Professional Documents

Culture Documents

Hydrotest Acceptance Questionnaire & Resources: Questions To Ask

Uploaded by

Michael HaiseOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hydrotest Acceptance Questionnaire & Resources: Questions To Ask

Uploaded by

Michael HaiseCopyright:

Available Formats

Hydrotest Acceptance Questionnaire & Resources

Client/Contractor: Project Name: Project Number: Supervisor:

Test Medium: Onshore/Offshore: Start Date-Time: Current Date-Time:

Pipe Size: Pipe Length: Wall Thickness: Exposed Piping:

Questions to Ask:

1. What is the overall trend?

2. Type of Test: HDD, Full test, Pre-pull, Post-pull

3. Is the pipe insulated?

4. How long has pipe been stabilized?

5. What is ambient temperature and history of it?

6. Where are temperature probes installed?

a. Exactly how is ground probe installed

b. What is test medium temperature and how is that gathered?

i. When did you fill it?

ii. What is the source (lake, frac tank) of test medium?

1. How deep is your filter?

2. Where was test medium temperature data gathered?

c. How are you reading pipe temperature

i. Is it representative of actual pipe temperature?

7. How far is pipe buried in the ground?

8. Are there any pressure discontinuities that appear on any chart(s)?

a. Was any volume of fluid collected? If so, what was the measurement?

9. Any failure during the test?

10. Did you leak test the connections?

11. What’s the data (at least 1/hr, preferably 2/hr)?

12. P-V plot look okay? No yielding of pipe?

13. Is the pipe restrained, free (visual leak test), submerged/buried?

14. Any jumpers? How long are they and what size are they?

15. What is the length of instrumentation hose, if not tied in directly to pipe?

16. Was the line pre-filled prior to WFT’s arrival?

17. All instrumentation calibrated within proper time limits?

18. Was procedure followed?

Questions for the Engineer to Answer:

1. Was fill water able to stabilize prior to testing consistent with calculations? (Reference:

Temperature Stabilization Excel Spreadsheet)

2. Are pressure inconsistencies accounted for?

Hydrotest Acceptance Questionnaire & Resources

Client/Contractor: Project Name: Project Number: Supervisor:

Test Medium: Onshore/Offshore: Start Date-Time: Current Date-Time:

Pipe Size: Pipe Length: Wall Thickness: Exposed Piping:

a. Temperature, leak other than pipe - volume, bumping chart, …

b. Was volume captured and does it correlate with pipe data?

i. (Reference: Pipe Data – Fill and Test Excel Spreadsheet)

c. If temperature plays a role, is the magnitude of the pressure change consistent to the

change in temperature? (Reference: Temperature vs Pressure Excel Spreadsheet)

i. Does the subsea temperature profile correlate with the known temperature data

(Reference: GOM Water Depth vs. Temp Chart and Seawater Temperature

Chart)

3. Does the pressure chart trend more like a leak or stabilization?

4. What is the calculated stabilization time and does it correlate with field data?

5. Has conduction of pipe been evaluated? Heat transfer between steel and water?

You might also like

- 18B-044-PE I - M Mid-PaperDocument5 pages18B-044-PE I - M Mid-PaperShabihNo ratings yet

- Journal of Natural Gas Science and Engineering: K.K. Botros, J. Crowe, V. Liu, J. LuDocument13 pagesJournal of Natural Gas Science and Engineering: K.K. Botros, J. Crowe, V. Liu, J. LuIvanRodriguezNo ratings yet

- CE 016 Laboratory 4 - Baxter, Ralph Lawrence R.Document6 pagesCE 016 Laboratory 4 - Baxter, Ralph Lawrence R.RALPH LAWRENCE BAXTERNo ratings yet

- Pipes Spec & Pipe ClassDocument19 pagesPipes Spec & Pipe Classryo asg5No ratings yet

- Cbems 140aDocument19 pagesCbems 140amdawg467No ratings yet

- 02 P FallingheadpermeabilitytestnewDocument8 pages02 P Fallingheadpermeabilitytestnewkavithrra krishnanNo ratings yet

