Professional Documents

Culture Documents

Aji 2

Uploaded by

Rizki TriajiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aji 2

Uploaded by

Rizki TriajiCopyright:

Available Formats

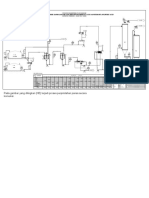

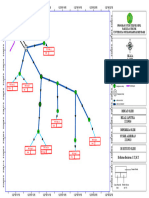

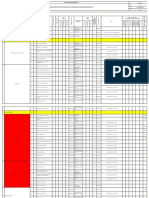

PROCESS ENGINEERING FLOW DIAGRAM

PRA RANCANGAN PABRIK METHYONINE DENGAN PROSES FERMENTASI

KAPASITAS 3.000 TON/TAHUN

STEAM

AIR PROSES

UDARA

1

30

1

1

30

Kode Keterangan

1

TC

CR-101 ST-JAGUNG Tangki Penyimpanan Jagung

ST-BAKTERI Tangki Penyimpanan Bakteri

ST-AMMONIA Tangki Penyimpanan NH3

ST-UDARA Tangki Penyimpanan Udara

ST-H2S Tangki Penyimpanan H2S

FC

RD-105 BE-10A Bucket Elevator

RVF-103

CR-101 Crusher

1

SC-102 Screw Conveyor

30

BE-10A RVF-103 Rotary Vacum Filter

1

SC-102 RD-105 Rotary Dryer

SC-106 Screw Conveyor

LI ST - JAGUNG SILO-PS Silo

1 MT Mixer

30

P - 104 EX-20C Expander

1 SC-106 EX-20D Expander

1

F-208A Fermentor

30

F-208B Fermentor

1 F-208C Fermentor

CF-210 Centrifuge

R-312 Reaktor

SD-314 Spray Dryer

SC-315 Screw Conveyor

S-PS LI SILO-PU Silo

BLOWER Blower

P-104 Pompa-104

P-20B Pompa-20B

P-207 Pompa-207

P-209 Pompa-209

P-311 Pompa-312

LI ST - BAKTERI LC P-313 Pompa-314

FC

P-316 Pompa-317

K-20C Kompresor

K-30D Kompresor

FC

FC

FC

MIXER

P - 207 Nomor Aliran

P – 20B

Tekanan (atm)

Temperatur (oC)

30

2

1

FC

FC

FC

Sinyal Pneumatic

Sinyal Elektrik

3

CE-210 Aliran Proses

2 30

30 1 Aliran Utilitas

ST - AMMONIA

K-20C

LI 10 TC Temperature Control

FC Flow Control

LC Liquid Control

PC

EX LC LC LC

PC Pressure Control

20C

30

3

1

PC

FC

F-208A F-208B F-208C

SD-313

PC

3

30

1

1 K-30D

P – 209

30

LI ST - UDARA 1 FC FC FC

1

BLOWER 30

1

PC

SC-314

LC

R-311

FC

3

-30

LI ST – H2S 19

S-PU LI

P - 312

EX-30D

PC

PACKING

KONDENSAT

UPL

UDARA PANAS

JURUSAN TEKNIK KIMIA FAKULTAS TEKNIK

Neraca Massa (kg/jam) UNIVERSITAS MUHAMMADIYAH JAKARTA

Crusher Rotary Vacum Filter Mixer Fermentor Reaktor CSTR Spray Dryer

KOMPONEN Masuk Keluar Masuk P-201 Masuk Utility Keluar P-104 Keluar Mixer Masuk RVF-103 Masuk P-20B Keluar P-207 Masuk P-208 Keluar P-312 Keluar P-311 Masuk P-132 Masuk EX-30D Keluar SD-313 Keluar UPL Masuk SD-313 Masuk Udara Keluar SC-314 Keluar UPL

Kg/Jam Kg/Jam Kg/Jam Kg/Jam Kg/Jam Kg/Jam Kg/Jam Kg/Jam Kg/Jam Kg/Jam Kg/Jam Kg/Jam Kg/Jam Kg/Jam Kg/Jam Kg/Jam Kg/Jam Kg/Jam Kg/Jam Kg/jam

Process Engineering Flow Diagram

Jagung 666.6271 533.3017 Pra-Rancangan Pabrik Methyonine dengan Proses Fermentasi

