Professional Documents

Culture Documents

E6 185 04

Uploaded by

donyaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

E6 185 04

Uploaded by

donyaCopyright:

Available Formats

PETROLEUM ENGINEERING – DOWNSTREAM - Surface Petroleum Operations - H. K.

Abdel-Aal

SURFACE PETROLEUM OPERATIONS

H. K. Abdel-Aal

National Research Center, Cairo, Egypt

Keywords: Crude-oil mixture, gas-oil separators, GOSP, oil emulsions, heating,

chemical treatment, desalting, electrostatic coalescence, stabilization, sour crude oil, gas

sweetening

Contents

1. Introduction

2. Gas-Oil Separation

2.1. Background

S

2.2 Mechanism of Separation

TE S

2.2.1. Flash Separation

R

AP LS

2.2.2. Oil Recovery

2.3. Functional Components of a Gas-oil Separator and Control Devices

2.4. Methods and Equipment used in Separation

C EO

2.5. Design Equations for Sizing Gas-Oil Separators

3. Emulsion Treatment and Dehydration of Crude Oil

3.1. Fundamentals

3.2. Forms of Water Associated with Produced Oil: Emulsion Formation

E –

3.2.1. Factors Promoting the Stability of Emulsions

H

3.3. Treating the Emulsions

PL O

3.3.1. Heating

3.3.2. Chemicals

M SC

4. Desalting of Crude Oil

4.1. Background

4.2. Description of Desalting Process

5. Stabilization and Sweetening of Sour Crude Oil

SA NE

5.1. Introduction

5.2. Process Description

6. Conclusions

U

Glossary

Bibliography

Biographical Sketch

Summary

The main objective of Surface Petroleum Operations, SPO, is the processing of

reservoir fluids-exit the well-head- in order to produce marketable products; namely

crude oil and natural gas. The proposed treatment of the subject matter of SPO follows a

chronological sequence of field operations in transient. Each is described in terms of the

unit operation concept when applicable as the oil-gas mixture moves from the well-head

until the crude oil is separated, treated, and finally stored. Unit operation is a powerful

tool that describes the physical changes involved in many chemical and petroleum

industries.

©Encyclopedia of Life Support Systems(EOLSS)

PETROLEUM ENGINEERING – DOWNSTREAM - Surface Petroleum Operations - H. K. Abdel-Aal

The first step in crude oil processing takes place in the gas-oil separation plant (GOSP),

where gases are separated from oil. When water exists in the stream produced from the

well, the separators are used to separate the free water. Oil leaving does not generally

meat the purchaser’s specifications, because it may contain emulsified water. Salt

present in emulsified water poses a serious problem in terms of corrosion and scaling

during transportation and in refinery operations. Further treatment of crude oil takes

place which involves emulsion treatment/dehydration and desalting. This brings the

crude oil to a maximum of 1% BS&W (Basic Sediments & Water) and salt content of

15-20 PTB (Pounds per Thousand Barrel). Further processing of crude oil may be

justified by a dual operation which involves both Stabilization and Sweetening when

dealing with sour crude oils that contain more than 400 ppm of hydrogen sulfide gas.

1. Introduction

S

Crude oil-gas mixture, once produced from oil wells, moves through two main

TE S

distinctive processing operations in order to obtain useful petroleum products. These are

R

AP LS

identified as:

1. Surface Petroleum Operations, where gases are separated from oil with further

treatment of the separated fluids.

C EO

2. Refining operations, where crude oil is fractionated into cuts with further chemical

conversion processes to produce different petroleum products.

E –

H

PL O

M SC

SA NE

U

Figure 1. A Schematic Illustration of the Three Different Operations in the Oil Industry

Thus we go from oil production at one hand to oil refining on the other end via SPO, as

sketched in Figure 1. SPO represents the 3rd stage in the series of oil stages as depicted

in Figure 2.

The need for field processing of crude oil-gas mixture is justified for four main

reasons:-

• These mixtures are very difficult to handle, meter, or transport.

• It is unsafe and uneconomical to ship or transport such two-phase mixtures over-

seas to refineries and gas plants.

