP Grating

• Non-Rusting

When ordering or specifying Molded FRP Grating,

• Fire-Retardant

please confirm:

• Non-Conductive

FRP grating

• Light Weight • Type

• Easy to Install • Resin

• Unlimited Color Options • Color

• Top Surface

Fabrication • Sheet Size

As with our other grating products, Nucor Grating offers

Example: Nucor Grating Molded FRP 1 1/2” deep square mesh,

full fabrication services with FRP grating. We can also supply

AN (Architectural Grade, Non Fire Retardant), dark grey, grit top,

a variety of FRP structural shapes that may be associated with

4’ x 12’ sheets

an FRP grating project. Please call us to discuss any of your

custom platform and stair requirements.

installation

molded frp grating resin systems FRP grating sheet size and lightweight construction permit

simple and economical installation. Fasteners, supports and

Type Description Resin Corrosion flame spread

hold-down clips permit total flexibility in achieving the desired

Resistance rating

Architectural Grade configuration of the final installation.

AN* Orthophthalic Good Not Rated

Non Fire Retardant

Architectural Grade Conventional hand tools such as a hack saw, sabre saw, band

AF* Orthophthalic Good Class 1:25 or Less

Fire Retardant saw or disc saw with metal cutting blade can be used to cut

Food Grade grating on-site and to cut around special openings as required.

FF Isophthalic Very Good Class 2:30 or Less

Fire Retardant

Industrial Grade Cut ends should be treated with Edge Sealing Kits.

IF Isophthalic Very Good Class 1:25 or Less

Fire Retardant

Chemical Proof

CF Vinyl Ester Excellent Class 1:25 or Less

Fire Retardant

Chemical Proof

CR+ Vinyl Ester Excellent Class 1:10 or Less

Fire Retardant Plus

*Stocked at most warehouses in dark grey color, grit top or smooth top.

30 NUCOR GRATING > 1-800-334-2047 (USA) • 1-800-268-6277 (Canada) • www.nucorgrating.com

molded frp grating

molded frp types

1” rectangular mesh 1” square mesh 1 1/2” square mesh 2” square mesh

1” x 4” x 1” 1 1/2” x 1 1/2” x 1” 1 1/2” x 1 1/2” x 1 1/2” 2” x 2” x 2”

(25mm x 100mm x 25mm) (38mm x 38mm x 25mm) (38mm x 38mm x 38mm) (51mm x 51mm x 51mm)

Molded FRP

Panel size Approx. Approx. bearing bar size Cross bar size Top surface % open area

feet Weight shipping inches (mm) inches (mm)

(mm) lbs./ft.2 weight WIDTH SPACE C-C WIDTH SPACE C-C

(kg/m2) lbs. (kg)

1” Rectangular Mesh

4’ x 12’ 3.1 149 5/16 1 5/16 4 Plain or

59%

(1220 x 3658) (15.13) (67.5) (8) (25) (8) (100) Grip Top

3’ x 10’ 3.1 93 5/16 1 5/16 4 Plain or

59%

(915 x 3048) (15.13) (42) (8) (25) (8) (100) Grip Top

1” Square Mesh

FRP grating

4’ x 12’ 2.5 120 1/4 1 1/2 1/4 1 1/2 Plain or

70%

(1220 x 3658) (12.2) (55) (6) (38) (6) (38) Grip Top

3’ x 10’ 2.5 75 1/4 1 1/2 1/4 1 1/2 Plain or

70%

(915 x 3048) (12.2) (34) (6) (38) (6) (38) Grip Top

1 1/2” Square Mesh

4’ x 12’ 3.7 180 1/4 1 1/2 1/4 1 1/2 Plain or

70%

(1220 x 3658) (18.1) (82) (6) (38) (6) (38) Grip Top

3’ x 10’ 3.7 111 1/4 1 1/2 1/4 1 1/2 Plain or

70%

(915 x 3048) (18.1) (50) (6) (38) (6) (38) Grip Top

2” Square Mesh

4’ x 12’ 4 192 1/4 2 1/4 2 Plain or

72%

(1220 x 3658) (19.53) (87) (6) (51) (6) (51) Grip Top

Molded FRP grating meets O.S.H.A. specifications 1910.23 paragraph (a) 9.

