Professional Documents

Culture Documents

How To Heat Treat 440 Stainless

Uploaded by

saiga3089417Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

How To Heat Treat 440 Stainless

Uploaded by

saiga3089417Copyright:

Available Formats

The 440 series of stainless steels are a good choice for knife-making because they have

reasonable resistance to stains and corrosion while retaining the hardness and toughness of

carbon steels. The 440A, 440B and 440C steels are too difficult to form in their hardened state,

so you will need to anneal the blank before you can form the blade. Fortunately, you do not have

to quench 440 stainless when you heat treat it; it reaches full hardness of 55 to 57 on the

Rockwell C scale with simple air cooling.

Instructions

Place the blank, the unfinished piece that will become your knife blade, in the heat treating

oven and heat slowly to between 1,550 and 1,650 degrees Fahrenheit to anneal it. This process

removes any prior heat treatment and makes the metal soft enough to grind or otherwise shape.

Do not heat faster than 400 degrees per hour. Hold the final temperature for one hour, then

gradually reduce the temperature to 1,000 degrees Fahrenheit. Do not cool faster than 50

degrees per hour. Remove the blank from the oven and allow it to air cool in a draft-free area at

normal room temperature. At this point, you may machine or grind the blank to its finished

shape.

Harden the blade. Place it into the oven and heat slowly to between 1,400 and 1,450 degrees

Fahrenheit. Do not allow the temperature to increase more than 400 degrees per hour. Hold the

blade at 1,400 to 1,450 degrees for one hour and then heat the blade as quickly as possible to

between 1,850 and 1,950 degrees Fahrenheit. Hold this temperature for 30 minutes.

Remove the blade from the oven and allow it to completely cool in still, room-temperature air.

As soon as the blade is cool, place it in the oven and heat it to 300 degrees Fahrenheit. Hold it

at that temperature for one hour.

Remove the blade from the oven and allow it to cool completely in still, room temperature air.

Tips & Warnings

Always use tongs, heat-resistant gloves and eye protection when working with hot metal.

You might also like

- Making GunCotton 7.6Document2 pagesMaking GunCotton 7.6saiga3089417No ratings yet

- Trixie 7 Dinghy - Study PlansDocument16 pagesTrixie 7 Dinghy - Study Planssaiga30894170% (1)

- Blueridge Master CatalogDocument1,380 pagesBlueridge Master Catalogsaiga3089417No ratings yet

- Biblical Flood and The Ice Epoch, The - Corporate Edition PDFDocument218 pagesBiblical Flood and The Ice Epoch, The - Corporate Edition PDFsaiga3089417100% (1)

- Dear Mr. Security Agent by Matt BrackenDocument15 pagesDear Mr. Security Agent by Matt Brackensaiga3089417100% (1)

- Biblical Flood and The Ice Epoch, The - Corporate EditionDocument218 pagesBiblical Flood and The Ice Epoch, The - Corporate Editionsaiga3089417No ratings yet

- How To Measure Eggshell TemperatureDocument6 pagesHow To Measure Eggshell Temperaturesaiga3089417No ratings yet

- Janka Wood Hardness RatingDocument3 pagesJanka Wood Hardness Ratingsaiga3089417No ratings yet

- Looming Disaster PDFDocument76 pagesLooming Disaster PDFsaiga3089417100% (1)

- Building The Norm Harris CanoeDocument21 pagesBuilding The Norm Harris Canoesaiga30894170% (2)

- EricRudolphPDFLinesOfDrift9!13!14 2ndeditionDocument248 pagesEricRudolphPDFLinesOfDrift9!13!14 2ndeditionsaiga3089417100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

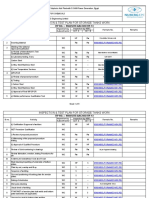

- Inspection & Test Plan For Storage Tanks Work: ITP NO.:-9560/SITE/QAC/022/ITP-13Document6 pagesInspection & Test Plan For Storage Tanks Work: ITP NO.:-9560/SITE/QAC/022/ITP-13Shubham ShuklaNo ratings yet

- 2013 CTD CatalogDocument302 pages2013 CTD CatalogLuis LopezNo ratings yet

- CPM3700 Acid Gas Removal PlantsDocument32 pagesCPM3700 Acid Gas Removal PlantsFawaz AlsaifNo ratings yet

