Professional Documents

Culture Documents

Borescope Belending

Uploaded by

ArabyAbdel Hamed SadekOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Borescope Belending

Uploaded by

ArabyAbdel Hamed SadekCopyright:

Available Formats

MTU Maintenance Berlin-Brandenburg

An MTU Aero Engines Company

Borescope blending for

CF34-10 engines

An MTU Aero Engines Company

MTU Maintenance Berlin-Brandenburg GmbH

Dr.-Ernst-Zimmernamnn-Straße 2

14974 Ludwigsfelde • Germany

Tel. +49 3378 824-00

GER 09/10/B/0300/DE/EB/E

Fax +49 3378 824-300

ludwigsfelde@mtu.de

www.mtu.com

MTU Maintenance Berlin-Brandenburg

Sales CF34

Tel. +49 3378 824-505

Mobile Repair Team CF34 Americas

and AOG Support 24/7

Tel. +49 3378 824-888

Borescope blending Process of boroblending Working time MTU’s CF34 on-site service

MTU Maintenance offers on-site support for all CF34-10 Until now the only way to repair FOD was to remove the Boroblending requires 1-2 hours per blade including • AOG hotline service 24/7/365

equipped regional jets. Based on many years of expe- engine from wing and to disassemble the compressor preparation, blending and completion. • on-site repair by Mobile Repair Team

rience with CF34 engine types, MTU can provide the case. Today you can correct the damage on wing and - FOD repair

borescope blending for compressor blades and vanes. without the need to disassemble the compressor case. - top case

Borescope blending minimizes the risk of crack pro- To carry out borescope blending it is only necessary to Possible airfoil damage - module replacement

longation by smoothing out the dent, nick or outbreak. simply open the cowling, remove the borescope plugs • borescope inspection (BSI)

The result is an engine ready for service without having and have electric power available. The boroblending Chord Missing • borescope blending

0.20 in (5.1 mm) percent tip corner

to be removed from wing. All blending procedures and tool can be inserted into through the borescope access Stages 5-9 • spare parts support

equipment are performed in accordance with the OEM port. A high speed grinding tip allows a technician to Tip curl • lease engine support

manual and are GE approved. The MTU Mobile Repair blend out damage on the blades and vanes. Specialist • engine trend monitoring

Nick

Team is available worldwide and ready for travel to the tools can be changed within a few seconds for opti-

customer location 24/7/365. mum efficiency. The blending process is observed

through a high resolution optical system. The techni- Normal leading Anytime. Anywhere. We care!

edge contour Nick depth

cian can directly control the working force on the dam-

Dent

MTU Maintenance Berlin-Brandenburg aged object to ensure only the minimum amount of

Note:

material is removed. MTU will issue a EASA Form 1 cer- Dent deflection

Typical boroblending areas

The center of excellence for CF34 engines from

Defect depth

tificate (or equivalent) confirming the work done. original contour

is in axis of

MTU Maintenance—a global partner damage

unless

MTU Maintenance is the largest and most experienced Exceptional advantages otherwise

independent engine maintenance, repair and overhaul • high precision handling noted.

provider for commercial aircraft engines and industrial • ideal field of view Dent depth Source: GE - Aviation

gas turbines. In order to better serve its costumers all • working angle adjustable

over the world, MTU Maintenance has built a global • time-saving and cost-effective

service network. Its locations ensure a local presence • simple way of measuring damage and blending Typical boroblending areas

in the most significant and fastest growing aviation results • HPC Stage 1 ~84 %

markets. “Repair beats Replacement” is the MTU Main- • HPC Stage 2, 6 ~80 %

tenance motto. MTU Maintenance still repairs parts • HPC Stage 3, 7- 9 ~100 %

where others have long resorted to replacement thus • HPC Stage 4 - 5 ~50 %

savaging material that would normally be scrapped.

