Professional Documents

Culture Documents

L.P.T Reports.

Uploaded by

Shaikh AdilCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

L.P.T Reports.

Uploaded by

Shaikh AdilCopyright:

Available Formats

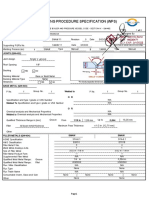

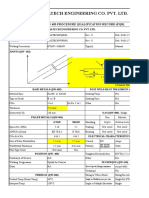

LARSEN & TOUBRO LIMITED REPORT No.

DP/IRL/CMS/1

LIQUID PENETRANT DATE 8-Aug-18

L&T DEFENCE EXAMINATION REPORT

PAGE No. 1

Project No. : 60541A Vendor Name : SCHLIM ENGINEERS

Part / Description : CHANNEL & GUSSETS Vendor P.O. No. : 06L011643

Part No. : 1&2 Quantity as per P.O. : 6 NOS

Drawing No. : DE-4541-1 Rev. :R 1 Code / Spec. : ASME SECTION Vlll DIV 1 APP 8

Examination Stage : AFTER WELDING Procedure No. : HE/NDE/LPE/001 Rev.:0

Date of Examination : 8-Aug-18 Time of Examination :11 AM TO 5 PM

Overall final Visual Inspection carried out prior to LPT and found Satisfactory Yes No

Visible (Non-Flouroscent) Water Washable

Flouroscent Solvent Removable

Cleaner Batch No, Make & Expiry date 6748 , SEP 2019 (PRADEEP MAKE)

Penetrant Batch No, Make & Expiry date 6579 , MAR 2019 (PRADEEP MAKE)

Developer Batch No, Make & Expiry date 6457, SEP 2018 (PRADEEP MAKE)

Material Type & Thk. IS 2062 GR A & GR B. 10mmTHK & 6mm THK

Seam Nos. / Part Nos

ALL WELDS

Inspected

Extent of Examination 100%

Light Intensity 1000 - 1200 LUX

Ground As Welded

Surface Condition

Machined Bend section

Surface Temperature ROOM TEMP Deg C

Dwell Time of Penetrant 10 Minutes

Developing Time 15 Minutes

Observation :-

No recordable, relevant indications were observed. PT acceptable in

accordance with the procedure.

Relevant indications observed.

Dimensions : Refer Annexure for Details

Indications have been ground / ground & weld repaired.

Re PT has been carried out on the above seams and found acceptable

in accordance with the procedure.

NOTES :-

Place of Test :- SCHLIM ENGINEERS, RABALE

Performed by Witnessed by Witnessed / Reviewed by

Vendor QC - Level - II L&T QC- Level II CQAE

Date Date Date

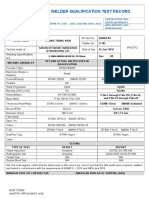

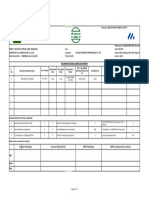

LARSEN & TOUBRO LIMITED REPORT No. DP/IRL/CMS/2

LIQUID PENETRANT DATE 29-Aug-18

L&T DEFENCE EXAMINATION REPORT

PAGE No. 1

Project No. : 60541A Vendor Name : SCHLIM ENGINEERS

Part / Description : CHANNEL Vendor P.O. No. : 06L011643

Part No. : 1 TO 1 Quantity as per P.O. : 2 NOS (PART QTY : 4 NOS)

Drawing No. : DE-4543 Rev. :R 1 Code / Spec. : ASME SECTION Vlll DIV 1 APP 8

Examination Stage : AFTER WELDING (ROOT DP) Procedure No. : HE/NDE/LPE/001 Rev.:0

Date of Examination : 29-Aug-18 Time of Examination :11 AM TO 6 PM

Overall final Visual Inspection carried out prior to LPT and found Satisfactory Yes No