©Encyclopedia of Life Support Systems(EOLSS)

PETROLEUM ENGINEERING – DOWNSTREAM - Surface Petroleum Operations - H. K. Abdel-Aal

• Oil producers have to abide with the specifications set for shipping and refining.

• Environmental constraints established for the safe handling of hydrocarbons and the

disposal of produced salt water.

In its broadest meaning, SPO may cover the processing of all three streams from well

head as indicated in Figure3. However, this chapter is limited to the handling and

processing of crude oil only.

Examples of some unit operations that are used in SPO are given:-

Unit Operation Application in SPO

Equilibrium Flash Separation Gas-Oil Separation

Distillation/Stripping Stabilizers/Sweetening

Absorption Treatment of Natural Gas

S

TE S

Fluid Flow All Operations

Heat transfer Most Operations

R

AP LS

C EO

E –

H

PL O

M SC

SA NE

U

Figure 2 Stages in the Oil Industry

©Encyclopedia of Life Support Systems(EOLSS)

PETROLEUM ENGINEERING – DOWNSTREAM - Surface Petroleum Operations - H. K. Abdel-Aal

S

TE S

R

AP LS Figure 3. An Outline of the Processing Surface Field Operations

C EO

2. Gas-Oil Separation

2.1. Background

E –

H

PL O

M SC

SA NE

U

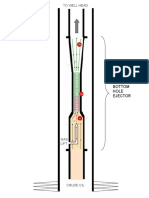

Figure 4. Effect of Operating Pressure on Separation

Well effluents flowing from producing wells are usually identified as turbulent, high

velocity mixtures of gases, oil and salt water. As these streams flow reaching the

surface, they undergo continuous reduction in temperature and pressure forming a two-

phase fluid flow: gas and liquid. The fluid emerges as a mixture of crude oil and gas

©Encyclopedia of Life Support Systems(EOLSS)

PETROLEUM ENGINEERING – DOWNSTREAM - Surface Petroleum Operations - H. K. Abdel-Aal

that is partly free and partly in solution. Crude oil has to be processed to separate the oil

from gases and from water as well. This is usually done by admitting the well fluid into

a GOSP through which pressure of the flowing mixture is successively reduced to

atmospheric pressure using few stages. As can be observed from Figure 4, the volume

of one barrel of the gas mixture, at a given reservoir conditions would shrink to a value

dependant on the operating pressure in the gas-oil separator.

2.2 Mechanism of Separation

The process involved in a gas-oil separator encompasses two main stages in order to

free oil from gas. These are recognized as: flash separation of the gas-oil mixture

followed by oil recovery.

2.2.1. Flash Separation

S

TE S

In order to understand the theory underlying the separation of well-effluents of

R

AP LS

hydrocarbon mixtures, it is assumed that such mixtures contain essentially three main

groups of hydrocarbons:-

C EO

• Light group which consists of methane(CH4) and ethane(C2H6)

• Intermediate group which consists of two subgroups: propane (C3H8)/butane (C4H10)

and pentane (C5H10)/hexane (C6H12)

• Heavy group which is the bulk of crude oil and is identified as C7H14+

E –

H

Basically our objective in separating the gas-oil mixture is a dual function:-

PL O

(a) To get rid of all C1 and C2, i.e. light gases

M SC

(b) Save the heavy-group components as our liquid product

In order to accomplish these objectives, we unavoidably loose part of the intermediate

SA NE

group in the gas stream, whose heavier components (C5 /C6) would belong definitely

belong to the oil product. The problem of separating gases in general from crude oil in

the well-fluid effluents breaks down to the well-known problem of flashing a feed

mixture into two streams: vapor and liquid. This takes place using a flashing column (a

U

vessel without trays). Gases liberated from the oil are kept in intimate contact. As a

result, thermodynamic equilibrium is established between the two phases .This is the

basis of flash calculations which is carried out to make material balance calculations for

the flashing streams.

