Professional Documents

Culture Documents

Duplex Welding Guidelines

Uploaded by

adelCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Duplex Welding Guidelines

Uploaded by

adelCopyright:

Available Formats

WELDING GUIDELINES FOR

DUPLEX & SUPERDUPLEX

STAINLESS STEELS

Metrode Products Limited

Welding Consumables for

Hanworth Lane, Chertsey,

Duplex & Superduplex Alloys

Surrey, KT16 9LL, UK

Tel: +44 (0)1932 566 721

Fax: +44 (0)1932 569 449

Email: info@metrode.com

http//www.metrode.com

Duplex & superduplex ferritic-austenitic stainless steels

Welding guidelines

CONTENTS

Page

1 Introduction 1

2 Joint preparation 1

3 Preheat 2

4 Interpass temperature 2

5 Heat input 2

6 Welding processes 3

7 Root welding 3

8 2nd “cold” pass 4

9 Filling runs 4

10 Thin wall tube 7

11 Post weld heat treatment 7

12 Dissimilar welding 7

Appendix 1 Welding Procedure Specifications

Appendix 2 Data sheets

See Data Sheets: -

B-60, B-61, B-62, B-63

in Data Sheets folder

© Metrode Products Ltd

Duplex & superduplex ferritic-austenitic stainless steels

Welding guidelines

1 Introduction

There is a range of stainless steel alloys with a duplex, ferritic-austenitic, microstructure and this

leaflet provides guidance on welding these alloys. Standard duplex is 22%Cr (eg. UNS S31803 and

S32205) and superduplex is 25%Cr with a pitting resistance equivalent number (PREN ) 40 (eg.

UNS S32760, S32750 and S32550). These guidelines are based on joints being left in the as-

welded condition. Metrode have a full range of consumables, and data sheets for all products are

included at the end.

2 Joint preparation

The joint preparations will be similar to those used for standard stainless steel fabrication but for

single sided joints it is important to have an open root gap to ensure the addition of adequate filler.

The joint preparation will vary depending on material thickness, see examples below.

Wall

Included Included Root gap, g Root face, f

Thickness

angle, angle, mm mm

mm

2–3 70 – 90 - 2–3 0.5 – 1.5

>4 65-75 - 2–4 0.5 – 1.5

f g

> 20 70 – 80 15 – 20 2–4 0.5 – 1.5

f g

Radius, R

> 20 15 – 30 mm 2–4 0.5 – 1.5

R

4–6

f g

© Metrode Products Ltd Page 1 of 7 Issue 1 February 2005

Tacking

Tacking is important to ensure the root gap does

not close. Bullet tacks or bridging tacks are

normally used and must be removed as each

segment is completed. All tacks should be

deposited following an approved weld

procedure. There must be sufficient tacks

evenly spaced round the joint to keep a

consistent root gap.

3 Preheat

Preheat is not necessary for most duplex and superduplex stainless steel joints unless the material

is below ~5°C or wet, in which case the material should be preheated (~75-100°C) to prevent

condensation. Heating must be uniform avoiding the creation of localised hot spots.

Some thick section joints to be welded with sub-arc may benefit from a low preheat of ~75-125°C.

On large, thick section joints, which have a significant heat sink the first submerged arc runs can be

prone to pin-hole porosity; a low preheat can help prevent this.

4 Interpass temperature

The interpass temperature for both duplex and superduplex should be controlled to ensure the best

results. For superduplex 150°C is the maximum but for 22%Cr duplex 250°C would probably be

acceptable although most codes do not differentiate between duplex and superduplex so 150°C

maximum should be used for all grades.

Forced air cooling

To improve productivity by reducing the time required to cool below the interpass temperature it is

possible, on some joints, to use forced air cooling. The main application that has taken advantage

of forced air cooling has been rotated submerged arc joints; because in situations where welding is

carried out continuously there is a risk of excessive heat build-up, this can be minimised by forced

cooling. Dried compressed air can be passed through the centre of the pipe once the gas purge has

been removed.

5 Heat input

Heat input needs to be kept within specified limits to ensure optimum properties. Heat inputs in the

range 0.5-2.5kJ/mm for duplex and 0.5-2.0kJ/mm for superduplex should be acceptable, but most

codes restrict the maximum to 1.75 or 2.0kJ.mm for duplex and 1.5 or 1.75kJ/mm for the

superduplex grades.

A maximum heat input is imposed to prevent overheating of the HAZ and previously deposited weld

metal. High heat inputs also produce slower cooling rates which, particularly in superduplex,

increase the risk of intermetallic formation. Very low heat inputs should also be avoided because

this will increase the number of runs required to fill a joint. If more runs are deposited the weld

metal is reheated more times and this again increases the risk of intermetallic formation. A

reasonable working range for the filling runs is about 1.0-1.75kJ/mm, depending on grade of

material and thickness.