- Proces ValveDocument98 pagesProces Valvehimansh871100% (1)

- SHRH DMW FailuresDocument1 pageSHRH DMW FailuresNandaNo ratings yet

- 016-08 - (GA) 002 - 1220mm Wide X 1165mm Coping StoneDocument1 page016-08 - (GA) 002 - 1220mm Wide X 1165mm Coping StoneKelvin bongNo ratings yet

- Manual de Abrazaderas VictaulicDocument27 pagesManual de Abrazaderas VictaulicSalvador LopezNo ratings yet

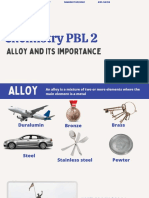

- Chemistry PBL 2 AlloyDocument10 pagesChemistry PBL 2 AlloyNAWARAH FARZANAH BINTI SEMILAH MoeNo ratings yet

- Iso 3506-1-2009Document11 pagesIso 3506-1-2009sharma.sumeet2290No ratings yet

- En SteelDocument2 pagesEn SteeldeshpravinNo ratings yet

- Stainless Steel - Properties and Applications of Ferritic Grade Stainless Steel by Austral Wright MetalsDocument5 pagesStainless Steel - Properties and Applications of Ferritic Grade Stainless Steel by Austral Wright Metalsbretariandhika_unsNo ratings yet

- CAFS Data Sheet2Document4 pagesCAFS Data Sheet2Forum PompieriiNo ratings yet

- Handbook of Spring Design Part 1Document51 pagesHandbook of Spring Design Part 1Anonymous jByA78100% (3)

- PC Boiler Corrosion Erosion White Paper r3Document16 pagesPC Boiler Corrosion Erosion White Paper r3José AndradeNo ratings yet

- Grade Data Sheet: Grade 301 Is A High Work-Hardening RateDocument1 pageGrade Data Sheet: Grade 301 Is A High Work-Hardening RateMunishTrichyNo ratings yet

- Sulfidic CorrosionDocument9 pagesSulfidic CorrosionMedina EldesNo ratings yet

- Handrail & Balustrade Solutions: Uniclass L442 Ci/Sfb (34) X Epic D4Document32 pagesHandrail & Balustrade Solutions: Uniclass L442 Ci/Sfb (34) X Epic D4ANNo ratings yet

- 00 Eeting BrazingDocument8 pages00 Eeting BrazingC AmantoNo ratings yet

- AXIS Catalogue 2018Document49 pagesAXIS Catalogue 2018Tran Quoc Thinh - M&ENo ratings yet

- 253 MA Flux-Cored Wire: Alloy Description and ApplicationDocument1 page253 MA Flux-Cored Wire: Alloy Description and ApplicationGuilherme AugustoNo ratings yet

- Tank Operating Manual Rev 3 PDFDocument54 pagesTank Operating Manual Rev 3 PDFCastoriadisNo ratings yet

- AguiaDocument2 pagesAguiaRemeNo ratings yet

- WWW Aws Org WJ Supplement Barnhouse Barnhouse PDFDocument17 pagesWWW Aws Org WJ Supplement Barnhouse Barnhouse PDFamitNo ratings yet

- Bolts and Nuts Stainless SteelDocument2 pagesBolts and Nuts Stainless SteelfedemochileroNo ratings yet

- Super Duplex Stainless SteelDocument3 pagesSuper Duplex Stainless SteelNisa_nisheNo ratings yet

- SPC-0804.02-20.06 Rev D2 Field-Erected Low Pressure Storage TankDocument14 pagesSPC-0804.02-20.06 Rev D2 Field-Erected Low Pressure Storage TankswehcctkNo ratings yet

- CG-2019022-00 Brahma Single Waterway MonitorDocument1 pageCG-2019022-00 Brahma Single Waterway MonitorErickNo ratings yet

- SPIROL Slotted Spring Pins UsDocument8 pagesSPIROL Slotted Spring Pins Uskertajaya ekaryaNo ratings yet

- Brochure - Endodontic FilesDocument8 pagesBrochure - Endodontic FilesHadil AltilbaniNo ratings yet

- Crosby BP Relief ValvesDocument12 pagesCrosby BP Relief Valvesgeverett2765No ratings yet