Professional Documents

Culture Documents

Vickers PLL 2078

Uploaded by

Rajan BediOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vickers PLL 2078

Uploaded by

Rajan BediCopyright:

Available Formats

Set-Up Procedure

Vickers®

Valves

Proportional Power Plug

EHH-AMP-702-D/E-10

Released 5/93 630

Introduction

Introduction Necessary Equipment Connection of power plug

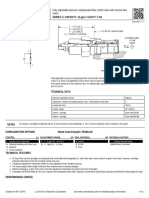

This set-up procedure describes the S EHH-AMP-702-D-10 or Referring to the schematic in Figure 1

adjustments on the Power Plug for EHH-AMP-702-E-10 power plug and the power plug diagram in Figure 2,

setting the dead-band, gain and ramp connect the power supplies, voltmeter,

S Compatible KDG series or KTG

rate on a non-feedback proportional command potentiometer and valve

series non-feedback type

valve. solenoid as shown.

proportional valve

Proportional valves with over-lapped S Hydraulic power source and load

spools have a range of spool travel circuit

where there is no flow from the valve.

This range of spool motion is called S 24 volt DC power source

dead-band. Adjusting the power plug

S 10 volt DC power source

allows the dead-band to be

electronically eliminated (dead-band S DC voltmeter

compensation) by making the spool

S 1000 ohm potentiometer

jump across the dead-band when a

(multi-turn preferred)

small input signal is applied to the

power plug. S Connecting cables

Output Flow

Gain +

Input Voltage

+ Power Power plug

input +

24V DC

Solenoid

The gain of the valve is the ratio of the

opening of the valve (or flow rate from it)

– – –

to the applied voltage input to the power

plug. Power R1 R2

+ volt

The ramp rate is the rate at which the supplies Ramp Gain Modulator

meter

power plug allows the valve to open (or –

close) when a step voltage input is

applied to the power plug. In many 10V DC Enable Power

applications this ramp would be used C amp.

1000W

to gradually accelerate or decelerate + command R3: deadband

an actuator. pot. compensation

Signal input

Installation precautions to Figure 1. Power plug set-up schematic

eliminate leaks into the power

plug

R1 – Ramp

S Use only cables with circular adjustment.

cross-sections and diameter Power input +24V

Turn clockwise

between 5–10 mm (.2” - .4”) to increase

S Ensure that sealing grommet is ramp time.

present and installed correctly. It

must be forced over the outer jacket R3 – Dead-

of the cable. band

S Ensure that all the gaskets are compensation

adjustment.

present and properly seated. LED Turn clockwise

S Ensure that the plastic cover seats command to reduce

firmly and correctly on the center signal deadband

body post. input compensation

ground current.

R2 – Gain adjustment.

Turn clockwise to

decrease gain.

Figure 2. Power plug connections

E Eaton Hydraulics, Incorporated, 2000

All rights reserved

Adjustment Procedures

Figure 1 shows the set-up for one Ramp rate adjustment

solenoid. If the valve contains two

solenoids, the set-up and the following A. For most applications:

Ramp time

procedure should be repeated. Set R1 fully clockwise

(minimum ramp rate). Run

CAUTION the actuator for different

increasing counter-

Applying more than 10 volts at input C

clockwise settings of the

may result in damage to the power plug.

potentiometer R1 until fully 20% 40% fully

Deadband adjustment slight hydraulic shocks in CW CCW

the system are observed.

A. Turn potentiometer R3 on Back-off R1 clockwise until Note that adjustment is very non-linear and

the power plug fully the shocks just disappear. most adjustment lies within 40% of the

clockwise (no deadband potentiometer rotation range for ramp-up

compensation) and R1 Fastest shock-free ramp and 20% of the adjustment range for

fully counter-clockwise rate is set. ramp-down.

(maximum ramp rate).The

red LED will turn off (it B. For any other ramp rate:

turns off to signify an “off” Run the actuator for Figure 5. Sensitivity of deadband

condition valve, when different increasing CCW adjustment to potentiometer R3 (typical).

input voltage is less than settings of the

100 mV). potentiometer R1, until the

desired velocity ramp is

B. Adjust command observed at the actuator.

potentiometer until the

voltmeter reads 0.25 volts

at connection C.