METRIC LEGEND IMPERIAL LEGEND

U = Safe Uniform Load (kg/m2) U = Safe Uniform Load (lb./ft.2)

C = Safe Concentrated Load C = Safe Concentrated Load

(kg/m of grating width) (lbs./ft of grating width)

Allowable Loads and Deflections D = Deflection (mm) D = Deflection (in.)

Loads below are based on a minimum safety factor of 3 or maximum deflection of 1% of the span.

style Load/ span in MILLIMETRES (mm) style Load/ span in inches

Deflection Deflection

300 450 600 900 1200 1525 12" 18" 24" 36" 48" 60"

U 13652 4045 1706 506 213 U 2662 789 333 99 42

1” D 3 5 6 9 12 1” D 0.120 0.180 0.240 0.360 0.480

Square Mesh C 2567 1141 642 285 160 Square Mesh C 1667 741 417 185 104

D 3 5 6 9 12 D 0.120 0.180 0.240 0.360 0.480

U 18578 5505 2322 688 290 U 3623 1073 453 134 57

1” 1”

D 3 5 6 9 12 D 0.120 0.180 0.240 0.360 0.480

Rectangular Rectangular

C 3411 1516 853 379 213 C 2222 988 556 247 139

Mesh Mesh

D 3 5 6 9 12 D 0.120 0.180 0.240 0.360 0.480

U 30837 9137 3855 1142 482 235 U 6013 1782 752 223 94 48

1 1/2” D 3 5 6 9 12 15 1 1/2” D 0.120 0.180 0.240 0.360 0.480 0.600

Square Mesh C 5133 2563 1442 641 360 223 Square Mesh C 3889 1667 938 417 234 150

D 3 5 6 9 12 15 D 0.120 0.180 0.240 0.360 0.480 0.600

U 29744* 13282 5600 1656 682 282 U 5800* 2590 1092 323 133 55

2” D 3 5 6 9 12 15 2” D 0.120 0.180 0.240 0.360 0.480 0.600

Square Mesh C 4462* 4183 2974 1403 846 581 Square Mesh C 2900 2719 1933 912 550 378

D 3 5 6 9 12 15 D 0.120 0.180 0.240 0.360 0.480 0.600

*Represents Shear Force Governs *Represents Shear Force Governs

www.nucorgrating.com • 1-800-268-6277 (Canada) • 1-800-334-2047 (USA) < NUCOR GRATING 31

pultruded frp grating

pultruded frp information

PULTRUDED FRP GRATING Pultruded FRP Resins

Pultruded FRP Grating has all the benefits of Molded FRP Pultruded FRP grating is available in two resin bases –

Grating including corrosion resistance, high strength to weight Isophthalic Polyester and Vinyl Ester. Isophthalic Polyester

ratio, and ease of installation. With its high fiberglass content resin is ideal for most industrial applications and is available

and I-bar or T-bar style bearing bars, Pultruded FRP Grating in standard light grey, yellow, or green. Vinyl Ester resin offers

has increased unidirectional strength and stiffness to superior corrosion resistance and comes standard dark grey.

accommodate longer span conditions. Pultruded FRP Gratings Both are fire retardant with ASTM E84 flame spread rating

Pultruded FRP

are offered in a variety of bar profiles and spacings, including Class 1:25 or less.

close mesh options that are designed for non-motorized wheel

Standard panel sizes are 4’ x 20’ (1219mm x 6096mm),

traffic and ADA compliance.

however custom panel sizes are available.

Pultruded FRP grating types Custom colors are also available.

Pultruded FRP I-Bar Types

How to Order Pultruded FRP Grating

When ordering or specifying Pultruded FRP Grating,

FRP grating

please confirm:

• Type

• Resin

• Color

part Approx. “X” Dimension “Y” Dimension % open

number Weight OPen space Load Bar Centers area

• Top Surface

• Sheet Size

METRIC IMperial metric IMperial metric IMperial

(kg/m2) (lbs./ft.2) (mm) (inches) (mm) (inches)

Example: Nucor Grating Pultruded FRP I-6015

I-BAR 1” Deep

I-4010 17.57 3.60 10 0.4 25 1.0 40%

(I-bar 60% open, 1 1/2” deep), Vinyl Ester resin

I-5010 14.74 3.02 15 0.6 30 1.2 50% (Chemical Grade, Fire Retardant), dark grey, grit top,