C12H22O11 133.3254 533.3017 53.3302 479.9715 479.9715 479.9715 23.9986 1.1999 22.7986 1.1999 1.1999 1.1951 1.1951

Kapasitas 3.000 Ton/Tahun

Padatan

133.3254 133.3254

(SOLID)

H20 33.3314 1.6666 31.6648 31.6648 31.6648 7.6662 1.9166 5.7497 1.9166 0.5750 1.3416 0.5726 0.0573 0.5154 Digambar Oleh :

Kultur Bakteri

6.4530 6.4530 6.4530 6.4530

CH1,64O0,52N0,16

O2 65.6892 2.5280 2.5280

Nama : Ahmad Muhamad Rizki Triaji (2014437001)

N2 0.5880 0.5880 Widy Maulana Iqbal (2014430031)

NH3

C6H12O6 22.8558 1.1428 21.7130 1.1428 1.1371 1.1325 0.1132 1.0192

C5H9NO4 373.3112 373.3112 373.3112 71.5513 71.2614 71.2614

Disetujui Oleh :

H2O2

CO2

H2O2 259.0322 259.0322

H2S 71.9534 2.1586

Impurities O2 0.2844 0.2844

Dosen Pembimbing,

Impurities N2 0.9362 0.9362 Dr. Ir. Tri Yuni Hendrawati., M.Si.,IPM

C5H11NO2S 305.8654 305.8654 305.8654 NIDN : 0311066902

Subtotal 666.6271 666.6271 666.6271 33.3314 188.3222 511.6363 511.6363 6.4530 518.0893 693.3170 377.5705 315.7465 377.5705 73.1740 380.3287 70.4100 380.0270 3.1160 378.4924 4.6506

Total 666.6271 666.6271 699.9585 699.9585 518.0893 518.0893 693.3170 693.3170 315.7465 450.7445 450.7387 383.1430 383.1430

You might also like

- Pefd 3 PDFDocument1 pagePefd 3 PDFRimalianiNo ratings yet

- PEFD Teknik Kimia PDFDocument1 pagePEFD Teknik Kimia PDFedwinNo ratings yet

- Flowsheet Proses Olein DEADocument3 pagesFlowsheet Proses Olein DEAWidharta Surya AlamNo ratings yet

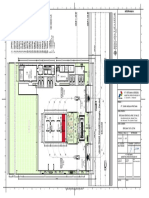

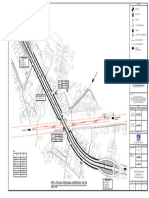

- PT - Anugrah Djam Sejati - Mamuju Utara-Layout1Document1 pagePT - Anugrah Djam Sejati - Mamuju Utara-Layout1Satlantas polres pasangkayu Polres pasangkayuNo ratings yet

- JARINGAN AIR BERSIH ADocument1 pageJARINGAN AIR BERSIH AChandra HasanNo ratings yet

- PS0121-DWG-B-003 Sheet 2 Jalur Pemipaan Dari WDO Fase 1 & 2 Menuju Drain Tank CCDS - Isometric Sect. 1 R.5Document1 pagePS0121-DWG-B-003 Sheet 2 Jalur Pemipaan Dari WDO Fase 1 & 2 Menuju Drain Tank CCDS - Isometric Sect. 1 R.5yusak adi setiawanNo ratings yet

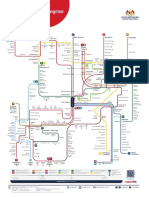

- Peta Lintasan (Lampiran C) PDFDocument1 pagePeta Lintasan (Lampiran C) PDFNada FauziyahNo ratings yet

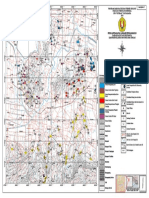

- Peta Geomorfologi TA 1 Revisi 3Document1 pagePeta Geomorfologi TA 1 Revisi 3Ringgit Aji PamungkasNo ratings yet

- Peta Dasar Pontianak 2009Document1 pagePeta Dasar Pontianak 2009Syamsul AkbarNo ratings yet

- LONG SECTION-tiong Keranji 1Document1 pageLONG SECTION-tiong Keranji 1Agustinus JokoNo ratings yet

- Flowsheet Pabrik Bio EthanolDocument1 pageFlowsheet Pabrik Bio EthanolAhmad Dzulfiqar FauziNo ratings yet

- Instalasi Ducting Vac Komposit Ceiling Lt.16.Par.1Document1 pageInstalasi Ducting Vac Komposit Ceiling Lt.16.Par.1Abraham LalangNo ratings yet

