Professional Documents

Culture Documents

Capstan Winch For Series

Uploaded by

mendper0 ratings0% found this document useful (0 votes)

84 views6 pagesCapstan Winch for Series

Original Title

Capstan Winch for Series

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCapstan Winch for Series

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

84 views6 pagesCapstan Winch For Series

Uploaded by

mendperCapstan Winch for Series

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 6

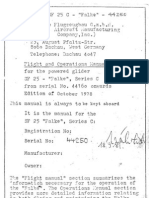

Capstan Winch for Series Il Ila,

and III Land Rovers. -

Supplied and Manufactured by:

AEROPARTS ENGINEERING CO. LTD., (R.T.Z.-Pillar Group)

COMMERCIAL ROAD : HEREFORD : ENGLAND : “Telephone Hereford 3068/9

HISTORY This unit basically conforms to the original designs by The Rover Co. Ltd.,-and

Manufactured by Aeroparts since the introduction of the Land Rover range. It

Taod to vehicles operating all over the world, in all climates, and has proved

tnd reliable under the most difficult conditions.

DESCRIPTION The winch is mechanicaly driven from the engine crankshaft, and is mounted or

plate between the front bumper and the radiator grille. It is designed for a maxi

3600 Ibs. (1360 kgs) and overload protection is supplied by a Shear Pin in the

The main function of the winch is self-recovery, 91 Straight hauling or pulling

Specification limits, and should be used with 4 Ti" (31.5 mm) diameter manilla

Wire Ropes are not recommended for constant use fe this will cause excessive V

Wire RRehich has a specially designed shape for gripping. If necessary the ent

every trough the winch, which has a starter dog fitted, accessible through

in the bumper bar, but if this is done, it is recommended that the shear pin is tempora

ine eeplaced by 2 5/16 dia Bolt. For Petrol-Engine Vehicles it is necessary to

ae te for maintaining an engine speed of 600 r-P.m.

OPERATION Pass therope twice round the bollard, leaving one end free for holding by the opera

Fase eeige of the winch. Pass the other end under the ‘guide roller and fasten 1

RRing pulled (or to a rigid stationery point for ‘Self-recovery) with engine runt

being Prvaintain a steady pull of the free end of the rope, Paying off as it winds in

. Front

°. From Engine Crankshaft

“23000 tbs. (1360 kgs)

‘Shear Pin (3000 _ Ibs

- Worm and Wheel 75:1

“1 20mm Viking Nylon

TECHNICAL _ Direction of Pull

INFORMATION Drive

Max. Pull.

Overload Protectio

Reduction Ratio

Ropes 5 5

TE" dia G15 mm) }

Weight of Winch ; Lae Balbs. (24 kgs)

Winch Speed) LT With 1000 ,.1.p.m.

16ft. (4.87 eh) per mil

Lubication eet EP90, SAE 90 Gear Oil

OVERHAULING :

errr Fr from the control rod;

Fer gpring washer securing the control rod eyebolt to ‘the support plate and drop th

an ert Ae dust cover from the front universal joint on the ‘winch propeller shaft.

2 Remove the nuts, spring and plain washers securing the support plate to the chassis

Re Oe ne plainr washers and self-locking nuts securing te front bumper to the ©

ae Mie per, support plate, rope guide and winch complete, the same time disengagir

eft irekn the universal joint sleeve on the winch. The sping ‘and plunger in the pror

shaft from this stage and care should be taken that these are not lost.

3 Remove the winch from the support plate.

4. Slide the rear dust cover along the propeller shaft and withdraw the propeller shaft

Sf the driving shaft, care being taken that the second ‘spring and plunger are not lost.

5 Extract the driving shaft from the shaft housing and remove the driving flange fre

with the selector fork.

6 Disconnect the control rod clevis from the control shaft and remove the drive shat

housing and control shaft complete from the brackets.

7 Remove the selector fork from the control shaft; remove the plug, spring and batl fror

housing and withdraw the control shaft; remove the ‘shaft housing from the plate.

8 Remove the radiator and grille pane! assembly.

PART No,

268698

2I2104

09561

219161

219686

543688,

234370

09581

506287

237006

‘8060

3078

218767

219089

233324

DESCRIPTION

Casing Assy. for Front Winch

Stud for Bottom Cover

Dowel for Thrust Washer

Bush for Bollard Shaft

Grease Nipple for Shaft

Breather Cup for Housing

Bollard and Shaft Assembly

Dowel Pin for Shaft

Safety Pin for Bollard 0.328 Dia,

Safety Pin for Bollard 0.265 Dia,

Plain Washer Fixing

Spring Washer Bollard

Set Bolt (#” BSF) Shaft

Thrust Washer For

Bollard

Shim

Bollard Cap

Set Bolt For Fixing

Bollard Cap

Spring Washer

form and Wheel Asseribly

Key For Worm Wheel

Circlip Fixing Worm Wheel

Roller Bearing for Worm

Washer for the above

Circlip fer Worm Shaft

Bearing for Worm Shafe

Distance Piece for Worm Shaft

il Seal for Worm Shaft

Oil Seal Retainer

Joint Washer for Retainer

Set Bolts 2BA: Fixing Retainer

Spring Washer for above

Starter Dog

Lock Washer for Dog.