© Metrode Products Ltd Page 2 of 7 Issue 1 February 2005

6 Welding processes

The joint can be considered in two parts – the root and the fill. The welding process and

consumable selection should reflect this. The root requires a controllable welding process and filler

capable of delivering the necessary corrosion resistance. The welding process for the filling runs

can be selected to provide maximum productivity, and the consumable selected to deliver the

required mechanical properties (strength and toughness). The range of suitable welding processes

are summarised on the following page:

7 Root welding

Filler wire must always be added, root runs should not be made autogenously. Because of the

control it allows root runs are nearly always deposited using the TIG process. The root run is

critical in order to achieve good corrosion resistance so care should be taken to ensure the root is

deposited correctly. The aim should be to add as much filler as practical within the heat input

restrictions that are imposed. As a guideline the root run thickness should be ~2mm on thin wall

tube (3-4mm) rising to 3 or 4mm as pipe thickness increases.

To ensure good corrosion properties (and good G48A performance) on 22%Cr duplex a superduplex

filler wire is often used for the root run; this approach is recommended for G48A tests at +25°C.

To optimise root corrosion performance in superduplex base material the superduplex filler can be

used in conjunction with argon 1.5-2.5% nitrogen shielding gas; this approach is recommended if

G48A testing is required at +40°C.

© Metrode Products Ltd Page 3 of 7 Issue 1 February 2005

Purging

A gas purge must be used for root runs deposited using the TIG process and will normally be

maintained for the first three layers or approximately 10mm of deposit. Commercially pure argon is

generally used as the purge gas. Purge flow rates are determined by the pipe size but it is

important that following the removal of tacks, grinding etc that the purge is allowed to stabilise

again before welding. The efficiency of the purge should be monitored with an oxygen monitor to

ensure the oxygen content is maintained below 0.5% oxygen.

8 2nd “cold” pass

The second pass is almost as important as the root run when it comes to ensuring good corrosion

performance. The second pass should aim to be about 75% the heat input of the root run to

prevent overheating of the root. The second pass should be a single run; the layer should not be

split to two runs until at least the third layer.

9 Filling runs

TIG (GTAW)

For small diameter tubes and pipes TIG is often used for filling the joint but the TIG process can

also be used for filling thicker wall pipes. The TIG process has the advantage of producing high

quality weld metal and there is no slag to be removed. The productivity of the TIG process can be

improved by using 3.2mm diameter wire.

Metrode has both a duplex (ER329N) and superduplex (Zeron 100X) wire. Commercial purity argon

(99.995%) should be used as the shielding gas or possibly argon-helium mixtures if preferred;

gases containing hydrogen should not be used. As mentioned earlier, for root runs in superduplex

corrosion performance can be improved by using an argon shielding gas containing 1.5-2.5%

nitrogen.

MMA (SMAW)

The MMA process is widely used because of its adaptability and simple equipment requirements.

For positional pipe welding and for applications that have impact requirements Metrode have three

basic coated electrodes: 2205XKS (duplex), 2507XKS and Zeron 100XKS (for superduplex). For

applications where operability and ease of use are the most important factors then there are also

two rutile coated electrodes: Ultramet 2205 (duplex) and Ultramet 2507 (superduplex).

© Metrode Products Ltd Page 4 of 7 Issue 1 February 2005

MIG (GMAW)

The MIG process has not been very widely used for duplex and superduplex. If the MIG process is

to be used it must be in conjunction with a pulsed current power source. The shielding gas that has

proved most successful is argon-35% helium-2% CO2 (there are a number of different proprietary

gases on the market with compositions similar to this).

The spooled wire is also often used for mechanised or automatic TIG welding, and in these

situations pure argon shielding gas is used.

FCAW

The flux cored arc welding process can provide productivity advantages over the TIG or MMA

processes when material is over ~15mm thick and ~200mm diameter. The process can be used

down to ~10mm wall thickness if the diameter is larger and ~150mm diameter if the wall thickness

is great enough. There are both downhand and positional wires available: Supercore 2205

(downhand) and Supercore 2205P (positional) are the 22%Cr duplex wires; Supercore 2507

(downhand) and Supercore Z100XP and Supercore 2507P (positional) are the superduplex wires.

The wires are designed to be used with argon-20% CO2 shielding gas (M21 or M24 in BS EN 439),

and although there are many proprietary gases that would be suitable the argon content should not

exceed 80%. The downhand wires (Supercore 2205 and Supercore 2507) can also be used with

100% CO2 (C1 in BS EN 439). The gas flow rate required is 20-25 l/min. The wire stickout, or

electrode extension, should be 15-20mm; for fixed pipe welding (ASME 5G/6G) it may be necessary

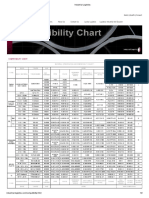

to reduce the electrode extension to 12-15mm. The parameter box for the flux cored wires is

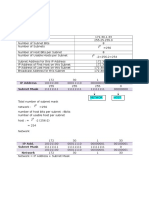

shown below.

