Professional Documents

Culture Documents

F Opt Opgwdno 6417-1

Uploaded by

gercubOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

F Opt Opgwdno 6417-1

Uploaded by

gercubCopyright:

Available Formats

PO Box 3127

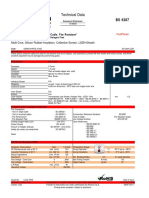

Specification DNO-6417

Spartanburg, SC 29304

Tel: 1 800 235 3423 MiniCore Optical Ground Wire

Fax: 1 864 433 5560

MC-102/41/626

Component Details

Component # OD Area

CENTER

Stainless Steel Tube 1 3.60 mm 0.1417 in 2.14 mm² 0.0033 in²

LAYER 1 - RIGHT HAND LAY

Aluminum Clad Steel (20.3% IACS) 4 3.60 mm 0.1417 in 40.72 mm² 0.0631 in²

Aluminum Alloy 6201 2 3.60 mm 0.1417 in 20.36 mm² 0.0316 in²

LAYER 2 - LEFT HAND LAY

Aluminum Alloy 6201 16 2.55 mm 0.1004 in 81.71 mm² 0.1267 in²

Standards

Designed and Manufactured in accordance with the following:

Cable IEEE 1138, IEC 60794-4

Fiber IEC 60793, ITU-T G.65x Series

Color Code ANSI/EIA 359-A, 598-A, IEC 60304

Stainless Steel Tubes ASTM A240, ASTM A632

Aluminum Alloy Wires ASTM B398, IEC 60104

Aluminum Clad Steel Wires ASTM B415

DNO-6417 10/18/2006 Version 18.0 Page 1 - 5

Printed on 8/31/2009

Specification DNO-6417

Mechanical / Electrical Details

Calculated Breaking Load 8,152 kg 17,972 lbs

Maximum Cable Design Tension 6,110 kg 13,470 lbs

Approximate Cable Diameter 15.90 mm 0.626 in

Total Cross-Sectional Area 144.92 mm² 0.2246 in²

Approximate Cable Weight 577 kg/km 2,047 lbs/mile

Modulus of Elasticity 9,413 kg/mm² 13,388 kpsi

Coefficient of Linear Expansion 1.79E-05 1/°C 9.97E-06 1/°F

Sag10™ Chart Number 1-1441 1-1441

Calculated DC Resistance (20°C) 0.2830 Ohms/km 0.4555 Ohms/mile

Short Circuit Rating 196 (kA)²•sec 196 (kA)²•sec

Short Circuit Ambient Temperature 40 °C 104 °F

Short Circuit Duration 1 sec 14.0 kA 14.0 kA

Short Circuit Max Cable Temperature 200 °C 392 °F

Optical Details

Attenuation Characteristics for ITU-T G.652 Single-mode Fiber

Max Individual

0.34 dB/km 1310 nm

0.22 dB/km 1550 nm

3.6mm Stainless Steel Tube Design Fiber

Unit Fiber Type Count

Tube 1 ITU-T G.652 Single-mode 24

Total Fiber Count 24

Standard Fiber Color Code

Fiber 1 2 3 4 5 6 7 8 9 10 11 12

Color Blue Orange Green Brown Slate White Red Black Yellow Violet Rose Aqua

Designs with more than 12 fibers per tube will use the standard color code and binders for identification of the fibers.

Installation and Handling Recommendations

Installation and cable preparation procedures are outlined in the AFL Telecommunications documents

listed below. Contact AFL to request copies.

Recommended Installation Procedures for Composite Optical Ground Wire

Installation Instructions for Installing Optical Ground Wire in an AFL Telecommunications Splice Enclosure

Fiber Optic Cable Receiving, Handling and Storage. Document ACS-WI-809

DNO-6417 10/18/2006 Version 18.0 Page 2 - 5

Printed on 8/31/2009

Specification DNO-6417

Quick Reference Installation Notes

Approximate Cable Diameter 15.90 mm 0.626 in

Maximum Stringing Tension (at tensioner)* 1,630 kg 3,594 lbs

Minimum Bull Wheel Diameter 112 cm 44 in

Stringing Sheave Diameter** 64 cm 25 in

Minimum Bending Radius

Cable

Static (No load) 24 cm 10 in

Dynamic (under tension) 32 cm 13 in

Fiber

Static (No load) 3.8 cm 1.5 in

Stainless Steel Tube

Static (No load) 16.2 cm 6.4 in

* - The stringing tension is always measured at the tensioner side. In general the maximum stringing

tension should be approximately half of the maximum sagging tension and should never exceed

20% RBS of the OPT-GW.