U.3. Sleeve

Bottom Cover

Joint Washer for Cover

Spring Washer for Cover

Nut Washer for Cover,

Draih Plug ,

Joint Washer for Plug

Dip Stick Assembly

Spica Bok } fixing Front

ipring Washer inch to

ue support plate

No,

BEALNE IS,

(SUITABLE

| ALL MODELS)

2a

2 LITRE PETROL

keg

~ 24 UTRE PETROL DIESEL

[>=

off

2Litre 21 Litre Series Il] REMARKS

Hl 1

10

1 1 SubsAssembly

i 2% Supplied Complete for Spares

(| 1

eee

1 '

1 NR 1 Alternatives. Check

| NR J! Diameter Belore Ordering

1 i

' '

1 t

As As

Req'd Req

bo ONR

SEaeNR|

3 NR

i t

Il '

1 '

! '

2 2

1 1

It 1

1 Il

2 2

t t

IL 1

4 4

4 4

t t

1 i

1 It

! | See Plate Ref, Nos. 126 & 127 & Now

I I

1010

leer 10)

' 1

1 i

! !

9 9

9 9

9 9 '

PART No, DESCRIPTION

268698 Casing Assy. for Frone Winch

U2104 Stud for Bottom Cover

09561 Dowel for Thrust Washer

U316l Bush for Bollard Shate

219696 Grease Nipple for Shate

543688 Breather Cup for Housing

234370 Bollard and Shatt Assembly

99561 Dowel Pin for Shaft

506287 Safety Pin for Bollard 0328 Dis,

237006 Safety Pin for Bollard 0.265 Dia

8060 Plain Washer Fixing

3078 Spring Wather Bollard

wis7e7 Seceee yg 8S.) Shaft

219089 Thrust Washer For

J Boltara

233324 Shim

Zi9i1s Bollard Cap

21978 Ser Bole For Fixing

3076 Spring Washer Bollard Cop

24807 Worm and Wheel Assenibly

Key For Worm Wheel

Gitelp Fang Worm Wheel

Roller Bearing for Worm

‘Washer for the above

Gircip fer Worm Sha

Bearing for Worm shate

Distance Plece for Worm Shafe

Gil'Seal for Worm Shate

Oil Seal Retainer

Joint Washer for Retainer

Set Bolts 254 Fining Retainer

Spring Washer for above

Stareer

tock Washer for Dog

Ur. Sleeve

+ Bly Pine

Bottom Cover

{pine Washer for Cover

Spring Washer for Cover

Nat Washer for Cover

Draft Plug on oo"

Joint Wather for Plog

Dip Suck Assembly

\_ Special Bote Fixing Front

, Spring Washer Winch to

fue” support plate

}

= 24 UTRE PETROL @ DIESEL

| BRACKETS

{SUITABLE

ALL MODELS)

f

=

No, off

2 Litre 2 Litre Series I REMARKS

1 It I

19 10

' ' 1! Sub-Assembly

2 2 2 Supplied Complete for Spares

1

t ' 1

! ann

It 1

' 1 NR Y Alternatives. Check

1 | NR J Diameter Before Ordering

1

1 t '

' ' 1

1 1 '

As As As

Req'd Req'd Req'd

1 ro oNR

3 3° ONR

3 3 NR

i i '

1 ' !

' 1 i

! i i

2 2 2

1 1 1

t i '

1 ' 1

2 2 2

1 t 1

1 ' t

4 4 4

4 4 4

t ' '

1 1 '

1 I 1

' I 1 See Plate Ref Nos, 126 & 127 & Note A

' 1 1

I I '

10 10 10

0 109

1 1 1

1 t I

1 ! !

9 9 9

9 9 9

9 9 9 1 a

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- AirTrails Classic Flying Models Fall1979Document90 pagesAirTrails Classic Flying Models Fall1979mendper100% (1)

- Easa Part FCL AmcDocument562 pagesEasa Part FCL AmcPavel Radu CristeaNo ratings yet

- Us Tools PricelistDocument20 pagesUs Tools PricelistmendperNo ratings yet

- Joubert Okoume Plywood SpecificationsDocument1 pageJoubert Okoume Plywood SpecificationsmendperNo ratings yet

- Beringer Wheels Brakes CatalogDocument18 pagesBeringer Wheels Brakes CatalogmendperNo ratings yet

- Sheds Storage ShedDocument6 pagesSheds Storage ShedmendperNo ratings yet

- 2007 CatalogDocument129 pages2007 CatalogmendperNo ratings yet

- Ip 5Document156 pagesIp 5Mark RayneyNo ratings yet

- The Glider - Stelio Frati English Version of "L'aliante"Document198 pagesThe Glider - Stelio Frati English Version of "L'aliante"Luca MicheliniNo ratings yet

- PiperJ3Cub EngDocument6 pagesPiperJ3Cub Engmendper0% (1)

- 20 Rick ChaleDocument27 pages20 Rick Chalemohd_interNo ratings yet

- RF5B Flight ManualDocument25 pagesRF5B Flight ManualmendperNo ratings yet

- Manual Sf25c Motorfalke FlightDocument19 pagesManual Sf25c Motorfalke FlightmendperNo ratings yet

- Manual Sf25c Motorfalke EngineDocument25 pagesManual Sf25c Motorfalke EnginemendperNo ratings yet

- Af447 17122009Document104 pagesAf447 17122009dahlenburgNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)