40.0

Tolerance Box

Optimum operating

35.0 conditions

30.0

25.0

20.0

15.0

90 110 130 150 170 190 210 230 250 270 290 310 330

© Metrode Products Ltd Page 5 of 7 Issue 1 February 2005

SAW

The submerged arc process provides the highest potential productivity using either 1.6mm or

2.4mm diameter wire. The process is only suitable for welding in the flat position so the component

to be welded must be capable of being positioned in the flat or of being rotated. Before starting the

submerged arc welding ~10mm of deposit needs to be built-up with another process (normally TIG

or MMA) to prevent burn through, or overheating of the root run. Metrode have both duplex

(ER329N) and superduplex (Zeron 100X) filler wires.

The process requires a separate flux and Metrode have two suitable fluxes: SSB and LA491. The

wire stickout is maintained at ~20mm and the flux pile at ~25mm. Handling of the flux is also

important, see next page. Typical welding parameters are:

1.6mm 275A 28V 300mm/min

2.4mm 350A 30V 350mm/min

These parameters are only a guideline and may need to be adjusted for specific applications.

When submerged arc welding on a rotated pipe the torch should be positioned just before the top

of the joint and be angled towards the centre, see below.

Store in a Heated At end of shift all

New Flux Hopper at >100 C Flux to be returned

50 – 150kg to Heated Hopper

Sub-Arc Machine

A Flux Hopper B

~10kg

Sieving

Welding

A or B

Vacuum Unused Flux

Recycling Unit

© Metrode Products Ltd Page 6 of 7 Issue 1 February 2005

10 Thin wall tube

When welding thin wall tube it is even more critical to use a carefully controlled weld procedure

because the tube can easily be overheated. The maximum interpass temperature should be

reduced to 100°C. Even on small diameter tube the weld should be split into segments/quarters to

prevent excessive heat build-up.

11 Post weld heat treatment

Most duplex and superduplex fabrication work in wrought material is left in the as-welded condition

but major repairs to castings are generally specified in the solution annealed condition. Experience

indicates good properties can be achieved with a heat treatment of 1120°C/3-6 hours followed by a

water quench. Heat treatment, other than solution annealing, should not be carried out because

duplex and superduplex alloys are prone to intermetallic formation.

12 Dissimilar welding

Each dissimilar combination has to be assessed on its own merit but some general

recommendations can be made for a number of commonly encountered combinations.

Austenitic

Mild and low

Superduplex 22%Cr duplex Nickel alloys stainless

alloy steel

steel

Zeron 100 (1) (2) (2)

Superduplex 22%Cr duplex Nickel alloy (eg. C22) 309Mo 309L/309Mo

2507

(1) (3) (3)

22%Cr duplex 22%Cr duplex 22%Cr duplex Nickel alloy (eg. C22) 309Mo 309L/309Mo

(1) If it simplifies consumable selection and weld procedures superduplex consumables could be used.

(2) If there are only a limited number of dissimilar joints the superduplex consumables could be used to

simplify the weld procedures and consumable control.

(3) If there are only a limited number of dissimilar joints the duplex consumables could be used to simplify the

weld procedures and consumable control.

© Metrode Products Ltd Page 7 of 7 Issue 1 February 2005

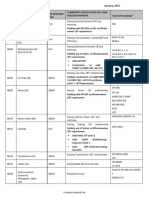

Welding Procedure Specification (WPS)

Welding Procedure No: Superduplex TIG/GTAW

Consumables Base Material

Welding process (root): TIG / GTAW Parent Material: Superduplex.

- Consumable: Zeron 100X (UNS S32750 & S32760).

- Specification: BS EN 12072: W 25 9 4 N L ASME IX: P or S number (QW422) =

Welding process (fill): TIG / GTAW 10H group 1.

- Consumable: Zeron 100X Thickness: 18.26mm (Schedule 160)

- Specification: BS EN 12072: W 25 9 4 N L Outside Diameter: 6 inch NB

Joint Details Joint Position

Joint Type: Single side butt Welding Position: ASME 6G

Manual/Mechanised: Manual

Joint Sketch Welding Sequences

6” NB 65°±5°

Schedule 160

Split layers (2 beads per layer) from runs 4/5 onwards.

18.26mm

0.5-1.5mm .

2-4mm

Welding Details

Travel Heat

Diameter Current Voltage speed Type of current

Run Process Consumable Input

mm A V mm/min / Polarity

kJ/mm

1 TIG Zeron 100X 2.4 80-100 ~12 ~50 DC- ~1.2

2 TIG Zeron 100X 2.4 90-130 ~12 ~125 DC- ~0.8

Fill TIG Zeron 100X 3.2 200-225 ~12 100-175 DC- ~1.5

Electrode Baking or Drying: NA Notes:

Gas – root (TIG) shielding: Ar + 2% N2

1. Tack joint securely to prevent root closure using four

backing: Ar

Gas - fill/cap (TIG) – Shielding: Ar

bridging tacks.

Purge: Ar

Tungsten Electrode Type/Size: 2%Th/2.4mm 2. Weld pipe in four 90° segments to prevent excessive

Details of Back Gouging/Backing: NA overheating.

Preheat Temperature: 20°C 3. Purge to maintain 0.5% oxygen max.

