Professional Documents

Culture Documents

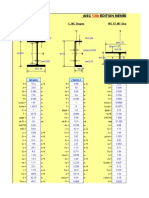

AISC Properties Viewer

Uploaded by

Irma AlmincoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AISC Properties Viewer

Uploaded by

Irma AlmincoCopyright:

Available Formats

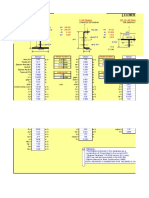

W, S, M, HP Shapes C, MC Shapes WT, ST, MT Shapes Single Angles Double Angles Rectangular HSS

Y Y Y

k1=0.8125 Y Y Y

k=1.12 tf=0.62 tf=0.501 b=5 t=0.349

bf=8.02 t=0.375

y=0.907 x=1.62

x(bar)=0.674 tf=0.62 d=6 t=0.375 X

d=10.1 T X d=1 X X d=3.5 H=8 X

d=5.05 X y=1.62

tw=0.35 tw=0.51 tw=0.35 b=6

(0, 3/8, or 3/4

bf=8.02 bf=3.17 gap) B=6

W10x45 C12x30 WT5x22.5 L6x6x3/8 2L5x3-1/2x3/8SLBB HSS8x6x3/8

A= 13.30 in.^2 A= 8.81 in.^2 A= 6.63 in.^2 d= 6 in. d= 3.5 in. d= 8 in.

d= 10.100 in. d= 12.000 in. d= 5.050 in. b= 6 in. b= 5 in. b= 6 in.

tw = 0.350 in. tw = 0.510 in. tw = 0.350 in. t= 0.375 in. t= 0.375 in. t= 0.349 in.

bf = 8.020 in. bf = 3.170 in. bf = 8.020 in. k= 0.8750 in. k= 0.8125 in. wt./ft. = 32.50 plf.

tf = 0.620 in. tf = 0.501 in. tf = 0.620 in. wt./ft. = 14.90 plf. wt./ft. = 20.80 plf. A= 8.97 in.^2

T= 7-1/2 in. T= 9-3/4 in. k= 1.1200 in. A= 4.38 in.^2 A= 6.10 in.^2 Ix = 79.10 in.^4

k= 1.1200 in. k= 1.1250 in. Ix = 10.20 in.^4 Ix = 15.40 in.^4 Ix = 6.31 in.^4 Sx = 19.80 in.^3

k1 = 0.8125 in. gage = 1-3/4 in. Sx = 2.47 in.^3 Sx = 3.51 in.^3 Sx = 2.38 in.^3 rx = 2.970 in.

gage = 5-1/2 in. x(bar) = 0.674 in. rx = 1.240 in. rx = 1.870 in. rx = 1.020 in. Iy = 50.60 in.^4

rt = 2.180 in. eo = 0.618 in. y= 0.907 in. y= 1.620 in. y= 0.854 in. Sy = 16.90 in.^3

d/Af = 2.03 d/Af = 7.55 Iy = 26.70 in.^4 Iy = 15.40 in.^4 ry(0) = 2.260 in. ry = 2.380 in.

Ix = 248.00 in.^4 Ix = 162.00 in.^4 Sy = 6.65 in.^3 Sy = 3.51 in.^3 ry(3/8) = 2.390 in. Zx = 24.10 in.^3

Sx = 49.10 in.^3 Sx = 27.00 in.^3 ry = 2.010 in. ry = 1.870 in. ry(3/4) = 2.540 in. Zy = 19.80 in.^3

rx = 4.320 in. rx = 4.290 in. J= 0.753 in.^4 x= 1.620 in. ro(bar) = 2.56 in. J= 100.00 in.^4

Iy = 53.40 in.^4 Iy = 5.12 in.^4 Cw = 0.981 in.^6 rz = 1.190 in. H= 0.933

Sy = 13.30 in.^3 Sy = 2.05 in.^3 a= 1.84 in. TAN(a) = 1.000 Round HSS & Pipes

ry = 2.010 in. ry = 0.762 in. ro(bar) = 2.43 in. J= 0.218 in.^4 Y

Zx = 54.90 in.^3 J= 0.86 in.^4 H= 0.940 Cw = 0.575 in.^6 Plates t=0.143

Zy = 20.30 in.^3 Cw = 151 in.^6 a= 2.61 in. Y

J= 1.51 in.^4 a= 21.31 in. ro(bar) = 3.33 in. t=0.375

Cw = 1200 in.^6 ro(bar) = 4.54 in. H= 0.630 X O.D.=2.375 X

a= 45.36 in. H= 0.919 b=12

Wno = 19.00 in.^2 I.D.=2.089

Sw = 23.60 in.^4 t= 3/ 8 in.