** - The value indicated is for the first and last structures of the pull and is based on 40 times the

diameter of the OPT-GW. Smaller diameters can be used at tangent structures. Reference AFL's

installation instructions for more details.

Reference AFL's "Recommended Installation Procedures for Composite Optical Ground Wire" for

detailed installation instructions.

Shipping Reels

Reel FL TR DR OW Tare FL TR DR OW Tare Capacity

Type (cm) (kgs) (in) (lbs) (meters) (feet)

Wood 147 81 71 97 200 58 32 28 38 441 3,470 11,380

Wood 168 91 91 107 260 66 36 36 42 573 4,660 15,280

Wood 183 91 91 107 300 72 36 36 42 662 5,890 19,320

Wood 213 86 89 104 385 84 34 35 41 849 5,890 19,320

Steel 152 81 81 97 345 60 32 32 38 761 3,440 11,280

Steel 183 91 102 107 540 72 36 40 42 1,191 5,540 18,170

Steel 213 114 107 130 773 84 45 42 51 1,704 5,890 19,320

FL - Flange Diameter; TR - Inside Traverse Width; DR - Drum Diameter; OW - Outside Overall Width

Arbor Hole Diameter: Wood: 3-1/4in (7.9cm)

Steel: 3in (7.6cm)

Maximum lengths shown are the longest lengths that AFL offers. Longer lengths may be possible.

Ordered lengths should include a distribution of lengths, i.e., all reels cannot be ordered at the maximum.

A typical reel length distribution is as follows:

6000m – 7000m ~ 15% of reels

4500m – 6000m ~ 55% of reels

2500m – 4500m ~ 25% of reels

<2500m ~ 5% of reels

Wood reels with flex-wrap covering are standard. Non-returnable steel reels and/or wood lagging are

available upon request. Additional reel sizes may be available upon request.

Steel reels are recommended for long term storage. Reference AFL's "Fiber Optic Cable Receiving,

Handling and Storage" document for additional information.

DNO-6417 10/18/2006 Version 18.0 Page 3 - 5

Printed on 8/31/2009

Specification DNO-6417

Electrical Characteristics

Composite DC Resistance [20°C] 0.2830 Ohms/km 0.4555 Ohms/mile

Geometric Mean Radius 0.62 cm 0.0203 feet

Inductive Reactance [60 Hz frequency] 0.2938 Ohms/km 0.4728 Ohms/mile

[one foot (0.3048 meter) spacing]

[50 Hz frequency] 0.2448 Ohms/km 0.3940 Ohms/mile

Capacitive Reactance [60 Hz frequency] 0.1741 MOhms·km 0.1082 MOhms·mile

[one foot (0.3048 meter) spacing]

[50 Hz frequency] 0.2089 MOhms·km 0.1298 MOhms·mile

Composite Coefficient of Thermal Resistance 0.00351 (1/°C)

Temperature DC Resistance AC Resistance

(°C) (°F) (Ohms/km) (Ohms/mile) (Ohms/km) (Ohms/mile)