Interpass Temperature: 150°C max 4. Ar + 2%N2 shielding gas is recommended for the root run

Post-Weld Heat Treatment and/or Ageing: None to ensure G48A properties.

Temperature: 5. Purging 20-30l/min (reduced to ~10l/min for tie-in).

Time: Maintain purge for first two runs.

6. Shielding gas flow rate 8-12l/min.

n:\tech\literature\technical profiles\duplex\wps superduplex.doc

Welding Procedure Specification (WPS)

Welding Procedure No: Superduplex MMA/SMAW

Consumables Base Material

Welding process (root): TIG / GTAW Parent Material: Superduplex.

- Consumable: Zeron 100X (UNS S32750 & S32760).

- Specification: BS EN 12072: W 25 9 4 N L ASME IX: P or S number (QW422) =

Welding process (fill): MMA / SMAW 10H group 1.

- Consumable: Zeron 100XKS / 2507XKS Thickness: 18.26mm (Schedule 160)

- Specification: BS EN 1600: E 25 9 4 N L B 4 2 Outside Diameter: 6 inch NB

Joint Details Joint Position

Joint Type: Single side butt Welding Position: ASME 6G

Manual/Mechanised: Manual

Joint Sketch Welding Sequences

6” NB 70°±5°

Schedule 160

18.26mm

0.5-1.5mm .

2-4mm

Welding Details

Travel Type of Heat

Diameter Current Voltage speed

Run Process Consumable current / Input

mm A V mm/min Polarity kJ/mm

1 TIG Zeron 100X 2.4 80-100 ~12 ~50 DC- ~1.2

2 TIG Zeron 100X 2.4 90-130 ~12 ~125 DC- ~0.8

Fill MMA Zeron 100XKS / 2507XKS 3.2 75-95 ~25 75-125 DC+ ~1.2

Electrode Baking or Drying: 200°C/2 hours Notes:

Gas – root (TIG) shielding: Ar + 2% N2

1. Tack joint securely to prevent root closure using four

backing: Ar

Gas - fill/cap: Not applicable bridging tacks.

Tungsten Electrode Type/Size: 2%Th/2.4mm 2. Weld pipe in four 90° segments to prevent excessive

Details of Back Gouging/Backing: NA overheating.

Preheat Temperature: 20°C 3. Purge to maintain 0.5% oxygen max.

Interpass Temperature: 150°C max 4. Ar + 2%N2 shielding gas is recommended for the root run

Post-Weld Heat Treatment and/or Ageing: None to ensure G48A properties.

Temperature: 5. Purging 20-30l/min (reduced to ~10l/min for tie-in).

Time: Maintain purge for first two runs.

6. Shielding gas flow rate 8-12l/min.

n:\tech\literature\technical profiles\duplex\wps superduplex.doc

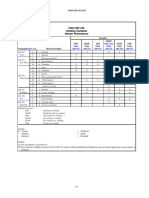

Welding Procedure Specification (WPS)

Welding Procedure No: Superduplex FCAW

Consumables Base Material

Welding process (root): TIG / GTAW Parent Material: Superduplex.

- Consumable: Zeron 100X (UNS S32750 & S32760).

- Specification: BS EN 12072: W 25 9 4 N L ASME IX: P or S number (QW422) =

Welding process (fill): FCAW 10H group 1.

- Consumable: Supercore Z100XP / 2507P Thickness: 23mm (Schedule 160)

- Specification: -- Outside Diameter: 8 inch NB

Joint Details Joint Position

Joint Type: Single side butt Welding Position: ASME 6G

Manual/Mechanised: Manual

Joint Sketch Welding Sequences

8” NB 70°±5°

Schedule 160

23mm

0.5-1.5mm .

2-4mm

Welding Details

Travel Type of Heat

Diameter Current Voltage

Run Process Consumable speed current / Input

mm A V

mm/min Polarity kJ/mm

1 TIG Zeron 100X 2.4 80-100 ~12 ~50 DC- ~1.2

2 TIG Zeron 100X 2.4 90-130 ~12 ~125 DC- ~0.8

3-4 TIG Zeron 100X 2.4 140-160 ~12 ~75 DC- ~1.5

Fill FCAW Supercore Z100XP/2507P 1.2 140-180 ~26 100-175 DC+ ~1.5

Electrode Baking or Drying: NA Notes:

Gas – root (TIG) shielding: Ar + 2% N2

1. Tack joint securely to prevent root closure using four

backing: Ar

Gas - fill/cap (FCAW) – Shielding: Ar-20% CO2 bridging tacks.

Tungsten Electrode Type/Size: 2%Th/2.4mm 2. Weld pipe in four 90° segments to prevent excessive

Details of Back Gouging/Backing: NA overheating.

Preheat Temperature: 20°C 3. Purge to maintain 0.5% oxygen max.

Interpass Temperature: 150°C max 4. Ar + 2%N2 shielding gas is recommended for the root run

Post-Weld Heat Treatment and/or Ageing: None to ensure G48A properties.

Temperature: 5. Purging 20-30l/min (reduced to ~10l/min for tie-in).