Boroblending areas

~84% ~80% 100% ~50% ~80% 100%

Borescope blending

R1 R2 R3 R4 R5 R6 R7 R8 R9

Source: GE - Aviation

You might also like

- Trent 1000 Bsi 23122016Document1 pageTrent 1000 Bsi 23122016Mohamed AbdelSalamNo ratings yet

- CFM56 NDT ManualDocument103 pagesCFM56 NDT Manualmanishprajapati707100% (3)

- CFM56 5B SB Rev 72-1073 TSN.01 R 20200117Document13 pagesCFM56 5B SB Rev 72-1073 TSN.01 R 20200117Irfan05No ratings yet

- CFM 56 Combustor Bsi GuideDocument36 pagesCFM 56 Combustor Bsi GuideGennaro Esposito100% (1)

- 19-Workscoping-WTT NashvilleDocument28 pages19-Workscoping-WTT NashvilleFaraz KhanNo ratings yet

- Borescope Inspection Report PK-TWXDocument8 pagesBorescope Inspection Report PK-TWXGranita pru24No ratings yet

- CTC-224 Engine SystemsDocument331 pagesCTC-224 Engine Systemsjivomir100% (1)

- Fan Lub CFM56-7 - HandbookDocument44 pagesFan Lub CFM56-7 - HandbookANDRANo ratings yet

- Engine MaintenanceConceptsPresentation PDFDocument46 pagesEngine MaintenanceConceptsPresentation PDFEnrico Gambini100% (1)

- CFM56-7B Major Module Replacement Training ManualDocument67 pagesCFM56-7B Major Module Replacement Training Manualutfyhjk100% (1)

- CF34 10 CompIDMarchPrint PDFDocument47 pagesCF34 10 CompIDMarchPrint PDFJulio Eme-ErreNo ratings yet

- CF34-3 Engine Notes Chapter 72 Course NotesDocument30 pagesCF34-3 Engine Notes Chapter 72 Course NotesinternetsurfingNo ratings yet

- CFM56-7B Fan Blade Lubrication CESM-005Document2 pagesCFM56-7B Fan Blade Lubrication CESM-005Keith Humphrey0% (2)

- WSPG CF34-10E Sep 2014Document98 pagesWSPG CF34-10E Sep 2014johala100% (2)

- Cf34-8e 72-A0221Document8 pagesCf34-8e 72-A0221Stephen Hyde100% (1)

- Aircrft EngineDocument120 pagesAircrft EngineM Rafiq RajaNo ratings yet

- HPC Shroud & VSV System ImprovementsDocument15 pagesHPC Shroud & VSV System Improvementsali100% (2)

- Done By:: Indian Institute of Space Science and Technology ThiruvananthapuramDocument48 pagesDone By:: Indian Institute of Space Science and Technology Thiruvananthapuramsrijani pal100% (1)

- Ata 75 CFM56-3Document17 pagesAta 75 CFM56-3ccoyure100% (1)

- 13 - CH74,80 - Starting & Ignition SystemDocument40 pages13 - CH74,80 - Starting & Ignition SystemaliNo ratings yet

- BSIDocument7 pagesBSIaliNo ratings yet

- CFM56-7 Blades PDFDocument7 pagesCFM56-7 Blades PDFrafajbsNo ratings yet

- Cfm56 - 5b New OriginalDocument469 pagesCfm56 - 5b New Originalcheemeng79No ratings yet

- CTC-070 Answerbook Oct13Document57 pagesCTC-070 Answerbook Oct13Giovanny Colorado100% (2)

- 11-CFM56-3 Las Vegas 2018 Preservation and TransportationDocument17 pages11-CFM56-3 Las Vegas 2018 Preservation and TransportationOrlando Pérez50% (2)

- LBM Day8Document9 pagesLBM Day8Genaro RodriguezNo ratings yet

- 544-11 - Secondary AirDocument42 pages544-11 - Secondary AirHENIGUEDRINo ratings yet

