Professional Documents

Culture Documents

Sizing Receivers

Uploaded by

jlcheefei9258Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sizing Receivers

Uploaded by

jlcheefei9258Copyright:

Available Formats

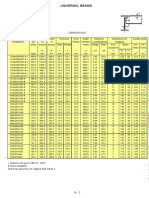

Nitrogen In breathing requirement do not chg

y input box

Ave stor T 60 degc n calcu box

Inbreathing Inbreathing

Tank exposed Max Max Max Min. total Max. total Consideration

Tank Top Tank Min due to due to Total Inbreathing at

Tank Tank Tank Tank Volume insulation Tank reduction medium medium retentionmonthly monthly of

No Tank No. insulation insulation Retention medium thermal Inbreathing simultaneous

size(MT) Height(m) diameter (m) (m3) rockwool Surface factor, R1 Inflow rate outflow rate time drawout drawout simultaneous

(y/n) area (m2) time (days) movement reduction (nm3/hr) op

(mm) area (m2) (m3/hr) (m3/hr) (days) rate (m3) rate (m3) op

(nm3/hr) (nm3/hr)

1 B02 250 18.288 4.85 337.8621735 50 297.1237 y 297.1237 0.166667 15 200 1 3 3379 10136 200 63.808687 263.8086867 y 263.8086867

2 B03 250 18.288 4.85 337.8621735 0 297.1237 y 0 1 15 200 1 3 3379 10136 200 382.85212 582.8521204 n 0

3 B04 250 18.288 4.85 337.8621735 100 297.1237 y 297.1237 0.090909 40 15 1 3 3379 10136 15 34.804738 49.80473822 n 0

4 B06 250 18.288 4.85 337.8621735 297.1237 y 0 1 15 200 1 3 3379 10136 200 382.85212 582.8521204 y 582.8521204

5 B07 250 18.288 4.85 337.8621735 297.1237 y 0 1 15 200 1 3 3379 10136 200 382.85212 582.8521204 n 0

6 B08 250 18.288 4.85 337.8621735 297.1237 y 0 1 40 15 1 3 3379 10136 15 382.85212 397.8521204 n 0

7 B10 250 18.288 4.85 337.8621735 297.1237 y 0 1 15 200 1 3 3379 10136 200 382.85212 582.8521204 n 0

8 B11 250 18.288 4.85 337.8621735 297.1237 y 0 1 15 200 1 3 3379 10136 200 382.85212 582.8521204 n 0

9 C03 500 18.288 6.3 570.0818224 393.1292 y 0 1 15 200 2 5 3420 8551 200 552.16566 752.1656578 n 0

10 C04 500 18.288 6.3 570.0818224 393.1292 y 0 1 200 200 2 5 3420 8551 200 552.16566 752.1656578 n 0

11 C05 500 18.288 6.3 570.0818224 393.1292 y 0 1 40 200 2 5 3420 8551 200 552.16566 752.1656578 n 0

12 C09 500 18.288 6.3 570.0818224 393.1292 y 0 1 200 200 2 5 3420 8551 200 552.16566 752.1656578 n 0

13 C10 500 18.288 6.3 570.0818224 393.1292 y 0 1 40 15 2 5 3420 8551 15 552.16566 567.1656578 n 0

14 D02 100 18.288 2.91 121.6303825 173.8404 y 0 1 15 200 1 3 1216 3649 200 187.25905 387.2590463 n 0

15 D03 100 18.288 2.91 121.6303825 173.8404 y 0 1 15 200 1 3 1216 3649 200 187.25905 387.2590463 n 0

16 D04 100 18.288 2.91 121.6303825 173.8404 y 0 1 15 200 1 3 1216 3649 200 187.25905 387.2590463 n 0

17 D05 100 18.288 2.91 121.6303825 173.8404 y 0 1 15 200 1 3 1216 3649 200 187.25905 387.2590463 n 0

18 D06 100 18.288 2.91 121.6303825 173.8404 y 0 1 15 200 1 3 1216 3649 200 187.25905 387.2590463 n 0

3045 50,213 142,088 Total Max 846.6608072 Nm3/hr

Product : Palm oil based Average consumption /mth = 96,150

Density : 900

Liquid Flow pressure : minimum 2bar and maximum 6bar

Pipe size for all tanks : 4" ID

N2 pressure : 100-150psig

Temperature : +60 to +70C

Application : Oxygen stripping

Type of impurities : Ketones and Oxygen

Inlet impurities ppm : 10,000ppm

Desired impurities ppm: 8000ppm

Sparger type : In line

You might also like

- Triaxial Compression Test: Sample#2Document46 pagesTriaxial Compression Test: Sample#2muhammad junaidNo ratings yet

