Professional Documents

Culture Documents

Kawasaki

Uploaded by

vdunlevyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kawasaki

Uploaded by

vdunlevyCopyright:

Available Formats

The World Best Performance

Electrical Efficiency 49%

NOx (at O2=0%) ≦ 200 ppm

Gas Engine

Electric power

5.0 - 7.5 MW (60Hz)

●Engine Lineup

5.2 - 7.8 MW (50Hz)

Standard Model High Efficiency Model

Engine model KG-12 KG-18 KG-12-V KG-18-V

No. of cylinders 12 18 12 18

Cylinder bore×Stroke (mm) 300 × 480

Electric 50Hz/750rpm 5,200 7,800 5,200 7,800

output(kW) ※1 60Hz/720rpm 5,000 7,500 5,000 7,500

Efficiency at generator terminal (%) ※2 48.5 49.0

NOx (ppm) 200 or less (at O2=0%)【 57 or less(at O2=15%) equivalent 】

Ignition system Spark plug ignition

Min. continuous operation load (%) ※3 35

Starting time ※4 within 10 min

Lube oil consumption less than 0.4g/kWh (as nominal data)

Exhaust Exhaust

Bypass System gas Air Variable Nozzle System gas Air

Bypass

Variable nozzle

Engine feature

Turbo- Turbo-

charger charger

Note ※1 ISO3046, Fuel:Standard gas in Japan (LHV:40.6MJ/Nm 3)

※2 Gas Methane Number shall be more than 65.

※3 30 ∼ 35% load is also operatable with time limitation 95 hour.

※4 From start order to rated load.

KAWASAKI GREEN GAS ENGINE

Typical Applications

Type 1 Power Generation Type 2 Power + Steam + Hot Water Generation

Exhaust Gas HRB Steam

Electric Electric

Fuel Gas Power Fuel Gas Power

Hot

Water

High Temp. water

Type 3 Power + Huge Steam Generation Type 4 Power + Hot Water or Chilled Water Generation

Steam HRB Hot

Exhaust Gas HRB Exhaust Gas Water

(winter)

Electric Electric

Fuel Gas Power Fuel Gas Power

Hot

water

One Through Chiller Chilled

Boiler Water

High Temp. water High Temp. water

(summer)

*HRB : Heat Recovery Boiler

Engine Outline KG-18

3,327 mm (3,204 mm) 13,687 mm (11,787 mm)

5,717 mm (4,988 mm)

Dry weight : 138 ton (104 ton)

Figure in bracket shows dimension of KG-12. Same dimension for Standard and High efficiency models.

・High partial load efficiency 30∼35%:With time limitation

・Wide power output range 35%∼ :With continuous operation GAS TURBINE & MACHINERY COMPANY

50 ENERGY SOLUTION DIVISION

Electrical Efficiency (%)

http://www.khi.co.jp

Tokyo Head Office

40 1-14-5, Kaigan, Minato-ku, Tokyo 105-8315, Japan

Phone: +81-3-3435-2211 Fax: +81-3-3435-2022

E-mail: green-ge-sales@khi.co.jp

30

30 40 50 60 70 80 90 100

Engine Load (%)

Cat. No.3G2613 May ’ 13 M

Printed in Japan

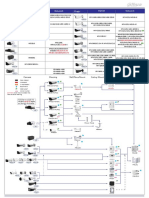

110MW Nihon Techno Sodegaura Green Power ■Plant outline < Total site area : 12,430.24 m2 (3.07acre) >

Plant N No.1 Gas Engine Building

■Project Description No.2 Gas Engine Building (7 units of KG-18-V)

(7 units of KG-18-V)

Kawasaki was awarded a full turnkey contract in October 2011 to construct a power plant for

Sodegaura Green Power. Its owner is Nihon Techno Co., Ltd., which is PPS*, a power Radiators

producer and supplier. This 110MW power plant consists of 14 Kawasaki Green Gas 66kV High Voltage

Switch Yard

Engines.

*PPS, a power producer and supplier, is defined under Japanese law as a type of independent electric

power company that produces over 50kW of high-voltage electricity and supplies it to high-voltage

electricity consumers such as factories and large-scale retail stores via the power grids of utility

companies. Common Lubrication Oil Tank

& Pump Room

■Overview

Plant Name: Nihon Techno Sodegaura Green Power Plant Common Urea Tank & De-NOx

System Control Room

Owner: Nihon Techno Co., Ltd.