Visible (Non-Flouroscent) Water Washable

Flouroscent Solvent Removable

Cleaner Batch No, Make & Expiry date 6748 , SEP 2019 (PRADEEP MAKE)

Penetrant Batch No, Make & Expiry date 6579 , MAR 2019 (PRADEEP MAKE)

Developer Batch No, Make & Expiry date 6457, SEP 2018 (PRADEEP MAKE)

Material Type & Thk. CHANNEL. 6 mm THK

Seam Nos. / Part Nos

ALL WELDS

Inspected

Extent of Examination 100%

Light Intensity 1000 - 1200 LUX

Ground As Welded

Surface Condition

Machined Bend section

Surface Temperature ROOM TEMP Deg C

Dwell Time of Penetrant 10 Minutes

Developing Time 15 Minutes

Observation :-

No recordable, relevant indications were observed. PT acceptable in

accordance with the procedure.

Relevant indications observed.

Dimensions : Refer Annexure for Details

Indications have been ground / ground & weld repaired.

Re PT has been carried out on the above seams and found acceptable

in accordance with the procedure.

NOTES :-

Place of Test :- SCHLIM ENGINEERS, RABALE

Performed by Witnessed by Witnessed / Reviewed by

Vendor QC - Level - II L&T QC- Level II CQAE

Date Date Date

LARSEN & TOUBRO LIMITED REPORT No. DP/IRL/CMS/1

LIQUID PENETRANT DATE 8-Aug-18

L&T DEFENCE EXAMINATION REPORT

PAGE No. 1

Project No. : 60541A Vendor Name : SCHLIM ENGINEERS

Part / Description : CHANNEL & GUSSETS Vendor P.O. No. : 06L011643

Part No. : 1&2 Quantity as per P.O. : 6 NOS

Drawing No. : DE-4541-1 Rev. :R 1 Code / Spec. : ASME SECTION Vlll DIV 1 APP 8

Examination Stage : AFTER WELDING Procedure No. : HE/NDE/LPE/001 Rev.:0

Date of Examination : 8-Aug-18 Time of Examination :11 AM TO 5 PM

Overall final Visual Inspection carried out prior to LPT and found Satisfactory Yes No

Visible (Non-Flouroscent) Water Washable

Flouroscent Solvent Removable

Cleaner Batch No, Make & Expiry date 6748 , SEP 2019 (PRADEEP MAKE)

Penetrant Batch No, Make & Expiry date 6579 , MAR 2019 (PRADEEP MAKE)

Developer Batch No, Make & Expiry date 6457, SEP 2018 (PRADEEP MAKE)

Material Type & Thk. IS 2062 GR A & GR B. 10mmTHK & 6mm THK

Seam Nos. / Part Nos

ALL WELDS

Inspected

Extent of Examination 100%

Light Intensity 1000 - 1200 LUX

Ground As Welded

Surface Condition

Machined Bend section

Surface Temperature ROOM TEMP Deg C

Dwell Time of Penetrant 10 Minutes

Developing Time 15 Minutes

Observation :-

No recordable, relevant indications were observed. PT acceptable in

accordance with the procedure.

Relevant indications observed.

Dimensions : Refer Annexure for Details

Indications have been ground / ground & weld repaired.

Re PT has been carried out on the above seams and found acceptable

in accordance with the procedure.

NOTES :-

Place of Test :- SCHLIM ENGINEERS, RABALE

Performed by Witnessed by Witnessed / Reviewed by

Vendor QC - Level - II L&T QC- Level II CQAE

Date Date Date

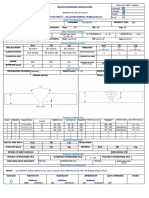

LARSEN & TOUBRO LIMITED REPORT No. DP/IRL/CMS/2

LIQUID PENETRANT DATE 25-Aug-18

L&T DEFENCE EXAMINATION REPORT

PAGE No. 1

Project No. : S067137A Vendor Name : SCHLIM ENGINEERS

Part / Description : CHANNEL Vendor P.O. No. : 06L011643

Part No. : 1 TO 1 Quantity as per P.O. : 2 NOS (PART QTY : 4 NOS)

