Professional Documents

Culture Documents

Performance of Recycled Aggregate in Concrete With Microsilica

Uploaded by

IJRASETPublicationsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Performance of Recycled Aggregate in Concrete With Microsilica

Uploaded by

IJRASETPublicationsCopyright:

Available Formats

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor: 6.887

Volume 6 Issue IX, Sep 2018- Available at www.ijraset.com

Performance of Recycled Aggregate in Concrete

with Microsilica

Akhil S Kumar1, Tincy Anna Yohannan2

1 2

PG Scholar, Asst.Professor, Department of Civil Engineering, Sri Vellappally Natesan College of Engineering

Abstract: Demand for infrastructure due to the continuous population growth, and increased urbanization, have led to greater

consumption of concrete. Addition or replacement of some of the materials may change the properties of the concrete..

Utilization of recycled aggregate in concrete has been employed due to awareness of society in natural resources protection by

efficient disposal of demolished wastes. However the concrete using recycled aggregate has obtained lower performance when

compared to concrete using natural aggregate. In this research, microsilica has been used for improving the performance of

recycled aggregate concrete. Concrete specimens containing various percentages of recycled aggregate (0%, 25%, 50% and 75%)

and (0%, 6%, 8%, 10% and 12%) has been prepared. Various tests were done on fresh concrete and compressive strength test,

split tensile strength test, flexural strength test on cured hardened concrete. From the work it was found that after 28 days, the

mix exhibited more compressive strength, split tensile strength and flexural strength than normal aggregate concrete.

Compressive strength of mix containing 25% recycled aggregate and 8% microsilica were increased by 7.25%, split tensile

strength increased by 16.04%, flexural strength increased by 9.09%. More properties were analysed by conducting durability

tests. Load deflection test on 28 days cured beam specimen with optimum mix exhibited better performance. The optimum mix

showed 9.14% higher strength than ordinary concrete..

Keywords: Recycle aggregate, Microsilica, Compressive strength test, Split tensile strength test, Flexural strength test, Load

deflection test

I. INTRODUCTION

Concrete is the premier construction material across the world and the most widely used in all types of civil engineering works,

including infrastructure, low and high-rise buildings, defence installations, environment protection and local or domestic

developments. Concrete is a manufactured product, essentially consisting of cement, aggregates, water and admixtures. Among

these, aggregates are inert granular materials such as sand; crushed stone forms the major part. Traditionally aggregates have been

readily available at economic price. However, in recent years the extraction and use of aggregates from natural resources has been

questioned. This is mainly because of the depletion of quality primary aggregates and greater awareness of environmental protection,

the availability of natural resources to future generations has also been realized. The recycling of waste concrete is seen as one of

the best ways to combat the rapid increase in the generation of construction and demolition waste concrete. Waste concrete is

crushed and processed into aggregates that are then used as a constituent of coarse aggregates in newly cast concrete. This is

referred to as recycled aggregate concrete (RAC). The process of recycling waste concrete is relatively simple, and it includes

breaking, removing, and crushing of concrete. There are a variety of benefits in recycling waste concrete rather than treating it as

ordinary rubbish. For instance, reusing crushed waste concrete as aggregate in concrete can reduce the landfill space and the need of

gravel mining as well as the pollution involved in burying or transporting them. In addition, in many places where the quality

aggregates are in a short supply, using RAC in construction is viable and economic.

Works have shown that aggregates from different sources, exhibit different engineering properties. Aggregates are the key

ingredients in concrete making up 70-80 % of volume in concrete and dictating the strength and density relationship. Hence using

recycled concrete as aggregate will require checking the quality of the aggregates, since they are collected from different sources,

grades of concrete and age. Works on recycled concrete have emphasized that the basic material properties, such as shape, texture,

specific gravity, absorption, moisture content, permeability, strength 3 characteristics, deleterious substance, resistance to freeze–

thaw, etc., need to be thoroughly evaluated before it is used to produce concrete. Technology of RAC production is different from

the production procedure for concrete with natural aggregate. Because of the attached mortar, recycled aggregate has significantly

higher water absorption than natural aggregate. Therefore, to obtain the desired workability of RAC it is necessary to add a certain

amount of water to saturate recycled aggregate before or during mixing, if no water-reducing admixture is applied. One option is to

©IJRASET: All Rights are Reserved 629

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor: 6.887

Volume 6 Issue IX, Sep 2018- Available at www.ijraset.com

first saturate recycled aggregate to the condition of water saturated surface dry, and the other is to use dried recycled aggregate and

to add the additional water quantity during mixing.