- Caprolacktam Ibnumu Upn 1Document2 pagesCaprolacktam Ibnumu Upn 1laboratorium preparasiNo ratings yet

- 01 Lay OutDocument1 page01 Lay OutfebriNo ratings yet

- Gambar PFD BaruDocument3 pagesGambar PFD BaruBayu RajindraNo ratings yet

- Kohort AncDocument1 pageKohort Ancpkm bulang100% (3)

- 1082 Peta Transit Berintegrasi Lembah Klang v12 FaDocument1 page1082 Peta Transit Berintegrasi Lembah Klang v12 FaHappy GuyNo ratings yet

- Dinas Penataan Ruang Dan Pertanahan: ME Denah Rencana Lampu Lantai Dasar Elv 0,00 1:200Document7 pagesDinas Penataan Ruang Dan Pertanahan: ME Denah Rencana Lampu Lantai Dasar Elv 0,00 1:200atsarsitekNo ratings yet

- Draft Gambar Kerja Kinsey Pet LandDocument6 pagesDraft Gambar Kerja Kinsey Pet Landmochtubagus rudianaNo ratings yet

- Denah Stan - Islamic Book Fair Pameran Buku Islam Terbesar Di Tanah Air Bahkan Asia Tenggara Dengan Menampilkan Ratusan Penerbit Dari Puluhan Ribu JudulDocument1 pageDenah Stan - Islamic Book Fair Pameran Buku Islam Terbesar Di Tanah Air Bahkan Asia Tenggara Dengan Menampilkan Ratusan Penerbit Dari Puluhan Ribu JudulMiqdar FadhilNo ratings yet

- Tanjung Merah Layout Draft 2Document1 pageTanjung Merah Layout Draft 2wandy RJNo ratings yet

- PETA-ADMIN-pontianak 2009 A3 PDFDocument1 pagePETA-ADMIN-pontianak 2009 A3 PDFbh0n4nkNo ratings yet

- Laporan Rasio LeverageDocument1 pageLaporan Rasio LeverageMuhamad FuadNo ratings yet

- Kontur Hilal 34Document1 pageKontur Hilal 34hilal SaputraNo ratings yet

- Peta Lintasan Per FormasiDocument1 pagePeta Lintasan Per FormasiwibsNo ratings yet

- Cad GabunganDocument8 pagesCad GabunganRivaldi HutabaratNo ratings yet

- Layout Plan Water Supply Projek Hutan Bandar USJ (Revised) PDFDocument1 pageLayout Plan Water Supply Projek Hutan Bandar USJ (Revised) PDFTarique ZiyadNo ratings yet

- Siteplan Blok B 15-05-2023Document1 pageSiteplan Blok B 15-05-2023Ridwan HambaliNo ratings yet

- Jakarta Urban Railway Map Jak Lingko 2023 TerbaruDocument1 pageJakarta Urban Railway Map Jak Lingko 2023 Terbaruwycnr2rn5mNo ratings yet

- 3010 - Ii PurbalinggaDocument1 page3010 - Ii PurbalinggaSILAHDATA TOPDAM IVNo ratings yet

- REV - ALT-7 General Layout LOTTDocument6 pagesREV - ALT-7 General Layout LOTTerlima pengasinanNo ratings yet

- 3.peta Situasi Rencana JPL99 - Edit U-TurnDocument1 page3.peta Situasi Rencana JPL99 - Edit U-TurnDodi RahmawanNo ratings yet

- Surat Ijin & Plan PengaspalanDocument2 pagesSurat Ijin & Plan PengaspalanBayu BiruNo ratings yet

- Fs Pengembanagn Pabrik IsopropylamineDocument1 pageFs Pengembanagn Pabrik IsopropylamineSeptyaDewiAnggraeniNo ratings yet

- Gambar Bida Ayu 3Document57 pagesGambar Bida Ayu 3mixx StudioNo ratings yet

- Flowsheet Asam LaktatDocument1 pageFlowsheet Asam Laktats a l t y100% (1)

- Hasil Ukur Kolaka Utara-ModelDocument1 pageHasil Ukur Kolaka Utara-ModelRizqi NoviantNo ratings yet

- Laporan - Keuangan - 30 - Juni - 2019 Nobu NationalDocument1 pageLaporan - Keuangan - 30 - Juni - 2019 Nobu Nationaldarma bonarNo ratings yet