- v2500lm01r02 General PDFDocument28 pagesv2500lm01r02 General PDFKamalVirk100% (1)

- V2500bsiissue01 150709152816 Lva1 App6892 PDFDocument163 pagesV2500bsiissue01 150709152816 Lva1 App6892 PDFMohd Hasrizam Che Man100% (1)

- 544-15 Thrust ReverserDocument70 pages544-15 Thrust ReverserHENIGUEDRINo ratings yet

- General Familiarization Training For CFM56!3!5 - 7 Engines - Magnetic MRODocument5 pagesGeneral Familiarization Training For CFM56!3!5 - 7 Engines - Magnetic MROArabyAbdel Hamed SadekNo ratings yet

- ATA 70 CFM56 B2: A318/19/20/21 Single Aisle FamilyDocument86 pagesATA 70 CFM56 B2: A318/19/20/21 Single Aisle FamilyZbor ZborNo ratings yet

- Emp RR PDFDocument142 pagesEmp RR PDFArabyAbdel Hamed SadekNo ratings yet

- Muza ReportDocument30 pagesMuza ReportVishvam Mistry100% (1)

- cfm56 5b PDFDocument6 pagescfm56 5b PDFTURBOJATO100% (1)

- 1 - Cowling&EBU (CF6-80E1)Document9 pages1 - Cowling&EBU (CF6-80E1)Chabou_r1627100% (3)

- JT8D JT8D 200series Borescope TrainingDocument78 pagesJT8D JT8D 200series Borescope TrainingAPU SHOP BTH MSNo ratings yet

- Fdocuments - in Engine Removal and Installation Cfm56 7 BDocument191 pagesFdocuments - in Engine Removal and Installation Cfm56 7 BpraveenNo ratings yet

- Toaz - Info Fan Removal PRDocument111 pagesToaz - Info Fan Removal PROsman ParlakNo ratings yet

- 70 Power Plant (V2500-A5)Document296 pages70 Power Plant (V2500-A5)Marcos Filho100% (1)

- CFM AMM ExtractsDocument126 pagesCFM AMM ExtractsIsrael De Sousa Oliveira (LATAM)No ratings yet

- VAR Part 7 - Aircraft Maintenance Basic Cat A: Training ManualDocument32 pagesVAR Part 7 - Aircraft Maintenance Basic Cat A: Training ManualPhạm Đức Huy100% (1)

- A330 RR Trent 700 Technical Training Manual Mechanical & Avionics Course - T1+T2 (LVL 2&3) APUDocument110 pagesA330 RR Trent 700 Technical Training Manual Mechanical & Avionics Course - T1+T2 (LVL 2&3) APULuiz Fernando MibachNo ratings yet

- CFM56 3 Book2PMC MECexerciseDocument4 pagesCFM56 3 Book2PMC MECexerciseDiniswari AlrinoNo ratings yet

- LEAP-1B Walkaround OverviewDocument22 pagesLEAP-1B Walkaround OverviewrakeshNo ratings yet

- Choice Global Support Capability: Flight HoursDocument9 pagesChoice Global Support Capability: Flight HoursGenaro Rodriguez100% (2)

- CFM Doc Leap 1B Co Bas 3 V2Document39 pagesCFM Doc Leap 1B Co Bas 3 V2Paulo Sanz100% (1)

- Cfm56-3 Comp IdxDocument54 pagesCfm56-3 Comp IdxDiniswari AlrinoNo ratings yet

- BSI Combustion Chamber LEAP NOV-01-2022Document45 pagesBSI Combustion Chamber LEAP NOV-01-2022Jason LapeNo ratings yet

- CF6-80C2 & 80E1. Line Maintenance Information.Document154 pagesCF6-80C2 & 80E1. Line Maintenance Information.NL NapsNo ratings yet

- 70 Power Plant CFM 56Document322 pages70 Power Plant CFM 56Agam Septiana100% (1)