Microsilica, also known as Silica fume is fine amorphous silica. Microsilica is a filter powder generated from the reduction of high

purity quartz – ferrosilicon metals or silicon metals. Microsilica consists primarily of very fine smooth spherical silicon oxide

particles with an extremely high surface area. Microsilica improves concrete through two mechanisms by pozzolanic effect and

filler effect. Pozzolanic effect is that when water is added to OPC, hydration occurs resulting in the formation of calcium silicate

hydrate (CSH) and calcium hydroxide. In the presence of microsilica, the silicon dioxide from the microsilica will react with the

calcium hydroxide to produce more aggregate binding CSH thereby increasing the binding property.

Microsilica is an extremely fine material, with an average diameter 100 times finer than cement. At a typical dosage of 8% by

weight of cement, approximately 100,000 particles for each grain of cement will fill the water spaces in fresh concrete. This

eliminates bleed and the weak transition zone between aggregate and paste found in normal concrete. This micro filler effect will

greatly reduced permeability and improves the paste-to-aggregate bond of silica fume concrete compared to conventional concrete.

Due to its very fine nature and thus greater surface area, microsilica will increase the water demand. The use of a super plasticizer to

compensate for the higher water demand is universally recommended. Super plasticizers have a greater effect in microsilica

concrete than in normal concretes because of the larger total surface area. It is possible now to dose high dosage of super plasticizers

for very low water cement ratios concrete without bleeding and segregation problems encountered with normal OPC concrete. It

enables us to produce very flow able concrete without segregation and very high strength concrete.

II. NEED FOR THE STUDY

The increasing demand for infrastructure due to the continuous population growth, and the high rate of urbanisation, has led to

increased consumption of concrete. The continuous use of natural aggregates in conventional concrete has serious environmental

and economic consequences as it can lead to the depletion of natural resources (aggregate), increasing disposal problems and

significant energy consumption in quarrying activities. The partial or full substitution of natural aggregate by recycled coarse

aggregate retrieved from demolition debris is a favourable alternative to mitigate the environmental and economic effects of using

natural aggregates. This project aims in effective utilization of recycled aggregates by percentages and the mechanical properties of

concrete are improved by microsilica

III. SCOPE AND OBJECTIVES

The project aims at conducting feasibility study of producing recycled aggregate concrete (RCA) with microsilica.

The specific objectives of the present work are,

A. To find out the mechanical properties of recycled aggregate incorporated with microsilica.

B. To estimate the durability of the microsilica incorporated recycled aggregate concrete.

C. To study the flexural behaviour of recycled aggregate beam with microsilica.

IV. METHODOLOGY

The experimental study consists of testing the mechanical and durability properties of recycled aggregate concrete containing the

various materials selected for the study. The additional materials used were microsilica and recycled aggregate in beam specimens.

Steps involved are,

A. Material Testing

B. Mix Design

C. Casting of specimens with different percentages of microsilica (6%, 8%, 10% and 12%) and recycled aggregate (0%, 25%, 50%

and 75%)

1) Slump Test

2) Compacting Factor Test

D. Curing

1) Compressive Strength Test

2) Split Tensile Strength Test

3) Flexural Strength Test

©IJRASET: All Rights are Reserved 630

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor: 6.887

Volume 6 Issue IX, Sep 2018- Available at www.ijraset.com

E. Casting of beam specimens with optimum percentage of recycled aggregate and microsilica

F. Curing and Testing of beam specimens

1) Load Deflection Test

G. Durability Test

1) Carbonation Test

2) Sulphate resistant Test

3) Bulk Diffusion Test

H. Comparison of Results

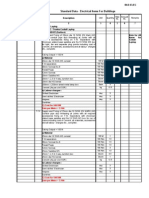

Table 1 Mix design

Material Quantity (kg/m3) Mix Proportion

Cement 425.733 1

Fine Aggregate 645.5 1.52

Coarse Aggregate 1158.28 2.72

Super Plasticizer 1.09 1.09

Water Cement Ratio 0.45 0.45

The mix proportion for the M30 grade of concrete was arrived through a number of trial mixes. The mix was designed in accordance

with IS 10262-2009. The mix proportion for M30 grade of concrete is shown in Table 1.

