Professional Documents

Culture Documents

Pile Foundation: Hindu School of Architecture

Uploaded by

Abhey VermaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pile Foundation: Hindu School of Architecture

Uploaded by

Abhey VermaCopyright:

Available Formats

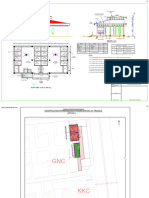

PRODUCED BY AN AUTODESK STUDENT VERSION

NOTE

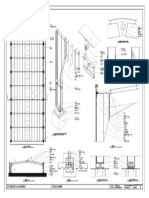

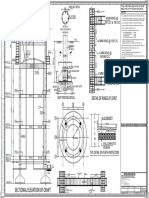

TUBULAR STEEL PILING

RIG ALL DRAWINGS ARE CONCEPTUAL AND MAY DIFFER

VALVE FROM IMAGES

300,350

400 or 450 STEAM OR AIR VALVE

TO OPERATE HAMMER

DRAWING IS NOT TO SCALE AND KINDLY REFER

HELICAL BINDING IN STEEL SHELL BANDS DIMENSIONS AND DETAILS .

EXTRACTING GEAR

HEAD

HEAD OF PILE STEEL MANDREL INSIDE CONCRETE FITTED TO

SHELL TOP OF HAMMER

40 COVER OF CONCRETE

TO MAIN REINFORCEMENT

CASING

PRESSED STEEL STEEL BANDS COATED

5,6 OR 8 LINKS IN BITUMEN AROUND 20 KG HAMMER

FORFOS EVERY 1.5 HAMMER

DROP HAMMER JOINT BETWEEN SHELLS

CONCRETE SHELL

STEEL BANDS COATED

LIFTING HOLE 600 REINFORCEMENT IN BITUME N AROUND

DRIVING HREAD 799,29

FROM HEAD CAGE JOINT BETWEEN

S H E L L S

DRIVING HREAD

20 TO 40 MM DIA BODY OF PILE REBATE FOR HAMMER CASING

REINFORCEMENT STEEL BAND

Section at AA' STEEL SHELL

BANDS

REINFORCED CONCRETE STEEL MANDREL

PRESSED STEEL SHELLS ARE THREADED ON TO INSIDE

FINISHED

FORKS STEEL MANDREL AND RAISED CONCRETE

BETWEEN TUBULAR STEEL SHELL HELMET REINFORCED

GUIDES OF PILING RIG CONCRETE

LIFTING HOLE STEEL MANDREL AND SHELLS INTO GROUND (BLOWS

FROM HAMMER DRIVE)

PILE SUB ECT

400 DIA. STEEL TUBE

BUILDING CONSTRUCTION AND

SPLIT AND TURNED ENDS

STEEL TUBE MATERIAL

65X10 M.S STRAPS CAST

A' A INTO CAST IRON SHOE

BASE OF PILING FRAME

LIFTING HOLE 51

LENGTH OF PILE FROM

TOE

CHILLED CAST IRON SHOE 3 PRO ECT

STEEL MANDREL AND SHELLS INTO GROUND 400 DIAMETER STEEL TUBE

MILD STEEL STRAP (BLOWS FROM HAMMER DRIVE)

CAST IRON SHOE

PILE FOUNDATION

SHOE OF PILE

CAST IRON SHOE

1

CHILLED CAST IRON

SHOE

PRECAST R.C.C. PILE

PILE FOUNDATION END OF TUBE

PRODUCED BY AN AUTODESK STUDENT VERSION

COLLEGE

PRODUCED BY AN AUTODESK STUDENT VERSION

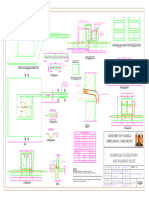

A PILE IS BASICALLY A LONG CYLINDER OF A STRONG MATERIAL SUCH

AS CONCRETE THAT IS PUSHED INTO THE GROUND TO ACT AS A STEADY

PUMP TO SUPPORT FOR STRUCTURE BUILT ON TOP OF IT.PILE FOUNDATIONS ARE

2 E:\(1) B.ARCH\(A) BONAFIDE\logo-image.png

Hindu School of Architecture

OPERATE JACK

EXISTING Sonepat, Haryana

WALL USED IN THE FOLLOWING SITUATIONS:

