Professional Documents

Culture Documents

LOX Storage Tank TDS

Uploaded by

h2odavidOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LOX Storage Tank TDS

Uploaded by

h2odavidCopyright:

Available Formats

Technical Datasheet

Lox Storage Tank

Classification

• LOX tanks are stationary, vacuum-insulated pressure

vessels and consist of an inner and an outer pressure

vessel.

• The inner vessel, designed for the storage of low-

temperature, liquefied oxygen is manufactured out of

cold-stretched material (stainless steel 1.4311 or

1.4301).

• The outer vessel is manufactured out of carbon steel.

• The space between the inner and outer vessel is filled

with perlite, a grained insulation material and is

evacuated up to a pressure of below 50 microns in a

warm state (20°C). In addition, a molecular sieve

ensures, by means of absorption, the improvement

and long-term stability of the vacuum during the

operation of the tank.

• An automatic regulation system helps maintain the

working pressure and minimizes losses in case of

lower withdrawal rates (economizer function).

• The density of the welding seams is subjected to a

leak test with helium, which secures long-term

durability of the vacuum.

• Paint finish

- Sandblasting: Sa 2 1/2, ISO 8501-1:1998

- Primer: Hempadur UNIQ 47741

- Top coat: Hempaxane Classic 55000

Services

• Oxygen

Dimensions

A Fill Connection

E

D

B

C Fill Connection

Refer to Table overleaf for dimension

information.

8102341148 Ed1

© Pneumatech Medical Gas Solutions 2015

E-Mail: sales@p-mgs.com • www.p-mgs.com

The right is reserved to change this technical specification without prior notice

Technical Datasheet

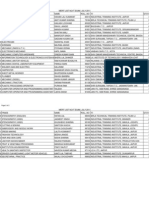

Model SCS 2200 3300 5000 6100 11000 13400 17000 20000 28000 32000 37000 41000 50000 60000 73000

Litre 2150 3300 4900 6100 11000 13300 17000 20000 28000 32300 36600 41000 50000 61000 73000

Gross capacity(1)

Net capacity (95%)(1) Litre 2045 3135 4655 5795 10450 12635 16150 19000 26600 30690 34770 38950 47500 57950 69350

Daily evaporation rate % 0.48 0.45 0.38 0.32 0.26 0.23 0.23 0.21 0.18 0.17 0.15 0.14 0.13 0.13 0.12

12 bar 260 260 260 260 530 800 530 530 800 800 800 800 800 800 800

Pressure build capacity 8 bar 400 400 400 400 820 1240 820 820 1240 1240 1240 1240 1240 1240 1240

at N2 in Nm³/h/ 8h

2 bar 1400 1400 1400 1400 2900 4400 2900 2900 4400 4400 4400 4400 4400 4400 4400

mm 3550 4850 6530 7400 6350 6000 8900 10050 10240 11940 12770 14150 11990 13990 16400

Total height A

mm 1600 1600 1600 1600 2200 2500 2200 2200 2500 2500 2500 2500 3000 3000 3000

Diameter B

mm 1500 1500 1500 1500 2000 2300 2000 2000 2300 2300 2300 2300 2800 2800 2800(3)

Foot hole circle C

mm 1800 1800 1800 1800 2400 2700 2400 2400 2700 2700 2700 2700 3200 3200 3200

Fill connection E

mm 500 500 500 500 500 500 500 500 500 500 500 500 500 500 500

Fill flange height D(2)

Weight of 18.5 bar kg 2250 3000 3950 4500 7150 9000 10150 11500 15100 16900 18700 23500 25800 30900 37000

empty 22 bar kg 2300 3100 4100 4700 7700 9500 11000 12600 16100 17900 19900 24900 27400 32800 38540

tank 37 bar kg 2650 3550 4800 5500 9200 11700 13100 15000 20000 22300 24800 30200 32300 38330 44930

(1) Geometric volumes can deviate as consequence of the cold stretch process.

(2) Height

of loading timbers to be considered: height of accessories to be added.

(3) SCS 73000 - fitted with 4 legs.