Drawing No. : DE-4543 Rev. :R 1 Code / Spec. : ASME SECTION Vlll DIV 1 APP 8

Examination Stage : AFTER WELDING (ROOT DP) Procedure No. : HE/NDE/LPE/001 Rev.:0

Date of Examination : 25-Aug-18 Time of Examination :02 PM TO 6 PM

Overall final Visual Inspection carried out prior to LPT and found Satisfactory Yes No

Visible (Non-Flouroscent) Water Washable

Flouroscent Solvent Removable

Cleaner Batch No, Make & Expiry date 6748 , SEP 2019 (PRADEEP MAKE)

Penetrant Batch No, Make & Expiry date 6579 , MAR 2019 (PRADEEP MAKE)

Developer Batch No, Make & Expiry date 6457, SEP 2018 (PRADEEP MAKE)

Material Type & Thk. CHANNEL. 6 mm THK

Seam Nos. / Part Nos

ALL WELDS

Inspected

Extent of Examination 100%

Light Intensity 1000 - 1200 LUX

Ground As Welded

Surface Condition

Machined Bend section

Surface Temperature ROOM TEMP Deg C

Dwell Time of Penetrant 10 Minutes

Developing Time 15 Minutes

Observation :-

No recordable, relevant indications were observed. PT acceptable in

accordance with the procedure.

Relevant indications observed.

Dimensions : Refer Annexure for Details

Indications have been ground / ground & weld repaired.

Re PT has been carried out on the above seams and found acceptable

in accordance with the procedure.

NOTES :-

Place of Test :- SCHLIM ENGINEERS, RABALE

Performed by Witnessed by Witnessed / Reviewed by

Vendor QC - Level - II L&T QC- Level II CQAE

Date Date Date

LARSEN & TOUBRO LIMITED REPORT No. DP/IRL/CMS/1

LIQUID PENETRANT DATE 8-Aug-18

L&T DEFENCE EXAMINATION REPORT

PAGE No. 1

Project No. : 60541A Vendor Name : SCHLIM ENGINEERS

Part / Description : CHANNEL & GUSSETS Vendor P.O. No. : 06L011643

Part No. : 1&2 Quantity as per P.O. : 6 NOS

Drawing No. : DE-4541-1 Rev. :R 1 Code / Spec. : ASME SECTION Vlll DIV 1 APP 8

Examination Stage : AFTER WELDING Procedure No. : HE/NDE/LPE/001 Rev.:0

Date of Examination : 8-Aug-18 Time of Examination :11 AM TO 5 PM

Overall final Visual Inspection carried out prior to LPT and found Satisfactory Yes No

Visible (Non-Flouroscent) Water Washable

Flouroscent Solvent Removable

Cleaner Batch No, Make & Expiry date 6748 , SEP 2019 (PRADEEP MAKE)

Penetrant Batch No, Make & Expiry date 6579 , MAR 2019 (PRADEEP MAKE)

Developer Batch No, Make & Expiry date 6457, SEP 2018 (PRADEEP MAKE)

Material Type & Thk. IS 2062 GR A & GR B. 10mmTHK & 6mm THK

Seam Nos. / Part Nos

ALL WELDS

Inspected

Extent of Examination 100%

Light Intensity 1000 - 1200 LUX

Ground As Welded

Surface Condition

Machined Bend section

Surface Temperature ROOM TEMP Deg C

Dwell Time of Penetrant 10 Minutes

Developing Time 15 Minutes

Observation :-

No recordable, relevant indications were observed. PT acceptable in

accordance with the procedure.

Relevant indications observed.

Dimensions : Refer Annexure for Details

Indications have been ground / ground & weld repaired.

Re PT has been carried out on the above seams and found acceptable

in accordance with the procedure.

