Professional Documents

Culture Documents

D. P.Vessel PDF

Uploaded by

Didit SusantoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

D. P.Vessel PDF

Uploaded by

Didit SusantoCopyright:

Available Formats

IOSR Journal of Mechanical and Civil Engineering (IOSR-JMCE)

e-ISSN: 2278-1684,p-ISSN: 2320-334X, Volume 13, Issue 1 Ver. II (Jan. - Feb. 2016), PP 28-34

www.iosrjournals.org

Design of Pressure Vessel and Prediction of Failure of Limpet

Coil

Zahiruddin Mohammed Farooque Khateeb1, Dr. Dhanraj P. Tambuskar2

1

(Department of Mechanical Engineering Pillai’s Institute of Information Technology, Engineering, Media

Studies & Research/ University of Mumbai, India)

2

(Department of Mechanical Engineering Pillai’s Institute of Information Technology, Engineering, Media

Studies & Research/ University of Mumbai, India)

Abstract: Pressure vessels are leak proof containers, as the name implies, their main purpose is to contain a

given medium under pressure and temperature. Pressure vessels are commonly used in industry to carry both

liquid and gases under required pressure and temperature limit. This pressure and temperature comes from an

external source or by the application of heat from a direct or indirect source or any combination of them. This

project deals with design and analysis of Acetic acid pressure vessel for pharm industry. This project

investigates, failure of half pipe jacket (limpet coil) on basis of thermal analysis, the work is carried out by the

designing of pressure vessel as per the ASME section VIII, division 1 for given design conditions for various

parameters. Validation is done on PV-ELLITE software for the same. Design model prepared in CREO 3 using

dimensions obtain in analytical design .FEA analysis is done for the vessel shell and limpet coil in Ansys 15 by

applying suitable conditions and results are compared with the section VIII, division 1, Thermal analysis for

external limpet coil for heating at design temperature at 275 oc and on pressure 20 kg/cm2 is done. Material for

limpet coil is suggested depending upon the result of thermal analysis.

Keywords: Pressure Vessel, ASME Section VIII Division I, Limpet Coil, PV-ELLITE, Ansys 15

I. Introduction

The pressure vessels (i.e. cylinder or tanks) are used to store fluids under pressure. Pressure vessel is

defined as a container with a pressure differential between inside and outside. The inside pressure is usually

higher than the outside. The fluid inside the vessel may undergo a change in state as in the case of steam boiler

or may combine with other reagent as in the case of chemical reactor. Pressure vessel often has a combination of

high pressure together with high temperature and in some cases flammable fluids or highly radioactive material.

Because of such hazards it is imperative that the design be such that no leakage can occur. . Pressure vessel and

tank are in fact essential to the chemical, petroleum, petrochemical and nuclear industry. It is in the class of

equipment that the reaction, separation and storage of raw material occur. In the same word, pressurized

equipment is required for a wide range of industrial plant for storage and manufacturing purpose. In the case of

shell, opening requiring reinforcement in vessel under internal pressure the metal removed must be replaced by

the metal of reinforcement. In addition to providing the area of reinforcement, adequate welds must be provided

to attach the metal of reinforcement and the induced stresses must be evaluated. Materials used for

reinforcement shall have an allowable stress value equal to or greater than of the material in this vessel wall

except that, when such material is not available, lower strength material may be used; provided, the

reinforcement is increased in inversed proportion to the ratio of the allowable stress values of the two materials

to the ratio of the two materials to compensate for the lower allowable stress value of any reinforcement having

a higher allowable stress value than that of the vessel wall.

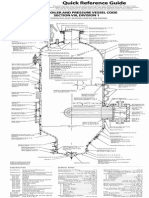

Fig.1 Pictorial view of pressure vessel

DOI: 10.9790/1684-13122834 www.iosrjournals.org 28 | Page

Design Of Pressure Vessel And Prediction Of Failure Of Limpet Coil

II. Literature Review

T. P. Pastor & D. A. Osage [13]

In year 2007 has done revision of ASME codes and design steps and modified, the standard for easy

use, wall thickness is changed for pressure vessel shell and head, change in welding, PWHT, and NDE costs,

consider as overall cost change.

A. Di Carluccio et al [2].

In year 2008 has done the work on ASME norms should be considered for designing. Seismic loads

should be considered while designing a pressure vessel. Wind load and seismic load creates moment at lug. The

greater moment should be consider for design to avoid accidents.

