Professional Documents

Culture Documents

Powell Electrical Systems, Inc. Guide Specification: Low and Medium Voltage Metal-Enclosed Cable Bus

Uploaded by

longnguyenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Powell Electrical Systems, Inc. Guide Specification: Low and Medium Voltage Metal-Enclosed Cable Bus

Uploaded by

longnguyenCopyright:

Available Formats

Powell Electrical Systems, Inc.

Guide Specification

Low and Medium Voltage Metal-Enclosed Cable Bus

1.0 General

1.1 This specification describes the electrical and mechanical requirements for metal-enclosed, non-

segregated phase cable bus duct from 600V through 38kV applications. The cable bus system

described is to be suitable for indoor or outdoor installations with nominal current ratings operating

in ambient temperatures to 40°C.

1.2 This specification covers only the general requirements of the cable bus duct assemblies. The

specific requirements of each assembly (plan, arrangement, components, etc.) will be shown on

drawings provided by the Purchaser. These drawings will form the basis for developing the

drawings to manufacture and install.

2.0 Standards and Codes

2.1 The assemblies shall be constructed, wired, and tested in accordance with all applicable sections

of the latest listed standards and codes.

2.1.1 American National Standards Institute (ANSI IEEE-C37.23-1987)

2.1.2 National Electric Code (NEC) (NFPA No. 70)

2.1.3 National Electrical Manufacturers Association (NEMA)

2.1.4 IEEE-IPCEA Power Cable Ampacities

2.2 It shall be the manufacturer's responsibility to be knowledgeable of the requirements of the above

Standards and Codes. Where standards or codes conflict, ANSI IEEE-C37.23-1987 shall be the

governing document.

2.3 Site Conditions

2.3.1 Ambient air temperature limits (-30°C To +40°C)

2.3.2 Altitude above sea level ______ feet.

2.3.3 Maximum wind velocity ______ miles per hour.

2.3.4 Ice load ______ pounds per square foot.

2.3.5 Snow load ______ pounds per square foot.

2.3.6 Seismic zone ______.

3.0 Basic Construction

3.1 The cable bus system shall be non-segregated phase type with adequate cable spacing as outlined

in the latest edition of IEEE S-135/IPCEA P-46-426.

3.2 Outdoor installations shall be ventilated with louvered top and bottom covers.

3.3 Indoor installations shall be ventilated with louvered top and bottom covers.

4.0 Ratings (Current ratings based on 40°C ambient)

4.1 Maximum voltage ______ V/kV rms

4.2 Basic impulse insulation level ______ kV

4.3 Rated frequency withstand ______ kV (1 min. dry) 60Hz

4.4 Rated continuous current ______ Amperes

4.5 Momentary withstand current ______ kA Asymmetrical 167mS

4.6 Temperature rise of splice joints shall not exceed cable temperature, and in no case shall the splice

joint temperature rise exceed 50°C.

Publication No. 05184 06/2012 v0

©2012 Powell Industries, Inc. All rights reserved.

Page 1 of 4

Powell Electrical Systems, Inc.

Guide Specification

Low and Medium Voltage Metal-Enclosed Cable Bus

4.7 Enclosure total temperature limit 80°C.

5.0 Conductors

5.1 Phase conductors shall be flexible (Class B Stranded) copper or aluminum cables, insulated,

shielded and jacketed in accordance with Purchaser's requirements, of sufficient cross-section to

assure full current rating without exceeding a hot spot temperature rise of 50°C in an ambient air

temperature of 40°C. Insulated cables are to be correctly interleaved, when practical, to assure

balanced current between phase cables, and to give minimum cable temperature rise.

5.2 Conductor supports must be provided to withstand short circuit currents and remain functional after

short circuit has been experienced.

6.0 Cable Terminations and Bus Joints

6.1 Contact surfaces of cable terminals shall be adequately electrically plated. All bolted connections

shall be capable of being properly tightened and locked in place, to provide and maintain full and

uniform pressure under all operating conditions. Torque requirements in foot-pounds (ft.-lb.) shall

be furnished by the manufacturer.