NOTES :-

Place of Test :- SCHLIM ENGINEERS, RABALE

Performed by Witnessed by Witnessed / Reviewed by

Vendor QC - Level - II L&T QC- Level II CQAE

Date Date Date

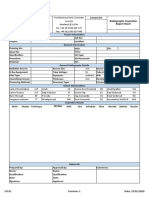

LARSEN & TOUBRO LIMITED REPORT No. DP/IRL/CMS/2

LIQUID PENETRANT DATE 22-Aug-18

L&T DEFENCE EXAMINATION REPORT

PAGE No. 1

Project No. : S067137B Vendor Name : SCHLIM ENGINEERS

Part / Description : CHANNEL Vendor P.O. No. : 06L011643

Part No. : 1 TO 1 Quantity as per P.O. : 2 NOS (PART QTY : 4 NOS)

Drawing No. : DE-4543 Rev. :R 1 Code / Spec. : ASME SECTION Vlll DIV 1 APP 8

Examination Stage : AFTER WELDING (ROOT DP) Procedure No. : HE/NDE/LPE/001 Rev.:0

Date of Examination : 22-Aug-18 Time of Examination :11 AM TO 1 PM

Overall final Visual Inspection carried out prior to LPT and found Satisfactory Yes No

Visible (Non-Flouroscent) Water Washable

Flouroscent Solvent Removable

Cleaner Batch No, Make & Expiry date 6748 , SEP 2019 (PRADEEP MAKE)

Penetrant Batch No, Make & Expiry date 6579 , MAR 2019 (PRADEEP MAKE)

Developer Batch No, Make & Expiry date 6457, SEP 2018 (PRADEEP MAKE)

Material Type & Thk. CHANNEL. 6 mm THK

Seam Nos. / Part Nos

ALL WELDS

Inspected

Extent of Examination 100%

Light Intensity 1000 - 1200 LUX

Ground As Welded

Surface Condition

Machined Bend section

Surface Temperature ROOM TEMP Deg C

Dwell Time of Penetrant 10 Minutes

Developing Time 15 Minutes

Observation :-

No recordable, relevant indications were observed. PT acceptable in

accordance with the procedure.

Relevant indications observed.

Dimensions : Refer Annexure for Details

Indications have been ground / ground & weld repaired.

Re PT has been carried out on the above seams and found acceptable

in accordance with the procedure.

NOTES :-

Place of Test :- SCHLIM ENGINEERS, RABALE

Performed by Witnessed by Witnessed / Reviewed by

Vendor QC - Level - II L&T QC- Level II CQAE

Date Date Date

You might also like

- Assure Solutions: Hydro Test ReportDocument1 pageAssure Solutions: Hydro Test ReportKailas NimbalkarNo ratings yet

- WPS - 024Document4 pagesWPS - 024MAT-LIONNo ratings yet

- QC FORMDocument3 pagesQC FORMRicardo LourençoNo ratings yet

- MPT Report FormatDocument1 pageMPT Report FormatRoshan ThomasNo ratings yet

- DP Format Bhel 1Document1 pageDP Format Bhel 1narayandasraikwar100% (1)

- Weld Repair Rev. 1Document3 pagesWeld Repair Rev. 1vinas kusdinarNo ratings yet

- Wps 1010 IfrDocument28 pagesWps 1010 IfrSyed Mahmud Habibur RahmanNo ratings yet

- Bolt Tightening ReportDocument1 pageBolt Tightening ReporttreyNo ratings yet

- Welding Procedure Specification (WPS) : Asme Boiler and Pressure Vessel Code - Section Ix - Qw-482Document2 pagesWelding Procedure Specification (WPS) : Asme Boiler and Pressure Vessel Code - Section Ix - Qw-482Edwin RomeroNo ratings yet

- WPQ-1083 3G PDFDocument2 pagesWPQ-1083 3G PDFduendex360100% (1)