- Rolls-Royce RB211 Trent 700 UCPG (Full Permission) - 2Document33 pagesRolls-Royce RB211 Trent 700 UCPG (Full Permission) - 2ArabyAbdel Hamed Sadek100% (1)

- Https Cwcs - cfm56 HPT BladeDocument8 pagesHttps Cwcs - cfm56 HPT Bladeali100% (1)

- ATA 24 Electrical Power R04Document121 pagesATA 24 Electrical Power R04srtrtyrtNo ratings yet

- T900 Pre Test Inspection BookletDocument51 pagesT900 Pre Test Inspection Bookletdeming9120100% (1)

- V2500 Line and Base Maintenance Engine OverviewDocument24 pagesV2500 Line and Base Maintenance Engine OverviewHENIGUEDRI100% (2)

- Santoprene Blow Molding Guide EnpdfDocument23 pagesSantoprene Blow Molding Guide EnpdfNikhil AherNo ratings yet

- Santoprene Blow Molding Guide enDocument23 pagesSantoprene Blow Molding Guide enasddsaNo ratings yet

- Rigging2002 PDFDocument89 pagesRigging2002 PDFJimmy Aleman0% (1)

- Supplementary Information Regarding Checking and Replacing Big-End Bearings On Medium-Speed Engines Cus 190Document4 pagesSupplementary Information Regarding Checking and Replacing Big-End Bearings On Medium-Speed Engines Cus 190mariodalNo ratings yet

- Rolls-Royce RB211 Trent 700 UCPG (Full Permission) - 2Document33 pagesRolls-Royce RB211 Trent 700 UCPG (Full Permission) - 2ArabyAbdel Hamed Sadek100% (1)

- T7BSI4v30 PDFDocument70 pagesT7BSI4v30 PDFArabyAbdel Hamed SadekNo ratings yet

- Planning and Measuring Your Papa Pump Site - Papa Ram Pump PDFDocument8 pagesPlanning and Measuring Your Papa Pump Site - Papa Ram Pump PDFArabyAbdel Hamed SadekNo ratings yet

- The Future of Borescope Inspections.: Iso 9001:2000 Registered As9000 CompliantDocument4 pagesThe Future of Borescope Inspections.: Iso 9001:2000 Registered As9000 CompliantArabyAbdel Hamed SadekNo ratings yet

- Turbojet Engine Maintenance Systems: Dragoljub Vujić, PHD (Eng)Document7 pagesTurbojet Engine Maintenance Systems: Dragoljub Vujić, PHD (Eng)ArabyAbdel Hamed SadekNo ratings yet

- Electronic Engine Logbook: Engine Number:-Engine Type: - Constructor: - Date of ConstructionDocument53 pagesElectronic Engine Logbook: Engine Number:-Engine Type: - Constructor: - Date of ConstructionArabyAbdel Hamed SadekNo ratings yet

- T7 BSI3 V 30Document24 pagesT7 BSI3 V 30ArabyAbdel Hamed SadekNo ratings yet

- Worksheet PW4158 Ahmed Hesham V2Document62 pagesWorksheet PW4158 Ahmed Hesham V2ArabyAbdel Hamed SadekNo ratings yet

- Emp RR PDFDocument142 pagesEmp RR PDFArabyAbdel Hamed SadekNo ratings yet

- EWIS Part 145 Course OutlineDocument4 pagesEWIS Part 145 Course OutlineArabyAbdel Hamed SadekNo ratings yet

- B Trent41368ATDocument81 pagesB Trent41368ATArabyAbdel Hamed SadekNo ratings yet

- Afd 070221 129 PDFDocument905 pagesAfd 070221 129 PDFArabyAbdel Hamed SadekNo ratings yet

- Product Support & Services: Maintenance TrainingDocument78 pagesProduct Support & Services: Maintenance TrainingArabyAbdel Hamed SadekNo ratings yet

- Cancelled: Pest Control Quality Assurance Evaluator Training HandbookDocument383 pagesCancelled: Pest Control Quality Assurance Evaluator Training HandbookArabyAbdel Hamed SadekNo ratings yet