6.2 Standard hardware shall be high strength plated steel; including bolts, nuts, flat washers, and (lock

washers for copper connections), or (Belleville spring washers for aluminum connections). Non-

magnetic hardware shall be supplied when specified.

6.3 All transition parts for connections to other equipment terminals shall be provided by the bus

manufacturer. The purchaser will provide the bus manufacturer with applicable coordination

drawings to make the mating connections.

7.0 Grounding

7.1 The bus housing shall be designed to carry the system ground fault current without excessive

temperature rise. When required a separate ground cable can be provided on the inside or outside

of the bus enclosure. Separate ground bus may terminate to equipment, or to a ground pad for

connection to the station ground.

7.2 The housing ground continuity shall be maintained at the shipping splits, by using housing ground

splice plates.

8.0 Conductor Support Systems

8.1 The individual cable bus conductors shall be supported to withstand the mechanical forces

imposed by the momentary current rating specified. These supports shall have maximum center-to-

center spacing of 36 inches for horizontal bus, and 18 inches for vertical bus.

8.2 Insulating supports shall be fabricated from clear, non-toxic treated and painted hard maple or

molded glass reinforced polyester.

8.3 The support blocks shall be assembled with zinc dichromate treated steel hardware, to provide the

strength for the short circuit forces.

9.0 Enclosures

9.1 Enclosures shall be constructed of aluminum to limit induced current losses and circulating

currents. This results in a great reduction in the effects of hysteresis or magnetic heating.

9.2 The enclosure shall utilize aluminum side rails and top and bottom covers and have a non-painted

natural aluminum finish.

9.3 Enclosure shall be designed for a maximum temperature rise of 40°C when carrying rated current

in a 40°C ambient.

Publication No. 05184 06/2012 v0

©2012 Powell Industries, Inc. All rights reserved.

Page 2 of 4

Powell Electrical Systems, Inc.

Guide Specification

Low and Medium Voltage Metal-Enclosed Cable Bus

9.4 Removable covers shall be provided throughout the bus duct run, both top and bottom, for ease in

laying the cable and having access to bus joints and supports, without the need for disassembling

the bus duct. Welded covers are unacceptable.

9.5 Ventilated Indoor and Outdoor Construction

9.5.1 Top and bottom covers shall be ventilated.

9.5.2 Vent openings shall prohibit entrance of a 1/4" diameter rod.

9.5.3 Assembly hardware shall be stainless steel.

9.6 Enclosure joints shall provide adjustment to accommodate site variances and linear expansion of

up to 1/4 inch per splice.

9.7 Expansion Joints will be furnished for every straight run exceeding 80 feet, and at building

entrances when specified.

9.8 Enclosures are to be shipped in the longest practical lengths (up to 18 feet straight) to minimize

field assembly labor.

10.0 Wall or Floor Entrances

10.1 Duct will include an internal vapor/fire barrier with one-half hour fire rating, at all wall, roof, and floor

penetrations when required. Optional fire ratings up to 4 hours shall be supplied as required.

11.0 Testing

11.1 Each cable and its termination shall be given a high voltage DC hi-pot field acceptance test, at 75%

of the factory voltage, following practices outlined by the cable manufacturer.

11.2 Manufacturer may be requested to submit any ANSI-37.23-1987 design tests listed below.

11.2.1 Temperature Rise

11.2.2 Insulation Withstand

11.2.3 Impulse

11.2.4 Power Frequency Withstand

11.2.5 Momentary

11.2.6 Insulation Flame Retardance

11.3 In lieu of actual testing, the manufacturer may submit design tests performed on similar ratings

along with technical data to substantiate the adequacy of the equipment being furnished.

12.0 Drawing Requirements

12.1 Dimensioned drawings with plan and elevation views, and other views as necessary for clarity.

12.2 Cross-sectional drawings with views of cable interleaving, support block locations, and housing

arrangement.

12.3 Housing, seal assembly, and other assembly drawings.

12.4 Bus termination drawings showing details to connecting equipment (transformers, switchgear, etc.).

13.0 Installation and Operating Instructions

13.1 Installation and operating instructions shall cover all of the equipment furnished.

Publication No. 05184 06/2012 v0

©2012 Powell Industries, Inc. All rights reserved.