Location: Sodegaura city, Chiba prefecture, Japan 1F : Electric Equipment Room

Background: The electricity sold by Nihon Techno has been obtained 2F : Office & Operation Room

Stepup Transformer Yard

externally through the electric power exchange market.

Nihon Techno, however, decided to construct its own Exhaust Gas Stack

Each Engine Configuration

110MW power plant with an eye to securing a Silencer For With Silencer

Sodegaura City Ventilation

stable supply of electricity in light of the (Abt. 40 km from Tokyo)

recent supply status where we are facing

Ventilation Air

the electricity shortage expected since the Intake Room

Gas Engine Building De-NOx

Great Earthquake disaster on Mar. 11, 2011. Reactor

■Plant Configurations & Features

Configuration

about 32 feet

about 10 m

Engine Type KG-18-V (Rated Gross Output 7,800 kw) Crane

Gross Electrical Output 109.2 MW (7.8 MW × 14 units)

Gross Electrical Efficiency 49.0%

Plant Operation Features 5 good points realize the outstanding flexible power plant.

It is possible to operate continuously for 24 hours a day, 7 days a week with 14 units. Gas Engine

Pump Unit For

Optimized DSS (Daily Start And Stop) operation by each individual unit. Cable Pit Individual Unit

■Picture Gallery

Fast start-up - less than 10 min. to full plant load.

Under construction

Gross electrical efficiency is kept at about 49% almost in the range of 7.8MW - 109.2MW. Unloading from barge Traverse by roller Settle to the position

Individual maintenance can be performed one unit at a time leaving the other 13 units running,

and power reduction can be kept at only 7.2% (1/14).

■Scope of Supply & Schedule

Kawasaki's scope of supply and project schedule are as follows.

No.1 Gas Engine Building / No.2 Gas Engine Building / Office & Electric Building De-NOx System

Civil Engineering and

Control Room / L.O. Pump Room / Cable Culvert Radiator & Trance Foundation / Exterior Works &

Construction Completed

Temporal Works

Transportation and Installation / Gas Engine Generator Packages & All Related Auxiliaries With All

Machinery Equipment

Pipe works

Electrical Equipment Step-up Transformer (11kV / 66kV) / High & Low Voltage Switchgear Control Panel / All Wiring Works

Construction Period: December 19, 2011 - August 15, 2012

Works Oct./2011 Nov. Dec. Jan./2012 Feb. Mar. Apr. May Jun. Jul. Aug.

Planning & Designing

Civil & Architecture Work

Machine Installation

Pipework

Electrical Work

Commissioning No.1 Gas Engine Building Exterior

You might also like

- Thermodynamic Challenges of High BMEP Medium Speed Gas EnginesDocument16 pagesThermodynamic Challenges of High BMEP Medium Speed Gas EnginespauloNo ratings yet

- Press-T G Ts0038uk03Document20 pagesPress-T G Ts0038uk03Berhanu GebreyohannesNo ratings yet

- Turbine FactsheetDocument13 pagesTurbine Factsheetsatz555No ratings yet

- Brochure MT333 FlexEnergy-1Document2 pagesBrochure MT333 FlexEnergy-1kemas biruNo ratings yet

- Weifang Haitai Power Machinery Co.,Ltd: To Be The Best Partner For PowerDocument4 pagesWeifang Haitai Power Machinery Co.,Ltd: To Be The Best Partner For PowerShaina OrnopiaNo ratings yet

- Deutz, TBG 616 K (323 - 700 KW)Document4 pagesDeutz, TBG 616 K (323 - 700 KW)Dexterous EngineeringNo ratings yet

- RIELLO P en RGDDocument10 pagesRIELLO P en RGDReggie HarvirNo ratings yet

- 380V-11kV Diesel Generator Set with Low Fuel ConsumptionDocument5 pages380V-11kV Diesel Generator Set with Low Fuel ConsumptionMahmudur RahmanNo ratings yet

- Burner Selection Chart 2021 2022Document1 pageBurner Selection Chart 2021 2022Hydel & Thermal PP S&MNo ratings yet

- Material Turbina A GásDocument47 pagesMaterial Turbina A GásGetúlio RibeiroNo ratings yet

- Gas Turbine Range OverviewDocument2 pagesGas Turbine Range Overviewyourikats6161No ratings yet