- SPE 63079 Well Testing With A Permanent Monitoring SystemDocument9 pagesSPE 63079 Well Testing With A Permanent Monitoring SystemyeralhNo ratings yet

- Falling Head Permeability Lab TestDocument6 pagesFalling Head Permeability Lab TestHamierul MohamadNo ratings yet

- Module 5: Short QuestionsDocument2 pagesModule 5: Short QuestionscaptainhassNo ratings yet

- Module 5: Short QuestionsDocument2 pagesModule 5: Short QuestionsanuNo ratings yet

- Module 5: Short QuestionsDocument2 pagesModule 5: Short Questionsjacky sparrowNo ratings yet

- OTC 1999-InsulationTestMethod TNODocument16 pagesOTC 1999-InsulationTestMethod TNOhan.velthuis431No ratings yet

- OPEN ENDED LAB 4 Bernoulli TheoremDocument4 pagesOPEN ENDED LAB 4 Bernoulli Theoremeris cameliaNo ratings yet

- 02 P ConstantheadpermeabilitytestnewDocument8 pages02 P ConstantheadpermeabilitytestnewAfiq AimanNo ratings yet

- Expt2 Sound PDFDocument3 pagesExpt2 Sound PDFaugustus willemNo ratings yet

- Mashao PA (221026681) Pre PracDocument9 pagesMashao PA (221026681) Pre PracPheza AndrewNo ratings yet

- Wang 2017Document15 pagesWang 2017Antony Manicka RajaNo ratings yet

- Water Level Measurement ProcedureDocument6 pagesWater Level Measurement Proceduresharjeel_geologistNo ratings yet

- LABORATORY ACTIVITY NO. 4 Discharge in An Open ChannelDocument6 pagesLABORATORY ACTIVITY NO. 4 Discharge in An Open ChannelApple SalaumNo ratings yet

- Soalan Dan Jawapan Untuk INIDocument7 pagesSoalan Dan Jawapan Untuk INIKam ariffNo ratings yet

- V NotchDocument21 pagesV NotchBenson Mwathi Mungai67% (3)

- Falling Head Permeability - 011Document8 pagesFalling Head Permeability - 011Bee-thumb FairusNo ratings yet

- Determination of Coefficient of Orifice Meter PDFDocument17 pagesDetermination of Coefficient of Orifice Meter PDFVerlon VincentNo ratings yet

- Lab 7Document18 pagesLab 7coopere23100% (1)

- Study On Temperature Distribution Along Wellbore oDocument8 pagesStudy On Temperature Distribution Along Wellbore oTAUFIQ HIDAYATNo ratings yet

- Well TestingDocument21 pagesWell TestingOvaid Mehmood100% (1)

- Laboratory Manual: Measurements & Instrumentation (ME-318-F)Document40 pagesLaboratory Manual: Measurements & Instrumentation (ME-318-F)Tony K PaulNo ratings yet

- Subject: Fluid Mecanics 2: Bloom's TaxonomyDocument18 pagesSubject: Fluid Mecanics 2: Bloom's TaxonomyrejohzvidzayiNo ratings yet

- Thesis AndreArsenio TUD FinalDocument166 pagesThesis AndreArsenio TUD FinalAmal KaNo ratings yet

- Geothermal Well TestingDocument15 pagesGeothermal Well TestingAly RasyidNo ratings yet

- Exp301 Linear ExpansionDocument4 pagesExp301 Linear ExpansionJhenz Santos Bayadas0% (1)

- Title: Falling Head Test: K Al LN (H H A T TDocument5 pagesTitle: Falling Head Test: K Al LN (H H A T TaimanNo ratings yet

- Group 1 Flow Rate of Water Over Weir Experiment REVISEDDocument7 pagesGroup 1 Flow Rate of Water Over Weir Experiment REVISEDPocavNo ratings yet

- Fluid Mechanics Lab: State Institute of Technical Teachers Training & Research, KalamasseryDocument53 pagesFluid Mechanics Lab: State Institute of Technical Teachers Training & Research, KalamasseryAeronautical Engineering HODNo ratings yet