Page 3 of 4

Powell Electrical Systems, Inc.

Guide Specification

Low and Medium Voltage Metal-Enclosed Cable Bus

For assistance regarding these specifications or with support questions, please contact Powell directly:

Powell Electrical Systems, Inc. 708.409.1200

Delta/Unibus Division 708.409.1211 fax

515 Railroad Avenue

Email: info@powellind.com

Northlake, IL 60164

Website: powellind.com

Publication No. 05184 06/2012 v0

©2012 Powell Industries, Inc. All rights reserved.

Page 4 of 4

You might also like

- Low and Medium Voltage Metal-Enclosed Bar Bus Guide Specification v0Document5 pagesLow and Medium Voltage Metal-Enclosed Bar Bus Guide Specification v0Bayu Suryo WirantoNo ratings yet

- Sandwhich BusductDocument5 pagesSandwhich BusductHarmandeep Ahluwalia100% (1)

- BESCOM Technical-Specification-HT-UG-CablesDocument15 pagesBESCOM Technical-Specification-HT-UG-Cablesಪರಮಮಿತ್ರಸಂಪತ್ಕುಮಾರ್ಶೆಟ್ಟಿNo ratings yet

- Technical Specification For Cross Linked Polyethylene Insulated 3 Core 11kv CablesDocument13 pagesTechnical Specification For Cross Linked Polyethylene Insulated 3 Core 11kv CablesNarendra SinghNo ratings yet

- Honeywell Office, Gurgaon HVAC System: Particular Conditions & Technical SpecificationDocument16 pagesHoneywell Office, Gurgaon HVAC System: Particular Conditions & Technical SpecificationAmitSamadiyaNo ratings yet

- Texas AM MV SpecificationDocument11 pagesTexas AM MV SpecificationDavid BurgessNo ratings yet

- 11kV GIS Specification PDFDocument44 pages11kV GIS Specification PDFRiyazNo ratings yet

- Insulator: PackingDocument8 pagesInsulator: PackingZeeshan SubhaniNo ratings yet

- Insulator: PackingDocument8 pagesInsulator: PackingZeeshan SubhaniNo ratings yet

- 11kV - 3-C - 300 - AL - Cable - Specification Final PDFDocument18 pages11kV - 3-C - 300 - AL - Cable - Specification Final PDFShubham BaderiyaNo ratings yet

- Low Voltage Metal Enclosed Drawout Arc Resistant Switchgear: MNS-SG Guideform SpecificationDocument16 pagesLow Voltage Metal Enclosed Drawout Arc Resistant Switchgear: MNS-SG Guideform SpecificationCharles RobiansyahNo ratings yet

- Technical Specification For Outdoor Type Distribution Transformer 3 PHASE 500 KVA, 11 kV/433 VDocument32 pagesTechnical Specification For Outdoor Type Distribution Transformer 3 PHASE 500 KVA, 11 kV/433 Vhamida douidaNo ratings yet

- TS of Cable AccessoriesDocument20 pagesTS of Cable AccessoriesMayur JainNo ratings yet

- 12-TMSS-10Document19 pages12-TMSS-10Fouad AliNo ratings yet

- FEWA LV Joints & TerminationsDocument13 pagesFEWA LV Joints & TerminationsMuhammad RazaNo ratings yet

- Technical Specification OF Expulsion Fuse Cutout: Ministry of Electricity Planning and Studies Office Baghdad - IraqDocument10 pagesTechnical Specification OF Expulsion Fuse Cutout: Ministry of Electricity Planning and Studies Office Baghdad - IraqAhmed JaNo ratings yet

- RMC Technical Material Specification SummaryDocument27 pagesRMC Technical Material Specification Summarysat palNo ratings yet

- 630 KvaDocument20 pages630 KvaNikita pandeNo ratings yet

- Is 7098 Part I 1998Document17 pagesIs 7098 Part I 1998Sanjeev DhariwalNo ratings yet

- EP-MS-P4-S3-075 - 11kV Heat Shrinkable Cable Terminations - KM Material..Document14 pagesEP-MS-P4-S3-075 - 11kV Heat Shrinkable Cable Terminations - KM Material..dimaomarNo ratings yet