20 68 0.2830 0.4555 0.2887 0.4646

25 77 0.2880 0.4635 0.2938 0.4727

30 86 0.2930 0.4715 0.2988 0.4809

35 95 0.2979 0.4795 0.3039 0.4890

40 104 0.3029 0.4874 0.3089 0.4972

45 113 0.3079 0.4954 0.3140 0.5053

50 122 0.3128 0.5034 0.3191 0.5135

55 131 0.3178 0.5114 0.3241 0.5216

60 140 0.3227 0.5194 0.3292 0.5298

65 149 0.3277 0.5274 0.3343 0.5379

70 158 0.3327 0.5354 0.3393 0.5461

75 167 0.3376 0.5434 0.3444 0.5542

80 176 0.3426 0.5514 0.3495 0.5624

85 185 0.3476 0.5594 0.3545 0.5705

90 194 0.3525 0.5673 0.3596 0.5787

95 203 0.3575 0.5753 0.3646 0.5868

100 212 0.3625 0.5833 0.3697 0.5950

105 221 0.3674 0.5913 0.3748 0.6031

110 230 0.3724 0.5993 0.3798 0.6113

115 239 0.3774 0.6073 0.3849 0.6194

120 248 0.3823 0.6153 0.3900 0.6276

125 257 0.3873 0.6233 0.3950 0.6357

130 266 0.3923 0.6313 0.4001 0.6439

135 275 0.3972 0.6393 0.4052 0.6520

140 284 0.4022 0.6473 0.4102 0.6602

145 293 0.4071 0.6552 0.4153 0.6683

150 302 0.4121 0.6632 0.4204 0.6765

DNO-6417 10/18/2006 Version 18.0 Page 4 - 5

Printed on 8/31/2009

Specification DNO-6417

PLS-CADD Inputs

Use simplified elastic cable model (no creep, no coefficient)

Name

Description AFL OPGW DNO-6417 MC-102/41/626

Cross section area (in^2) 0.2246 Unit weight (lbs/ft) 0.388

Number of independent wires 1

Outside diameter (in) 0.626 Ultimate tension (lbs) 17,972

(above should be 1 unless cables

Temperature at which strand data below obtained (deg F) 73 are separated by spacers)

Outer Strands Core Strands (if different from outer strands)

Final Modulus of elasticity (psi/100) 130000 Final Modulus of elasticity (psi/100)

Thermal expansion coeff. (/100 deg) 0.001000 Thermal expansion coeff. (/100 deg)

Polynomial coefficients (all strains in %) Polynomial coefficients (all strains in %)

A0 A1 A2 A3 A4 A0 A1 A2 A3 A4

Stress-strain 117.6 44000.5 489072 -1342969 1119215 Stress-strain

Creep 631.8 60923.3 63703.5 -171879 119846 Creep

Thermal Rating Properties

Resistance at two different temperatures Emissivity coefficient 0.5

Resistance (Ohm/mile) 0.4635 at (deg F) 77 Solar absorption coefficient 0.5

Resistance (Ohm/mile) 0.5434 at (deg F) 167

* Outer strands heat capacity (Watt-s/ft-deg F)

* Core heat capacity (Watt-s/ft-deg F)

Generate Coefficients from points on stress-strain OK Cancel

* These two fields do not need to be entered for OPGW - intentionally left blank.

DNO-6417 10/18/2006 Version 18.0 Page 5 - 5

Printed on 8/31/2009

You might also like

- An Introduction To ElectronicsDocument269 pagesAn Introduction To ElectronicsParas JainNo ratings yet

- Specs ZTT OPGW 24 Fibers PDFDocument9 pagesSpecs ZTT OPGW 24 Fibers PDFVictor DoyoganNo ratings yet

- Diagrama Eléctrico de Cargador Compacto 906Document2 pagesDiagrama Eléctrico de Cargador Compacto 906Claudio Jofre Gordillo100% (1)

- Cobham FiltersDocument168 pagesCobham Filtershozra100% (1)

- Study On The Jamming To Synthetic Aperture RadarDocument4 pagesStudy On The Jamming To Synthetic Aperture Radarapi-19919509No ratings yet

- Vortx Vibration Damper - En-Ss-1004-2 PDFDocument4 pagesVortx Vibration Damper - En-Ss-1004-2 PDFgercubNo ratings yet

- Vortx Vibration Damper - En-Ss-1004-2 PDFDocument4 pagesVortx Vibration Damper - En-Ss-1004-2 PDFgercubNo ratings yet