- Liquid Phase Heat Transfer in Helical Coiled Heat ExchangerDocument66 pagesLiquid Phase Heat Transfer in Helical Coiled Heat ExchangerTushar Mahale50% (2)

- University of Soran Faculty of Engineering Chemical Department SIMDocument5 pagesUniversity of Soran Faculty of Engineering Chemical Department SIMZhiar KoyeNo ratings yet

- Lab 3 Exp 4Document16 pagesLab 3 Exp 4dennisalejaga08No ratings yet

- The Effect of Temperature and Material On Mains Pipe Breaks in GothenburgDocument74 pagesThe Effect of Temperature and Material On Mains Pipe Breaks in GothenburgArjun KoduriNo ratings yet

- Experiment 4 - Friction Losses in Pipes 2Document13 pagesExperiment 4 - Friction Losses in Pipes 2Dyas FerNo ratings yet

- High-Pressure, High-Temperature Well Logging, Perforating and TestingDocument18 pagesHigh-Pressure, High-Temperature Well Logging, Perforating and TestingDwi Apriliantono100% (2)

- HMT Lab ReportDocument13 pagesHMT Lab Reportsomeguy64No ratings yet

- Ef Ux Time From Vertical Cylindrical Tank Design and ConstructionDocument9 pagesEf Ux Time From Vertical Cylindrical Tank Design and ConstructionMehdi KhfifiNo ratings yet

- 4368 PDFDocument153 pages4368 PDFAhmed AmirNo ratings yet

- Expt Guide A2 - Efflux TimeDocument3 pagesExpt Guide A2 - Efflux Timeariana religiosoNo ratings yet

- Sui DissertationDocument138 pagesSui DissertationVinicius SacramentoNo ratings yet

- Falling HeadDocument4 pagesFalling HeadSyed Zulfaizzuan AljufriNo ratings yet

- 2 +energy+losses+in+pipesDocument4 pages2 +energy+losses+in+pipesFahad Abu-ThntynNo ratings yet

- Boiler Remaining Life AssessDocument33 pagesBoiler Remaining Life AssessSSudhakar100% (1)

- Lecture 1Document20 pagesLecture 1Ap OnNo ratings yet

- Analysis and Evaluation of Pumping Test Data PDFDocument373 pagesAnalysis and Evaluation of Pumping Test Data PDFAnonymous hE0IDl70% (1)

- Lab Session 02 FM 2Document9 pagesLab Session 02 FM 2Haid AshfaqueNo ratings yet

- ENM200 Subsurface Course Work 2 FinalDocument9 pagesENM200 Subsurface Course Work 2 FinalArief Budiman Hermani100% (1)

- Experiment No. 9 Demonstration of Fluid Flow Through An Orifice I. ObjectiveDocument5 pagesExperiment No. 9 Demonstration of Fluid Flow Through An Orifice I. ObjectiveMark B. BarrogaNo ratings yet

- Hydraulic Laboratory Manual: Philadelphia UniversityDocument45 pagesHydraulic Laboratory Manual: Philadelphia UniversityRacknarockNo ratings yet

- Seminarreport 150410092207 Conversion Gate01Document21 pagesSeminarreport 150410092207 Conversion Gate01Abdla DoskiNo ratings yet

- Heat Transfer Lab ManualDocument43 pagesHeat Transfer Lab ManualA SESHADRINo ratings yet

- Respiration Calorimeters for Studying the Respiratory Exchange and Energy Transformations of ManFrom EverandRespiration Calorimeters for Studying the Respiratory Exchange and Energy Transformations of ManNo ratings yet

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- A Treatise on Meteorological Instruments Explanatory of Their Scientific Principles, Method of Construction, and Practical UtilityFrom EverandA Treatise on Meteorological Instruments Explanatory of Their Scientific Principles, Method of Construction, and Practical UtilityNo ratings yet

- Pipeline Design for Water EngineersFrom EverandPipeline Design for Water EngineersRating: 5 out of 5 stars5/5 (1)

- Desuperheater Boiler Feed Water RequirementDocument2 pagesDesuperheater Boiler Feed Water RequirementMichael HaiseNo ratings yet