- Cidco of Maharashtra Limited. SL - Pg.NoDocument7 pagesCidco of Maharashtra Limited. SL - Pg.Nordeepak99No ratings yet

- IS-7098 PT - 1.Document17 pagesIS-7098 PT - 1.Rishi PalNo ratings yet

- Grounding and Bonding - Electrical Design GuideDocument2 pagesGrounding and Bonding - Electrical Design GuideJasm MutingNo ratings yet

- TES-P-104.04-R0 Splices and Termination of Power CablesDocument9 pagesTES-P-104.04-R0 Splices and Termination of Power CablesSalmanEjazNo ratings yet

- ZNCC USAID/USACE Project Technical SpecificationDocument1 pageZNCC USAID/USACE Project Technical SpecificationAbdul Mosawer ZahidNo ratings yet

- DO Fuse UnitDocument8 pagesDO Fuse UnitImran KhanNo ratings yet

- Cable Accessories: Systems, IncDocument4 pagesCable Accessories: Systems, IncLuis MurilloNo ratings yet

- 02 CSS SpecsDocument23 pages02 CSS Specsshimla kaurNo ratings yet

- Low Voltage Switchgear: Maxsg SpecificationsDocument18 pagesLow Voltage Switchgear: Maxsg SpecificationssuvarnapreyasNo ratings yet

- Medium Voltage Cable SpecDocument3 pagesMedium Voltage Cable SpecOanh NguyenNo ratings yet

- XLPE cable for ungrounded 33kV systemsDocument12 pagesXLPE cable for ungrounded 33kV systemssaurabh kumarNo ratings yet

- 12-TMSS-11Document29 pages12-TMSS-11Fouad AliNo ratings yet

- Sec-09 Electrical Works and InstallationDocument6 pagesSec-09 Electrical Works and InstallationOmer HayatNo ratings yet

- Technical Specification For 11 KV AB Switch 400ADocument8 pagesTechnical Specification For 11 KV AB Switch 400AdillehNo ratings yet

- 2TDC490003 MNS-SG NON AR Guideform Specification Rev. ADocument15 pages2TDC490003 MNS-SG NON AR Guideform Specification Rev. ALokesh BabuNo ratings yet

- PowlVac 5-15kV Metal-Clad Switchgear Guide Specification v7Document8 pagesPowlVac 5-15kV Metal-Clad Switchgear Guide Specification v7ahmadgce04No ratings yet

- 15 Sec Technical Rev 0Document13 pages15 Sec Technical Rev 0mohanksebNo ratings yet

- SECTION 28 05 26 Grounding and Bonding For Electronic Safety and SecurityDocument8 pagesSECTION 28 05 26 Grounding and Bonding For Electronic Safety and SecurityDenyNo ratings yet

- LV Electrical Works SpecDocument38 pagesLV Electrical Works SpecAlex SimNo ratings yet

- FEWA HV Joints & TerminationsDocument29 pagesFEWA HV Joints & TerminationsMuhammad RazaNo ratings yet

- Medium-Voltage Cables InstallationDocument10 pagesMedium-Voltage Cables InstallationRa ArNo ratings yet

- Medium Voltage CableDocument5 pagesMedium Voltage CableNaveenNavabNo ratings yet

- Panelboards SpecificationsDocument7 pagesPanelboards SpecificationsBladimir MichelNo ratings yet

- ANNEX E - Amended - Technical Specs of L.T TWISTED INSULATED CABLEDocument7 pagesANNEX E - Amended - Technical Specs of L.T TWISTED INSULATED CABLEsajjad_pirzadaNo ratings yet

- 16126Document13 pages16126uddinnadeemNo ratings yet

- Low Voltage Electrical Power Conductors and Cables 600 Volts and BelowDocument6 pagesLow Voltage Electrical Power Conductors and Cables 600 Volts and BelowyonnatanzewdduNo ratings yet

- MV Cable InstallationDocument10 pagesMV Cable Installationjesus marquez arvaezNo ratings yet