- Brosur CcsiDocument38 pagesBrosur CcsiTyrion LannisterNo ratings yet

- Caract Tecnicas Opgw Lsgs-11-Po0186 24sDocument4 pagesCaract Tecnicas Opgw Lsgs-11-Po0186 24sKamal ArreazaNo ratings yet

- Chapter 09 AC Editor ETAPDocument29 pagesChapter 09 AC Editor ETAPfchuecoNo ratings yet

- ZTT Et Expressway Tacsr'Aw TW Conductor 22 - Xj10296Document5 pagesZTT Et Expressway Tacsr'Aw TW Conductor 22 - Xj10296Benjamin SalinasNo ratings yet

- Iecex Ine 11.0006XDocument15 pagesIecex Ine 11.0006XFrancesco_CNo ratings yet

- 2.3 Cable de Guardia - OPGW SPEC (15-53931)Document9 pages2.3 Cable de Guardia - OPGW SPEC (15-53931)xcazor morayNo ratings yet

- Opgw Fiber Spec Dno 91391Document5 pagesOpgw Fiber Spec Dno 91391carlos diazNo ratings yet

- Dno-6282-OPGW 12 HILOS PDFDocument2 pagesDno-6282-OPGW 12 HILOS PDFCristyan Marcelo Rosero ChingalNo ratings yet

- Specification DNA-31734 Tracking Resistant ADSS CableDocument5 pagesSpecification DNA-31734 Tracking Resistant ADSS CableDerrick Kojo SenyoNo ratings yet

- DNA-7120 - 24F 100m PDFDocument2 pagesDNA-7120 - 24F 100m PDFMoises TorresNo ratings yet

- Dna-7231 24F V500 PDFDocument3 pagesDna-7231 24F V500 PDFjoaquicNo ratings yet

- InAir ADSS 192 Ultra 8.13kN Dry 0.748 (IAL)Document3 pagesInAir ADSS 192 Ultra 8.13kN Dry 0.748 (IAL)Tony Daniel Aguilar AlvarezNo ratings yet

- Line Item 25 To 28 # Datasheet - 4F, 6F, 8F, 12F D UTA 2SW SS PE BK 7.5MM - GYXTWDocument3 pagesLine Item 25 To 28 # Datasheet - 4F, 6F, 8F, 12F D UTA 2SW SS PE BK 7.5MM - GYXTWSadiqNo ratings yet

- Technical Specification: Optical Ground WireDocument9 pagesTechnical Specification: Optical Ground WireMiftahul KhairNo ratings yet

- ZTT OPGW 18-96689-56 Hilos Con 2 Capas - Ver.CDocument9 pagesZTT OPGW 18-96689-56 Hilos Con 2 Capas - Ver.CGiancarlos OliveraNo ratings yet

- Norway OPGW DUAL TUBE 96 G.652D-13.9mm 26042018Document5 pagesNorway OPGW DUAL TUBE 96 G.652D-13.9mm 26042018satyam_scribdNo ratings yet

- 24 Fiber OPGW ANDES PDFDocument7 pages24 Fiber OPGW ANDES PDFMAN TNo ratings yet

- Opgw-12b1-48 (62.7 12.7)Document9 pagesOpgw-12b1-48 (62.7 12.7)Palle YulianNo ratings yet

- TDS 3x150 11kV CTS+LEADDocument2 pagesTDS 3x150 11kV CTS+LEADNabeelNo ratings yet

- YOFC DataSaheet de ADSS Cable-All Dry ADSS Cable - 100m 200m Span Single JacketDocument8 pagesYOFC DataSaheet de ADSS Cable-All Dry ADSS Cable - 100m 200m Span Single JacketEstefany Murga LauraNo ratings yet

- OPGW-24B1.3-105 (58 100.0) ITU-TG.652.D Fibers: Characteristics of Cable Cable Construction and ParameterDocument5 pagesOPGW-24B1.3-105 (58 100.0) ITU-TG.652.D Fibers: Characteristics of Cable Cable Construction and ParameterAdanNo ratings yet