Time: 6. Shielding gas flow rate: TIG = 8-12l/min, FCAW = 20-25

l/min.

n:\tech\literature\technical profiles\duplex\wps superduplex.doc

Welding Procedure Specification (WPS)

Welding Procedure No: Superduplex SAW

Consumables Base Material

Welding process (root): TIG / GTAW Parent Material: Superduplex.

- Consumable: Zeron 100X (UNS S32750 & S32760).

- Specification: BS EN 12072: W 25 9 4 N L ASME IX: P or S number (QW422) =

Welding process (fill): SAW 10H group 1.

- Consumable: Zeron 100X Thickness: ~25mm

- Specification: BS EN 12072: W 25 9 4 N L Outside Diameter: Not applicable

Joint Details Joint Position

Joint Type: Single side butt Welding Position: ASME 1G

Manual/Mechanised: Mechanised

Joint Sketch Welding Sequences

65°±5°

Split layers (2 beads per layer) from runs 4/5 onwards.

25mm

0.5-1.5mm .

2-4mm

Welding Details

Travel Heat

Diameter Current Voltage speed Type of current

Run Process Consumable Input

mm A V mm/min / Polarity

kJ/mm

1 TIG Zeron 100X 2.4 80-100 ~12 ~50 DC- ~1.2

2 TIG Zeron 100X 2.4 90-130 ~12 ~125 DC- ~0.8

3-4 TIG Zeron 100X 2.4 140-160 ~12 ~75 DC- ~1.5

Fill SAW Zeron 100X 2.4 300-400 ~30 300-500 DC+ ~1.5

Electrode Baking or Drying: NA Notes:

Gas – root (TIG) shielding: Ar + 2% N2

1. Tack joint securely to prevent root closure using four

backing: Ar

Flux - fill/cap (SAW) – LA491 bridging tacks.

Tungsten Electrode Type/Size: 2%Th/2.4mm 2. Purge to maintain 0.5% oxygen max.

Details of Back Gouging/Backing: NA 3. Ar + 2%N2 shielding gas is recommended for the root run

Preheat Temperature: 20°C to ensure G48A properties.

Interpass Temperature: 150°C max 4. Purging 20-30l/min (reduced to ~10l/min for tie-in).

Post-Weld Heat Treatment and/or Ageing: None Maintain purge for first two runs.

Temperature: 5. Shielding gas flow rate 8-12l/min.

Time:

n:\tech\literature\technical profiles\duplex\wps superduplex.doc

You might also like

- P1 A C LHDocument2 pagesP1 A C LHMohamed Reda HusseinNo ratings yet

- Oxygen Level in Purging Gas During Welding of Duplex Stainless Steel - Google GroupsDocument6 pagesOxygen Level in Purging Gas During Welding of Duplex Stainless Steel - Google GroupssanketNo ratings yet

- CBT QuestionsDocument17 pagesCBT QuestionsNaseer Ahmed SokhalNo ratings yet

- Materials System SpecificationDocument11 pagesMaterials System Specificationimranb_001100% (1)

- Welding - Fissures DefectDocument12 pagesWelding - Fissures DefectthanhNo ratings yet

- ASME 9 Multi Process Welding Procedures QW200Document2 pagesASME 9 Multi Process Welding Procedures QW200Teodor EzaruNo ratings yet

- Welding Inspection Questions WisDocument5 pagesWelding Inspection Questions WisBhavani PrasadNo ratings yet

- ARAMCO QM Number ListDocument3 pagesARAMCO QM Number ListMohamed Yousuf Syed MohamedNo ratings yet

- TDS PDF Intertherm - 751CSADocument4 pagesTDS PDF Intertherm - 751CSAwilliam sukyonoNo ratings yet

- Test Pack ProcedureDocument10 pagesTest Pack ProcedureDaengkulle Firmansyah PuteraNo ratings yet

- Duplex and Super Duplex Stainless Steel Fittings (Amendments/Supplements To Astm A 815)Document13 pagesDuplex and Super Duplex Stainless Steel Fittings (Amendments/Supplements To Astm A 815)aleeimeran100% (1)

- Submerged Arc Welding (Saw)Document5 pagesSubmerged Arc Welding (Saw)Nnaji Chukwuma SlamNo ratings yet

- Validating ILI Run With and Without Data Loss PDFDocument11 pagesValidating ILI Run With and Without Data Loss PDFMubeenNo ratings yet

- 16mo3 MıgMagDocument4 pages16mo3 MıgMagKerem İnanNo ratings yet

- Air Compressor Guide AICIP and CAAA - Guidelines and Requirements For Asset Management of Pressure VesselsDocument4 pagesAir Compressor Guide AICIP and CAAA - Guidelines and Requirements For Asset Management of Pressure VesselsTim WilsonNo ratings yet

- Sa 263Document8 pagesSa 263Wagner Renato AraújoNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PeraneeshjokayNo ratings yet

- Ipa 510 Ad 2Document3 pagesIpa 510 Ad 2Santiago Cordova AlvaNo ratings yet

- Weld Joint Preparation ISO 9692Document46 pagesWeld Joint Preparation ISO 9692biancogallazziNo ratings yet