Qf = 11.30 in.^3 b= 12 in. HSS2.375x0.154

Qw = 27.00 in.^3 wt./ft. = 15.31 plf. O.D. = 2.375 in.

Reference:

A= 4.500 in.^2 I.D. = 2.089 in.

The shapes contained in this database are a

compilation of those listed in the current AISC Ix = 0.053 in.^4 t= 0.143 in.

"Shapes Database" CD-ROM Version 3.0 (June, Sx = 0.281 in.^3 wt./ft. = 3.66 plf.

2001), as well as those listed in the AISC 9th rx = 0.108 in. A= 1.00 in.^2

Edition Manual of Steel Construction (1989). Iy = 54.000 in.^4 I= 0.63 in.^4

Sy = 9.000 in.^3 S= 0.53 in.^3

ry = 3.464 in. r= 0.791 in.

J= 54.053 in.^4 J= 1.25 in.^4

NOMENCLATURE FOR AISC MEMBER PROPERTIES AND DIMENSIONS:

A= Cross-sectional area of member (in.^2)

d= Overall depth of member, parallel to X-axis (in.)

tw = Thickness of web of member (in.)

bf = Width of flange of member (in.)

tf = Thickness of flange of member (in.)

T= Distance between fillets for wide-flange or channel shape (in.) = d-(2*k)

k= Distance from outer face of flange to web toe of fillet (in.)

k1 = Distance from web centerline to flange toe of fillet (in.)

gage = Standard gage (bolt spacing) for member (in.) (Note: gages for angles are available by viewing comment box at cell K18.)

rt = Radius of gyration of compression flange plus 1/3 of compression web area, taken about an axis in plane of web (in.)

d/Af = Ratio of of total depth of member to area of compression flange of member = d/(b f*tf)

Ix = Moment of inertia of member taken about X-axis (in.^4)

Sx = Elastic section modulus of member taken about X-axis (in.^3)

rx = Radius of gyration of member taken about X-axis (in.) = SQRT(I x/A)

Iy = Moment of inertia of member taken about Y-axis (in.^4)

Sy = Elastic section modulus of member taken about Y-axis (in.^3)

ry = Radius of gyration of member taken about Y-axis (in.) = SQRT(I y/A)

Zx = Plastic section modulus of member taken about X-axis (in.^3)

Zy = Plastic section modulus of member taken about Y-axis (in.^3)

J= Torsional constant of member (in.^4)

Cw = Warping constant (in.^6)

a= Torsional property, a = SQRT(E*Cw/G*J)

E= Modulus of elasticity of steel = 29,000 ksi

G= Shear modulus of elasticity of steel = 11,200 ksi

Wno = Normalized warping function at a point at the flange edge (in.^2)

Sw = Warping statical moment at a point on the cross section (in.^4)

Qf = Statical moment for a point in the flange directly above the vertical edge of the web (in.^3)

Qw = Statical moment at the mid-depth of the section (in.^3)

x(bar) = Distance from outside face of web of channel shape to Y-axis (in.)

eo = Horizontal distance from the outer edge of a channel web to its shear center (in.) = (approx.) t f*(d-tf)^2*(bf-tw/2)^2/(4*Ix)-tw/2

xo = x-coordinate of shear center with respect to the centroid of the section (in.)

yo = y-coordinate of shear center with respect to the centroid of the section (in.)

ro(bar) = Polar radius of gyration about the shear center (in.) = SQRT(x o^2+yo^2+(Ix+Iy)/A)

H= Flexural constant, H = 1-(xo^2+yo^2)/ro(bar)^2)

LLBB = Long legs back-to-back for double angles

SLBB = Short legs back-to-back for double angles

STD = Standard weight (Schedule 40) pipe section

XS = Extra strong (Schedule 80) pipe section

XXS = Double-extra strong pipe section

You might also like

- Differential and Integral Calculus by Feliciano and Uy PDFDocument39 pagesDifferential and Integral Calculus by Feliciano and Uy PDFRafael Alarcon64% (14)