B.S.Thakkar, et al [4]

In year 2012 has done work on has defined the conditions for proper selection of vessel. Hydrostatic

test should be done and vessel should pass that test. for design and fabrication ASME standards should be

followed.

Yogesh Borse, et al [11]

In year 2012 has done work on different shapes of head of pressure vessel. Finite element model is

developed and coparisons are done by taking one half of head thickness than shell. Modeling and validation of

zones are identified and solution is provided. The equivalent von-misses stresses depict the clear picture.

Prof. Nitinchandra R. Patel1, et al [5]

In year 2013 has done work on pressure vessel design in marine application material of different

grades are taken and thickness for shell is calculated and suitable material is suggested.analytical results are

validated by using matlab program.

K.S.J.Prakash, et al [6] in year 2014

In this study two pressure vessels are compared, one with soild material and other with multi layered

material and it is been found that multilayered material pressure vessel save the material And it is economic..

Vijay Kumar et al [9]

In year 2014 designed the pressure vessel according to the ASME and various parameters are

calculated like shell, head, nozzle, thickness and results are validated by the PV_ELLITE software.

Gongfeng Jiang , Gang Chen, Liang Sun, Yiliang Zhang, Xiaoliang Jia & Yinghua Liu[17]

In year 2014 SS 304 is tested for uniaxial load condition at room temperature. tests for that the elastic

domain was increased to study the behaviour. ratcheting strain and viscoelastic strain rates changes with the

increase of elastic domain, and the total strain will be reaching to the saturated point.

Piotr Dzierwa & Jan Taler[15]

In year 2015 developed a method for studying time-optimum medium temperature changes in element

.heating is the done with time variation. circumferential stress and thermal stresses are kept within the allowable

range to study the stress concentration.

Christopher J. Evans & Timothy F. Miller[18]

In year 2015 investigates using nonlinear finite element analysis (FEA) to determine the failure of

pressure vessel using symmetric shape and unsymmetrical shape and suitable changes are made to report.

III. Design Methodology

Code Selection .There are many engineering standards which give information on the design, and

fittings of a pressure vessel. The ASME is normally followed in India, but other national or international

standards may also be used. For this design, ASME VIII (division 1) "Construction of Pressure vessel Codes"

are selected according to above statement. It is, however, emphasized that any standard selected for manufacture

of the pressure vessel must be followed and complied with in entirety and the design must not be based on

provisions from different standards.

A. Selection Of Material

Several of materials have been use in pressure vessel fabrication. The selection of material is based on

the appropriateness of the design requirement. AU the materials used in the manufacture of the receivers shall

comply with the requirements of the relevant design code, and be identifiable with mill sheets. The selection of

materials of the shell shall take into account the suitability of the materials with the maximum working pressure

and fabrication process. For this kind of pressure vessel, the selection of material use is based on Appendix B.

B. Design Pressure

The pressure use in the design of a vessel is call design pressure. It is recommended to design a vessel

and its parts for a higher pressure than the operating pressure. A design pressure higher than the operating

pressure with 10 percent, whichever is the greater, will satisfy the requirement. The pressure of the fluid will

also be considering. The maximum allowable working pressure (MAWP) for a vessel is the permissible pressure

DOI: 10.9790/1684-13122834 www.iosrjournals.org 29 | Page

Design Of Pressure Vessel And Prediction Of Failure Of Limpet Coil

at the top of the vessel in its normal operating position at a specific temperature. This pressure is based on

calculations for every element of the vessel using nominal thicknesses exclusive of corrosion allowance. It is the

basis for establishing the set pressures of any pressure-relieving devices protecting the vessel. The design

pressure may be substituted if the MAWP is not calculated. (UG22, ASME VIII.) [1]

C. Design Temperature

Design temperature is the temperature that will be maintained in the metal of the part of the vessel

being considered for the specified operation of the vessel. For most vessels, it is the temperature that

corresponds to the design pressure. However, there is a maximum design temperature and a minimum design

temperature (MDMT) for any given vessel. The MDMT shall be the lowest temperature expected in service or

the lowest allowable temperature as calculated for the individual parts. Design temperature for vessels un-der

external pressure shall not exceed the maximum temperatures. [1]

D. Corrosion Allowance

Corrosion occurring over the life of a vessel is taken care by a corrosion allowance, the design value of

which de-pends upon the vessel duty and the corrosiveness of its con-tent. A design criterion of corrosion

allowance is 2 mm for a pressure vessel. As stainless steel is used for design of pressure vessel there is no need

of addition of corrosion allowance.