Table 2 Mix designation

Mixes Microsilica (%) Recycled aggregate (%)

RCA0MS0 0 0

RCA0MS6 6 0

RCA0MS8 8 0

RCA0MS10 10 0

RCA0MS12 12 0

RCA25MS6 6 25

RCA25MS8 8 25

RCA25MS10 10 25

RCA25MS12 12 25

RCA50MS6 6 50

RCA50MS8 8 50

RCA50MS10 10 50

RCA50MS12 12 50

RCA75MS6 6 75

RCA75MS8 8 75

RCA75MS10 10 75

RCA75MS12 12 75

RCA0MS0 is our control mix which has 0% recycled aggregate and 0% microsilica. On considering mix RCA0MS6, 6% of

microsilica is added to 0% recycled aggregate. While considering RCA25MS6 denotes that the mix contains 25% recycled

©IJRASET: All Rights are Reserved 631

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor: 6.887

Volume 6 Issue IX, Sep 2018- Available at www.ijraset.com

aggregate and 6% microsilica in it similarly in other mixes. Total 17 different mixes were used in the study to find out which mix

shows better performance in recycled aggregate concrete with microsilica.

V. RESULTS AND DISCUSSION

The results obtained from the experimental investigations are discussed below. Initially the workability properties such as slump

value and compaction factor are discussed. Then the results from mechanical strength tests such as compressive strength, split

tensile strength, flexural strength of 7th day and 28th day cured normal concrete are also discussed.

A. Compressive Strength

Fig. 2 Comparison of compressive strength of normal

Fig. 1 Compressive strength of normal aggregate concrete aggregate concrete and 25% recycled aggregate mixes

mixes with varying percentages of microsilica

Fig. 3 Comparison of compressive strength of normal Fig. 4 Comparison of compressive strength of normal

aggregate concrete and 50% recycled aggregate mixes aggregate concrete and 75% recycled aggregate mixes

with varying percentages of microsilica with varying percentages of microsilica

Fig. 1 shows the optimum of microsilica in normal aggregate concrete mixes. It is obtained that 8% microsilica as optimum.

Fig. 2 shows the mixes with 25% recycled aggregate with 6%, 8%, 10% and 12% of microsilica. Fig. 3 shows the mixes with 50%

recycled aggregate with 6%, 8%, 10% and 12% of microsilica and Fig. 4 shows the mixes with 50% recycled aggregate with 6%,

8%, 10% and 12% of microsilica. From all the mixes the optimum of microsilica obtained is 8% indicated that microsilica is

independent of aggregate used. From compressive strength test recycled aggregate concrete mix with 25% RCA with 8% showed

greater strength than characteristic mean strength fck’ hence it is taken as optimum mix.

©IJRASET: All Rights are Reserved 632

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor: 6.887

Volume 6 Issue IX, Sep 2018- Available at www.ijraset.com

B. Split Tensile Strength

Fig. 5 Split tensile strength of normal aggregate concrete Fig. 6 Comparison of split tensile strength of normal

mixes aggregate concrete and 25% recycled aggregate mixes

with varying percentages of microsilica

Fig. 7 Comparison of split tensile strength of normal Fig. 8 Comparison of split tensile strength of normal

aggregate concrete and 50% recycled aggregate mixes aggregate concrete and 75% recycled aggregate mixes

with varying percentages of microsilica with varying percentages of microsilica

C. Flexural Strength Test

Fig. 9 Comparison of flexural strength of normal Fig. 10 Comparison of split tensile strength of normal

aggregate concrete mixes aggregate concrete and 25% recycled aggregate mixes

with varying percentages of microsilica

©IJRASET: All Rights are Reserved 633

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor: 6.887

Volume 6 Issue IX, Sep 2018- Available at www.ijraset.com

Fig. 11 Comparison of split tensile strength of normal Fig. 12 Comparison of split tensile strength of normal

aggregate concrete and 50% recycled aggregate mixes aggregate concrete and 75% recycled aggregate mixes

with varying percentages of microsilica with varying percentages of microsilica

D. Durability Test

1) Carbonation Test

Fig. 13 Variation of carbonation depth after 56 days

From Fig. 13, it is observed that the carbonation effect gets reduced in the mix with optimum percentage of microsilica in 25%

recycled aggregate concrete than the control mix. It is because of the pore filling capability of microsilica.