- AISC Properties ViewerDocument81 pagesAISC Properties ViewerHomero Silva100% (22)

- Secondary 4 SASMO 2015 Booklet N CoverDocument16 pagesSecondary 4 SASMO 2015 Booklet N CoverSophaVisa Khun100% (8)

- Advanced Electric Circuits: The Commonwealth and International Library: Applied Electricity and Electronics DivisionFrom EverandAdvanced Electric Circuits: The Commonwealth and International Library: Applied Electricity and Electronics DivisionNo ratings yet

- Trigonometric Ratios to Transformations (Trigonometry) Mathematics E-Book For Public ExamsFrom EverandTrigonometric Ratios to Transformations (Trigonometry) Mathematics E-Book For Public ExamsRating: 5 out of 5 stars5/5 (1)

- Instructor's Manual to Accompany CALCULUS WITH ANALYTIC GEOMETRYFrom EverandInstructor's Manual to Accompany CALCULUS WITH ANALYTIC GEOMETRYNo ratings yet

- AISC Properties DatabaseDocument7 pagesAISC Properties DatabaseShekh Muhsen Uddin AhmedNo ratings yet

- Irodov Fundamental Laws of Mechanics PDFDocument139 pagesIrodov Fundamental Laws of Mechanics PDFsedanya67% (3)

- Diseño de Elementos en Tracción - LRFDDocument263 pagesDiseño de Elementos en Tracción - LRFDAlejandro CardenasNo ratings yet

- Answers to Selected Problems in Multivariable Calculus with Linear Algebra and SeriesFrom EverandAnswers to Selected Problems in Multivariable Calculus with Linear Algebra and SeriesRating: 1.5 out of 5 stars1.5/5 (2)

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- Aisc Edition Member Dimensions and Properties ViewerDocument2 pagesAisc Edition Member Dimensions and Properties Viewermuh2006No ratings yet

- Department of Education: Cot For Third QuarterDocument6 pagesDepartment of Education: Cot For Third QuarterAlvin Bugayong100% (1)

- Workbook to Accompany Physics for Students of Science and EngineeringFrom EverandWorkbook to Accompany Physics for Students of Science and EngineeringNo ratings yet

- Second Midterm Exam Math 212 Fall 2010Document7 pagesSecond Midterm Exam Math 212 Fall 2010Mark LevitzNo ratings yet

- AISC Properties ViewerDocument4 pagesAISC Properties ViewerGANESHNo ratings yet

- Tabla de Perfiles - AiscDocument3 pagesTabla de Perfiles - AiscAndres MCNo ratings yet

- Calculus Graphical Numerical Algebraic 3rd Edition AnswersDocument1 pageCalculus Graphical Numerical Algebraic 3rd Edition AnswersVeerendra cbse0% (1)

- Diseño Cercha Metalica Tipo I VerificadoDocument36 pagesDiseño Cercha Metalica Tipo I VerificadoJosé Mario Blacutt AléNo ratings yet

- Aisc Member Dimensions and Properties ViewerDocument3 pagesAisc Member Dimensions and Properties ViewerFernando Chunga AtalayaNo ratings yet

- AISC Properties Viewer Tabla OkDocument3 pagesAISC Properties Viewer Tabla OkLaura HernandezNo ratings yet

- AISC Properties ViewerDocument3 pagesAISC Properties Viewerchriscivil12No ratings yet

- AISC Properties Viewer - JMVDocument3 pagesAISC Properties Viewer - JMVpelotoNo ratings yet

- Perfiles de AceroDocument8 pagesPerfiles de AceroAriel UrietaNo ratings yet

- Propiedades de PerfilesDocument10 pagesPropiedades de PerfilesAndy GarciaNo ratings yet

- Aisc Member Dimensions and Properties ViewerDocument3 pagesAisc Member Dimensions and Properties ViewerAmi PutraNo ratings yet

- Aisc Member Dimensions and Properties ViewerDocument23 pagesAisc Member Dimensions and Properties ViewerMadara Uchija100% (1)

- AISC Properties ViewerDocument3 pagesAISC Properties ViewerrubenNo ratings yet

- Aisc Member Dimensions and Properties ViewerDocument3 pagesAisc Member Dimensions and Properties ViewerHoward VelasquezNo ratings yet