- WPS Format For AWS D1.1 - WPS - FCAWDocument1 pageWPS Format For AWS D1.1 - WPS - FCAWThe Welding Inspections CommunityNo ratings yet

- Weld Repair ReportDocument1 pageWeld Repair Reportkerons100% (1)

- HOANG TRUNG KIEN - 6G GTAW + SMAW (Duplex, T 18.26mm)Document3 pagesHOANG TRUNG KIEN - 6G GTAW + SMAW (Duplex, T 18.26mm)TuTuy AnNo ratings yet

- IRN - 18.07.2019 - Harshad Panchal - Revision-0 - Furnace Fabrica - JNK - PORVAIR - RIL PDFDocument3 pagesIRN - 18.07.2019 - Harshad Panchal - Revision-0 - Furnace Fabrica - JNK - PORVAIR - RIL PDFsaptarshi jashNo ratings yet

- DPT Report - FormatDocument1 pageDPT Report - Formatskc0% (1)

- Welder Visual Inspection ReportsDocument24 pagesWelder Visual Inspection ReportsKyNo ratings yet

- Ultrasonic Testing Report For PipingDocument54 pagesUltrasonic Testing Report For Pipingeldobie3No ratings yet

- WPS ISO 15614-1 WeldNote MetricDocument1 pageWPS ISO 15614-1 WeldNote MetricVirgil SorcaruNo ratings yet

- Fcaw 16 THKDocument5 pagesFcaw 16 THKparesh2387No ratings yet

- Welding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Document5 pagesWelding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Rajesh Owaiyar100% (1)

- RT Report FormatDocument1 pageRT Report FormatRonanki RaviNo ratings yet

- WPQDocument10 pagesWPQayoki100% (3)

- Wps Is 2062 GR B Butt-OkDocument2 pagesWps Is 2062 GR B Butt-OkAnand Kesarkar33% (3)

- WPS Asme IxDocument4 pagesWPS Asme Ixjcarlosherrerac7100% (1)

- LBW WOPQ REV. 2010a Interactive FormDocument1 pageLBW WOPQ REV. 2010a Interactive Formcosmicbunny100% (1)

- Super Duplex Stainless SteelDocument1 pageSuper Duplex Stainless SteelUma Shankar100% (1)

- Welding Procedure Specification For Storage Tank & Piping SystemDocument3 pagesWelding Procedure Specification For Storage Tank & Piping SystemAhmad MohammadNo ratings yet

- Ut Format Report For Ut Libra (Naidu)Document4 pagesUt Format Report For Ut Libra (Naidu)vsnaiduqcNo ratings yet

- WPQR Welding Procedure Qualification RecordsDocument3 pagesWPQR Welding Procedure Qualification Recordsramesh rajaNo ratings yet

- WPS SUMMARYDocument10 pagesWPS SUMMARYbhavin178No ratings yet

- LPT ReportDocument2 pagesLPT ReportAnonymous OEUUoKHYR100% (1)

- Wps p91 - BhelDocument2 pagesWps p91 - BhelAshish Gupta100% (4)

- Welder Qualification Form for Rana Pratap ChouhanDocument1 pageWelder Qualification Form for Rana Pratap ChouhanMahendra singhNo ratings yet

- Dimensional Inspection Report TemplateDocument1 pageDimensional Inspection Report TemplateAlfian ImaduddinNo ratings yet

- WPQR Welding Procedure QualificationDocument3 pagesWPQR Welding Procedure QualificationThanasis KyrgiazoglouNo ratings yet

- Piping Daily Fit Up Quality Control and Inspection Report FormDocument4 pagesPiping Daily Fit Up Quality Control and Inspection Report FormnguyenquanghiepNo ratings yet

- WPS Pipe 08'' SHD 40 SMAW REV02Document2 pagesWPS Pipe 08'' SHD 40 SMAW REV02Amine MaalejNo ratings yet