- Welding SymbolsDocument21 pagesWelding Symbolstuna61No ratings yet

- API 510 Case Study - 7Document2 pagesAPI 510 Case Study - 7Khaled FatnassiNo ratings yet

- QW-193 Tube To Tube-Sheet Mock Up and Macro (Etching) ExaminationDocument8 pagesQW-193 Tube To Tube-Sheet Mock Up and Macro (Etching) Examinationডঃ শুভম চ্যাটার্জীNo ratings yet

- ASME P NumbersDocument6 pagesASME P NumbersAbdul KharisNo ratings yet

- Piping Systems Inspection ProcedureDocument7 pagesPiping Systems Inspection Procedureabdullah buttNo ratings yet

- 02 Samss 011Document36 pages02 Samss 011OMER ELFADILNo ratings yet

- Saudi Aramco: Company General UseDocument8 pagesSaudi Aramco: Company General UseMasudhBashaNo ratings yet

- Piping, General Mech PDFDocument8 pagesPiping, General Mech PDFAhmed Shaban KotbNo ratings yet

- Public-: Rev. D E English 03 / 2014Document33 pagesPublic-: Rev. D E English 03 / 2014xaviereduardoNo ratings yet

- ASME P-NumbersDocument9 pagesASME P-NumbersAamer MohammedNo ratings yet

- UG Piping, Hydro QC List-InterviewDocument6 pagesUG Piping, Hydro QC List-InterviewSyed M. Imran Ali100% (1)

- Cswip 3.1Document2 pagesCswip 3.1Anna PariniNo ratings yet

- 24 Astm A815Document8 pages24 Astm A815FYNo ratings yet

- De-119951 Monel Sheathing InstallationDocument8 pagesDe-119951 Monel Sheathing InstallationJithuJohn100% (1)

- Sis Book Asme IxDocument107 pagesSis Book Asme IxHamza AlamNo ratings yet

- Ni 2301Document26 pagesNi 2301marguepaNo ratings yet

- Asme b31.3 Allowable StressDocument23 pagesAsme b31.3 Allowable Stressjoaquin torrano veraNo ratings yet

- GE Hardness-testing-FAQ MIC 10Document19 pagesGE Hardness-testing-FAQ MIC 10Harshit MehtaNo ratings yet

- Table - Qw-416 Welding Variables For Welder PerformanceDocument1 pageTable - Qw-416 Welding Variables For Welder PerformanceAnonymous VohpMtUSN100% (1)

- Asme BPVC - Ssc.iv - Ii.v.ix - Xiii-2023Document42 pagesAsme BPVC - Ssc.iv - Ii.v.ix - Xiii-2023mmendozagNo ratings yet

- QW-403.2 InterpretationDocument1 pageQW-403.2 Interpretationlaz_kNo ratings yet

- QW-352 QW-353 QW-354 (Note (2) ) QW-355 QW-356 QW-357 (Note (1) )Document1 pageQW-352 QW-353 QW-354 (Note (2) ) QW-355 QW-356 QW-357 (Note (1) )Deepanshu KhatriNo ratings yet

- Exam Narative Cswip 3.2Document5 pagesExam Narative Cswip 3.2yuwantoniNo ratings yet

- Mohamed Ashim: Mechanical InspectorDocument5 pagesMohamed Ashim: Mechanical InspectorMad TahaNo ratings yet

- Cranfield University Entry For IWE PDFDocument2 pagesCranfield University Entry For IWE PDFbharani dharanNo ratings yet

- Module3 - Welding ProcessesDocument155 pagesModule3 - Welding ProcessesPurvesh NanavatiNo ratings yet

- GTL WPSDocument6 pagesGTL WPSYoucef ChorfaNo ratings yet

- Bolted JointDocument9 pagesBolted JointkhanhtruongNo ratings yet

- Saep 321Document25 pagesSaep 321AbdullahNo ratings yet

- N Ace Direct Assessment StandardsDocument22 pagesN Ace Direct Assessment StandardsAngelTinocoNo ratings yet

- Aramco-Guide Testing QC Candidates (Piping-Hydro-Welding - Part 2 PDFDocument8 pagesAramco-Guide Testing QC Candidates (Piping-Hydro-Welding - Part 2 PDFanon_585140390100% (1)

- Asme Section II A Sa-216 Sa-216mDocument4 pagesAsme Section II A Sa-216 Sa-216mAnonymous GhPzn1xNo ratings yet

- ASP Procedures For Testing Characteristics of Automotive Sheet Steel LubricantsDocument31 pagesASP Procedures For Testing Characteristics of Automotive Sheet Steel LubricantsSamsudin AhmadNo ratings yet

- SAEP-379 Quality Issues NotificationDocument4 pagesSAEP-379 Quality Issues NotificationMusic And FunNo ratings yet

- ASME IX Tables-WPS-PQR-WPQTDocument33 pagesASME IX Tables-WPS-PQR-WPQTBabel THIAMNo ratings yet