-

-

-

TO ACCESS ALL THE 20 PAGES OF THIS CHAPTER,

Visit: http://www.eolss.net/Eolss-sampleAllChapter.aspx

©Encyclopedia of Life Support Systems(EOLSS)

PETROLEUM ENGINEERING – DOWNSTREAM - Surface Petroleum Operations - H. K. Abdel-Aal

Bibliography

Abdel-Aal H.K. (1973) AMBIO, Royal Swedish of Sciences, Volume 2 [Special issue on “Energy in

Society is the reference for Figure 2].

Abdel-Aal H.K. (1998). Surface Petroleum Operations, Saudi Publishing House, Jeddah, Saudi

Arabia.[This represents a compilation of notes prepared by the author while teaching at King Fahd

Univ. of Petroleum & Minerals ,KFUPM, Dhaharan, Saudi Arabia].

Abdel-Aal H.K., Aggour M., Fahim M.A. (2003) Petroleum and Gas Field Processing, Marcel Dekker

Inc., New York.[This is ajoint work by the authors focusing on the processing and treatment of the

reservoir fluids : oil, gas and water from production to storage].

Arnold K. and Stewart M. (1993). Surface Production Operations, Volume 2, Gulf Publishing Company,

Houston, TX [This text covers production operations other than crude oil processing].

Bradely H.B.(1992). Petroleum Engineering Handbook, Marcel Dekker Inc., New York. [Source of data

on Gas-oil separation].

Mc Ketta John J (1992) Petroleum Processing Handbook, Marcel Dekker Inc., New York [Useful

S

TE S

reference on Crude-oil desalting and gas sweetening].

R

AP LS

Biographical Sketch

Hussein K. Abdel-Aal born in Egypt, 1935. He has B.S. Ch E, Alexandria University, 1956, M.S. &

C EO

Ph.D. Ch E, Texas A.& M., TX, USA, 1962, 1965.Major field of study: chemical engineering.

He has more than 50 years of industrial experience, academic research and university teaching. He was a

faculty member at NRC, Cairo, Egypt, 1965-70, Post-Doctoral fellow at UMIST, England, 1970-71,

Visiting Prof., Texas A & M., College Station, TX 1980-81, Prof. at KFUPM, Dhahran, Saudi Arabia

1971-98. Currently, he is Emeritus Prof., NRC, Cairo, Egypt. He is the author of more than 50

E –

publications and two books: Petroleum Economics & Engineering, Marcel Dekker Inc., New York 1992,

H

Petroleum & Gas Field Processing, Marcel Dekker Inc., New York, 2003.

PL O

Prof. Abdel-Aal is a founding member of the International Association of Hydrogen Energy, FL, USA,

member of the editorial board of the International Journal of Hydrogen Energy, member, AICHE,

M SC

member, Egyptian Syndicate of engineering at Cairo.

SA NE

U

©Encyclopedia of Life Support Systems(EOLSS)

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Flame Arrester Technical Form: SocietyDocument7 pagesFlame Arrester Technical Form: SocietyHmd MokhtariNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Chemical Engineering CommunicationsDocument15 pagesChemical Engineering CommunicationsdonyaNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Questionnaire For: Liquid Jet Vacuum Ejectors For Continuous OperationDocument2 pagesQuestionnaire For: Liquid Jet Vacuum Ejectors For Continuous OperationdonyaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- © Association For Scientific Research: Mathematical and Computational Applications, Vol. 15, No. 1, Pp. 137-147, 2010Document11 pages© Association For Scientific Research: Mathematical and Computational Applications, Vol. 15, No. 1, Pp. 137-147, 2010Mocheedy UbahNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- (translate68.ir مترجم متن) 10.1088 - 0959-5309 - 57 - 4 - 301Document13 pages(translate68.ir مترجم متن) 10.1088 - 0959-5309 - 57 - 4 - 301donyaNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Option Selection Program: Select Your Reason For Using This ProgramDocument2 pagesOption Selection Program: Select Your Reason For Using This ProgramdonyaNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- BOTTOMHOLEEJECTORDocument1 pageBOTTOMHOLEEJECTORdonyaNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Pressure Drop Measurements in Distillatio ColumnsDocument5 pagesPressure Drop Measurements in Distillatio Columnsdonya100% (1)