- MTU 16V4000 DS2500 Generator Set for 380V PowerDocument6 pagesMTU 16V4000 DS2500 Generator Set for 380V Powermohsen_cumminsNo ratings yet

- Pramac BrochureDocument8 pagesPramac BrochureAllen 艾倫 EgarNo ratings yet

- 1b Technical Description - JMS 320C47 11barDocument11 pages1b Technical Description - JMS 320C47 11barRyan Meta PratamaNo ratings yet

- Diesel Generating Set BF-C395-60: Standby Power 60Hz Prime Power 60HzDocument5 pagesDiesel Generating Set BF-C395-60: Standby Power 60Hz Prime Power 60Hzkevindelmonte1996No ratings yet

- File CtaDocument20 pagesFile Ctathibault martinNo ratings yet

- 4008TESI HC Spark Gas Electrounit Tech DataDocument6 pages4008TESI HC Spark Gas Electrounit Tech Datadwi monikaNo ratings yet

- Recommended accessories and advantages of stationary natural gas enginesDocument2 pagesRecommended accessories and advantages of stationary natural gas enginesDan StroescuNo ratings yet

- Jual Burne FBR GasDocument2 pagesJual Burne FBR GasHabibie BoilerNo ratings yet

- IBG.U.253 Rev0 127WS60 3phase 220VDocument6 pagesIBG.U.253 Rev0 127WS60 3phase 220VMohamed ShafeeqNo ratings yet

- GCC 1650 enDocument6 pagesGCC 1650 enEduardo VicoNo ratings yet

- Cummins c1675 d5 Spec Sheet With Kta50 Specs Appended Ado PDFDocument3 pagesCummins c1675 d5 Spec Sheet With Kta50 Specs Appended Ado PDFAdil Elyousfaoui100% (1)

- Nominal Performance: Hermetic Compressor Model: La 5590exg BOM ID: 016-A0Document1 pageNominal Performance: Hermetic Compressor Model: La 5590exg BOM ID: 016-A0Zikko FirmansyahNo ratings yet

- JMS-320 GS NL (1065kw)Document4 pagesJMS-320 GS NL (1065kw)Dexterous EngineeringNo ratings yet

- PG Spec 16V4000DS2500 2360kVA 3F NEA 50HzDocument5 pagesPG Spec 16V4000DS2500 2360kVA 3F NEA 50HzYousefNo ratings yet

- EXH-200-07 Boiler SpecificationsDocument3 pagesEXH-200-07 Boiler SpecificationsSuresh ArsNo ratings yet

- Max GasDocument12 pagesMax GasGuillermo E.No ratings yet

- Riello Rls M MX Ts0064uk03 Rev1Document32 pagesRiello Rls M MX Ts0064uk03 Rev1weweqweqwNo ratings yet

- KA-5560EXG-032-A0Document1 pageKA-5560EXG-032-A0loayradwan12No ratings yet

- InTech-Micro Gas TurbinesDocument26 pagesInTech-Micro Gas Turbinesntik 23No ratings yet

- PRESS G_TS0037UK01Document16 pagesPRESS G_TS0037UK01Jacki FirdausNo ratings yet

- J 312Document4 pagesJ 312shahzad 28390% (1)

- CmaiDocument17 pagesCmaiharvin95No ratings yet

- GCC 900 enDocument6 pagesGCC 900 enEduardo VicoNo ratings yet

- Rolls Royce Gas Engine of 5.255 MWDocument1 pageRolls Royce Gas Engine of 5.255 MWRashid Mahmood0% (1)

- GP25 Generator Technical Data SheetDocument6 pagesGP25 Generator Technical Data Sheetmiguelvl25No ratings yet

- 210923-HL-ClassFactSheet-05-pdf - Original FileDocument2 pages210923-HL-ClassFactSheet-05-pdf - Original Filejohnward19951995No ratings yet

- TM820TDocument4 pagesTM820Tdargom salamanNo ratings yet

- Catalogue Generator 12v4000ds1650Document5 pagesCatalogue Generator 12v4000ds1650Trung TrầnNo ratings yet

- JMS 420 GS-N.L: Technical SpecificationDocument4 pagesJMS 420 GS-N.L: Technical SpecificationАлександр ПедашNo ratings yet