E. Shell design [1]

The minimum thickness for shell or maximum allowable working pressure for cylindrical shells is

given by (1) or (2) below.

When t=r/2, or P does not exceed 0.385SE, the following formulas shall apply.

1. Circumferential stress ------UG-27(c) (1)

2. Longitudinal stress ------UG-27(c) (2)

Fig.2. shell [1]

P = internal pressure

Di, Do, = inside/outside diameter

S = allowable or calculated stress

E =joint efficiency

L =crown radius

Ri, Ro, = inside/ outside radius

R= mean radius of shell

t =thickness of shell, head,

r =knuckle radius

F. Closure Design

The head thickness is calculated by (UG-16). And other, loading is taken in account by UG-22.

DOI: 10.9790/1684-13122834 www.iosrjournals.org 30 | Page

Design Of Pressure Vessel And Prediction Of Failure Of Limpet Coil

Fig.3. Dimension of Dish [1]

L =crown radius

r =knuckle radius

h =depth of head

RL =latitudinal radius of curvature.

Rm = meridional radius of curvature.

P =internal pressure.

G. Nozzles, Openings And Reinforcements

Openings in cylindrical or conical portions of vessels, or in formed heads, shall preferably be circular,

elliptical, or obround. When the long dimension of an elliptical or obround opening exceeds twice the short

dimensions, the reinforcement across the short dimensions shall be increased as necessary to provide against

excessive distortion due to twisting moment.

H. Supports for Vessels [1]

Cylindrical and other types of vessels have to be supported by different methods. Vertical vessels are

supported by brackets, column, skirt, or stool supports, while saddles support horizontal vessels.

I. Skirt

Vertical vessels are normally supported by means of suitable structure resting on a reinforced concrete

foundation. This support structure between the vessel and the foundation may consist of a cylindrical shell

termed as skirt. The skirt is usually welded to the vessel because the skirts are not required to withstand the

pressure in the vessel; the selection of material is not limited to codes. The skirt may be welded directly to the

bottom dished head, flush with the shell or to the outside of shell. There will be no stress from internal and

external pressure for the skirt, unlike for the shell, but the stresses from dead weight and from wind or seismic

bending moments will be maximum.

J. Loads On Pressure Vessels [1]

A pressure vessel is subjected to various types of loading individually and in various possible

combinations. The loading to be considered in designing a vessel shall include those from

1) Loads due to Internal and External pressure:

A cylindrical vessel under internal pressure tends to retain its shape on that any out-of-roundness or

dents resulting from shop fabrication or erection tend to be removed when foe vessel is placed under internal

pressure. Thus any deformations resulting form internal assure tends to make an imperfect cylinder more

cylindrical. However the opposite is for imperfect cylindrical vessels subjected to external pressure and any

imperfection will tend to be aggravated with the result of possible collapse of the vessel.

2) Dead Loads:

The dead load acting on the vessel is determined by the weight and location of all the exterior and

interior attachments such as trays, overhead condensers, platforms, insulation, and so on. Stresses caused by

dead loads may be considered in three groups for convenience:

a) Stress induced by shell and insulation

b) Stress induced by liquid in the vessel

DOI: 10.9790/1684-13122834 www.iosrjournals.org 31 | Page

Design Of Pressure Vessel And Prediction Of Failure Of Limpet Coil

c) Stress induced by attached equipment

The total dead-load stress acting along the longitudinal axis of the shell is then the sum of above given three

dead-weight stresses

3) Wind Loading:

Stresses produced in a self-supporting vertical vessel by the action of the wind are calculated by

considering the vessel to be a vertical, uniformly loaded cantilever beam. Wind loading is a function of the

wind velocity, air density, and the shape of the distinctly different kinds of design considerations result from

wind loading. First, lie static force from the wind loading pressure against the vessel causes an overturning

moment that

iv. Earthquake loading: Earthquake phenomena in certain geographic locations result in the production of loads.

In tall vessels, one cause of stresses in the vessel is the overturning lot from the lateral force of an earthquake

loading.