Data subject to changes without prior notice

8102341148 Ed1

© Pneumatech Medical Gas Solutions 2015

E-Mail: sales@p-mgs.com • www.p-mgs.com

The right is reserved to change this technical specification without prior notice

You might also like

- Piezo SwitchesDocument11 pagesPiezo Switchesh2odavidNo ratings yet

- DrillsDocument237 pagesDrillssimon reidNo ratings yet

- Induction Units For Suspen-Ded Ceilings: Type DID312Document22 pagesInduction Units For Suspen-Ded Ceilings: Type DID312h2odavidNo ratings yet

- Ashrae Tc0909 Power White Paper 22 June 2016 RevisedDocument60 pagesAshrae Tc0909 Power White Paper 22 June 2016 RevisedivukNo ratings yet

- JohnsonSuisse A5 Consumer CatalogueDocument98 pagesJohnsonSuisse A5 Consumer Catalogueh2odavidNo ratings yet

- STULZ WholeRange DataCenterCooling Brochure 1214 enDocument52 pagesSTULZ WholeRange DataCenterCooling Brochure 1214 enAnonymous LwH2t4No ratings yet

- IntellectualDocument24 pagesIntellectualAnonymous 6cQRWqNo ratings yet

- Hot Plate-ThermoproDocument1 pageHot Plate-Thermoproh2odavidNo ratings yet

- Technical Data: 1. DescriptionDocument6 pagesTechnical Data: 1. Descriptionh2odavidNo ratings yet

- Chilled Beams Event PDFDocument79 pagesChilled Beams Event PDFh2odavidNo ratings yet

- Whole Wall Performance Analysis of Autoclaved Aerated Concrete An Example of Collaboration Between Industry and A Research Lab On Development of Energy Efficient Building Envelope SystemsDocument12 pagesWhole Wall Performance Analysis of Autoclaved Aerated Concrete An Example of Collaboration Between Industry and A Research Lab On Development of Energy Efficient Building Envelope Systemsh2odavidNo ratings yet

- 2 Cable SlabDocument12 pages2 Cable Slabh2odavidNo ratings yet

- Nfpa 72 Emergency CallDocument10 pagesNfpa 72 Emergency CallDani AhmadNo ratings yet

- Fire Alarm Inspection and Testing RequirementsDocument58 pagesFire Alarm Inspection and Testing RequirementsYago MendozaNo ratings yet

- VRV Ahu System Pcxdmt1805Document12 pagesVRV Ahu System Pcxdmt1805h2odavidNo ratings yet

- Operation Manual - 0 PDFDocument82 pagesOperation Manual - 0 PDFh2odavidNo ratings yet

- B-Series B HW-series: The Taste of Quality Worldwide The Taste of Quality WorldwideDocument4 pagesB-Series B HW-series: The Taste of Quality Worldwide The Taste of Quality WorldwideEdnei SilverioNo ratings yet

- Operating Instructions: Round Filter Coffee Brewer With Hot Water TapDocument62 pagesOperating Instructions: Round Filter Coffee Brewer With Hot Water Taph2odavidNo ratings yet

- B-Series B HW-series: The Taste of Quality Worldwide The Taste of Quality WorldwideDocument4 pagesB-Series B HW-series: The Taste of Quality Worldwide The Taste of Quality WorldwideEdnei SilverioNo ratings yet

- VRF ControlerDocument1 pageVRF Controlerh2odavidNo ratings yet

- 11 Pegasus ECH 6645150 VER 3Document2 pages11 Pegasus ECH 6645150 VER 3h2odavidNo ratings yet

- Hot Water RecircDocument3 pagesHot Water RecircJamie Mahoney100% (1)

- Solar Electric System Design Operation and InstallationDocument35 pagesSolar Electric System Design Operation and InstallationEmmanuelNo ratings yet

- 10 Pegasus Ecm 6l45160 Ver2Document2 pages10 Pegasus Ecm 6l45160 Ver2h2odavidNo ratings yet

- 07 Pegasus Ibms v5.2Document4 pages07 Pegasus Ibms v5.2h2odavidNo ratings yet

- VRV Ahu System Pcxdmt1805Document12 pagesVRV Ahu System Pcxdmt1805h2odavidNo ratings yet

- 08 Pegasus GCU9001Document3 pages08 Pegasus GCU9001h2odavidNo ratings yet

- 09 Pegasus GCU9002 Rev0Document3 pages09 Pegasus GCU9002 Rev0h2odavidNo ratings yet

- Air Heated Vaporisers Tcm19 407185Document22 pagesAir Heated Vaporisers Tcm19 407185h2odavid100% (1)

- Hot Water Storage Tank VintekDocument12 pagesHot Water Storage Tank Vintekh2odavidNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Acceptance To An Offer Is What A Lighted Matchstick Is To A Train of GunpowderDocument2 pagesAcceptance To An Offer Is What A Lighted Matchstick Is To A Train of GunpowderAnushka SharmaNo ratings yet