- Distillation Trays That Operate Beyond The Limits of Gravity by Using Centrifugal SeparationDocument6 pagesDistillation Trays That Operate Beyond The Limits of Gravity by Using Centrifugal SeparationdonyaNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- (Doi 10.1002/0471238961), - Kirk-Othmer Encyclopedia of Chemical TechnologyDocument13 pages(Doi 10.1002/0471238961), - Kirk-Othmer Encyclopedia of Chemical TechnologyHenry ArenasNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- E-03.0) General Static-Mixing Customer Specification QuestionnaireDocument2 pagesE-03.0) General Static-Mixing Customer Specification QuestionnairedonyaNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- 6200 Area - Urea Plant: Process OverviewDocument8 pages6200 Area - Urea Plant: Process OverviewtreyzzztylerNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Size Distributions in Strongly Coalescing Agitated Liquid-Liquid SystemsDocument4 pagesSize Distributions in Strongly Coalescing Agitated Liquid-Liquid SystemsdonyaNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Size Distributions in Strongly Coalescing Agitated Liquid-Liquid SystemsDocument4 pagesSize Distributions in Strongly Coalescing Agitated Liquid-Liquid SystemsdonyaNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- (Paperhub Ir) 10 1021@ie950674wDocument14 pages(Paperhub Ir) 10 1021@ie950674wdonyaNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Processes MTP 03 00684 v2Document15 pagesProcesses MTP 03 00684 v2akshaykgNo ratings yet

- Theresa Renee Anthony: All Rights ReservedDocument53 pagesTheresa Renee Anthony: All Rights ReserveddonyaNo ratings yet

- FF - Mar-Apr - 2018 - Zero Waste Urea Production - ONLINEDocument3 pagesFF - Mar-Apr - 2018 - Zero Waste Urea Production - ONLINEdonyaNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Experimental Investigation of An Ejector: Received 6 September 1985 Revised 16 September 1985Document3 pagesExperimental Investigation of An Ejector: Received 6 September 1985 Revised 16 September 1985donyaNo ratings yet

- Objectlistview Python Edition StableDocument77 pagesObjectlistview Python Edition StabledonyaNo ratings yet

- Inventions 04 00016Document54 pagesInventions 04 00016donyaNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Entropy: Thermodynamic Modelling of An Ejector With Compressible Flow by A One-Dimensional ApproachDocument15 pagesEntropy: Thermodynamic Modelling of An Ejector With Compressible Flow by A One-Dimensional Approachkoustavghosh1986No ratings yet

- Modelling Gas Liquid Flow in Venturi SCR PDFDocument7 pagesModelling Gas Liquid Flow in Venturi SCR PDFdonyaNo ratings yet

- Questionnaire For: Liquid Jet Liquid EjectorsDocument2 pagesQuestionnaire For: Liquid Jet Liquid EjectorsdonyaNo ratings yet

- 1975163Document2 pages1975163donyaNo ratings yet

- 4244 12672 1 PB PDFDocument15 pages4244 12672 1 PB PDFVinh Do ThanhNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- 291-Questionnaire-Jet and Venturi scrubbers-EN-161202-STDocument2 pages291-Questionnaire-Jet and Venturi scrubbers-EN-161202-STdonyaNo ratings yet

- Processes MTP 03 00684 v2Document15 pagesProcesses MTP 03 00684 v2akshaykgNo ratings yet

- Data Sheet Ejector PDFDocument1 pageData Sheet Ejector PDFdonyaNo ratings yet

- 7) Improvement and Characterization of Sabkha Soil PDFDocument11 pages7) Improvement and Characterization of Sabkha Soil PDFMuhammad ImranNo ratings yet

- FiatDocument10 pagesFiatrgi178100% (1)

- Heats Sodium Hydroxide Solutions: SpecificDocument4 pagesHeats Sodium Hydroxide Solutions: SpecificTJ ArciagaNo ratings yet

- PhilosophyofTheism 10036021 PDFDocument354 pagesPhilosophyofTheism 10036021 PDFdydycookyNo ratings yet