Table.1 Design Results

Sr no Part name Minimum design Validation by Finished Remark

parameter as per PV Elite thickness

Asme design

1. Shell t= 19.77mm passed t=20mm Adequate

2. Elliptical head t= 19.77mm passed t=21 Adequate

3. Coil t=0.43mm passed t=5mm Adequate

4. N1 t=16 mm passed t=3.65 Adequate

5. N2 t=6.22 passed t=6.22 Adequate

6. N3 t =3.42 passed t=4.85 Adequate

7. N4 t=5.27 passed t =5.27 Adequate

8. N5 t=3.42 passed t=4.85 Adequate

9. N6 t=3.42 passed t =4.85 Adequate

10. N7 t=3.42 passed t =4.85 Adequate

11. N8 t=3.22 passed t =4.85 Adequate

12. N9 t=3.22 passed t =4.85 Adequate

13. N10 t = 0.43 passed t=3.98 Adequate

14. N 11 t =0.43 passed t=3.98 Adequate

15. N 12 t=0.43 passed t=3.98 Adequate

16. N13 t=0.43 passed t=3.98 Adequate

17. N14 t=2.96 passed t=3.98 Adequate

18. N15 t=3.42 passed t=4.85 Adequate

19. N 16 t=5.73 passed t=5.73 Adequate

20. N17 t=.73 passed t=5.73 Adequate

21. N 18 t=3.42 passed t=4.85 Adequate

22. N 19 t=3.42 passed t=4.85 Adequate

23. N 20 t =6.22 passed t=6.22 Adequate

24. N 21 t=3.22 passed t 4.45 Adequate

25. Moment at lug passed

Wind load -------------- -------------

=8692.73 nm

26. Moment at lug passed

Seismic load -------------- -------------

=29602.13 nm

Table.2 Analysis Results on Limpet Coil for SS 304(SA 240 GR 304

SS 304(SA 240 GR 304 Allowable parameters Result from ANSYSIS 15 Remark

Equivalent stresses Tensile Yield stress 206 174 Mpa (on shell side) Safety factor=1.18

Mpa and 119 Mpa at bottom Safety factor=1.73

Deformation Elastic Elastic Safe

Table.3 Analysis Results on Limpet Coil for 2.SA 285 GR C

2.SA 285 GR C Allowable parameters Result from ANSYSIS 15 Remark

Equivalent stresses Tensile Yield stress 206 343 to 457 Mpa (on shell Safety factor=0.45

Mpa side) and 281 Mpa at Safety factor=0.73

bottom

Deformation Elastic plastic failed

DOI: 10.9790/1684-13122834 www.iosrjournals.org 32 | Page

Design Of Pressure Vessel And Prediction Of Failure Of Limpet Coil

on comparison of result it is clear that SA 285 gr C material is failing under the high thermal stresses hence it is

recommended that SS 304 (SA 240 GR C) material should consider for the final manufacturing of limpet coil.

IV. Thermal Analysis On Limpet Coil In Ansys 15

Thermal analysis on limpet coil of SS 304 material:

Fig.4. Equivalent stresses on SS 304 material coil

Thermal analysis on limpet coil of SA 285 grade C material:

Fig.5. Equivalent stresses on SA 285 grade C material coil

V. Conclusion

A. Design of 15 kl pressure vessel satisfies the standard set by ASME section VIII division 1.

B. As acetic acid is non-hazardous lethal service as per UW -2 is not required.

C. Fiber elongation as per UG-79 & UHA-44 is 4.46% hence cold rolling process can be selected for

fabrication.

D. All materials are compared with code UG-20(f) & UHA- 51 for impact testing.

E. Impact testing for material is not required.

F. PWHT is not mandatory as per the Uw-2,Ucs-56 and Ucs-68

G. Analysis on limpet coil is done in Ansys 15 and it is found that limpet coil with SS304

(SA 240 gr 304) is having equivalent stresses within the tensile yield limit with safety factor 1.18 at shell

side and 1.73 at the bottom side and deformation is elastic.

H. Analysis on limpet coil is done in Ansys 15 and it is found that limpet coil with SA 285 GR C is having

equivalent stresses more than the tensile yield limit with safety factor 0.45 at shell side and 0.73 at the

bottom side and deformation is plastic.