- Saep 325Document43 pagesSaep 325AbdullahNo ratings yet

- High-Resolution EMAT As A Diagnostic Tool For Analysis of SCC and Crack-Like Pipeline Defects - IOGPC2015-7940 Thomas Beuker / ROSEN Matthias Hilvert / ROSENDocument24 pagesHigh-Resolution EMAT As A Diagnostic Tool For Analysis of SCC and Crack-Like Pipeline Defects - IOGPC2015-7940 Thomas Beuker / ROSEN Matthias Hilvert / ROSENrajnish14feb8516No ratings yet

- Penetrants TESTINGDocument86 pagesPenetrants TESTINGsankaran_muthukumarNo ratings yet

- Sr. Inspection Engineer Sample ResumeDocument4 pagesSr. Inspection Engineer Sample ResumemaheshNo ratings yet

- GEIT 20022EN Thickness Gage ProbesDocument4 pagesGEIT 20022EN Thickness Gage ProbesBen MedNo ratings yet

- Weld Repair Procedure Tapis RevaDocument3 pagesWeld Repair Procedure Tapis RevaadelNo ratings yet

- GEIT 20022EN Thickness Gage ProbesDocument4 pagesGEIT 20022EN Thickness Gage ProbesBen MedNo ratings yet

- GEIT 20022EN Thickness Gage ProbesDocument4 pagesGEIT 20022EN Thickness Gage ProbesBen MedNo ratings yet

- GEIT 20022EN Thickness Gage ProbesDocument4 pagesGEIT 20022EN Thickness Gage ProbesBen MedNo ratings yet

- LiPro - Profile-Test01 Without DoucDocument15 pagesLiPro - Profile-Test01 Without DoucadelNo ratings yet

- Structurix Chemicals Brochure EnglishDocument7 pagesStructurix Chemicals Brochure EnglishadelNo ratings yet

- PDF-2 CRxVision High Resolution Weld Inspection ScannerDocument8 pagesPDF-2 CRxVision High Resolution Weld Inspection ScanneradelNo ratings yet

- PDF-1 Structurix - Processing - Equipment - Brochure - EnglishDocument2 pagesPDF-1 Structurix - Processing - Equipment - Brochure - EnglishadelNo ratings yet

- PDF-2 CRxVision High Resolution Weld Inspection ScannerDocument8 pagesPDF-2 CRxVision High Resolution Weld Inspection ScanneradelNo ratings yet

- PDF-1 Structurix - Processing - Equipment - Brochure - EnglishDocument2 pagesPDF-1 Structurix - Processing - Equipment - Brochure - EnglishadelNo ratings yet

- Eresco Mf4: Reliable, Lightweight, Portable X-Ray GeneratorDocument8 pagesEresco Mf4: Reliable, Lightweight, Portable X-Ray GeneratoradelNo ratings yet

- Eresco Mf4: Reliable, Lightweight, Portable X-Ray GeneratorDocument8 pagesEresco Mf4: Reliable, Lightweight, Portable X-Ray GeneratoradelNo ratings yet

- City of Liberty Gas Company Repair ReportDocument5 pagesCity of Liberty Gas Company Repair ReportadelNo ratings yet

- Welding Defects - Classification, Causes and Remedies - Welding & NDTDocument11 pagesWelding Defects - Classification, Causes and Remedies - Welding & NDTadel100% (1)

- Welding Manual Nov 2010Document187 pagesWelding Manual Nov 2010Sumit Chaurasia100% (4)

- Welder Qualification Tests WQT DL QC 001 2019Document24 pagesWelder Qualification Tests WQT DL QC 001 2019adelNo ratings yet

- Welder Qualification Tests WQT DL QC 001 2019Document24 pagesWelder Qualification Tests WQT DL QC 001 2019adelNo ratings yet

- Industrial LogisticsDocument2 pagesIndustrial LogisticsadelNo ratings yet

- Welding Defects - Classification, Causes and Remedies - Welding & NDTDocument11 pagesWelding Defects - Classification, Causes and Remedies - Welding & NDTadel100% (1)

- Handbook - Filler Metal ASTM SteelsDocument1 pageHandbook - Filler Metal ASTM SteelsadelNo ratings yet

- Welding Qualification: Poyyara Consultants 1Document45 pagesWelding Qualification: Poyyara Consultants 1MuhammadShabbirNo ratings yet

- Handbook - Filler Metal ASTM SteelsDocument1 pageHandbook - Filler Metal ASTM SteelsadelNo ratings yet

- Handbook - Filler Metal ASTM SteelsDocument1 pageHandbook - Filler Metal ASTM SteelsadelNo ratings yet

- Industrial LogisticsDocument2 pagesIndustrial LogisticsadelNo ratings yet

- Norsok Material Data Sheet (M-630r2)Document77 pagesNorsok Material Data Sheet (M-630r2)karuna346No ratings yet

- NDT Films Guide-201510 PDFDocument1 pageNDT Films Guide-201510 PDFjar_2No ratings yet

- Set Through and Set OnDocument4 pagesSet Through and Set OnadelNo ratings yet

- The Propose of Training Program For Welding Inspectors 2021Document5 pagesThe Propose of Training Program For Welding Inspectors 2021adelNo ratings yet