- ASME Stamp Companies in KSADocument10 pagesASME Stamp Companies in KSASantanu SahaNo ratings yet

- Paper BioDocument17 pagesPaper BioI-hana D'yanaNo ratings yet

- DPP 15-17 PDFDocument5 pagesDPP 15-17 PDFAnkur GoyalNo ratings yet

- Fertilizer CompanyDocument5 pagesFertilizer CompanyParth Patel100% (1)

- GE Healthcare: Instructions For Sephadex MediaDocument2 pagesGE Healthcare: Instructions For Sephadex Mediaponbohacop0% (1)

- Design Os Sewers (Blue Book)Document388 pagesDesign Os Sewers (Blue Book)savanotrebor100% (1)

- Compressible Fluid FlowDocument41 pagesCompressible Fluid FlowSushil Thakkar100% (1)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Mechanical Engineering Board Exam SubjectsDocument4 pagesMechanical Engineering Board Exam Subjectsbenny narrido100% (1)

- 8 AdsorptionDocument85 pages8 AdsorptionRush WahabNo ratings yet

- B 91 - 12Document5 pagesB 91 - 12phaindikaNo ratings yet

- 015 - NH - 1003 Thermal and Acoustic InsulationDocument26 pages015 - NH - 1003 Thermal and Acoustic InsulationSaif AhmedNo ratings yet

- Laser Cutting SystemDocument21 pagesLaser Cutting SystemSamo FelicijanNo ratings yet

- 4D Mechanical - Mechanical EngineeringDocument27 pages4D Mechanical - Mechanical EngineeringSulist N WahyudieNo ratings yet

- THE EFFECT OF FOAMY SLAG IN THE ELECTRIC ARC FURNACES ON ELECTRIC Energy Consumption PDFDocument10 pagesTHE EFFECT OF FOAMY SLAG IN THE ELECTRIC ARC FURNACES ON ELECTRIC Energy Consumption PDFManojlovic VasoNo ratings yet

- Procast ManualDocument471 pagesProcast Manualtudorima100% (4)

- Non Protein NitrogenousDocument19 pagesNon Protein NitrogenousWina AdrianNo ratings yet

- Design Calculation For Oil Skimmer CapacityDocument4 pagesDesign Calculation For Oil Skimmer CapacityAyon BoseNo ratings yet

- Estimation of Glucose Concentration PDFDocument3 pagesEstimation of Glucose Concentration PDFAmiel DionisioNo ratings yet

- Airconditioning Feb 2018 Rev 4 Presentation-7Document59 pagesAirconditioning Feb 2018 Rev 4 Presentation-7darius james del mar86% (7)

- Revision 1 200520062007Document5 pagesRevision 1 200520062007alvin2282No ratings yet

- Balabanoff F19Document11 pagesBalabanoff F19asoooomi_11No ratings yet

- Chap 1 Thermodynamics Exercise PDFDocument25 pagesChap 1 Thermodynamics Exercise PDFRanveer GautamNo ratings yet

- Music TherapyDocument13 pagesMusic TherapyXavier KiranNo ratings yet

- Mechanical Properties of Carbon Fiber Composite MaterialsDocument2 pagesMechanical Properties of Carbon Fiber Composite MaterialsmehtabpathanNo ratings yet

- Harsh PatelDocument14 pagesHarsh PatelPradeepNo ratings yet

- Nutrition of The Tamandua I. Nutrient Composition of Termites and Stomach Contents From Wild TAMANDUA BANDEIRA PDFDocument16 pagesNutrition of The Tamandua I. Nutrient Composition of Termites and Stomach Contents From Wild TAMANDUA BANDEIRA PDFgabrielwerneckNo ratings yet

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideFrom Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideRating: 3.5 out of 5 stars3.5/5 (7)

- The Laws of Thermodynamics: A Very Short IntroductionFrom EverandThe Laws of Thermodynamics: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (10)

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseFrom EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseRating: 4.5 out of 5 stars4.5/5 (51)

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionFrom EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionRating: 4.5 out of 5 stars4.5/5 (3)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)