- Radiographic Inspection Report SheetDocument1 pageRadiographic Inspection Report SheetMike BoyesNo ratings yet

- For Fillet Weld Joint Project:Production ManifoldDocument1 pageFor Fillet Weld Joint Project:Production Manifoldabdallah ahmed50% (2)

- Procedure Qualification Record (PQR) : Jl. Brigjend Katamso KM 5.6 Tanjung Uncang - Batam IndonesiaDocument2 pagesProcedure Qualification Record (PQR) : Jl. Brigjend Katamso KM 5.6 Tanjung Uncang - Batam IndonesiaMulPXNo ratings yet

- Fit Up Welding Visual Inspection ReportDocument2 pagesFit Up Welding Visual Inspection Reportgst ajah100% (1)

- Request for Welding Procedure ApprovalDocument10 pagesRequest for Welding Procedure ApprovalAlam MD SazidNo ratings yet

- Aws 001Document1 pageAws 001akshay sarfareNo ratings yet

- PQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpDocument1 pagePQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpSatish KeskarNo ratings yet

- PQR Is7307Document1 pagePQR Is7307Tridib Dey100% (1)

- Certificate of Origin Form F For China-Chile FTADocument2 pagesCertificate of Origin Form F For China-Chile FTAinspectormetNo ratings yet

- Aws D1.1 - WPS - Smaw-Fcaw PDFDocument1 pageAws D1.1 - WPS - Smaw-Fcaw PDFThe Welding Inspections CommunityNo ratings yet

- WPS E6013+e7018Document2 pagesWPS E6013+e7018Anvesh Vaddi100% (1)

- TDC PP742 F2Document3 pagesTDC PP742 F2Arjun PrajapatiNo ratings yet

- CALTECH ENGINEERING PQR PROCEDUREDocument8 pagesCALTECH ENGINEERING PQR PROCEDURESrikant GanjiNo ratings yet

- Welding ReportDocument52 pagesWelding ReportalidadNo ratings yet

- EQT ChecklistDocument5 pagesEQT Checklistvijayachidu100% (1)

- Plate Inspection ReportDocument1 pagePlate Inspection ReportlalitaliNo ratings yet

- D.P. Test ReportDocument1 pageD.P. Test Reportvirendra katkeNo ratings yet

- Incoming Material Inspection Report: Date of ReceiptDocument1 pageIncoming Material Inspection Report: Date of ReceiptRaj MNo ratings yet

- FGD Transformer Inspection ReportDocument5 pagesFGD Transformer Inspection ReportMas LilikNo ratings yet

- Hydro TestDocument2 pagesHydro TestRajeev KumarNo ratings yet

- CT - For SwitchayrdDocument12 pagesCT - For SwitchayrdSindhuKumarNo ratings yet

- Checklist Fire StopDocument9 pagesChecklist Fire StopAnonymous DMdGdsOENo ratings yet

- Power Transformer - For SwitchayrdDocument20 pagesPower Transformer - For SwitchayrdSindhuKumarNo ratings yet

- General Notes. 04.gasket Contact Finish Shall Be Serrated Finish To 125 To 250 (3.2 To 6.3um) & Waviness High of 0.05 MaxDocument1 pageGeneral Notes. 04.gasket Contact Finish Shall Be Serrated Finish To 125 To 250 (3.2 To 6.3um) & Waviness High of 0.05 MaxShaikh AdilNo ratings yet

- Api 650Document1 pageApi 650Shaikh AdilNo ratings yet

- Huqooq Al Ibaad Booklet PDFDocument88 pagesHuqooq Al Ibaad Booklet PDFJaved AkhtarNo ratings yet

- PC records for PMP personnel hardware tagsDocument2 pagesPC records for PMP personnel hardware tagsShaikh AdilNo ratings yet

- RR Items ReportsDocument54 pagesRR Items ReportsShaikh AdilNo ratings yet

- 3 OoboDocument1 page3 OoboShaikh AdilNo ratings yet

- India's Imports From China: Chapter-5Document30 pagesIndia's Imports From China: Chapter-5Shaikh AdilNo ratings yet