- 6 Task Handover Log PR-15Document1 page6 Task Handover Log PR-15ArabyAbdel Hamed SadekNo ratings yet

- User User Tools List Teg Tool Stores Lists Teg Stores Engine Engine Lists Shop FOR EWS INSIDE Tool Stores FOR EWS OUTSIDE Tool StoresDocument2 pagesUser User Tools List Teg Tool Stores Lists Teg Stores Engine Engine Lists Shop FOR EWS INSIDE Tool Stores FOR EWS OUTSIDE Tool StoresArabyAbdel Hamed SadekNo ratings yet

- All Tool ListsDocument367 pagesAll Tool ListsArabyAbdel Hamed Sadek0% (1)

- Name: License No License No: 2862 License Issue Date Issue Date:11/7/2007 License Expiry Date Expiry Date:10/7/2019Document139 pagesName: License No License No: 2862 License Issue Date Issue Date:11/7/2007 License Expiry Date Expiry Date:10/7/2019ArabyAbdel Hamed SadekNo ratings yet

- Fan Blade Sheet: Production EngineeringDocument2 pagesFan Blade Sheet: Production EngineeringArabyAbdel Hamed SadekNo ratings yet

- 7 Defect ReportDocument1 page7 Defect ReportArabyAbdel Hamed SadekNo ratings yet

- Ea PTRJR: Engine Non-Routine CardDocument1 pageEa PTRJR: Engine Non-Routine CardArabyAbdel Hamed SadekNo ratings yet

- Name: License No License No: 2862 License Issue Date Issue Date:11/7/2007 License Expiry Date Expiry Date:10/7/2019Document139 pagesName: License No License No: 2862 License Issue Date Issue Date:11/7/2007 License Expiry Date Expiry Date:10/7/2019ArabyAbdel Hamed SadekNo ratings yet

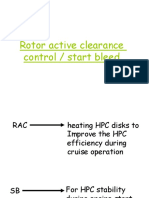

- Rotor Active Clearance Control / Start BleedDocument21 pagesRotor Active Clearance Control / Start BleedArabyAbdel Hamed SadekNo ratings yet

- F05 Life Limited PartsDocument1 pageF05 Life Limited PartsArabyAbdel Hamed SadekNo ratings yet

- F32 Annulus Fairing SheetDocument2 pagesF32 Annulus Fairing SheetArabyAbdel Hamed SadekNo ratings yet

- Final 856167 Acc Form - Modified On LPM PL06 After Test11Document26 pagesFinal 856167 Acc Form - Modified On LPM PL06 After Test11ArabyAbdel Hamed SadekNo ratings yet

- F15 Global Work ScopeDocument1 pageF15 Global Work ScopeArabyAbdel Hamed SadekNo ratings yet

- 3 Missed Tool PR-33 F01 العدة المفقودهDocument1 page3 Missed Tool PR-33 F01 العدة المفقودهArabyAbdel Hamed SadekNo ratings yet

- CFM56-5C Workscope Planning GuideDocument195 pagesCFM56-5C Workscope Planning GuideArabyAbdel Hamed Sadek100% (7)

- SRT Es Epr CapabilitylistDocument1 pageSRT Es Epr CapabilitylistArabyAbdel Hamed SadekNo ratings yet

- The Construction of Optimal Portfolio Using Sharpe's Single Index Model - An Empirical Study On Nifty Metal IndexDocument9 pagesThe Construction of Optimal Portfolio Using Sharpe's Single Index Model - An Empirical Study On Nifty Metal IndexRevanKumarBattuNo ratings yet

- Week 7 Sex Limited InfluencedDocument19 pagesWeek 7 Sex Limited InfluencedLorelyn VillamorNo ratings yet

- Making Effective Powerpoint Presentations: October 2014Document18 pagesMaking Effective Powerpoint Presentations: October 2014Mariam TchkoidzeNo ratings yet