2) Sulphate Resistance Test

Fig. 14 Strength variation of mixes after 56 days

Fig. 14 shows the percentage loss of strength after 56 days of each specimen was compared. The strength loss were found to be less

than that of control mix for specimen containing 25% recycled aggregate with 8% microsilica.

©IJRASET: All Rights are Reserved 634

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor: 6.887

Volume 6 Issue IX, Sep 2018- Available at www.ijraset.com

3) Bulk Diffusion Test

Table 3 Depth of penetration and diffusion coefficient for mixes

Mix Depth of penetration (mm) Diffusion coefficient (10-12) m2/s

RCA0MS0 18 4.18

RCA25MS8 10 1.29

Based on the result shown in Table 3, it was analyzed that both the mixes are in the range of average permeability based on concrete

society recommendations, that is in the range of (1 to 5) x 10-12 m2/s. but on comparing mix with 25% recycled with 8% microsilica

showed less permeability than control mix.

4) Load deflection characteristics: The beam specimens of 1500 x 200 x 300 mm were subjected for load deflection testing. 28

days cured specimen was given load to study its behaviour. The ultimate load and deflection of control beams and microsilica

admixed recycled aggregate beams were shown in Table 4 and results obtained from load deflection test were shown in Table 5.

Table 4 Ultimate load and deflection of control and optimum specimen

Specimen Ultimate load (kN) Maximum deflection (mm)

Control beam (RCA0MS0) 212.1 12.28

Final mix (RCA25MS8) 231.5 13.37

Table 5 Deflection of comparison

Deflection (mm)

Load (kN)

RCA0MS0 RCA25MS8

0 0 0

25 0.99 1

50 1.62 1.4

75 2.53 2.1

100 3.34 2.93

125 4.3 3.86

150 5.1 4.62

175 6.18 5.79

200 8.64 7.79

225 10.23

The ultimate load obtained for the concrete containing 25% recycled aggregate and 8% microsilica (RCA25MS8) shows 9.14%

higher strength than ordinary concrete mix (RCA0MS0). Ordinary recycled aggregate concrete performs lower strength than normal

mix, this enhance in strength is due to the pozzolanic activity of optimum percentage of microsilica in recycled aggregate concrete.

Fig. 15 shows the load deflection curve.

Fig. 15 Load deflection curve

©IJRASET: All Rights are Reserved 635

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor: 6.887

Volume 6 Issue IX, Sep 2018- Available at www.ijraset.com

5) Crack pattern: For crack pattern study the specimen of RCA25MS8 mix were compared with RCA0MS0 mix specimens. The

crack developed on specimens after two point loading is described in this section. In all specimens the first crack developed is

due to the flexural failure and the complete failure of specimen is due to shear. Fig. 16 shows the cracks developed in the

control specimen. The crack developed in the middle of the beam is due to flexure. These are the first cracks developed. By the

increase of load the shear crack at the support will be produced and get widens. The failure of control beam occurred at lower

loads and greater cracks were developed.

Fig. 16 Development of cracks in control specimen

The cracks developed in RCA25MS8 specimen were also by flexure and shear failure. There were only small flexural cracks as

compared with control specimen. The width of the flexural cracks was less than control specimen. Deflection of RCA25MS8 was

also found to be lesser when compared with control specimen under same loads. Even though recycled aggregate reduces the

mechanical performance of specimen, microsilica under optimum percentage can enhance up to a certain limit. At the ultimate load

shear failure and shear cracks are developed. The ultimate load carrying capacity of RCA25MS8 was higher than control specimen.

Fig. 17 shows the cracks developed in RCA25MS8 specimen.

Fig. 17 Development of cracks in RCA25MS8 specimen

©IJRASET: All Rights are Reserved 636

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor: 6.887

Volume 6 Issue IX, Sep 2018- Available at www.ijraset.com

VI. CONCLUSION

Experimental investigations were carried out to study the properties of admixed recycled aggregate with microsilica, properties

includes compressive strength, flexural strength, split tensile strength and durability properties such as carbonation, bulk diffusion

and sulphate resistance were studied. Strength enhanced optimum mix were subjected to load deflection test. Based on the

observations the following conclusions can be arrived.