- Tax Invoice for Mi LED TV 4A Pro 80cm (32) LMDocument1 pageTax Invoice for Mi LED TV 4A Pro 80cm (32) LMShaikh AdilNo ratings yet

- India's Imports From China: Chapter-5Document30 pagesIndia's Imports From China: Chapter-5Shaikh AdilNo ratings yet

- Kingdom of Saudi Arabia: Saudi Standards, Metrology and Quality OrganizationDocument41 pagesKingdom of Saudi Arabia: Saudi Standards, Metrology and Quality OrganizationShaikh AdilNo ratings yet

- List of Applicable Specifications For 190043 As Per A98-RC-A-1320374, Sheet 2 of 2, Rev.BDocument15 pagesList of Applicable Specifications For 190043 As Per A98-RC-A-1320374, Sheet 2 of 2, Rev.BShaikh AdilNo ratings yet

- List of Applicable Specifications For 190043 As Per A98-RC-A-1320374, Sheet 2 of 2, Rev.BDocument15 pagesList of Applicable Specifications For 190043 As Per A98-RC-A-1320374, Sheet 2 of 2, Rev.BShaikh AdilNo ratings yet

- Paper 4Document1 pagePaper 4Shaikh AdilNo ratings yet

- Transmital 24Document1 pageTransmital 24Shaikh AdilNo ratings yet

- Testcert2452815 1 PDFDocument2 pagesTestcert2452815 1 PDFShaikh AdilNo ratings yet

- Is 875 (Part 4) - Code of Practice For Design Loads (Other Than Earthquake) For Buildings and StructuresDocument11 pagesIs 875 (Part 4) - Code of Practice For Design Loads (Other Than Earthquake) For Buildings and StructuresShaikh AdilNo ratings yet

- Is - 2062.2011 PDFDocument17 pagesIs - 2062.2011 PDFN GANESAMOORTHYNo ratings yet

- Mail Format 2Document1 pageMail Format 2Shaikh AdilNo ratings yet

- Updated ResumeDocument14 pagesUpdated ResumeShaikh AdilNo ratings yet

- PDFDocument3 pagesPDFShaikh AdilNo ratings yet

- Carlton RT Report NewDocument2 pagesCarlton RT Report NewShaikh AdilNo ratings yet

- IRNItem 3Document3 pagesIRNItem 3Shaikh AdilNo ratings yet

- Oil Field Job Application FormDocument3 pagesOil Field Job Application FormShaikh AdilNo ratings yet

- Repair Procedure ANNEXUREDocument16 pagesRepair Procedure ANNEXUREShaikh AdilNo ratings yet

- Carlton Industrial Engineers: Nde RequisitionDocument1 pageCarlton Industrial Engineers: Nde RequisitionShaikh AdilNo ratings yet

- Is 875 (Part 5) - Code of Practice For Design Loads (Other Than Earthquake) For Buildings and StructuresDocument26 pagesIs 875 (Part 5) - Code of Practice For Design Loads (Other Than Earthquake) For Buildings and StructuresShaikh AdilNo ratings yet

- Flange - Bolt Size ChartDocument6 pagesFlange - Bolt Size ChartShaikh AdilNo ratings yet

- IITK-GSDMA Wind Codes DocumentDocument105 pagesIITK-GSDMA Wind Codes DocumentMadusha Galappaththi100% (2)

- IITK-GSDMA Wind Codes DocumentDocument105 pagesIITK-GSDMA Wind Codes DocumentMadusha Galappaththi100% (2)

- Lesson Planning Product-Based Performance TaskDocument8 pagesLesson Planning Product-Based Performance TaskMaricarElizagaFontanilla-LeeNo ratings yet