- Baifac825v 50 eDocument5 pagesBaifac825v 50 ekoko blueNo ratings yet

- IBG.T.145 Specs 220V 60Hz 150W60 150WS60 Rev1-1Document6 pagesIBG.T.145 Specs 220V 60Hz 150W60 150WS60 Rev1-1Mohamed ShafeeqNo ratings yet

- Mtu 20V4000 DS4000: Diesel Generator SetDocument15 pagesMtu 20V4000 DS4000: Diesel Generator SetSlick72No ratings yet

- Steam Turbine Performance FactorsDocument93 pagesSteam Turbine Performance FactorsMas Zuhad100% (1)

- Diesel Generating Set BF-C825-60: Standby Power 60Hz Prime Power 60HzDocument5 pagesDiesel Generating Set BF-C825-60: Standby Power 60Hz Prime Power 60Hzkevindelmonte1996No ratings yet

- B4 Engine Range B4AF40 Operation DatasheetDocument3 pagesB4 Engine Range B4AF40 Operation DatasheetTruong NguyenNo ratings yet

- Energy Consumption Breakdown of An Industrial Plant Is Given Below: Measured Data For Existing Chiller SystemsDocument2 pagesEnergy Consumption Breakdown of An Industrial Plant Is Given Below: Measured Data For Existing Chiller SystemsMeriem NguirNo ratings yet

- Performance Observations Plate 70603-40 Page 1 (2) : SuhvvDocument2 pagesPerformance Observations Plate 70603-40 Page 1 (2) : SuhvvMax MaksNo ratings yet

- Janbacher 312 MergedDocument10 pagesJanbacher 312 MergedБогдан СендецькийNo ratings yet

- JMS 320 GS-B.L: Jenbacher Gas EnginesDocument4 pagesJMS 320 GS-B.L: Jenbacher Gas EnginesSergioNo ratings yet

- N67te8w 250kvaDocument3 pagesN67te8w 250kvaOGNo ratings yet

- BF C688 60 E GeneratorDocument5 pagesBF C688 60 E GeneratorJb CabaloNo ratings yet

- Motordatenblatt MTU 12V4000G63 PDFDocument2 pagesMotordatenblatt MTU 12V4000G63 PDFTaz UddinNo ratings yet

- Ecoflam MAX GAS 250Document11 pagesEcoflam MAX GAS 250Pattaravoot SutiphanNo ratings yet

- Ae 2420ZK 301 A0Document1 pageAe 2420ZK 301 A0Adam NabawiNo ratings yet

- 513203001... E-FFU160HAX (L - MBP) - DatasheetDocument5 pages513203001... E-FFU160HAX (L - MBP) - Datasheetdesenvolvimento appNo ratings yet

- BP400 Diesel Generating Set: Standby Power 50Hz Prime Power 50HzDocument5 pagesBP400 Diesel Generating Set: Standby Power 50Hz Prime Power 50HzAlwinNo ratings yet

- Natural Gas Conversion Guide PDFDocument52 pagesNatural Gas Conversion Guide PDFTinuoye Folusho OmotayoNo ratings yet

- AppleTV SetupGuideDocument40 pagesAppleTV SetupGuideVanessa ReyesNo ratings yet

- Welcome. You're Watching Apple TV.: This Guide Contains All The Information You Need To Get From Setup To Your SofaDocument36 pagesWelcome. You're Watching Apple TV.: This Guide Contains All The Information You Need To Get From Setup To Your SofaJhonis E. Bermudez de ArmasNo ratings yet

- Fewa Earthing SystemDocument7 pagesFewa Earthing SystemPaul HastieNo ratings yet

- LCOE SolarPaperDocument7 pagesLCOE SolarPapervdunlevyNo ratings yet

- Cat StandarPowerModuleDocument6 pagesCat StandarPowerModulevdunlevyNo ratings yet

- Himsen: Engine EngineDocument42 pagesHimsen: Engine Enginevdunlevy0% (1)

- Gravel Roads Maintenance and Design ManualDocument104 pagesGravel Roads Maintenance and Design ManualBruben Jerome BellsNo ratings yet

- Gravel Roads Maintenance and Design ManualDocument104 pagesGravel Roads Maintenance and Design ManualBruben Jerome BellsNo ratings yet

- GPS and The Quest For Pizza: National Aeronautics and Space AdministrationDocument1 pageGPS and The Quest For Pizza: National Aeronautics and Space Administrationvijay maddiNo ratings yet