EXISTING

FOUNDATION

WHEN THERE IS A LAYER OF WEAK SOIL AT THE SURFACE. THIS LAYER

SHORT LENGTH OF BEAM AND

BEARING PLATE TO SPREAD

FOUNDATION IN FOUNDATION

CANNOT SUPPORT THE WEIGHT OF THE BUILDING, SO THE LOADS OF

THE BUILDING HAVE TO BYPASS THIS LAYER AND BE TRANSFERRED TO

DRAWING TITLE

JACK THE LAYER OF STRONGER SOIL OR ROCK THAT IS BELOW THE WEAK

LAYER. PILE FOUNDATION

PILE SECTION BEING JACKED IN

WHEN A BUILDING HAS VERY HEAVY, CONCENTRATED LOADS, SUCH AS DETAIL

IN CONCRETE IS PLACED IN BORING TUBES AND

COMPACTED BY AIR PRESSURE

EXCAVATION

A HIGH RISE STRUCTURE, BRIDGE, OR WATER TANK. MOTAR ANDCABLE SHEAR AIR LINE

PRESSURE

CAP

LEG

STARTER BARS

LENGTH OF STEEL TUBE GROUNTED THERE ARE TWO FUNDAMENTAL TYPES OF PILE FOUNDATIONS (BASED

INTO HOLE TO JOIN PILE SECTION

AIR

ON FUNCTION AND USES), EACH OF WHICH WORKS IN ITS OWN WAY. PRESSURE

HELPS TO

CONCRETE UNDER

SHEET PILE STEEL BARING TUBES

LIFT TUBES

AS

PRESSURE FILLS WEAK

POCKETS OF SUBSOIL

CONCRETE

LOAD BEARING PILE DRIVEN IN A CLAY CUTTER

TAKES OUT SOIL IS

COMPACTED

FRICTION PILE

SOIL COMPACT PILE BORING TUBES

DRIVEN IN A SHELL

STEEL SHOE END BEARING PILE TAKES OUT

GRANULAR SOIL COMPLETED

PILE

WHEN BORING HAS REACHED

REQUIRED DEPTH, REINFORCING

CAGE IS LOWEVED INTO TUBES

PILING FRAME 9.0 TO 16.5M HIGH

CABLE ATTACHED TO CONCRETE COMPACTED UNDER NAME ROLL NO. SEM

TOP OF TUBE HOLD 420 TO 470 O/D AT TUBE

IT IN POSITION

PRESSURE IN PILE BORING ENLARGED TOE FORMED

GAGAN METHIL 14025006024 IX TH

BY CONCRETE

TUBE GRADUALLY

WITHDRAWN AS CONC.

IS HAMMERED IN BORING

BORING TUBE

STEEL TUBE

TUBE DATE 24/07/2018

DRAWN STEEL TUBE SUPPORTED

IN LEADERS OF PILING FRAME

SHEET NO.