- Dss Paper 1Document2 pagesDss Paper 1hemalNo ratings yet

- Lecture Notes in Computational Science and EngineeringDocument434 pagesLecture Notes in Computational Science and Engineeringmuhammad nurulNo ratings yet

- MICREC1 Complete Lecture Notes - TermDocument168 pagesMICREC1 Complete Lecture Notes - TermdsttuserNo ratings yet

- Reed - Camion - XT39R4 - 1003 - Technical Manual - Panel de Control PDFDocument293 pagesReed - Camion - XT39R4 - 1003 - Technical Manual - Panel de Control PDFLuisEduardoHerreraCamargo100% (1)

- TONISITASDocument17 pagesTONISITASDewi Ria ONo ratings yet

- Oracle Dumps PDFDocument6 pagesOracle Dumps PDFindira selvarajNo ratings yet

- Clinical Microscopy ReviewerDocument31 pagesClinical Microscopy ReviewerbokbokbokNo ratings yet

- Stheory Balagtas Activity Lesson 15Document6 pagesStheory Balagtas Activity Lesson 15xVlad LedesmaNo ratings yet

- Primary Reformer TubesDocument10 pagesPrimary Reformer TubesAhmed ELmlahyNo ratings yet

- Science - Abm8566 SMDocument51 pagesScience - Abm8566 SMBhabaniNo ratings yet

- As Statistics Mechanics 1Document240 pagesAs Statistics Mechanics 1claire zhouNo ratings yet

- Vitamins With Minerals Oral PowderDocument8 pagesVitamins With Minerals Oral PowderWH PANDWNo ratings yet

- LED Linear Highbay LightingDocument7 pagesLED Linear Highbay LightingMohammed YasarNo ratings yet

- Justifying The CMM: (Coordinate Measuring Machine)Document6 pagesJustifying The CMM: (Coordinate Measuring Machine)pm089No ratings yet

- Ground Plane AntennaDocument7 pagesGround Plane AntennaarijeetdguyNo ratings yet

- A-019730-1647416754604-137865-W.M.Supun Anjana DSADocument175 pagesA-019730-1647416754604-137865-W.M.Supun Anjana DSADishan SanjayaNo ratings yet

- Powerful Production Pumps for Deep Geothermal ProjectsDocument4 pagesPowerful Production Pumps for Deep Geothermal ProjectsAchraf AkidNo ratings yet

- Technical Data: That W IntoDocument5 pagesTechnical Data: That W Intoradium7No ratings yet

- Massive Transfusion ProtocolDocument2 pagesMassive Transfusion ProtocolmukriNo ratings yet

- Parker 1991Document17 pagesParker 1991Rodrigo GarcíaNo ratings yet

- Lec11 Amortized Loans Homework SolutionsDocument3 pagesLec11 Amortized Loans Homework SolutionsJerickson MauricioNo ratings yet

- Experiment 1 - Friction Losses in PipesDocument34 pagesExperiment 1 - Friction Losses in PipesKhairil Ikram33% (3)

- The Role of Pets in PreadolescentDocument17 pagesThe Role of Pets in PreadolescentshimmyNo ratings yet

- The 2009 ACM ASIA Programming Contest Dhaka Site: Hosted by North South University Dhaka, BangladeshDocument21 pagesThe 2009 ACM ASIA Programming Contest Dhaka Site: Hosted by North South University Dhaka, BangladeshPhạm Hữu Thạnh ĐạtNo ratings yet

- C - Brim - 1909 80 - QDocument40 pagesC - Brim - 1909 80 - Qmanohar rathodNo ratings yet

- Peabody y Movent ABCDocument11 pagesPeabody y Movent ABCIngrid BarkoNo ratings yet

- Barium Strontium TitanateDocument15 pagesBarium Strontium Titanatekanita_jawwNo ratings yet

- Elec4602 NotesDocument34 pagesElec4602 NotesDavid VangNo ratings yet

- Drum RudimentsDocument4 pagesDrum Rudimentsmaame nyarkoaNo ratings yet