A. Microsilica contributes strength to both conventional and recycled concrete. But In recycled aggregate admixed with

microsilica, recycled aggregate reduces the strength when compared with microsilica admixed normal aggregate mix.

B. 25% recycled aggregate admixed with 8% microsilica showed greater strength than mixes containing 50% and 75% recycled

aggregate admixed with microsilica. 50% recycled aggregate with 8% microsilica has slight comparable strength with normal

aggregate concrete.

C. Increase in microsilica and recycled aggregate reduces the workability of concrete, compressive strength increased by 7.25%,

split tensile strength increased by 16.04%, flexural strength increased by 9.09%.

D. By the durability tests such as bulk diffusion, carbonation and sulphate resistance test, mix containing 25% RCA with 8%

showed good characteristics.

E. By the load deflection test, the ultimate load carrying capacities of RCA25MS8 specimens were found to be 9.14% higher

strength than ordinary concrete mix.

VII. SCOPE FOR FUTURE WORK

A. The present study was based on M30 grade. The work can be extended by considering other grades of concrete.

B. Work can be done using other cement replacing materials such as metakaolin, GGBS, fly ash etc.

C. Studies can be planned for concrete reinforced with different fibres.

REFERENCES

[1] Ahmed S F U, “Properties of Concrete Containing Construction and Demolition Wastes and Fly Ash”, Journal of Materials in Civil Engineering, Vol. 25,

2013.

[2] Ajibola I T, Jian Y and Samir D, “Enhancing the Performance of Recycled Aggregate Concrete with Microsilica”, International Journal of Structural and

Civil Engineering Research, Vol. 4, 2015.

[3] Akshaykumar H, Brijesh R, Kaushal K and Jatinkumar B P, “Use of Micro Silica in Concrete”, International Journal for Innovative Research in Science &

Technology, Vol. 2, 2016.

[4] Alok K, Monendra S, Dheeraj K S, Krishan J and Dinesh, “Addition of silica fume and fly ash to enhance the compressive and flexural strength of concrete”,

SSRG International Journal of Civil Engineering, Vol. 3, 2016.

[5] Amudhavalli N K and Jeena M, “Effect Of Silica Fume On Strength And Durability Parameters Of Concrete”, International Journal of Engineering Sciences

& Emerging Technologies, Vol. 3, 2012.

[6] Giner V T, Ivorra S , Baeza F J, Zornoza E and Ferrer B, “Silica fume admixture effect on the dynamic properties of concrete”, Construction and Building

Materials, Vol. 25, 2011.

[7] Hanumesh B M, Varun B K and Harish B A, “The Mechanical Properties of Concrete Incorporating Silica Fume as Partial Replacement of Cement”,

International Journal of Emerging Technology and Advanced Engineering, Vol. 5, 2015.

[8] Mudasir H P and Renuka P D, “High Density Concrete Using Fly Ash, Micro Silica and Recycled Aggregate – An Experimental Study”, International

Journal of Engineering Trends and Technology, Vol. 10, 2014.

[9] Revathi P, Ramesh R A and Lavanya K, “Influence of Treatment Methods on the Strength and Performance Characteristics of Recycled Aggregate

Concrete”, Journal of Materials in Civil Engineering, Vol. 27, 2015.

[10] Sabale V, Borgave M and Shinde S, “Study the Effect of Addition of Silica Fume on Properties of High Strength Concrete”, International Journal of

Engineering Research & Technology, Vol. 3, 2014.

©IJRASET: All Rights are Reserved 637

You might also like

- Design and Analysis of Fixed-Segment Carrier at Carbon Thrust BearingDocument10 pagesDesign and Analysis of Fixed-Segment Carrier at Carbon Thrust BearingIJRASETPublicationsNo ratings yet

- Air Conditioning Heat Load Analysis of A CabinDocument9 pagesAir Conditioning Heat Load Analysis of A CabinIJRASETPublicationsNo ratings yet

- Advanced Wireless Multipurpose Mine Detection RobotDocument7 pagesAdvanced Wireless Multipurpose Mine Detection RobotIJRASETPublicationsNo ratings yet

- Design and Analysis of Components in Off-Road VehicleDocument23 pagesDesign and Analysis of Components in Off-Road VehicleIJRASETPublicationsNo ratings yet

- Credit Card Fraud Detection Using Machine Learning and BlockchainDocument9 pagesCredit Card Fraud Detection Using Machine Learning and BlockchainIJRASETPublications100% (1)