REINFORCEMENT LIFTING

CAGE ARM

COMPLETED

REINFORCED PILE

STEEL BORING TUBES

WITH MALE & FEMALE

THREADS ARE

6.0 LONG CYLINDRICAL DROP SCREWED TOGETHER STEEL

CHECKED BY

HAMMER WEIGHING 2000 TO 3000 CUTTING CUTTING

KG TUBE TUBE

HAMMER

BRACE

DROP HAMMER

DROP HAMMER

CIRCULAR CAST IRON CLACK

PLATE HINGES TO OPEN

STIFF CONCRETE UPWARDS TO SHELL RING

WINCH DIESEL MOTOR HAMMERED

ENLARGED TOE

REMARKS

CONCRETE CLAY

REINFORCEMENT

CUTTER

AS PLUG OF GRAVEL IS

HAMMERED INTO GROUND

CAGE

5

FRICTION BETWEEN IT AND

TUBE DRAGS INTO THE GROUND

2 WHILE TUBE IS HELD THE DROP HAMMER

LEAD HOE WITH

CUTTING EDGE IS

BORING TUBE

CLAY

CUTTER SHELL

FORCES PLUG OF GRAVEL OUT OF TUBE TO FILLED TO RING

FORCES PLUG OF GRAVEL OUT OF TUBE TO AND LEAD

FORM AN ENLARGED TOE AND THEN SHIFT LOWEST BORING

FORM AN ENLARGED TOE AND THEN SHIFT SHOE

CONCRETE IS HAMMERED INTO TUBE TUBE

BORED CAST IN PLACE CONCRETE PILE STEEL CUTTING SHOE SCREWED TO

CUTTING TUBE

3

1 600 TO 900 DEEP PLUG OF GRAVEL

BEING COMPACTED IN BOTTOM OF

SHELL CUTTER FOR GRANULAR SOIL

TUBE BY DROP HAMMER 4

PRODUCED BY AN AUTODESK STUDENT VERSION

You might also like

- Water Supply DetailsDocument1 pageWater Supply DetailsUsha CastagneNo ratings yet

- GNC-Bathrooms-PlansDocument2 pagesGNC-Bathrooms-Plansakankshitha.kakinada045No ratings yet

- Proposed four storied residential building planDocument1 pageProposed four storied residential building planMANNANo ratings yet

- TWSDocument1 pageTWSManoj H MNo ratings yet

- Basic Structuraaal-20x30.3Document1 pageBasic Structuraaal-20x30.3Jom Asagra100% (1)

- Plate 1 Portal FrmaesDocument1 pagePlate 1 Portal FrmaesMAHAK GUPTANo ratings yet

- Rly. Platform DrawingDocument1 pageRly. Platform DrawingAtul Kumar MishraNo ratings yet

- New IPCamDocument1 pageNew IPCamChandra KiranaNo ratings yet

- Fire Fighting ModelDocument1 pageFire Fighting ModelPrashantNo ratings yet

- Home electrical plan legend and symbolsDocument1 pageHome electrical plan legend and symbolsMõhâmméd WassimNo ratings yet

- Cross Section at Ch.8700 M: EXST. RAIL LEVEL 163.669Document1 pageCross Section at Ch.8700 M: EXST. RAIL LEVEL 163.669Atul Kumar MishraNo ratings yet

- Produced by An Autodesk Student Version: Open HR Coil StorageDocument1 pageProduced by An Autodesk Student Version: Open HR Coil StorageIT MalurNo ratings yet

- QGTL1 Pro 07 00001 001 - 11Document1 pageQGTL1 Pro 07 00001 001 - 11Muhammad Arham KhalilNo ratings yet

- Engineer Annotations for Key Plan Stretches A and CDocument1 pageEngineer Annotations for Key Plan Stretches A and CSatyanarayana MukkuNo ratings yet

- G 1646 A-5 Stair Section Details May 01 2018Document1 pageG 1646 A-5 Stair Section Details May 01 2018autocadplease6213No ratings yet

- B787-9 VistaraDocument8 pagesB787-9 VistaraSandmanNo ratings yet

- Bef-Floor Plans and ElevationsDocument1 pageBef-Floor Plans and ElevationsbiencvalencerinaNo ratings yet

- Ab ArDocument1 pageAb Ararainzada807No ratings yet

- Ab Arch B124 110Document1 pageAb Arch B124 110arainzada807No ratings yet

- Foundation Offset To ExcavtionDocument1 pageFoundation Offset To ExcavtionAhmed KarimNo ratings yet

- Hopper Guide Plate DWG - RDDocument1 pageHopper Guide Plate DWG - RDRaj KumarNo ratings yet

- USUGAN Package 2 Gen - DrawingDocument1 pageUSUGAN Package 2 Gen - DrawingabigailNo ratings yet

- xb8 2017 Set Up Sheet BasicDocument1 pagexb8 2017 Set Up Sheet BasicFernando ArranzNo ratings yet

- Xb8e 2018 Set Up Sheet v2 EditableDocument1 pageXb8e 2018 Set Up Sheet v2 EditableyasinonnNo ratings yet

- ARCH463P5SCSDocument1 pageARCH463P5SCSJay-r MiñozaNo ratings yet

- 18.detail Standard Fire FightingDocument1 page18.detail Standard Fire FightingMuhammad ArifNo ratings yet