I. Based on Ansysis 15 report SA 240 GR 304 is suitable material for construction.

J. The driving factor for failure of SA 285 GR C is coefficient of thermal expansion.

Acknowledgements

I extend my thanks to the Head of Department, Dr. Dhanraj P. Tambuskar who gave me motivation and

support; also to the coordinator, Prof. Divya P. for her guidance and help whenever it was needed, also to

Prof.G.Thokal for valuable suggestion in regard with finding properties of material selection, also to the Mr

Udaye Prabhu (Director Of Desha Engineering Pvt) who offered me to work on this industrial project also to Mr

DOI: 10.9790/1684-13122834 www.iosrjournals.org 33 | Page

Design Of Pressure Vessel And Prediction Of Failure Of Limpet Coil

Ibrahim Shah for teaching me Ansys 15,Also to Mr Manoj, prof Aftab mukadam ,prof Asif khan and Mr Afzal

Usmani for teaching pv-ellite software and designing concepts and also to prof Jamiluddin Talukdar for

suggetions regarding thermal concept.

References

[1]. Moss,Dennis,(2003)“Pressure Vessel Design Manual: Illustrated Procedures For Solving Major Pressure Dennis r. Moss.-3rd ed”.

British library cataloguing-in-publication data.

[2]. Di Carluccio,.(2008), “Analysis Of Pressurized Horizontal Vessels Under Seismic Excitation”, the 14th world conference on

earthquake engineering october , Beijing, China.

[3]. The American Society Of Mechanical Engineers, (2013) “Asme Boiler & Pressure Vessel Code” Section Viii Divisions 2,

alternative rules for construction of pressure vessels, part-5, design by analysis requirements.

[4]. B.S.Thakkar,& S.A.Thakkar, (2012),” Design Of Pressure Vessel Using Asme Code, Section Viii, Division 1” Ijaers/vol. i/ issue

ii/January-march, 2012/228-234c.

[5]. Nitinchandra.R.Patel,(2013) “ Design And Analysis Of Pressure Vessel Amalgamating With Selection Of Material Used In Marine

Application”, International journal of innovative research in science, engineering and technology vol. 2, issue 6, June.

[6]. K.S.J.Prakash, T.Mastanaiah , (2014)“ Industrial Spherical Pressure Vessel Design & Analysis Using FEA”, Vol, 04 , Issue, 10

,October.

[7]. Henry H.Bednar “ Pressure Vessel Code Book”2013.

[8]. X.Charles,(2014) “Stress Analysis Of Pressure Vessel Due To Load And Temperature”, middle-east journal of scientific

research 20 (11): 1390-1395, 2014.

[9]. Vijay Kumar,(2014) “Mechanical Design Of Pressure Vessel By Using PV-ELITE Software” ,international journal of scientific and

research publications, volume 4, issue 4, April 2014.

[10]. Yogesh Borse & Avadesh K. Sharma,( 2012 ) “ Design Analysis of Pressure Vessels at high stress zones using Pro/E v4.0”,

International Journal of Modern Engineering Research, Vol.2, Issue.3, May-June pp-991-995.

[11]. American Standard Pipe Diameters; http://en.wikipedia.org/wiki/nominal_pipe_size.

[12]. V.B.Bhandari, design of machine elements, (Tata Mcgraw Hill Publishing Co. Ltd, new Delhi, 2005).

[13]. Joseph Edward Shigley, Mechanical Engineering Design, (Mcgraw Hill, 2009).

[14]. T.P.Pastor,(2007) “Modernization Of Pressure Vessel Design Codes Asme SectionVIII”, division 2,.

[15]. Piotr Dzierwa,(2015) “Optimum Heating Of Pressure Vessels With Holes” Journal Of Pressure Vessel Technology February , vol.

137 / 011202-7.

[16]. Christopher j. Evans, “Failure Prediction Of Pressure Vessels Using Finite Element Analysis” journal of pressure vessel technology

2014 by Asme October 2014, vol. 137 / 051206-1.

[17]. Gongfeng Jiang , Gang Chen, Liang Sun, Yiliang Zhang, Xiaoliang Jia & Yinghua Liu,(2014),A “Noncyclic Method For

Determination Of Accumulated Strain In Stainless Steel 304 Pressure Vessels”, DECEMBER 2014, Vol. 136 / 061204-7.

[18]. 2010 ASME Boiler and Pressure Vessel Code “An International Code II part d” Properties (Customary).

[19]. 2013 ASME Boiler and Pressure Vessel Code An International Code II Materials Part A Ferrous Material Specifications (Beginning

to SA-450).