- Electrical LV Panel Form ClassificationDocument2 pagesElectrical LV Panel Form Classificationjlcheefei9258No ratings yet

- Soil Bearing Capacity CalcuationsDocument26 pagesSoil Bearing Capacity CalcuationsBishal Thapa MagarNo ratings yet

- Section TableDocument52 pagesSection TableNurin Irdina RoslanNo ratings yet

- Determination of Specific Gravity: ReferencesDocument26 pagesDetermination of Specific Gravity: ReferencesSagheer AhmedNo ratings yet

- Flowserve CPX BrochureDocument28 pagesFlowserve CPX BrochureRenz PascualNo ratings yet

- Water Content Sample Compaction Test ResultDocument157 pagesWater Content Sample Compaction Test ResultSuci Angraeni SaputriNo ratings yet

- CbsDocument3 pagesCbsBharat ChatrathNo ratings yet

- Softening PointDocument8 pagesSoftening PointMauricio CruzNo ratings yet

- GI Sheet Kg-m2Document1 pageGI Sheet Kg-m2farshan296015No ratings yet

- Glo Sika RCC Concrete Dams HandbookDocument51 pagesGlo Sika RCC Concrete Dams Handbooksravan_rubyNo ratings yet

- Distillation Report - Rotation 1Document23 pagesDistillation Report - Rotation 1Рада МарјановићNo ratings yet

- Sombrerito BoinaDocument6 pagesSombrerito BoinaSil100% (1)

- Ejectors: Wide Uses & Selection GuideDocument6 pagesEjectors: Wide Uses & Selection Guidehappale2002No ratings yet

- Diseño de ColumnasDocument4 pagesDiseño de ColumnasLuiz Fernando Alarcon RojasNo ratings yet

- Tugas Hidrologi Nama: Irham Fauzan Hidayat NPM: 1811085 Kelas: Sipil C UASDocument10 pagesTugas Hidrologi Nama: Irham Fauzan Hidayat NPM: 1811085 Kelas: Sipil C UASUdung DudungNo ratings yet

- Tugass BTADocument26 pagesTugass BTAHabib PijarNo ratings yet

- Data Validation OutputDocument14 pagesData Validation OutputDaniel BravoNo ratings yet

- The following data were obtained in a pressure build test on an oil well producing above the bubb P (PSI) Δt (hrs)Document9 pagesThe following data were obtained in a pressure build test on an oil well producing above the bubb P (PSI) Δt (hrs)Ritesh PoudiyalNo ratings yet

- Assignment Stepped April20thDocument1,748 pagesAssignment Stepped April20thMegh Raj KCNo ratings yet

- Tabla ArmadurasDocument8 pagesTabla ArmadurasLuis Rodrigo AldunateNo ratings yet

- NO Outside Trata 1 1 2 3 4 2 5 6 3 7: A1 A2 U o 3Document3 pagesNO Outside Trata 1 1 2 3 4 2 5 6 3 7: A1 A2 U o 3Fauziah Nur AzmiNo ratings yet

- Metodo de Standing-Katz para El Factor de CompresibilidadDocument7 pagesMetodo de Standing-Katz para El Factor de CompresibilidadCesar Ivan Hernandez JimenezNo ratings yet

- BS Section PDFDocument96 pagesBS Section PDFUpendra WalinjkarNo ratings yet

- Pile Capacity (version 1)Document6 pagesPile Capacity (version 1)Rajesh GangwalNo ratings yet

- Shell and Tube Heat Exchanger AnalysisDocument14 pagesShell and Tube Heat Exchanger AnalysisAbdul rahman WahidNo ratings yet

- Informe N°10Document3 pagesInforme N°10Vladimir Jerson Alferez VargasNo ratings yet

- Design Report: Feed ConditionDocument20 pagesDesign Report: Feed ConditionKashan AslamNo ratings yet

- End Ones DeaDocument26 pagesEnd Ones DeadeaNo ratings yet

- Tutorial 5 - SolutionDocument10 pagesTutorial 5 - SolutiondaniellamirimbaNo ratings yet

- Sample Number Temp T1 (°C) Temp T2 (°C) Temp T3 (°C) Temp T4 (°C) Temp T5 (°C) Temp T6 (°C) Temp T7 (°C)Document13 pagesSample Number Temp T1 (°C) Temp T2 (°C) Temp T3 (°C) Temp T4 (°C) Temp T5 (°C) Temp T6 (°C) Temp T7 (°C)urikelNo ratings yet