- NDT Films Guide-201510 PDFDocument1 pageNDT Films Guide-201510 PDFjar_2No ratings yet

- Computer Programming: College of Civil Engineering - First StageDocument5 pagesComputer Programming: College of Civil Engineering - First StageAli ANo ratings yet

- Muhammad Ajmal Farooqi: Chemical EngineerDocument4 pagesMuhammad Ajmal Farooqi: Chemical EngineeromercomsatNo ratings yet

- File: OPL3.java Software Implementation of The Yamaha YMF262 Sound Generator. Version 1.0.6Document18 pagesFile: OPL3.java Software Implementation of The Yamaha YMF262 Sound Generator. Version 1.0.6mendofriulNo ratings yet

- Biology Transportation in PlantsDocument6 pagesBiology Transportation in PlantsTanaka ChirawuNo ratings yet

- Reflective Lesson Plan 4 Pythagorean TheoremDocument9 pagesReflective Lesson Plan 4 Pythagorean Theoremapi-339897912100% (1)

- The Sacred Number Forty-NineDocument12 pagesThe Sacred Number Forty-NinePatrick Mulcahy100% (6)

- DF-760/DF-760 (B) BF-720 MT-720/MT-720 (B) PH-5A/5C/5D: Parts ListDocument83 pagesDF-760/DF-760 (B) BF-720 MT-720/MT-720 (B) PH-5A/5C/5D: Parts ListJose Rojas ValeroNo ratings yet

- Coding Bobol ExcelDocument4 pagesCoding Bobol ExcelMuhammad IsmunandarsyahNo ratings yet

- AQUATOOL A Generalized Decision Support System For Water Resources Planning and Operational Management 1996 Journal of HydrologyDocument23 pagesAQUATOOL A Generalized Decision Support System For Water Resources Planning and Operational Management 1996 Journal of Hydrologyhoc_kinowNo ratings yet

- Assigment Sheet Tast 2 Aina MardianaDocument10 pagesAssigment Sheet Tast 2 Aina MardianaAina MardianaNo ratings yet

- Kolkata and North-East Centre at Tezpur: Indian Statistical InstituteDocument1 pageKolkata and North-East Centre at Tezpur: Indian Statistical InstitutePoonam NaiduNo ratings yet

- Automatic Control Systems, 9th Edition: Chapter 9Document50 pagesAutomatic Control Systems, 9th Edition: Chapter 9physisisNo ratings yet

- Jawaharlal Nehru Technological University Anantapur B.Tech. I - I Sem. L C 4 2 Part-A LABDocument2 pagesJawaharlal Nehru Technological University Anantapur B.Tech. I - I Sem. L C 4 2 Part-A LABHappa1No ratings yet

- ReportDocument1 pageReportDrew DacanayNo ratings yet

- Neeraj Pal 2Document1 pageNeeraj Pal 2NeerajPalNo ratings yet

- SWT 2 3 101 Brochure.Document8 pagesSWT 2 3 101 Brochure.Uhrin ImreNo ratings yet

- LoadRunner BasicsDocument74 pagesLoadRunner BasicsmadhugangulaNo ratings yet

- 8 The Future Value of Money and The Present Value of MoneyDocument26 pages8 The Future Value of Money and The Present Value of Moneyrommel legaspi62% (13)

- In Gov cbse-SSCMP-221966102021Document1 pageIn Gov cbse-SSCMP-221966102021Amod KumarNo ratings yet

- Electrical BEE Latest 2022 2023 Quantum Series (Searchable)Document116 pagesElectrical BEE Latest 2022 2023 Quantum Series (Searchable)ritamlyrisNo ratings yet

- Easy Harmony XA2 - XA2ED33Document5 pagesEasy Harmony XA2 - XA2ED33Rogger CriolloNo ratings yet

- Operational Information Bearing MaterialsDocument2 pagesOperational Information Bearing MaterialsHim SatiNo ratings yet

- Jj503 - Mechanical Workshop Practise 4Document2 pagesJj503 - Mechanical Workshop Practise 4jayadarsini2113No ratings yet

- Forensic BallisticDocument18 pagesForensic BallisticFranco Angelo ReyesNo ratings yet

- Boxer EngineDocument84 pagesBoxer EngineTOONGA100% (7)

- Unit No 1Document64 pagesUnit No 1Aadil VahoraNo ratings yet

- Electronic Door LockDocument2 pagesElectronic Door LocktaindiNo ratings yet

- 06a Consolidation and Settlement in ClayDocument10 pages06a Consolidation and Settlement in ClayAlly KhooNo ratings yet

- MATLAB Modeling of SPT and Grain Size Data in Producing Soil-ProfileDocument5 pagesMATLAB Modeling of SPT and Grain Size Data in Producing Soil-Profileicv.xaviNo ratings yet

- Chapter Seven: GS Ohlins Installation, Adjustment Tips & TricksDocument29 pagesChapter Seven: GS Ohlins Installation, Adjustment Tips & TricksWhattonNo ratings yet