C. Slowly adjust

potentiometer R3

counter-clockwise until

100% Deadband

compensation

movement at the actuator

is detected.

Deadband compensation is set.

Gain adjustment

A. For many applications the 0% ~40% fully CCW

valve gain may simply be

set to a maximum by Note that all adjustment lies within

turning potentiometer R2 40% of the potentiometer rotation.

fully clockwise.

Figure 3. Sensitivity of deadband

For any other gain setting: adjustment to potentiometer R3 (typical).

A.. Calculate the maximum

speed of the actuator.

Calculate 80% of this

maximum speed.

B.. Set command

potentiometer to provide 8

volt input (or “gain”)

volts at C (8 volts is 80% of

maximum input voltage.

C.. Slowly adjust

flow rate

potentiometer R2 until this

80% speed is observed at

the actuator.

Valve gain is set. fully CW 40% fully CCW

Repeat the deadband adjustment and

the gain adjustment steps at least once Figure 4. Sensitivity of deadband

more since adjusting one parameter adjustment to potentiometer R3 (typical).

affects the setting of the other.

Wiring Preparation

Use single cable

with round outer Attachment screw

3 x 0,5–1,0 mm2 jacket such as:

(20AWG-18AWG) Alpha #1952/3

Belden #8770

5 (0.2)

Stretch cable Cover

grommet

over outer

jacket

O5 – 10

(0.197–0.394 dia.) GCenter body post gasket

GCover gasket

Electronic module

0V Power input

Command signal input R1: Ramp adjustment. Turn clockwise

to increase ramp time.

LED

R3: Deadband compensation

adjustment.

Turn clockwise to reduce deadband

compensation current

WARNING

R2: Gain adjustment. Turn clockwise to

Ensure cable clamp nut is adequately decrease gain.

tightened to secure the cable.

Do not connect or disconnect the Body

plug while power is on.

Do not mount or dismount the plug

when power is on.

Cable grommet

G All seals must be fitted correctly at plug

installation to provide protection to IP65 Grommet cinch nut

(IEC 529) GMounting gasket

Figure 6. Power plug exploded view

Vickers, Incorporated

A TRINOVA Company

5445 Corporate Drive

Troy, MI 48007–0302

Phone: (313) 641–4500

Fax: (313) 641–4948

630 Rel 5/93 Printed in U.S.A.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Existential ThreatsDocument6 pagesExistential Threatslolab_4No ratings yet

- TIMO Final 2020-2021 P3Document5 pagesTIMO Final 2020-2021 P3An Nguyen100% (2)

- Shuttle Valve - Tuscon - 5-710Document2 pagesShuttle Valve - Tuscon - 5-710Rajan BediNo ratings yet

- Heavy - Duty - Foot - Switches - BCH IndiaDocument4 pagesHeavy - Duty - Foot - Switches - BCH IndiaRajan BediNo ratings yet

- Ppppu CDocument2 pagesPpppu CRajan BediNo ratings yet

- Model Dual Cavity, Accepts Standard and Weatherized CoilsDocument6 pagesModel Dual Cavity, Accepts Standard and Weatherized CoilsRajan BediNo ratings yet

- High Pressure Regulator Gps 420 Series For 100 BarDocument2 pagesHigh Pressure Regulator Gps 420 Series For 100 BarRajan BediNo ratings yet

- Probability!: Notes Examples Sample ProblemsDocument12 pagesProbability!: Notes Examples Sample ProblemsRajan BediNo ratings yet

- Model Fully Adjustable Pressure Compensated Flow Control Valve With Reverse Flow CheckDocument2 pagesModel Fully Adjustable Pressure Compensated Flow Control Valve With Reverse Flow CheckRajan BediNo ratings yet

- Other Technologies Book 2 ChaptDocument1 pageOther Technologies Book 2 ChaptRajan BediNo ratings yet

- Dialogue Au Restaurant, Clients Et ServeurDocument9 pagesDialogue Au Restaurant, Clients Et ServeurbanuNo ratings yet