- Jumbo 355 CHS: EN 10210 S355J2H Hot Finished Circular Hollow SectionsDocument1 pageJumbo 355 CHS: EN 10210 S355J2H Hot Finished Circular Hollow SectionsDivan YeungNo ratings yet

- Data Penelitian: Grafik X Kuadrat Vs yDocument5 pagesData Penelitian: Grafik X Kuadrat Vs ysaefulNo ratings yet

- Sheet1 Raceway AmpacityDocument18 pagesSheet1 Raceway AmpacityAngel CalderonNo ratings yet

- Nozzle Effi Ciency Vs Overall Pressure RatioDocument2 pagesNozzle Effi Ciency Vs Overall Pressure Ratioyoga satoeNo ratings yet

- Torsion Test: Civil Engineering Department Mechanics of Materials Lab (10601202) Second Semester 2019/2020 Report SheetDocument10 pagesTorsion Test: Civil Engineering Department Mechanics of Materials Lab (10601202) Second Semester 2019/2020 Report SheetTahseen QashouNo ratings yet

- Diagrama de Iteracciones ColumnaDocument7 pagesDiagrama de Iteracciones Columnafranz llanosNo ratings yet

- Laboratory ExperimentDocument10 pagesLaboratory ExperimentladheedhaNo ratings yet

- Metal SpecificationsDocument1 pageMetal SpecificationsJain EngineeringNo ratings yet

- Lutfi Purnama R - 220411913 - Latihan 1 Tugas MandiriDocument5 pagesLutfi Purnama R - 220411913 - Latihan 1 Tugas MandiriNaon WelahNo ratings yet

- Result TableDocument1 pageResult Tableme23m032No ratings yet

- Aluminio y acero experimentan deformación por tensiónDocument19 pagesAluminio y acero experimentan deformación por tensiónSANDRA XIMENA PEREZ PERALTANo ratings yet

- Wetico Water Tank 70m Shell Ultimate ChecksDocument2 pagesWetico Water Tank 70m Shell Ultimate ChecksChristian Paul SanguyoNo ratings yet

- Moment at Each SectionDocument9 pagesMoment at Each SectionSanket BhaleraoNo ratings yet

- Rotameter Venturi Pressure Flow Rate Test ResultsDocument10 pagesRotameter Venturi Pressure Flow Rate Test ResultsesnowNo ratings yet

- Datos Arquitectonicos Cálculos Datos de Columna Atiezadores Comp Sentido B CompDocument11 pagesDatos Arquitectonicos Cálculos Datos de Columna Atiezadores Comp Sentido B CompFernanda JaramilloNo ratings yet

- Hidrograma Escorrentia Directa: T (Horas)Document8 pagesHidrograma Escorrentia Directa: T (Horas)Andres Felipe Rincon PabonNo ratings yet

- Design of Btm. Reinf. of Beam/Slab Design of Top Reinf. of Beam/SlabDocument10 pagesDesign of Btm. Reinf. of Beam/Slab Design of Top Reinf. of Beam/Slabvikas WaghmareNo ratings yet

- TG056 Fig8 FTTP SagTensionDocument2 pagesTG056 Fig8 FTTP SagTensionphugogang1No ratings yet

- PROGRMA DE TIEMPOS OkDocument5 pagesPROGRMA DE TIEMPOS OkMarlon MassimoNo ratings yet

- Include Additional Worksheets With Calculations For Partial Credits in The Event Your Final Answer Is Not CorrectDocument5 pagesInclude Additional Worksheets With Calculations For Partial Credits in The Event Your Final Answer Is Not Correctalisafaa974No ratings yet

- Jacket Vessel FixDocument3 pagesJacket Vessel FixAnonymous 5ZNwm8muuNo ratings yet

- Flange DesignDocument45 pagesFlange Design7761430100% (1)

- Comparison of Actual and Theoretical Flow RatesDocument3 pagesComparison of Actual and Theoretical Flow RatesNavisNo ratings yet

- Carga-Momento Mampostería ReforzadaDocument30 pagesCarga-Momento Mampostería ReforzadaPamelaCalderónNo ratings yet

- Caudal Maximo Caudal Descarga Concen.: Caudal de DiseñoDocument3 pagesCaudal Maximo Caudal Descarga Concen.: Caudal de DiseñoAndrea Caro CocaNo ratings yet

- Price List: Spring Lock WashersDocument8 pagesPrice List: Spring Lock WashersnitintshNo ratings yet