- There Is Only One.: ELEVATION 9,998' ELEVATION 10,026'Document1 pageThere Is Only One.: ELEVATION 9,998' ELEVATION 10,026'Timothy J O'HearnNo ratings yet

- Community Water Point - and Washing PlaceDocument1 pageCommunity Water Point - and Washing PlaceRic ReeNo ratings yet

- SiteDocument1 pageSiteHet lifeNo ratings yet

- Edoc - Pub 938giihydraulicsystemDocument2 pagesEdoc - Pub 938giihydraulicsystemGeobel HernandezNo ratings yet

- Electrical Schematic 750L and 850L CRAWLER: V M P TDocument1 pageElectrical Schematic 750L and 850L CRAWLER: V M P TfeliizzNo ratings yet

- Wa0007Document1 pageWa0007Jonny WijayaNo ratings yet

- Cabana StructuralDocument1 pageCabana StructuralAlsean Soriano DetubioNo ratings yet

- Ground Floor Plan Sheet 2Document1 pageGround Floor Plan Sheet 2riteshNo ratings yet

- Vie Pc01 STN DWG MP Sub 01151 0Document1 pageVie Pc01 STN DWG MP Sub 01151 0Ashish BhartiNo ratings yet

- Bautista - A4Document1 pageBautista - A4Wilfredo MinaNo ratings yet

- 1802 A 423-1 G Toilet Elevation-Type 04Document1 page1802 A 423-1 G Toilet Elevation-Type 04nanieNo ratings yet

- Ejemplo Plano de AlcantarilladoDocument1 pageEjemplo Plano de AlcantarilladoCamila AguilarNo ratings yet

- Mock Room-WashroomDocument1 pageMock Room-Washroomroschcrete 08No ratings yet

- Catwalk Detailed Plan: Sta. Lucia MallDocument1 pageCatwalk Detailed Plan: Sta. Lucia MallJohn Henry AsuncionNo ratings yet

- QAHD Office Building 30 M Structural Plans-S101.0Document1 pageQAHD Office Building 30 M Structural Plans-S101.0Adrian PachecoNo ratings yet

- Schedule of Doors Schedule of WindowsDocument1 pageSchedule of Doors Schedule of WindowsJem CapistranoNo ratings yet

- ADNEC Roller SkatingDocument1 pageADNEC Roller SkatingAkif YazıcıNo ratings yet

- Crif Door Window Detail-601Document1 pageCrif Door Window Detail-601surbhi aggarwalNo ratings yet

- Ilovepdf MergedDocument2 pagesIlovepdf MergedRandolph QuilingNo ratings yet

- Legend:: 09 01 2020 Electrical System Design of A Commercial BuildingDocument1 pageLegend:: 09 01 2020 Electrical System Design of A Commercial BuildingMarkLloydValleNo ratings yet

- Typical reinforced concrete beam detailDocument1 pageTypical reinforced concrete beam detailMARKCHRISTMASNo ratings yet

- A406 -MEP TYPICAL DETAILSDocument1 pageA406 -MEP TYPICAL DETAILSØwięs MØhãmmedNo ratings yet

- Ballasted Track DepotDocument1 pageBallasted Track Depotsahilsharma703No ratings yet

- 17 NDocument1 page17 NSumeet MohantyNo ratings yet

- CBP Wall - DWGDocument1 pageCBP Wall - DWGsambasivammeNo ratings yet

- Harda Front Raft 75klDocument1 pageHarda Front Raft 75klNoor AfshanNo ratings yet

- Notes:: Water Line Gate Valve DetailDocument1 pageNotes:: Water Line Gate Valve DetailDJNo ratings yet

- Alta Prima Conv S-2Document1 pageAlta Prima Conv S-2Ronnel John CruzNo ratings yet

- (Comment) 508-SAR.02-EAR-005 - C - Remedial Hazard Erosion at JL. Gunung PaniDocument1 page(Comment) 508-SAR.02-EAR-005 - C - Remedial Hazard Erosion at JL. Gunung Panifaldo.effendyNo ratings yet

- J3BGDF02BR009 01 05Document1 pageJ3BGDF02BR009 01 05Naheed AkhtarNo ratings yet

- J3BGDF02BR011 01 01Document1 pageJ3BGDF02BR011 01 01saleem naheedNo ratings yet