- Long Section - Sta 15 + Sta 22.5-Long - 71Document1 pageLong Section - Sta 15 + Sta 22.5-Long - 71Galih molinggeyNo ratings yet

- Peta KPN - 23 JUNI 22.47Document1 pagePeta KPN - 23 JUNI 22.47taufik ahmadNo ratings yet

- 343.normalisasi Kali Rementes TAMSELDocument12 pages343.normalisasi Kali Rementes TAMSELDamar MKNo ratings yet

- 8-1 Metro Tabagsel FCDocument1 page8-1 Metro Tabagsel FCAbdulNo ratings yet

- Format Laporan Bulanan PKMDocument3 pagesFormat Laporan Bulanan PKMFiani NurbaetiNo ratings yet

- Gambar Ruas JalanDocument16 pagesGambar Ruas JalannanangbrNo ratings yet

- IBPR GeotechnicDocument18 pagesIBPR GeotechnicAISYA MAULIANANo ratings yet

- Layakkah Aku-InC-PianoDocument2 pagesLayakkah Aku-InC-PianoHanendyo WicaksonoNo ratings yet

- Ar-001 Denah LT - BasementDocument1 pageAr-001 Denah LT - BasementTito Berlianto AlamNo ratings yet

- Ars Rssa 2 LantaiDocument38 pagesArs Rssa 2 LantaiPurnama HelmiNo ratings yet

- PS0121-DWG-B-003 Sheet 1 Jalur Pemipaan Dari WDO Fase 1 & 2 Menuju Drain Tank CCDS - Layout R.6Document1 pagePS0121-DWG-B-003 Sheet 1 Jalur Pemipaan Dari WDO Fase 1 & 2 Menuju Drain Tank CCDS - Layout R.6yusak adi setiawanNo ratings yet

- Pra Rancangan Pabrik Asam Salisilat Dari Phenol Dan Natrium Hidroksida Dengan Proses Kolbe Schmitt Kapasitas 10.000 Ton/TahunDocument8 pagesPra Rancangan Pabrik Asam Salisilat Dari Phenol Dan Natrium Hidroksida Dengan Proses Kolbe Schmitt Kapasitas 10.000 Ton/TahunAhmad HermanNo ratings yet

- Bab V Analisis Data Survei Dan Keb TransportasiDocument33 pagesBab V Analisis Data Survei Dan Keb Transportasianon_393563846No ratings yet

- 001 Jaringan Jalan PT - MJSDocument1 page001 Jaringan Jalan PT - MJSslf pertashopNo ratings yet

- Peta GaltimDocument1 pagePeta Galtimperc.srslawi baruNo ratings yet

- 1712 - 33 (Tiwingan) PDFDocument1 page1712 - 33 (Tiwingan) PDFbn_butonNo ratings yet

- 3.peta Situasi Rencana JPL99 - A4Document1 page3.peta Situasi Rencana JPL99 - A4Dodi RahmawanNo ratings yet

- TPT Art CenterDocument5 pagesTPT Art Centerrio wahyuNo ratings yet

- Shop Drawing Summarecon Bandung Revisi-Pju (6X11) PDFDocument1 pageShop Drawing Summarecon Bandung Revisi-Pju (6X11) PDFkristian kumajayaNo ratings yet

- Lampiran IiDocument5 pagesLampiran IinovrialNo ratings yet

- Bab Ii - 3 - 1 - 2020Document24 pagesBab Ii - 3 - 1 - 2020Rizki TriajiNo ratings yet

- Bab Iii - 3 - 1 - 2020Document6 pagesBab Iii - 3 - 1 - 2020Rizki TriajiNo ratings yet

- Bab 1 - 3 - 1 - 2020Document4 pagesBab 1 - 3 - 1 - 2020Rizki TriajiNo ratings yet

- TesisDocument1 pageTesisRizki TriajiNo ratings yet

- Laporan Pelaksanaan Tugas WFH Tahap 1-3Document7 pagesLaporan Pelaksanaan Tugas WFH Tahap 1-3Rizki TriajiNo ratings yet

- Data Ekspor - Impor Dl-Methionine 2011 - 2016Document10 pagesData Ekspor - Impor Dl-Methionine 2011 - 2016Rizki TriajiNo ratings yet

- 4 Absorber Stripper d3Document10 pages4 Absorber Stripper d3Sandy SetiyoNo ratings yet

- Pkmi06 071 PDFDocument9 pagesPkmi06 071 PDFYanuar Rufianti WongiNo ratings yet