- Tiempo (Min) Lectura (CM) Recarga (CM) Dif Lectura (CM) 0 20 Infiltración (Cm/min) Infiltración (CM/H) Tiempo Acumulado (Min)Document4 pagesTiempo (Min) Lectura (CM) Recarga (CM) Dif Lectura (CM) 0 20 Infiltración (Cm/min) Infiltración (CM/H) Tiempo Acumulado (Min)Azly VasquEzNo ratings yet

- Lare Reservoir CapacityDocument15 pagesLare Reservoir CapacityAbiued EjigueNo ratings yet

- Objects And Elements - Joints TABLEDocument4 pagesObjects And Elements - Joints TABLEyaquiycjNo ratings yet

- Fan speed test data analysis and heat transfer calculationDocument5 pagesFan speed test data analysis and heat transfer calculationFauziah Nur AzmiNo ratings yet

- HE Kel 7&8 FixDocument32 pagesHE Kel 7&8 FixRozan AjahNo ratings yet

- Calculo de Erosion UsleDocument10 pagesCalculo de Erosion UsleJose Luis EstupiñanNo ratings yet

- Baiq Gita AuliaDocument6 pagesBaiq Gita AuliaSUHARTINo ratings yet

- Tabel Hidrograf Inflow: Baiq Gita Aulia F1A019030Document6 pagesTabel Hidrograf Inflow: Baiq Gita Aulia F1A019030SUHARTINo ratings yet

- Seismic Analysis Results for Building Z3S2Document7 pagesSeismic Analysis Results for Building Z3S2Luis TorresNo ratings yet

- Incendiu - SprinklereDocument8 pagesIncendiu - SprinklereimepsystemsNo ratings yet

- Impact of Ecigarettes On LungDocument1 pageImpact of Ecigarettes On Lungjlcheefei9258No ratings yet

- Sizing ReceiversDocument3 pagesSizing Receiversjlcheefei9258No ratings yet

- Distillation Report - Rotation 1Document1 pageDistillation Report - Rotation 1jlcheefei9258No ratings yet

- Thermon Steam Tracing PDFDocument4 pagesThermon Steam Tracing PDFCarlos SopasNo ratings yet

- Sizing For Condensate Receivers: (Reprinted From MECHANICAL CONTRACTOR Magazine)Document2 pagesSizing For Condensate Receivers: (Reprinted From MECHANICAL CONTRACTOR Magazine)iranbodNo ratings yet

- Figure2 - Diesel Bulk ModulusDocument3 pagesFigure2 - Diesel Bulk ModulusLuis MechánNo ratings yet

- Orifice Eng TipDocument8 pagesOrifice Eng Tipjlcheefei9258No ratings yet

- Industrial Slabs: The Steel Fiber With Industrial-Strength ToughnessDocument2 pagesIndustrial Slabs: The Steel Fiber With Industrial-Strength Toughnessjlcheefei9258No ratings yet

- Ideal AirDocument6 pagesIdeal Airjlcheefei9258No ratings yet

- Sizing For Condensate Receivers: (Reprinted From MECHANICAL CONTRACTOR Magazine)Document2 pagesSizing For Condensate Receivers: (Reprinted From MECHANICAL CONTRACTOR Magazine)iranbodNo ratings yet

- Citric Acid DensityDocument1 pageCitric Acid Densityjlcheefei9258No ratings yet

- NPSH Calculations Explained: Net Positive Suction Head and Pump DesignDocument3 pagesNPSH Calculations Explained: Net Positive Suction Head and Pump DesignEdward YanceNo ratings yet

- Siemens SIMATIC TI Direct User's Guide PDFDocument38 pagesSiemens SIMATIC TI Direct User's Guide PDFjlcheefei9258No ratings yet

- 00 Drainage FlowTables 100 To 500 MMDocument1 page00 Drainage FlowTables 100 To 500 MMjlcheefei9258No ratings yet

- Asean Haccp enDocument98 pagesAsean Haccp enzyrtylNo ratings yet

- Concentration Cheat SheetDocument2 pagesConcentration Cheat Sheetjlcheefei9258No ratings yet

- Steel Fibres FlooringDocument8 pagesSteel Fibres Flooringjlcheefei9258No ratings yet

- Gearbox SelectionDocument3 pagesGearbox Selectionjlcheefei9258No ratings yet

- Sound InsulationDocument6 pagesSound Insulationjlcheefei9258No ratings yet

- Abl12e 09Document2 pagesAbl12e 09jlcheefei9258No ratings yet

- 5066452Document53 pages5066452jlcheefei9258No ratings yet

- Chemical Enzymatic InteresterificationDocument37 pagesChemical Enzymatic Interesterificationjlcheefei9258No ratings yet