- J3BGDF02BR010 01 05Document1 pageJ3BGDF02BR010 01 05Naheed AkhtarNo ratings yet

- J3BGDF02BR009 01 01Document1 pageJ3BGDF02BR009 01 01saleem naheedNo ratings yet

- D 5898 - 96Document16 pagesD 5898 - 96Luis LunaNo ratings yet

- Conbextra GPDocument4 pagesConbextra GPMuhammad ShoaibNo ratings yet

- ULPI uPVC Price List June 2017Document12 pagesULPI uPVC Price List June 2017ulpigm100% (1)

- European Standards For Destructive Test MethodsDocument6 pagesEuropean Standards For Destructive Test MethodsAdil HasanovNo ratings yet

- Welding Engineering and Technology by R S ParmarDocument652 pagesWelding Engineering and Technology by R S ParmarMohamed Sohaib100% (5)

- Surface Grinding Process ExplainedDocument4 pagesSurface Grinding Process ExplainedyowiskieNo ratings yet

- 1 57Document23 pages1 57Ricardo Argentton FicanhaNo ratings yet

- Product Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'wangshengfffNo ratings yet

- Major Mineral Reserves Around The WorldDocument18 pagesMajor Mineral Reserves Around The WorldWalter Mijael Canchari ZuñigaNo ratings yet

- Zurn Z886 6-1/4Document1 pageZurn Z886 6-1/4Enak CenirNo ratings yet

- LG AHU CatalogueDocument48 pagesLG AHU CatalogueKiran Kumar Nethrakere/EMD/UAENo ratings yet

- Steel Melting ShopDocument6 pagesSteel Melting ShopsamrezviNo ratings yet

- Piers Catalog 2018 Ver1Document68 pagesPiers Catalog 2018 Ver1ashutosh sharmaNo ratings yet

- Complete Work As Per The DrawingDocument31 pagesComplete Work As Per The DrawingDawit SolomonNo ratings yet

- The Reinforced Concrete Beam Deflection and Cracking Behavior With Additional Fiber SteelDocument5 pagesThe Reinforced Concrete Beam Deflection and Cracking Behavior With Additional Fiber SteelNamaku AndaNo ratings yet

- Piers PDFDocument3 pagesPiers PDFmahmoud elkhedrNo ratings yet

- Cable Gland Selection GuideDocument15 pagesCable Gland Selection GuideProcurement PardisanNo ratings yet

- Welding Before HDG - American Galvanizers AssociationDocument2 pagesWelding Before HDG - American Galvanizers AssociationRicardo MurgaNo ratings yet

- PHP PIPE SUPPORT SOLUTIONSDocument119 pagesPHP PIPE SUPPORT SOLUTIONSAaron EasleyNo ratings yet

- Krayushkina 2019 IOP Conf. Ser. Mater. Sci. Eng. 708 012088Document10 pagesKrayushkina 2019 IOP Conf. Ser. Mater. Sci. Eng. 708 012088Kristophe WatsonNo ratings yet

- Lining OK Card Lot 05 21.02.2017Document2 pagesLining OK Card Lot 05 21.02.2017Pratik PaulNo ratings yet

- Soluble Silicates in Refractory MixturesDocument6 pagesSoluble Silicates in Refractory MixturesnameNo ratings yet

- 11e411 1Document44 pages11e411 1Sai GowthamNo ratings yet

- 1 Level:: 2.1 Material PropertiesDocument7 pages1 Level:: 2.1 Material PropertiesAkhmad Syibli HusniNo ratings yet

- BladderDocument18 pagesBladderpsNo ratings yet

- Pile Capacity TableDocument1 pagePile Capacity TablepapaNo ratings yet

- Dissolves Marine Growth Calcium Rust Mussels SafelyDocument2 pagesDissolves Marine Growth Calcium Rust Mussels SafelyIvan TonjaNo ratings yet

- Exolit AP 740, AP 750 (F (EXOLITAP) GB)Document2 pagesExolit AP 740, AP 750 (F (EXOLITAP) GB)Maximiliano MackeviciusNo ratings yet

- MSS SP 54 Radiographic Examination MethodDocument9 pagesMSS SP 54 Radiographic Examination MethodSunil Kumar100% (1)