- Spe For Opgw 48F IndiaDocument9 pagesSpe For Opgw 48F IndiaMahesh GKNo ratings yet

- Opgw - 24g652-Ast-177 (69.8 - 256.7)Document9 pagesOpgw - 24g652-Ast-177 (69.8 - 256.7)pedro torresNo ratings yet

- Mini-Breakout Cables (Distribution) Universal - Indoor / Outdoor - Corrugated Steel Tape Armor (CST) A/I-VQ (ZN) H (SR) HDocument6 pagesMini-Breakout Cables (Distribution) Universal - Indoor / Outdoor - Corrugated Steel Tape Armor (CST) A/I-VQ (ZN) H (SR) HMarcos SerrãoNo ratings yet

- OPGWDocument18 pagesOPGWGuilhermeNo ratings yet

- Duplex Zipcord - J-V (ZN) HDocument2 pagesDuplex Zipcord - J-V (ZN) HMohsin SiddiqiNo ratings yet

- NFC Aaac Al4 - 34.4&54.6 Ees CableDocument5 pagesNFC Aaac Al4 - 34.4&54.6 Ees CableazzouzimedNo ratings yet

- TDS 1x300 11kV CTS+LEADDocument2 pagesTDS 1x300 11kV CTS+LEADNabeelNo ratings yet

- 24 SM Aerial-Duct FibreDocument5 pages24 SM Aerial-Duct FibrePulsmade MalawiNo ratings yet

- ZTT Et Expressway AAAC Conductor 21-Xj00486Document4 pagesZTT Et Expressway AAAC Conductor 21-Xj00486HarisNo ratings yet

- Drop Wire (DW) Cable - 4 Core - Specifications PDFDocument3 pagesDrop Wire (DW) Cable - 4 Core - Specifications PDFinti lestariNo ratings yet

- 1 K V, 4 C X 185 Cu (Cl2) /XLP E /P VC/S WA/P VC: BS 5467 IEC 60332 - 1Document2 pages1 K V, 4 C X 185 Cu (Cl2) /XLP E /P VC/S WA/P VC: BS 5467 IEC 60332 - 1WesaamNo ratings yet

- 9 - 32" (7.32 MM) Monoconductor 1N29-S77 Corrosion Resistant - Camesa EMCDocument2 pages9 - 32" (7.32 MM) Monoconductor 1N29-S77 Corrosion Resistant - Camesa EMCwaynecruzz29No ratings yet

- Tech. Gyfty53Document6 pagesTech. Gyfty53Guss SarangoNo ratings yet

- Technical Submittal For MV - Cable Data SheetsDocument4 pagesTechnical Submittal For MV - Cable Data SheetskhaledelgamalNo ratings yet

- TPG OPGW 42 MM Dukong Manggar ZTTDocument4 pagesTPG OPGW 42 MM Dukong Manggar ZTTPalle YulianNo ratings yet

- Ficha Tecnica Del Cable de Fibra ADSS SJ RP LSZHDocument9 pagesFicha Tecnica Del Cable de Fibra ADSS SJ RP LSZHGersson ColmenaresNo ratings yet

- ZTT AdssDocument9 pagesZTT AdssJose GonzalesNo ratings yet

- GTP-GPIL-ENERFRA-ACSR DOG With Current RatingDocument2 pagesGTP-GPIL-ENERFRA-ACSR DOG With Current RatingShashikumar SNo ratings yet

- Cable Fo Huawei b.5.10 HW Adss-Pe-24,120 b1.3 (80m)Document7 pagesCable Fo Huawei b.5.10 HW Adss-Pe-24,120 b1.3 (80m)Evelyn TorrezNo ratings yet

- Technical Specification - Grounding - WP4Document6 pagesTechnical Specification - Grounding - WP4nnNo ratings yet

- Technical Data Sheet: Description Values Technical ParticularsDocument2 pagesTechnical Data Sheet: Description Values Technical ParticularsAli ShahzadNo ratings yet

- Multicom Armored Specs - MDocument8 pagesMulticom Armored Specs - Mnaseem AhamdNo ratings yet