I-6010 11.37 2.33 23 0.9 38 1.5 60% standard 4’ x 20’ sheets

I-BAR 1 1/4” Deep

I-4012 18.40 3.77 10 0.4 25 1.0 40%

I-6012 13.03 2.67 23 0.9 38 1.5 60% load table information

I-BAR 1 1/2” Deep

I-4015 21.97 4.50 10 0.4 25 1.0 40% Load Tables Available Upon Request

I-5015 18.16 3.72 15 0.6 30 1.2 50%

I-6015 16.11 3.30 23 0.9 38 1.5 60%

Pultruded FRP T-Bar Types

part Approx. “X” Dimension “Y” Dimension % open

number Weight OPen space Load Bar Centers area

METRIC IMperial metric IMperial metric IMperial

(kg/m2) (lbs./ft.2) (mm) (inches) (mm) (inches)

T-BAR 2” Deep

T-3320 21.67 4.44 13 0.5 38 1.5 33%

T-5020 16.74 3.43 25 1.0 51 2.0 50%

32 NUCOR GRATING > 1-800-334-2047 (USA) • 1-800-268-6277 (Canada) • www.nucorgrating.com

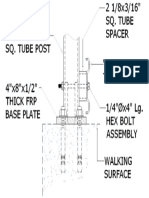

grating fastening methods

www.nucorgrating.com • 1-800-268-6277 (Canada) • 1-800-334-2047 (USA) < NUCOR GRATING 33

grating fastening methods

fastening methods information

BAR GRATING fasteners

Bar Grating Fastening Methods

Type D Saddle Clip Type D Saddle Clip

(complete with stainless steel self tapping screw) (complete with C-clamp and bolt)

SELF-DRILLING/SELF-TAPPING SCREW

grating fastening methods

Eliminates the need to drill supports or have access beneath

Our most common and cost-effective fastening method. the grating during installation. The C-clamp slides between

Designed for use with Tru-Weld Type 19 and Type 15 bar the bearing bars to clamp the flange of the supporting

grating only (in 1/8” and 3/16” bar sizes). member and is tightened from above using a hex-driver.

For use with Tru-Weld Type 19 and Type 15 bar grating only

Available in standard galvanized or bare steel and stainless

(in 1/8” and 3/16” bar sizes).

steel options.

Available in standard galvanized or bare steel and stainless

steel options.

Type D Saddle Clip

(complete with nut, bolt, and bottom clamp) Type B Clamping Bolt, Nut, and Bottom Clamp

For close mesh Type 11 and Type 9.5 grating, a square collared

This combination allows for fastening grating without drilling

clamping bolt can be inserted directly between the ends of the

into the supports. The Type D Saddle Clip holds the grating

bearing bars and fitted through a bottom clamp. The rounded

from the top as the bottom clamp is tightened under the

bolt head rests directly on the bearing bars eliminating the

flange of the supporting member. Designed for use with

need for a top saddle clip.

Tru-Weld Type 19 and Type 15 bar grating only (in 1/8” and

3/16” bar sizes). Available by special order in bare steel, galvanized, and

stainless steel.

Available in standard galvanized or bare steel and stainless

steel options.

34 NUCOR GRATING > 1-800-334-2047 (USA) • 1-800-268-6277 (Canada) • www.nucorgrating.com

grating fastening methods

molded FRP GRATING PULTRUDED FRP GRATING

FRP Grating Fastening Methods

Molded FRP Clip Assembly Lower Flange Clip Assembly

grating fastening methods

Offers a fastening solution for below-surface attachment

of pultruded grating. Includes FRP Lower Flange Clamp and

hardware. This style of clip should be used in pairs on either

side of the pultruded grating bar being clamped.

Comes complete with a stainless steel top “M” bracket

with nut, bolt, and washer to suit molded FRP style and

depth. When ordering, please specify style of molded FRP

being fastened.

www.nucorgrating.com • 1-800-268-6277 (Canada) • 1-800-334-2047 (USA) < NUCOR GRATING 35

UNITED STATES CANADA

Illinois Ontario

1115 E 5000 N Road ISO 9001-2008 Certified

Bourbonnais, Il 60914 750 Appleby Line

Tel: 1-815-614-2527 PO Box 5025

Burlington, ON L7R 3Y8

Kentucky Tel: 905-632-2121

6900 Houston Road Fax: 905-632-6295

Building 500, #8