- Ricoh IM C2000 IM C2500: Full Colour Multi Function PrinterDocument4 pagesRicoh IM C2000 IM C2500: Full Colour Multi Function PrinterKothapalli ChiranjeeviNo ratings yet

- II 2022 06 Baena-Rojas CanoDocument11 pagesII 2022 06 Baena-Rojas CanoSebastian GaonaNo ratings yet

- Ozone Therapy - A Clinical Review A. M. Elvis and J. S. EktaDocument5 pagesOzone Therapy - A Clinical Review A. M. Elvis and J. S. Ektatahuti696No ratings yet

- Quantitative Methods For Economics and Business Lecture N. 5Document20 pagesQuantitative Methods For Economics and Business Lecture N. 5ghassen msakenNo ratings yet

- Appendix - Pcmc2Document8 pagesAppendix - Pcmc2Siva PNo ratings yet

- Movie Piracy in Ethiopian CinemaDocument22 pagesMovie Piracy in Ethiopian CinemaBehailu Shiferaw MihireteNo ratings yet

- MRBR ATR 72 Rev18Document424 pagesMRBR ATR 72 Rev18Juan Forero OrtizNo ratings yet

- Agnes de MilleDocument3 pagesAgnes de MilleMarie-Maxence De RouckNo ratings yet

- Project ManagementDocument11 pagesProject ManagementBonaventure NzeyimanaNo ratings yet

- All You Need To Know About Egg YolkDocument7 pagesAll You Need To Know About Egg YolkGolden Era BookwormNo ratings yet

- LM74680 Fasson® Fastrans NG Synthetic PE (ST) / S-2050/ CK40Document2 pagesLM74680 Fasson® Fastrans NG Synthetic PE (ST) / S-2050/ CK40Nishant JhaNo ratings yet

- 11-03 TB Value Chains and BPs - WolfDocument3 pages11-03 TB Value Chains and BPs - WolfPrakash PandeyNo ratings yet

- Heterogeneity in Macroeconomics: Macroeconomic Theory II (ECO-504) - Spring 2018Document5 pagesHeterogeneity in Macroeconomics: Macroeconomic Theory II (ECO-504) - Spring 2018Gabriel RoblesNo ratings yet

- Lesson 6 ComprogDocument25 pagesLesson 6 ComprogmarkvillaplazaNo ratings yet

- Rule 113 114Document7 pagesRule 113 114Shaila GonzalesNo ratings yet

- Partes de La Fascia Opteva Y MODULOSDocument182 pagesPartes de La Fascia Opteva Y MODULOSJuan De la RivaNo ratings yet

- Project Scheduling and TrackingDocument47 pagesProject Scheduling and TrackingArun VinodhNo ratings yet

- Problem Set-02Document2 pagesProblem Set-02linn.pa.pa.khaing.2020.2021.fbNo ratings yet

- History of The Sikhs by Major Henry Cour PDFDocument338 pagesHistory of The Sikhs by Major Henry Cour PDFDr. Kamalroop SinghNo ratings yet

- Environmental Economics Pollution Control: Mrinal Kanti DuttaDocument253 pagesEnvironmental Economics Pollution Control: Mrinal Kanti DuttashubhamNo ratings yet

- Origami Oso HormigueroDocument9 pagesOrigami Oso HormigueroRogelio CerdaNo ratings yet

- On Derridean Différance - UsiefDocument16 pagesOn Derridean Différance - UsiefS JEROME 2070505No ratings yet

- Famous Russian PianoDocument10 pagesFamous Russian PianoClara-Schumann-198550% (2)

- Washing Machine: Service ManualDocument66 pagesWashing Machine: Service ManualFernando AlmeidaNo ratings yet

- My Personal Code of Ethics1Document1 pageMy Personal Code of Ethics1Princess Angel LucanasNo ratings yet

- Vendor Information Sheet - LFPR-F-002b Rev. 04Document6 pagesVendor Information Sheet - LFPR-F-002b Rev. 04Chelsea EsparagozaNo ratings yet

- Organizational ConflictDocument22 pagesOrganizational ConflictTannya AlexandraNo ratings yet