- Products and Services For Consumers: True / False QuestionsDocument65 pagesProducts and Services For Consumers: True / False QuestionsThúy HiềnNo ratings yet

- Ampersand MenuDocument5 pagesAmpersand MenuJozefNo ratings yet

- Sample Field Trip ReportDocument6 pagesSample Field Trip ReportBILAL JTTCNo ratings yet

- History: Ludwig Hunger: About Us: Home - Ludwig Hunger GMBHDocument3 pagesHistory: Ludwig Hunger: About Us: Home - Ludwig Hunger GMBHPatrizio MassaroNo ratings yet

- Fatigue Life Prediction of A320-200 Aileron Lever Structure of A Transport AircraftDocument4 pagesFatigue Life Prediction of A320-200 Aileron Lever Structure of A Transport AircraftMohamed IbrahimNo ratings yet

- Navmesh Plus: How ToDocument7 pagesNavmesh Plus: How TobladimirNo ratings yet

- Cutter Wheel - H1140Document4 pagesCutter Wheel - H1140Sebastián Fernando Canul Mendez100% (2)

- BMW Mini COoper Installation InstructionsDocument1 pageBMW Mini COoper Installation InstructionsEdiJonNo ratings yet

- 366 Community Service IdeasDocument5 pages366 Community Service IdeasAhmetYılmazVuralNo ratings yet

- Coloi Eeml Disease: Original ArticlesDocument67 pagesColoi Eeml Disease: Original ArticlesLuisAngelPonceTorresNo ratings yet

- District: Surkhet: PopulationDocument13 pagesDistrict: Surkhet: PopulationkarunNo ratings yet

- Chemistry 12: Provincial ExaminationDocument25 pagesChemistry 12: Provincial ExaminationCát TriệuNo ratings yet

- Appendix C: Time Value of MoneyDocument15 pagesAppendix C: Time Value of MoneyrockerNo ratings yet

- PepsicoDocument18 pagesPepsicorahil virani0% (1)

- POLIOMYELITISDocument26 pagesPOLIOMYELITISIzhra Margate100% (1)

- Dahua Pfa130 e Korisnicko Uputstvo EngleskiDocument5 pagesDahua Pfa130 e Korisnicko Uputstvo EngleskiSaša CucakNo ratings yet

- Personality Types and Character TraitsDocument5 pagesPersonality Types and Character TraitspensleepeNo ratings yet

- Arta Fridei Kahlo A Fost Intotdeauna o ReactieDocument13 pagesArta Fridei Kahlo A Fost Intotdeauna o ReactieAlta DaianNo ratings yet

- Analysis of Financial Statements Project: GUL AHMAD Textile MillsDocument32 pagesAnalysis of Financial Statements Project: GUL AHMAD Textile MillsHanzala AsifNo ratings yet

- Anxiolytics Sedatives Hypnotics Pharm 3Document38 pagesAnxiolytics Sedatives Hypnotics Pharm 3Peter Harris100% (1)

- Electrical EngineerDocument3 pagesElectrical Engineer12343567890No ratings yet

- High Risk Medications in AyurvedaDocument3 pagesHigh Risk Medications in AyurvedaRaviraj Pishe100% (1)

- 4thinternationalconferencetheimportanceofplace Proceedings 2017 PDFDocument428 pages4thinternationalconferencetheimportanceofplace Proceedings 2017 PDFnerko86No ratings yet

- 19 - Speed, Velocity and Acceleration (Answers)Document4 pages19 - Speed, Velocity and Acceleration (Answers)keyur.gala100% (1)

- 500 Important Spoken Tamil Situations Into Spoken English Sentences SampleDocument7 pages500 Important Spoken Tamil Situations Into Spoken English Sentences SamplerameshdurairajNo ratings yet

- Kingspan Spectrum™: Premium Organic Coating SystemDocument4 pagesKingspan Spectrum™: Premium Organic Coating SystemNikolaNo ratings yet

- DGPS Sensor JLR-4331W Instruction ManualDocument42 pagesDGPS Sensor JLR-4331W Instruction ManualantonioNo ratings yet

- Semen RetentionDocument3 pagesSemen RetentionMattNo ratings yet

- CH 10Document125 pagesCH 10Lisset Soraya Huamán QuispeNo ratings yet