- AISC Member Dimensions and Properties Viewer (9th Edition and 2001 CD)Document3 pagesAISC Member Dimensions and Properties Viewer (9th Edition and 2001 CD)AndreCostaNo ratings yet

- AISC Properties ViewerDocument3 pagesAISC Properties ViewertambokNo ratings yet

- Dimensions and Properties ViewerDocument3 pagesDimensions and Properties ViewerEduardo PinedoNo ratings yet

- AISC Properties ViewerDocument6 pagesAISC Properties Viewermiguel soto100% (1)

- Aisc Tablas de Dimensiones Y Propiedades de Secciones de AcerosDocument3 pagesAisc Tablas de Dimensiones Y Propiedades de Secciones de AcerosJharri E HuertoNo ratings yet

- ACERO - ULTIMO - Sin NLDocument111 pagesACERO - ULTIMO - Sin NLedgehard ramosNo ratings yet

- AISC - Check Slender+Underhung CraneDocument39 pagesAISC - Check Slender+Underhung CraneMinh HoangNo ratings yet

- Tabla de PerfilesDocument3 pagesTabla de PerfilesYomara Vera GonzálezNo ratings yet

- Programas Mas Base de DatosDocument100 pagesProgramas Mas Base de DatosJesus SolorzanoNo ratings yet

- Programas-mas-base-de-Datos ColonosDocument135 pagesProgramas-mas-base-de-Datos ColonosJesus SolorzanoNo ratings yet

- AISC Properties ViewerDocument5 pagesAISC Properties ViewerChris RetardoNo ratings yet

- Aisc Asd-1989Document29 pagesAisc Asd-1989Alvaro LozanoNo ratings yet

- Aisc Edition Member Dimensions and Properties ViewerDocument10 pagesAisc Edition Member Dimensions and Properties ViewerManuel Esteban Chamorro NarvaezNo ratings yet

- AISC Properties ViewerDocument30 pagesAISC Properties ViewerLibero Leiva GonzalezNo ratings yet

- Aisc Member Dimensions and Properties ViewerDocument129 pagesAisc Member Dimensions and Properties ViewerTatyana AnthuanetNo ratings yet

- Bases de Diseño AiscDocument127 pagesBases de Diseño AiscZain AndabloNo ratings yet

- Tablas AiscDocument25 pagesTablas Aiscbrayan gonzales alcantaraNo ratings yet

- Aisc Member Dimensions and Properties ViewerDocument25 pagesAisc Member Dimensions and Properties ViewerManuel Angel Samaniego RafaeleNo ratings yet

- Aisc Edition Member Dimensions and Properties ViewerDocument30 pagesAisc Edition Member Dimensions and Properties ViewerManuel DaniloNo ratings yet

- Aisc Edition Member Dimensions and Properties ViewerDocument4 pagesAisc Edition Member Dimensions and Properties Viewerjuan carlos tinta mamaniNo ratings yet

- Propiedades Del AceroDocument116 pagesPropiedades Del Acero'Melanie RosadoNo ratings yet

- AISC Steel Properties (Metric-English)Document6 pagesAISC Steel Properties (Metric-English)KevinNo ratings yet

- LincolnElectric Alimentadores Automaticos Semi NA5Document61 pagesLincolnElectric Alimentadores Automaticos Semi NA5juan montufarNo ratings yet

- (Ac) Dimensiones de Elementos Y Propiedades Fisicas: W, S, M, HP Shapes C, MC Shapes WT, ST, MT Shapes Single AnglesDocument41 pages(Ac) Dimensiones de Elementos Y Propiedades Fisicas: W, S, M, HP Shapes C, MC Shapes WT, ST, MT Shapes Single AnglesrichardNo ratings yet

- AISC Propiedades y Pesos - TOTALDocument41 pagesAISC Propiedades y Pesos - TOTALjuanchi1979scribdNo ratings yet

- AISC Propiedades y Pesos - TOTALDocument57 pagesAISC Propiedades y Pesos - TOTALRoobens SC LaraNo ratings yet

- Per FilesDocument144 pagesPer FilesPaúl A Vasquez GonzalezNo ratings yet

- Ion Beams for Materials AnalysisFrom EverandIon Beams for Materials AnalysisR. Curtis BirdNo ratings yet