- Gemini Dollar WhitepaperDocument7 pagesGemini Dollar WhitepaperdazeeeNo ratings yet

- PM CH 14Document24 pagesPM CH 14phani chowdaryNo ratings yet

- (500eboard) Version Coding Model 140 As of MY 1995Document1 page(500eboard) Version Coding Model 140 As of MY 1995Saimir SaliajNo ratings yet

- Aleksandrov I Dis 1-50.ru - enDocument50 pagesAleksandrov I Dis 1-50.ru - enNabeel AdilNo ratings yet

- OZO Player SDK User Guide 1.2.1Document16 pagesOZO Player SDK User Guide 1.2.1aryan9411No ratings yet

- Monkey Says, Monkey Does Security andDocument11 pagesMonkey Says, Monkey Does Security andNudeNo ratings yet

- (123doc) - Toefl-Reading-Comprehension-Test-41Document8 pages(123doc) - Toefl-Reading-Comprehension-Test-41Steve XNo ratings yet

- ISO 9001 2015 AwarenessDocument23 pagesISO 9001 2015 AwarenessSeni Oke0% (1)

- Traveling Salesman ProblemDocument11 pagesTraveling Salesman ProblemdeardestinyNo ratings yet

- Nutrition and CKDDocument20 pagesNutrition and CKDElisa SalakayNo ratings yet

- Law of EvidenceDocument14 pagesLaw of EvidenceIsha ChavanNo ratings yet

- Working Capital in YamahaDocument64 pagesWorking Capital in YamahaRenu Jindal50% (2)

- Dialogue Au Restaurant, Clients Et ServeurDocument9 pagesDialogue Au Restaurant, Clients Et ServeurbanuNo ratings yet

- Electives - ArchitDocument36 pagesElectives - Architkshitiz singhNo ratings yet

- Mastertop 1230 Plus PDFDocument3 pagesMastertop 1230 Plus PDFFrancois-No ratings yet

- Chapter 2 ProblemsDocument6 pagesChapter 2 ProblemsYour MaterialsNo ratings yet

- Cisco SDWAN Case Study Large Global WANDocument174 pagesCisco SDWAN Case Study Large Global WANroniegrokNo ratings yet

- DP 2 Human IngenuityDocument8 pagesDP 2 Human Ingenuityamacodoudiouf02No ratings yet

- GPS Spoofing (2002-2003)Document8 pagesGPS Spoofing (2002-2003)Roger JohnstonNo ratings yet

- School of Mathematics 2021 Semester 1 MAT1841 Continuous Mathematics For Computer Science Assignment 1Document2 pagesSchool of Mathematics 2021 Semester 1 MAT1841 Continuous Mathematics For Computer Science Assignment 1STEM Education Vung TauNo ratings yet

- Dynamics of Machinery PDFDocument18 pagesDynamics of Machinery PDFThomas VictorNo ratings yet

- A Case Study of Coustomer Satisfaction in Demat Account At: A Summer Training ReportDocument110 pagesA Case Study of Coustomer Satisfaction in Demat Account At: A Summer Training ReportDeepak SinghalNo ratings yet

- Prelim Examination MaternalDocument23 pagesPrelim Examination MaternalAaron ConstantinoNo ratings yet

- E0 UoE Unit 7Document16 pagesE0 UoE Unit 7Patrick GutierrezNo ratings yet

- Heterogeneity in Macroeconomics: Macroeconomic Theory II (ECO-504) - Spring 2018Document5 pagesHeterogeneity in Macroeconomics: Macroeconomic Theory II (ECO-504) - Spring 2018Gabriel RoblesNo ratings yet

- Deal Report Feb 14 - Apr 14Document26 pagesDeal Report Feb 14 - Apr 14BonviNo ratings yet

- Hole CapacityDocument2 pagesHole CapacityAbdul Hameed OmarNo ratings yet