- Air Inclusion Report PDFDocument1 pageAir Inclusion Report PDFMichael HaiseNo ratings yet

- CalculationsDocument6 pagesCalculationsMichael Haise100% (1)

- 1st Stage in Frac Water Reuse System - Rev1Document2 pages1st Stage in Frac Water Reuse System - Rev1Michael HaiseNo ratings yet

- Reuse of Flowback Produced Water For Hydraulic FracturingDocument34 pagesReuse of Flowback Produced Water For Hydraulic FracturingAnonymous 3nevEoNo ratings yet

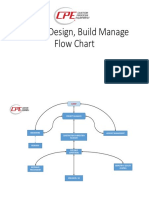

- Project Design, Build Manage Flow ChartDocument2 pagesProject Design, Build Manage Flow ChartMichael HaiseNo ratings yet

- Pump (English) TemplateDocument1 pagePump (English) TemplateMichael HaiseNo ratings yet

- Vessel Data Sheet: Design CriteriaDocument8 pagesVessel Data Sheet: Design CriteriaMichael HaiseNo ratings yet

- Inputs Inputs: Top TriangleDocument4 pagesInputs Inputs: Top TriangleMichael HaiseNo ratings yet

- Heat Exchanger Specification Sheet: Performance of One Unit Shell Side Tube SideDocument1 pageHeat Exchanger Specification Sheet: Performance of One Unit Shell Side Tube SideMichael HaiseNo ratings yet

- Beam ConverterDocument13 pagesBeam ConvertervindyavNo ratings yet

- Karman DPDocument4 pagesKarman DPFrancisco RenteriaNo ratings yet

- Vessel Data Sheet: Design CriteriaDocument8 pagesVessel Data Sheet: Design CriteriaMichael HaiseNo ratings yet

- Vessel Sizing Calculation Data Sheets: Customer Name: Project Title: Cpe Job #: Document #Document13 pagesVessel Sizing Calculation Data Sheets: Customer Name: Project Title: Cpe Job #: Document #Michael HaiseNo ratings yet

- Basic Pipe AnalysisDocument29 pagesBasic Pipe AnalysisMichael HaiseNo ratings yet

- Karman DPDocument4 pagesKarman DPFrancisco RenteriaNo ratings yet

- Fired Furnace Excess Air CalculationDocument3 pagesFired Furnace Excess Air CalculationAtul kumar KushwahaNo ratings yet

- PSVsDocument8 pagesPSVsMichael HaiseNo ratings yet

- Insulation Thickness CalculationDocument2 pagesInsulation Thickness Calculationrajpal14667% (6)

- Mechanical Calcualtions: Date: 3/28/2006 By: MH Checked: ApprovedDocument1 pageMechanical Calcualtions: Date: 3/28/2006 By: MH Checked: ApprovedMichael HaiseNo ratings yet

- Cost EstimationDocument28 pagesCost Estimationmayur1980100% (1)

- Condensate Line SizingDocument2 pagesCondensate Line Sizingemmanuilmoulos6339100% (1)

- Wrench SizesDocument6 pagesWrench SizesMichael HaiseNo ratings yet

- Pump Suction ArrangementsDocument24 pagesPump Suction ArrangementskidseismicNo ratings yet

- Column Base Connections Baniotopoulos CCDocument16 pagesColumn Base Connections Baniotopoulos CCmutlu_seçerNo ratings yet

- Wind LoadDocument2 pagesWind LoadMichael Haise100% (1)

- Saddle CalculationDocument7 pagesSaddle CalculationMichael HaiseNo ratings yet

- Firetube FrameDocument1 pageFiretube FrameMichael HaiseNo ratings yet

- Structural Steel SkidsDocument2 pagesStructural Steel SkidsMichael HaiseNo ratings yet

- Optimizing Patient Flow: Innovation Series 2003Document16 pagesOptimizing Patient Flow: Innovation Series 2003Jeff SavageNo ratings yet

- Grade 7 - R & C - Where Tigers Swim - JanDocument15 pagesGrade 7 - R & C - Where Tigers Swim - JanKritti Vivek100% (3)