- I. Company Data 1.1. Company ProfileDocument19 pagesI. Company Data 1.1. Company ProfileMhy AcajaNo ratings yet

- Key Shortcuts WinDocument26 pagesKey Shortcuts WinrockskartikNo ratings yet

- Software Testing and Quality AssuranceDocument26 pagesSoftware Testing and Quality Assurancemanoj hNo ratings yet

- Design Data 610 3450 9.5 1650 2 3300 2 1650 120Document3 pagesDesign Data 610 3450 9.5 1650 2 3300 2 1650 120miteshpatel191100% (1)

- Mae 1202: Aerospace Practicum: Lecture 4: Introduction To Basic Aerodynamics 3Document38 pagesMae 1202: Aerospace Practicum: Lecture 4: Introduction To Basic Aerodynamics 3زهديابوانسNo ratings yet

- Alsabei ThesisDocument279 pagesAlsabei Thesisrayzo2182No ratings yet

- Akruti Marathi MultiFont Engine ReadmeDocument22 pagesAkruti Marathi MultiFont Engine Readmenmshingote2779% (38)

- Basic - Concepts - in - Pharmaceutical - Care CLINICAL PHARMACYDocument17 pagesBasic - Concepts - in - Pharmaceutical - Care CLINICAL PHARMACYPrincess RonsableNo ratings yet

- Binary Arithmetic Operations: Prof. R.Ezhilarasie Assistant Professor School of Computing SASTRA Deemed To Be UniversityDocument26 pagesBinary Arithmetic Operations: Prof. R.Ezhilarasie Assistant Professor School of Computing SASTRA Deemed To Be UniversityEzhil RamanathanNo ratings yet

- List of BooksDocument13 pagesList of Booksbharan16No ratings yet

- PMP Itto GuideDocument11 pagesPMP Itto GuideSocrates XavierNo ratings yet

- CSR of Pidilite PDFDocument2 pagesCSR of Pidilite PDFtarang keraiNo ratings yet

- Uniden Bearcat Scanner BC365CRS Owners ManualDocument32 pagesUniden Bearcat Scanner BC365CRS Owners ManualBenjamin DoverNo ratings yet

- Measuring PovertyDocument47 pagesMeasuring PovertyPranabes DuttaNo ratings yet

- (Revised) Dale Carnegie-How To Win Friends and Influence People-Simon and Schuster (1981)Document12 pages(Revised) Dale Carnegie-How To Win Friends and Influence People-Simon and Schuster (1981)TomasUreñaNo ratings yet

- Connecting Your Database and Auto Generate ID Using VB - Net 2008 and MySQL DatabaseDocument1 pageConnecting Your Database and Auto Generate ID Using VB - Net 2008 and MySQL DatabaseAgusWibowoNo ratings yet

- Michael J. Flynn - Some Computer Organizations and Their Effectiveness, 1972Document13 pagesMichael J. Flynn - Some Computer Organizations and Their Effectiveness, 1972earthcrosserNo ratings yet

- Cop4600 Exam1 sp13Document2 pagesCop4600 Exam1 sp13chavNo ratings yet

- Hydraulics Laboratory ManualDocument37 pagesHydraulics Laboratory ManualHarold Taylor100% (2)

- GE 8 ETHICS Week2 9Document54 pagesGE 8 ETHICS Week2 9Jay Ar OmbleroNo ratings yet

- CertificateofAnalysis 2019 11 9 879766Document2 pagesCertificateofAnalysis 2019 11 9 879766Trọng TínNo ratings yet

- Education and Learning: Good Study HabitsDocument3 pagesEducation and Learning: Good Study Habitsزهرة ZaraNo ratings yet

- Aitkensmethod 170829115234Document17 pagesAitkensmethod 170829115234Yumi koshaNo ratings yet

- CBSE Class 6 - MCQ Separation of SubstancesDocument4 pagesCBSE Class 6 - MCQ Separation of Substancesvinod1577100% (1)

- Report - Roche Pharmaceuticals LTD (Human Resource Planning & Development) 222Document23 pagesReport - Roche Pharmaceuticals LTD (Human Resource Planning & Development) 222jawwadraja100% (1)

- Intro To RMAN-10g-okDocument41 pagesIntro To RMAN-10g-okAnbao ChengNo ratings yet

- Ballsim DirectDocument58 pagesBallsim DirectDiego GaliciaNo ratings yet

- Ass AsDocument2 pagesAss AsMukesh BishtNo ratings yet

- Jeeves in The SpringtimeDocument14 pagesJeeves in The SpringtimearavindpunnaNo ratings yet