- Ten-Decimal Tables of the Logarithms of Complex Numbers and for the Transformation from Cartesian to Polar Coordinates: Volume 33 in Mathematical Tables SeriesFrom EverandTen-Decimal Tables of the Logarithms of Complex Numbers and for the Transformation from Cartesian to Polar Coordinates: Volume 33 in Mathematical Tables SeriesNo ratings yet

- On the Tangent Space to the Space of Algebraic Cycles on a Smooth Algebraic Variety. (AM-157)From EverandOn the Tangent Space to the Space of Algebraic Cycles on a Smooth Algebraic Variety. (AM-157)No ratings yet

- Final NMDocument17 pagesFinal NMMausoomNo ratings yet

- Trial p1 STPM 2015 MT Q & AnsDocument14 pagesTrial p1 STPM 2015 MT Q & AnsAbdul ShariffNo ratings yet

- HW 4Document2 pagesHW 4Daniel LeungNo ratings yet

- Trigonometry - Question PaperDocument7 pagesTrigonometry - Question PaperAdavan BhavyNo ratings yet

- Lecture Notes On Vector Bundles and Characteristic ClassesDocument38 pagesLecture Notes On Vector Bundles and Characteristic Classesvacilando2011No ratings yet

- Entrance Exam 10-11Document6 pagesEntrance Exam 10-11Madhavi NarayanNo ratings yet

- 16 12Cm, Sin: Ab BXC $ B?ADocument44 pages16 12Cm, Sin: Ab BXC $ B?AJavariaNo ratings yet

- CT4145 CT2031 Mechanics of Structures Module Introduction Into Continuum MechanicsDocument80 pagesCT4145 CT2031 Mechanics of Structures Module Introduction Into Continuum MechanicsMarcoNo ratings yet

- Igcse June 2015 Question Paper 11 PDFDocument16 pagesIgcse June 2015 Question Paper 11 PDFYagna LallNo ratings yet

- Geogebra Basic Tutorial On Point & LineDocument8 pagesGeogebra Basic Tutorial On Point & LineJanak Singh Karki0% (1)

- Mathematics: Quarter 2 - Module 3Document14 pagesMathematics: Quarter 2 - Module 3FATIMA ULINo ratings yet

- 9758 H2 Mathematics Topic 3: Graphing Techniques I (Standard Graphs) Tutorial QuestionsDocument23 pages9758 H2 Mathematics Topic 3: Graphing Techniques I (Standard Graphs) Tutorial QuestionsTimothy HandokoNo ratings yet

- Geometric Transformations in OpenGLDocument44 pagesGeometric Transformations in OpenGLWinnie TandaNo ratings yet

- Mathematics 317 Solutions To Ass2Document2 pagesMathematics 317 Solutions To Ass2rkdyeeNo ratings yet

- Core Topics SL Chapter Summaries PDFDocument6 pagesCore Topics SL Chapter Summaries PDFsinbad SailorNo ratings yet

- Robotics LabDocument7 pagesRobotics LabAbdul Moiz QarniNo ratings yet

- 2023 Grade 9 Mathematics ATP MediationDocument8 pages2023 Grade 9 Mathematics ATP MediationLemson MadhimbaNo ratings yet

- Radu Precup (Auth.) - Methods in Nonlinear Integral Equations-Springer Netherlands (2002)Document205 pagesRadu Precup (Auth.) - Methods in Nonlinear Integral Equations-Springer Netherlands (2002)Marky Mark100% (1)

- Rotation Matrix - WikipediaDocument23 pagesRotation Matrix - WikipediaEfessosNo ratings yet

- Interdisciplinary UnitDocument4 pagesInterdisciplinary Unitapi-209093515No ratings yet

- Hal 19-21Document3 pagesHal 19-21Ridho Agio NestaNo ratings yet

- Cambridge Lower Secondary English: E2: Rukundo Rwomushana 931Document4 pagesCambridge Lower Secondary English: E2: Rukundo Rwomushana 931Rukundo RwomushanaNo ratings yet

- Physics Problems: Fei Liu October 25, 2019Document17 pagesPhysics Problems: Fei Liu October 25, 2019Boldie LutwigNo ratings yet

- 6.8.1 Study - Area and Sectors (Study Guide)Document7 pages6.8.1 Study - Area and Sectors (Study Guide)WAYLON JAMESNo ratings yet