[20]. II Materials Part Ferrous Material Specifications (SA-451 to End). 2013 ASME Boiler and Pressure Vessel Code An International

Code II Materials Part D Properties (customary). Asme boiler and pressure vessel committee on materials.

[21]. John F. Harvey, “Theory and Design of Pressure Vessel”, Van Nostrand Reinhold Company, Edition-1987, reprint-2001.

[22]. Jinyang Zheng et al,(2012), “Investigation on Influence Factors of Mechanical Properties of Austenitic Stainless Steels for Cold

Stretched Pressure Vessels” Journal of Pressure Vessel Technology by ASME DECEMBER , Vol. 134 / 061407-1.

DOI: 10.9790/1684-13122834 www.iosrjournals.org 34 | Page

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- DIB Vs DBB PDFDocument1 pageDIB Vs DBB PDFDidit SusantoNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Coil Platforms Provide Proper AlignmentDocument4 pagesCoil Platforms Provide Proper AlignmentDidit SusantoNo ratings yet

- Color Monitor: Service ManualDocument34 pagesColor Monitor: Service Manualcinematic30060% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- p5gcmx1333 enDocument92 pagesp5gcmx1333 enPruteanu VeaceslavNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- DIB-vs-DBB BALL VALVE PDFDocument1 pageDIB-vs-DBB BALL VALVE PDFDidit SusantoNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- p5gcmx1333 enDocument92 pagesp5gcmx1333 enPruteanu VeaceslavNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Pulsed RT PDFDocument4 pagesPulsed RT PDFDidit SusantoNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Color Monitor: Service ManualDocument34 pagesColor Monitor: Service Manualcinematic30060% (1)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Fault Detection and Diagnostics of A Three-Phase SeparatorDocument31 pagesFault Detection and Diagnostics of A Three-Phase SeparatorDidit SusantoNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Elna 3: Product BriefDocument2 pagesElna 3: Product BriefDidit SusantoNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- NDTDocument2 pagesNDTDidit SusantoNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Vessel 1 PDFDocument7 pagesVessel 1 PDFDidit SusantoNo ratings yet

- Color Monitor: Service ManualDocument34 pagesColor Monitor: Service Manualcinematic30060% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Demagnetizers: and Tube During ProductionDocument4 pagesDemagnetizers: and Tube During ProductionDidit SusantoNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- GEIT 20117EN - Ultrasonic Transducer CatalogDocument47 pagesGEIT 20117EN - Ultrasonic Transducer CatalogMd Firoz Alam KhanNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- ECT BasicDocument10 pagesECT BasicSaddam HossainNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Pulsed RT PDFDocument4 pagesPulsed RT PDFDidit SusantoNo ratings yet

- GEIT Transducer CatalogDocument1 pageGEIT Transducer CatalogDidit SusantoNo ratings yet

- Blue BookDocument1 pageBlue BookDidit SusantoNo ratings yet

- Operating Principle of The Alternating Field Leakage Flux MethodDocument2 pagesOperating Principle of The Alternating Field Leakage Flux MethodDidit SusantoNo ratings yet

- Charpy Energy-Lateral Expansion Relations For A Wide Range of SteelsDocument8 pagesCharpy Energy-Lateral Expansion Relations For A Wide Range of SteelsDidit SusantoNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Vessel 1 PDFDocument7 pagesVessel 1 PDFDidit SusantoNo ratings yet

- GEIT 20117EN - Ultrasonic Transducer CatalogDocument47 pagesGEIT 20117EN - Ultrasonic Transducer CatalogMd Firoz Alam KhanNo ratings yet

- Theory and Application of Magnetic Flux Leakage Pipeline DetectionDocument20 pagesTheory and Application of Magnetic Flux Leakage Pipeline DetectionGuillermo Henry Ramirez UlloaNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Vessel 1 PDFDocument7 pagesVessel 1 PDFDidit SusantoNo ratings yet

- 1056 2203 1 SM - 2Document6 pages1056 2203 1 SM - 2Veky PamintuNo ratings yet

- 1056 2203 1 SM - 2Document6 pages1056 2203 1 SM - 2Veky PamintuNo ratings yet

- Quick Reference Guide - Boiler & Pressure VesselDocument1 pageQuick Reference Guide - Boiler & Pressure VesselRival Coelho CoelhoNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Corrosion at Oil IndustryDocument66 pagesCorrosion at Oil Industrymah_abdelaalNo ratings yet