- TNP Portal Using Web Development and Machine LearningDocument9 pagesTNP Portal Using Web Development and Machine LearningIJRASETPublicationsNo ratings yet

- Real Time Human Body Posture Analysis Using Deep LearningDocument7 pagesReal Time Human Body Posture Analysis Using Deep LearningIJRASETPublications100% (1)

- IoT-Based Smart Medicine DispenserDocument8 pagesIoT-Based Smart Medicine DispenserIJRASETPublications100% (1)

- 11 V May 2023Document34 pages11 V May 2023IJRASETPublicationsNo ratings yet

- Controlled Hand Gestures Using Python and OpenCVDocument7 pagesControlled Hand Gestures Using Python and OpenCVIJRASETPublicationsNo ratings yet

- BIM Data Analysis and Visualization WorkflowDocument7 pagesBIM Data Analysis and Visualization WorkflowIJRASETPublicationsNo ratings yet

- Comparative in Vivo Study On Quality Analysis On Bisacodyl of Different BrandsDocument17 pagesComparative in Vivo Study On Quality Analysis On Bisacodyl of Different BrandsIJRASETPublicationsNo ratings yet

- Skill Verification System Using Blockchain SkillVioDocument6 pagesSkill Verification System Using Blockchain SkillVioIJRASETPublicationsNo ratings yet

- Design and Analysis of Fixed Brake Caliper Using Additive ManufacturingDocument9 pagesDesign and Analysis of Fixed Brake Caliper Using Additive ManufacturingIJRASETPublicationsNo ratings yet

- A Review On Speech Emotion Classification Using Linear Predictive Coding and Neural NetworksDocument5 pagesA Review On Speech Emotion Classification Using Linear Predictive Coding and Neural NetworksIJRASETPublicationsNo ratings yet

- Low Cost Scada System For Micro IndustryDocument5 pagesLow Cost Scada System For Micro IndustryIJRASETPublicationsNo ratings yet

- A Blockchain and Edge-Computing-Based Secure Framework For Government Tender AllocationDocument10 pagesA Blockchain and Edge-Computing-Based Secure Framework For Government Tender AllocationIJRASETPublicationsNo ratings yet

- CryptoDrive A Decentralized Car Sharing SystemDocument9 pagesCryptoDrive A Decentralized Car Sharing SystemIJRASETPublications100% (1)

- Real-Time Video Violence Detection Using CNNDocument7 pagesReal-Time Video Violence Detection Using CNNIJRASETPublicationsNo ratings yet

- Smart Video Surveillance Using YOLO Algorithm and OpenCVDocument8 pagesSmart Video Surveillance Using YOLO Algorithm and OpenCVIJRASETPublications100% (1)

- An Automatic Driver's Drowsiness Alert SystemDocument7 pagesAn Automatic Driver's Drowsiness Alert SystemIJRASETPublications100% (1)

- Experimental Study of Partial Replacement of Cement by Pozzolanic MaterialsDocument9 pagesExperimental Study of Partial Replacement of Cement by Pozzolanic MaterialsIJRASETPublicationsNo ratings yet

- Literature Review For Study of Characteristics of Traffic FlowDocument10 pagesLiterature Review For Study of Characteristics of Traffic FlowIJRASETPublicationsNo ratings yet

- Skin Lesions Detection Using Deep Learning TechniquesDocument5 pagesSkin Lesions Detection Using Deep Learning TechniquesIJRASETPublicationsNo ratings yet

- Achieving Maximum Power Point Tracking With Partial ShadingDocument10 pagesAchieving Maximum Power Point Tracking With Partial ShadingIJRASETPublicationsNo ratings yet

- Structural Design of Underwater Drone Using Brushless DC MotorDocument9 pagesStructural Design of Underwater Drone Using Brushless DC MotorIJRASETPublicationsNo ratings yet

- Design and Development of Cost-Effective 3D-PrinterDocument7 pagesDesign and Development of Cost-Effective 3D-PrinterIJRASETPublicationsNo ratings yet

- Vehicles Exhaust Smoke Detection and Location TrackingDocument8 pagesVehicles Exhaust Smoke Detection and Location TrackingIJRASETPublications100% (1)

- Application For Road Accident RescueDocument18 pagesApplication For Road Accident RescueIJRASETPublications100% (1)