- IGCSE Religious Studies (Edexcel - 2009 - Be Careful Not To Choose The New' IGCSE)Document8 pagesIGCSE Religious Studies (Edexcel - 2009 - Be Careful Not To Choose The New' IGCSE)Robbie TurnerNo ratings yet

- Selling AIESEC To Your TargetsDocument7 pagesSelling AIESEC To Your TargetspijoowiseNo ratings yet

- PQM Quiz FinalDocument11 pagesPQM Quiz FinalSyeda Sadaf ZahraNo ratings yet

- UW Mathematics Professor Evaluations For Fall 2011Document241 pagesUW Mathematics Professor Evaluations For Fall 2011DPNo ratings yet

- Glorious Mysteries 1Document5 pagesGlorious Mysteries 1Vincent safariNo ratings yet

- Bsee 36: Survey of English and American Literature Learning Material 2: Introduction To Literary Theories and CriticismDocument4 pagesBsee 36: Survey of English and American Literature Learning Material 2: Introduction To Literary Theories and CriticismCarlosNorielCabanaNo ratings yet

- Kumleben Commission ReportDocument232 pagesKumleben Commission ReportJulian Rademeyer100% (2)

- Application List: Required Items: A: Cpu-95 Ignition ModuleDocument12 pagesApplication List: Required Items: A: Cpu-95 Ignition ModuleShubra DebNo ratings yet

- Republic of The Philippines Department of Education Deped Complex, Pasig City Science Iii K To 12 Curriculum Guide Planner / Budget of WorkDocument3 pagesRepublic of The Philippines Department of Education Deped Complex, Pasig City Science Iii K To 12 Curriculum Guide Planner / Budget of WorkLedie Lou Cetoy SuperalesNo ratings yet

- LoperAmid 1Document5 pagesLoperAmid 1Hemma KusumaningrumNo ratings yet

- 9709 w05 Ms 2Document5 pages9709 w05 Ms 2michael hengNo ratings yet

- What Is E-CollaborationDocument7 pagesWhat Is E-CollaborationToumba LimbreNo ratings yet

- Tabulation Sheet (LABO)Document9 pagesTabulation Sheet (LABO)KetIanCotalesNo ratings yet

- Heat Cured ElastomersDocument40 pagesHeat Cured ElastomerslberrierNo ratings yet

- 实用多元统计分析Document611 pages实用多元统计分析foo-hoat LimNo ratings yet

- ErtlDocument64 pagesErtlManpreet SinghNo ratings yet

- Capital Structure UploadDocument17 pagesCapital Structure UploadLakshmi Harshitha mNo ratings yet

- Pengaruh Pemberian Dosis Pupuk Urea Terhadap Pertumbuhan Tanaman Bayam Cabut Putih (AmaranthusDocument10 pagesPengaruh Pemberian Dosis Pupuk Urea Terhadap Pertumbuhan Tanaman Bayam Cabut Putih (AmaranthusMartha YhunickeNo ratings yet

- Net June 2013Document22 pagesNet June 2013Sunil PandeyNo ratings yet

- Theater InstallationDocument7 pagesTheater InstallationtemamNo ratings yet

- Russian Sec 2023-24Document2 pagesRussian Sec 2023-24Shivank PandeyNo ratings yet

- Ga2 27:6:23Document1 pageGa2 27:6:23john HuntNo ratings yet

- Combustion FundamentalsDocument30 pagesCombustion FundamentalsPrem SagarNo ratings yet

- State Partnership Program 101 Brief (Jan 2022)Document7 pagesState Partnership Program 101 Brief (Jan 2022)Paulo FranciscoNo ratings yet

- Scan 03-Jan-2020 PDFDocument2 pagesScan 03-Jan-2020 PDFPavanSharmaNo ratings yet

- GundamDocument25 pagesGundamBattlecruiser ScharnhorstNo ratings yet

- Obat Keras N0vember 2021Document137 pagesObat Keras N0vember 2021antonNo ratings yet

- Hunk (Aakc) - (Nov 2015)Document68 pagesHunk (Aakc) - (Nov 2015)Russell RiderNo ratings yet