- Steam EjectorDocument4 pagesSteam Ejectorjlcheefei9258No ratings yet

- Steam Consumption of Jet Pumps: E K Ø 18 Kg/kmol 300 °CDocument2 pagesSteam Consumption of Jet Pumps: E K Ø 18 Kg/kmol 300 °Cjlcheefei9258No ratings yet

- Lessons From The Field - Ejector SystemsDocument5 pagesLessons From The Field - Ejector SystemsAnibal AriasNo ratings yet

- Trouble SourcesDocument14 pagesTrouble Sourcesjlcheefei9258No ratings yet

- DigesterDocument2 pagesDigesterEce TUĞRULÖZNo ratings yet

- Ellamera BI THIN 602Document2 pagesEllamera BI THIN 602Waides Silva PachecoNo ratings yet

- Comparison Anti Fouling Coating 2020Document12 pagesComparison Anti Fouling Coating 2020Mohamad JammalNo ratings yet

- Ferrofluids (Introduction, Future Horizons and Applications)Document21 pagesFerrofluids (Introduction, Future Horizons and Applications)Makhdoom Luqman HashmiNo ratings yet

- Unit 1: Oxidation-Reduction (Redox) : Engage/ExplainDocument19 pagesUnit 1: Oxidation-Reduction (Redox) : Engage/ExplainKeigh KimmNo ratings yet

- Slides: - High Quality Furniture FittingsDocument44 pagesSlides: - High Quality Furniture FittingsGetziNo ratings yet

- Arvind AcademyDocument10 pagesArvind AcademyGhantaNo ratings yet

- Iso 17804 2020Document13 pagesIso 17804 2020Kerem ErtemNo ratings yet

- HDPE Wire Insulation CompoundDocument2 pagesHDPE Wire Insulation CompoundLeonardoNo ratings yet

- Custom Home Design Plan #211 by SDS-CAD Specialized Design SystemsDocument24 pagesCustom Home Design Plan #211 by SDS-CAD Specialized Design Systemsmasood khanNo ratings yet

- Almacenamiento de TuberiaDocument4 pagesAlmacenamiento de TuberiaYesid Cruz Yesid CruzNo ratings yet

- Notes of Is Matter Around Us Pure - Class 9Document13 pagesNotes of Is Matter Around Us Pure - Class 9Atharva VarshneyNo ratings yet

- Chemistry ks4 Lesson CHM Y10 U2 l6Document9 pagesChemistry ks4 Lesson CHM Y10 U2 l6rukhNo ratings yet

- Admix 225 MB: SBR Latex-Based Bonding AgentDocument2 pagesAdmix 225 MB: SBR Latex-Based Bonding Agentmaga2292No ratings yet

- Blending SiloTechniquesDocument6 pagesBlending SiloTechniquesYaserElkelawy100% (1)

- TC 132 - en 1396-1997Document22 pagesTC 132 - en 1396-1997Tuyen NguyenNo ratings yet

- Hood and Duct Material & Gage SelectionDocument3 pagesHood and Duct Material & Gage SelectionJan Marvin TamseNo ratings yet

- Furnace PDFDocument32 pagesFurnace PDFJEFY JEAN ANo ratings yet

- Ammonia and The Haber Process Notes by Sean Chua Winners EducationDocument8 pagesAmmonia and The Haber Process Notes by Sean Chua Winners EducationHå LàåndNo ratings yet

- Maz 10 Ym - Mip Ea 151 - 02 - RNCCDocument62 pagesMaz 10 Ym - Mip Ea 151 - 02 - RNCCFilipe Areas100% (1)

- NAQPDocument9 pagesNAQProhitNo ratings yet

- 2083 ESR DatasheetDocument1 page2083 ESR Datasheetfuransu777No ratings yet

- Iso 7203-1-2019Document50 pagesIso 7203-1-2019alejandroNo ratings yet

- Blast Furnace Slag Aggregates for Base and Subbase ConstructionDocument2 pagesBlast Furnace Slag Aggregates for Base and Subbase ConstructionGreissy ReynagaNo ratings yet

- Summer Training Presentation Department of Chemistry By-Abhishek ROLL NO.-2K17CHUN01002Document14 pagesSummer Training Presentation Department of Chemistry By-Abhishek ROLL NO.-2K17CHUN01002Ishu AttriNo ratings yet