- 2.4.3 Especificaciones tecnicas-AerialCable-ADSS-PEAT-Xm-48B1.3Document12 pages2.4.3 Especificaciones tecnicas-AerialCable-ADSS-PEAT-Xm-48B1.3Felipe Martínez CalderónNo ratings yet

- GTMETRPSOD XX X X - 2018v2Document4 pagesGTMETRPSOD XX X X - 2018v2Stone123456789No ratings yet

- Sc. Cl. - 001 - SAR0214HFESL-F3 (IE) CDocument1 pageSc. Cl. - 001 - SAR0214HFESL-F3 (IE) CSudarshika SumathipalaNo ratings yet

- BCC 23120008Document2 pagesBCC 23120008abdulkawi alasharyNo ratings yet

- NFC 1kv ABC 2&4c16 Ees CableDocument5 pagesNFC 1kv ABC 2&4c16 Ees CableazzouzimedNo ratings yet

- Bare Copper Conductor: Standards / Testing SpecificationsDocument5 pagesBare Copper Conductor: Standards / Testing SpecificationskjkljkljlkjljlkNo ratings yet

- Technical Specification For GD TC435077 2021 OPGW 24B1 100 (82 71)Document2 pagesTechnical Specification For GD TC435077 2021 OPGW 24B1 100 (82 71)William CalleNo ratings yet

- ADSS Single Jacket Span 100m 2200nDocument4 pagesADSS Single Jacket Span 100m 2200nJoseph Tael DHNo ratings yet

- Technology Department Technical Data Sheet Low Voltage Power CableDocument2 pagesTechnology Department Technical Data Sheet Low Voltage Power CableMuhammad ShahidNo ratings yet

- OPGW Design Data Sheet (SFSJ-J-11090) - LUXDocument2 pagesOPGW Design Data Sheet (SFSJ-J-11090) - LUXandersonNo ratings yet

- Nextramicro 24 48 72 96 144 192 216 288 432 576G652DDocument8 pagesNextramicro 24 48 72 96 144 192 216 288 432 576G652Dgeorgeta.dumitrache50No ratings yet

- Ducab: Technical DataDocument1 pageDucab: Technical DataGhiles AOUICHENo ratings yet

- Technical Data Sheet FOR Optical Fiber Cable Duct ApplicationsDocument5 pagesTechnical Data Sheet FOR Optical Fiber Cable Duct ApplicationsAngel Hernando MartinezNo ratings yet

- Brochure - Drop Cable 1 CoreDocument3 pagesBrochure - Drop Cable 1 Coretomi mulkiNo ratings yet

- Ficha Tecnica CableDocument2 pagesFicha Tecnica CableAriel HerreraNo ratings yet

- Ficha Tecnica - 3X70+50 MM y 3X95+50 MMDocument1 pageFicha Tecnica - 3X70+50 MM y 3X95+50 MMjohana leonNo ratings yet

- Millimetre Wave Antennas for Gigabit Wireless Communications: A Practical Guide to Design and Analysis in a System ContextFrom EverandMillimetre Wave Antennas for Gigabit Wireless Communications: A Practical Guide to Design and Analysis in a System ContextNo ratings yet

- 2.1 Ficha Técnica Aluminio CorrugadoDocument3 pages2.1 Ficha Técnica Aluminio CorrugadogercubNo ratings yet

- Dibujo de Las Distancias de AislamientoDocument1 pageDibujo de Las Distancias de AislamientogercubNo ratings yet

- The U.S. Patents of Nikola Tesla: .PDF Assembled at The Bipolar Planet Using Pdfedit995Document250 pagesThe U.S. Patents of Nikola Tesla: .PDF Assembled at The Bipolar Planet Using Pdfedit995gercubNo ratings yet

- Velocidad Maxima Del Viento PDFDocument1 pageVelocidad Maxima Del Viento PDFgercubNo ratings yet

- TeslaListaCopletaDePantentes Parte1Document250 pagesTeslaListaCopletaDePantentes Parte1gercubNo ratings yet