- SF6 SwitchgearDocument7 pagesSF6 SwitchgearkarimakkiNo ratings yet

- Technical Specfication For TR 500 PDFDocument23 pagesTechnical Specfication For TR 500 PDFMahmoud AbuziadNo ratings yet

- Specification of 11kv SF6 Insulated Ring Main UnitsDocument8 pagesSpecification of 11kv SF6 Insulated Ring Main UnitsGAGANNo ratings yet

- Pipelines, Cathodic Protection Systems 670.840 : Rocess Ystems Ngineering Fabrication and Erection SpecificationDocument9 pagesPipelines, Cathodic Protection Systems 670.840 : Rocess Ystems Ngineering Fabrication and Erection Specificationpuwarin najaNo ratings yet

- Earthing Protection SpecificationDocument5 pagesEarthing Protection SpecificationNi ReNo ratings yet

- Annexure - A Part-I (Technical Bid)Document19 pagesAnnexure - A Part-I (Technical Bid)Prachi DongreNo ratings yet

- Medium Voltage CablesDocument12 pagesMedium Voltage Cableswafikmh4No ratings yet

- Simple Sample Electrical Installation SpecificationDocument3 pagesSimple Sample Electrical Installation SpecificationHansika Rajapaksha0% (1)

- MV and LV cable technical requirementsDocument5 pagesMV and LV cable technical requirementsFor AppsNo ratings yet

- Automatic Power Factor Correction Equipment /capacitor Banks For Low Voltage Distribution NetworksDocument13 pagesAutomatic Power Factor Correction Equipment /capacitor Banks For Low Voltage Distribution NetworksBrajan's B.No ratings yet

- Rockwell Pf7000 Line/Motor Cable Recommendation.: Power Wiring SelectionDocument4 pagesRockwell Pf7000 Line/Motor Cable Recommendation.: Power Wiring SelectionIsaac SanchezNo ratings yet

- Installations 102 PresentationDocument40 pagesInstallations 102 PresentationMohamad HssanNo ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- or 26 25 00 20 Non Seg Phase BusductDocument6 pagesor 26 25 00 20 Non Seg Phase BusductlongnguyenNo ratings yet

- or 26 25 00 20 Non Seg Phase BusductDocument6 pagesor 26 25 00 20 Non Seg Phase BusductlongnguyenNo ratings yet

- I. Circle The Correct Answer1Document1 pageI. Circle The Correct Answer1longnguyenNo ratings yet

- Active and Passive Voice: I. Circle The Correct AnswerDocument2 pagesActive and Passive Voice: I. Circle The Correct AnswerlongnguyenNo ratings yet

- Active and Passive Voice: I. Circle The Correct AnswerDocument2 pagesActive and Passive Voice: I. Circle The Correct AnswerlongnguyenNo ratings yet

- Application: Instrument Commissioning Technician: Jignesh I PatelDocument7 pagesApplication: Instrument Commissioning Technician: Jignesh I PatellongnguyenNo ratings yet

- Application: Instrument Commissioning Technician: Jignesh I PatelDocument7 pagesApplication: Instrument Commissioning Technician: Jignesh I PatellongnguyenNo ratings yet

- Loop Test Sheet PDFDocument1 pageLoop Test Sheet PDFTrí NguyễnNo ratings yet

- LapkehoachxuatkhauDocument141 pagesLapkehoachxuatkhauTố Trân ĐàmNo ratings yet

- QLNN Ve KT - On ThemDocument8 pagesQLNN Ve KT - On ThemlongnguyenNo ratings yet

- LapkehoachxuatkhauDocument141 pagesLapkehoachxuatkhauTố Trân ĐàmNo ratings yet

- Canberra As A Planned CityDocument12 pagesCanberra As A Planned Citybrumbies15100% (1)

- Effects of Zero Moment of Truth On Consumer Behavior For FMCGDocument14 pagesEffects of Zero Moment of Truth On Consumer Behavior For FMCGBoogii EnkhboldNo ratings yet

- 1989 Volvo 740 Instruments and ControlsDocument107 pages1989 Volvo 740 Instruments and Controlsskyliner538No ratings yet