- Preparation of Herbal Hair DyeDocument12 pagesPreparation of Herbal Hair DyeIJRASETPublications100% (1)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- VinylCorp - 8 17 17Document116 pagesVinylCorp - 8 17 17bicoboNo ratings yet

- Knauf CeilingsDocument32 pagesKnauf CeilingsSebastian BadilaNo ratings yet

- Pengaruh Penambahan Serat Roving Terhada PDFDocument13 pagesPengaruh Penambahan Serat Roving Terhada PDFRifki RizalNo ratings yet

- Ball Bearing Units: NG S.CDocument6 pagesBall Bearing Units: NG S.CFery FebryantoNo ratings yet

- Cable Gland Selection GuideDocument15 pagesCable Gland Selection GuideProcurement PardisanNo ratings yet

- Technical SpecificationDocument211 pagesTechnical SpecificationVitali MihalachiNo ratings yet

- Retaining Wall Design Parameters: U.S Army Corps of Engineers Middle East DistrictDocument1 pageRetaining Wall Design Parameters: U.S Army Corps of Engineers Middle East DistrictSafi Zabihullah SafiNo ratings yet

- Standards Publication: (Special Applications - Non-Sour Service)Document30 pagesStandards Publication: (Special Applications - Non-Sour Service)p.abdulameen1234No ratings yet

- TipsDocument90 pagesTipsSagari IsukapalliNo ratings yet

- Huehoco Composite Materials Co., LTD. ANT D 4012 /A277-CN (W111)Document1 pageHuehoco Composite Materials Co., LTD. ANT D 4012 /A277-CN (W111)anbu2810wsNo ratings yet

- Contact and technical specifications for Nexans underground cablesDocument4 pagesContact and technical specifications for Nexans underground cableskaloresibluNo ratings yet

- PVC ValvesDocument40 pagesPVC ValvesAbu Anas M.SalaheldinNo ratings yet

- IS 3548 Code of Practice for Glazing BuildingsDocument12 pagesIS 3548 Code of Practice for Glazing BuildingsUp VickyNo ratings yet

- Paper On Casthouse Refractories - Tata SteelDocument5 pagesPaper On Casthouse Refractories - Tata SteelSaumit PalNo ratings yet

- BCM Unit 5Document113 pagesBCM Unit 5Keerthi k.cNo ratings yet

- Appron Ref 1Document1 pageAppron Ref 1Jay PardesiNo ratings yet

- ListDocument12 pagesListashishtaneja30No ratings yet

- SKF16078 DB Simplex Simplan FWD Seal Web 160506Document2 pagesSKF16078 DB Simplex Simplan FWD Seal Web 160506Marlon Alejandro Arboleda TapiaNo ratings yet

- Seismic Retrofit of Historic Mani Mandir ComplexDocument19 pagesSeismic Retrofit of Historic Mani Mandir ComplexJahanvi SinhaNo ratings yet

- Block Plastering and Tile Scope Sheet FinalDocument12 pagesBlock Plastering and Tile Scope Sheet FinalMOHAMED MOINUDDIN KHANNo ratings yet

- 05-5 QCS 2014Document31 pages05-5 QCS 2014Raja Ahmed Hassan100% (11)

- Clay PowerpointDocument21 pagesClay PowerpointGopal N. Suthar100% (1)

- Cover FluxDocument1 pageCover FluxKeshav BhardwajNo ratings yet

- Revised Standard Data For ElectrificationDocument120 pagesRevised Standard Data For ElectrificationKishore Ainavilli100% (1)

- Tico S PDFDocument4 pagesTico S PDFjittshong8072No ratings yet

- MKI Bore Pile CaculateDocument2 pagesMKI Bore Pile CaculateMaha KaryaNo ratings yet

- Bleed ResistanceDocument4 pagesBleed ResistanceMaeon Laboratories100% (1)

- 318CS-14 - Building Code Requirements For Structural Concrete and Commentary (Chinese Simplified)Document21 pages318CS-14 - Building Code Requirements For Structural Concrete and Commentary (Chinese Simplified)NGUYEN LAMNo ratings yet

- Hydraulic Hose Types GuideDocument67 pagesHydraulic Hose Types Guidepaolomoreano88No ratings yet

- Aqua-Cure VOXDocument2 pagesAqua-Cure VOXChris ChanonaNo ratings yet