- Angelica 1Document7 pagesAngelica 1gercubNo ratings yet

- Eurotest 61557 User ManualDocument96 pagesEurotest 61557 User Manualmoj_scribdNo ratings yet

- Circuit Analysis I With MATLAB ApplicationsDocument2 pagesCircuit Analysis I With MATLAB ApplicationsgercubNo ratings yet

- Footstep Power Generation Using Piezoelectric SensorDocument16 pagesFootstep Power Generation Using Piezoelectric SensorShivam KumarNo ratings yet

- Lenovo AiO C260 COMPAL LA-B001P (ZAA00) 2013-12-27 Rev 1.0 SchematicDocument48 pagesLenovo AiO C260 COMPAL LA-B001P (ZAA00) 2013-12-27 Rev 1.0 Schematicrichar0% (1)

- lm2940 NDocument33 pageslm2940 NFly Jesus Yesca PrzNo ratings yet

- Phillips DFR1600 ManualDocument29 pagesPhillips DFR1600 Manualkosarob33% (3)

- Speed Sensor and Blockage Detector Data PDFDocument16 pagesSpeed Sensor and Blockage Detector Data PDFAhmad DagamsehNo ratings yet

- Wind Turbine DetailsDocument22 pagesWind Turbine DetailsAdithi RNo ratings yet

- Max3107 Spi/I C Uart With 128-Word Fifos: General Description Benefits and FeaturesDocument52 pagesMax3107 Spi/I C Uart With 128-Word Fifos: General Description Benefits and Featuressanthosha rkNo ratings yet

- Precision AntennasDocument16 pagesPrecision AntennasJaime AvilesNo ratings yet

- Option EntryDocument6 pagesOption EntryManoj RajahulliNo ratings yet

- DC Brake SLDC SeriesDocument1 pageDC Brake SLDC SeriesswaroopNo ratings yet

- Chapter 1 SolutionDocument35 pagesChapter 1 SolutionUsama BlochNo ratings yet

- Raptor Techn RevCA 704010EN WebDocument194 pagesRaptor Techn RevCA 704010EN WebFranciscoNo ratings yet

- Mindray iMEC Service Manual - V6.0 - EN PDFDocument148 pagesMindray iMEC Service Manual - V6.0 - EN PDFPrecision Medical Resources PMRNo ratings yet

- Television: Operating InstructionsDocument32 pagesTelevision: Operating InstructionsAsantha Buddhi HerathNo ratings yet

- 70V - 60W Dmos Audio Amplifier With Mute/St-By: Multipower BCD TechnologyDocument13 pages70V - 60W Dmos Audio Amplifier With Mute/St-By: Multipower BCD TechnologyGokayAkayNo ratings yet

- English User Manual K3110Document14 pagesEnglish User Manual K3110rohitrizNo ratings yet

- Askey rtl0200 5g NR Cpe DatasheetDocument2 pagesAskey rtl0200 5g NR Cpe DatasheetMSI IngenieriaNo ratings yet

- 5G OTA Introduction Slides PDFDocument41 pages5G OTA Introduction Slides PDFViswanaathNo ratings yet

- Digital Integrated Circuit ApplicationsDocument3 pagesDigital Integrated Circuit ApplicationsShammu KandepuNo ratings yet

- Elsewedy Catalogue 2019Document132 pagesElsewedy Catalogue 2019Moustafa Mahmoud0% (1)

- Lab Viva QuestionDocument13 pagesLab Viva QuestionNarasimman Don100% (1)

- KA 70 - Users ManualDocument32 pagesKA 70 - Users ManualNagy GabrielNo ratings yet

- Belden 8777 Data SheetDocument2 pagesBelden 8777 Data SheetCá ThuNo ratings yet

- 8259 PicDocument6 pages8259 PicpreethipattabiramanNo ratings yet

- Volume II - Ericsson Field Guide For UTRAN P1-Lite: Feature Parameters and Best PracticesDocument71 pagesVolume II - Ericsson Field Guide For UTRAN P1-Lite: Feature Parameters and Best Practicessara y santi becerra barreto100% (2)