- Gr.10 Music History ModuleDocument45 pagesGr.10 Music History ModuleKyle du PreezNo ratings yet

- 1 FrameworkDocument26 pages1 FrameworkIrenataNo ratings yet

- Valhalla Repair ManualDocument8 pagesValhalla Repair ManualKirby AllenNo ratings yet

- P-H Agua PDFDocument1 pageP-H Agua PDFSarah B. LopesNo ratings yet

- Securing Obligations Through Pledge and MortgageDocument4 pagesSecuring Obligations Through Pledge and MortgagePrincessAngelaDeLeon100% (1)

- A Secret Baby by The Bratva by Lexi AsherDocument184 pagesA Secret Baby by The Bratva by Lexi Asheralisa sanchez100% (1)

- WFP-Remote Household Food Security Survey Brief-Sri Lanka Aug 2022Document18 pagesWFP-Remote Household Food Security Survey Brief-Sri Lanka Aug 2022Adaderana OnlineNo ratings yet

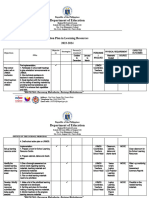

- aCTION PLAN IN HEALTHDocument13 pagesaCTION PLAN IN HEALTHCATHERINE FAJARDONo ratings yet

- 2018 JC2 H2 Maths SA2 River Valley High SchoolDocument50 pages2018 JC2 H2 Maths SA2 River Valley High SchoolZtolenstarNo ratings yet

- Hics 203-Organization Assignment ListDocument2 pagesHics 203-Organization Assignment ListslusafNo ratings yet

- Import Sample 2Document63 pagesImport Sample 2akkyNo ratings yet

- 3 5 3Document4 pages3 5 3Amr Mohamed RedaNo ratings yet

- Chapter 20: Sleep Garzon Maaks: Burns' Pediatric Primary Care, 7th EditionDocument4 pagesChapter 20: Sleep Garzon Maaks: Burns' Pediatric Primary Care, 7th EditionHelen UgochukwuNo ratings yet

- Berserker - Lifting Wood and Stone Like A Viking Strongman Bodybuilding Functional StrengthDocument10 pagesBerserker - Lifting Wood and Stone Like A Viking Strongman Bodybuilding Functional Strengthluciferr71No ratings yet

- Bylaw 16232 High Park RezoningDocument9 pagesBylaw 16232 High Park RezoningJamie_PostNo ratings yet

- How To Retract BPS Data Back To R3 When There Is No Standard RetractorDocument3 pagesHow To Retract BPS Data Back To R3 When There Is No Standard Retractorraphavega2010No ratings yet

- ASTRO UserguideDocument1,054 pagesASTRO UserguideMarwan Ahmed100% (1)

- Procedure For NC and CapaDocument2 pagesProcedure For NC and CapaSAKTHIVEL ANo ratings yet

- Sustainability 15 06202Document28 pagesSustainability 15 06202Somesh AgrawalNo ratings yet

- TheSun 2008-11-04 Page16 Asian Stocks Rally Continues On Policy HopesDocument1 pageTheSun 2008-11-04 Page16 Asian Stocks Rally Continues On Policy HopesImpulsive collectorNo ratings yet

- Proforma Invoice: DescriptionDocument3 pagesProforma Invoice: Descriptionanon-690278No ratings yet

- Kamera Basler Aca2500-20gmDocument20 pagesKamera Basler Aca2500-20gmJan KubalaNo ratings yet

- Chapter 5Document11 pagesChapter 5XDXDXDNo ratings yet

- 45 - Altivar 61 Plus Variable Speed DrivesDocument130 pages45 - Altivar 61 Plus Variable Speed Drivesabdul aziz alfiNo ratings yet

- Raj Priya Civil Court Clerk FinalDocument1 pageRaj Priya Civil Court Clerk FinalRaj KamalNo ratings yet

- CSIR AnalysisDocument1 pageCSIR Analysisசெபா செல்வாNo ratings yet

- Eladio Dieste's Free-Standing Barrel VaultsDocument18 pagesEladio Dieste's Free-Standing Barrel Vaultssoniamoise100% (1)