- Basic Technology Js AssignmentDocument4 pagesBasic Technology Js AssignmentsulayajannyNo ratings yet

- Switched Reluctance Motor 17 I TaeDocument114 pagesSwitched Reluctance Motor 17 I TaeAnonymous zzfx7mz3No ratings yet

- City Sanitation Plan, UttarakhandDocument101 pagesCity Sanitation Plan, UttarakhandHarish Kumar Mahavar100% (1)

- F4C PDFDocument52 pagesF4C PDFalvaroNo ratings yet

- Flywheel UPS PresentationDocument34 pagesFlywheel UPS PresentationcarlosmandopintoNo ratings yet

- World's Longest BridgeDocument17 pagesWorld's Longest BridgemohammedNo ratings yet

- 0298 704 1 Sys El en 144Document230 pages0298 704 1 Sys El en 144api-19483250100% (3)

- Positioner Serie XL - Vlatb048Document16 pagesPositioner Serie XL - Vlatb048Felipe Gamboa GálvezNo ratings yet

- b-757 Rev 31Document173 pagesb-757 Rev 31Pero PericNo ratings yet

- Complete Parking Lot Design: Pdhonline Course C620 (6 PDH)Document51 pagesComplete Parking Lot Design: Pdhonline Course C620 (6 PDH)Sahit NgjeçiNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- WTP 3032 Painting WorksDocument9 pagesWTP 3032 Painting WorksWan AnisNo ratings yet

- JCB 506cDocument8 pagesJCB 506cdanielNo ratings yet

- Emma J. Rose, CVDocument14 pagesEmma J. Rose, CVEmma RoseNo ratings yet

- kk731056 enDocument40 pageskk731056 enIulianCiobanuNo ratings yet

- Energy Regulation No. 1-94Document14 pagesEnergy Regulation No. 1-94Aries MatibagNo ratings yet

- Scada Specification Rdso DocumentDocument35 pagesScada Specification Rdso DocumentbhaskarjalanNo ratings yet

- BS 812-109 1990Document12 pagesBS 812-109 1990nicu1212No ratings yet

- GPR MS enDocument68 pagesGPR MS enJMNo ratings yet

- Waterfall Hf3 Ip Us NoticeDocument2 pagesWaterfall Hf3 Ip Us NoticeVishal SuryawaniNo ratings yet

- Iffco ReportDocument34 pagesIffco ReportVarun Kaushal0% (1)

- UHTC4Document55 pagesUHTC4Hari Baddipalli100% (1)

- Corrosion CAUSES and MECHANISM Arumugam Anna University, Chennai, IndiaDocument76 pagesCorrosion CAUSES and MECHANISM Arumugam Anna University, Chennai, Indiadeviprasadh.a100% (3)

- Directional Control ValvesDocument68 pagesDirectional Control ValvesRasoolKhadibiNo ratings yet

- M.karthik Manufacturing Industries WorksheetDocument16 pagesM.karthik Manufacturing Industries WorksheetMalyala KarthikNo ratings yet

- Piping QuestionsDocument8 pagesPiping Questionsjijimon85No ratings yet

- Israel Shalom - Ha'galilDocument11 pagesIsrael Shalom - Ha'galilsamrasamara2014100% (1)

- Laurentiu Pahon CVDocument4 pagesLaurentiu Pahon CVpa_flaviaaNo ratings yet

- WarrickDocument1 pageWarrickChristian DanyNo ratings yet

- Intern ReportDocument38 pagesIntern ReportMardi Mude100% (1)

- The End of Craving: Recovering the Lost Wisdom of Eating WellFrom EverandThe End of Craving: Recovering the Lost Wisdom of Eating WellRating: 4.5 out of 5 stars4.5/5 (80)

- Sully: The Untold Story Behind the Miracle on the HudsonFrom EverandSully: The Untold Story Behind the Miracle on the HudsonRating: 4 out of 5 stars4/5 (103)

- Hero Found: The Greatest POW Escape of the Vietnam WarFrom EverandHero Found: The Greatest POW Escape of the Vietnam WarRating: 4 out of 5 stars4/5 (19)

- The Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaFrom EverandThe Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaNo ratings yet

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindFrom EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNo ratings yet

- The Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyFrom EverandThe Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyNo ratings yet

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestFrom EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestRating: 4 out of 5 stars4/5 (28)