Professional Documents

Culture Documents

Interview Questions PDF

Uploaded by

anilOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Interview Questions PDF

Uploaded by

anilCopyright:

Available Formats

CIVIL ENGINEERING INTERVIEW QUESTIONS & ANSWERS:

1.What is the bending moment (BM) & Shear force (SF) – Explain.

Ans- Shear Forces occurs when two parallel forces act out of alignment with each other.

For example, in a large boiler made from sections of sheet metal plate riveted together,

there is an equal and opposite force exerted on the rivets, owing to the expansion and

contraction of the plates.

Bending Moments are rotational forces within the beam that cause bending. At

any point within a beam, the Bending Moment is the sum of: each external force

multiplied by the distance that is perpendicular to the direction of the force.

2.What are the steps involved in the concreting process, explain?

Ans-1. Batching: The process of measuring different concrete materials such as cement,

coarse aggregate, sand, water for the making of concrete is known as batching.

2. Mixing: In this process, all the materials are thoroughly mixed in required

proportions until the paste shows uniform color and consistency.

3. Transporting: When the mixing is done properly the freshly made concrete is

then transported to the construction site. After that, the concrete is correctly placed

on the formworks.

4. Compaction: Compaction is the process in which the air bubbles are eliminated from

the freshly placed concrete. It is required to enhance ultimate strength of concrete.

5. Curing: Curing is the process in which the concrete keeps its moisture for a certain

time period to complete the hydration process

3.Describe briefly the various methods of concrete curing.

• Shading concrete work

• Covering concrete surfaces with hessian or gunny bags

• Sprinkling of water

• Ponding method

• Membrane curing

• Steam curing

4.What is the minimum curing period?

Ans-After concrete is placed, the concrete increases in strength very quickly for a period of

3-7 days. Concrete which is moist cured for 7 days is about 50% stronger than uncured

concrete. Read about properly curing concrete slabs.

Water curing can be done after the slab pour by building dams with soil around the house

and flooding the slab. The enclosed area is continually flooded with water. Ideally, the slab

could be water cured for 7 days.Some builders on a tight schedule water cure for 3 days as

this achieves approximately 80% of the benefit of water curing for 7 days.

[Type here] civil4m [Type here]

CIVIL ENGINEERING INTERVIEW QUESTIONS & ANSWERS:

Consider planning your job to pour at the end of the week, build berms, then flood over the

weekend. You get the benefit of water curing without losing too much time in the schedule.

5. What Do You Understand by M25 Concrete?

Ans-Jatin Chauhan. Re: What is meaning of M25 grade Answer. # 3 M refers Mix and 25

refers the characteristic compressive. strength of concrete cube of 150mm X150mm

X150mm tested at. the end of 28 days should be minimum 25 N/Sq.mm.

6. What is Water-Cement Ratio and How it is related to the strength

of concrete?

Ans-The water–cement ratio is the ratio of the weight of water to the weight of cement used

in a concrete mix. A lower ratio leads to higher strength and durability, but may make the

mix difficult to work with and form. Workability can be resolved with the use of plasticizers

or super-plasticizers.

7. What is a bearing capacity of soil?

Ans-The bearing capacity of soil is the maximum average contact pressure between

the foundation and the soil which should not produce shear failure in the soil.

8. How to increase the bearing capacity of soil?

Ans-The following techniques can be used for improving bearing capacity of soil as per

the site condition.

• Increasing depth of foundation

• Draining the soil

• Compacting the soil

• Confining the soil

• Replacing the poor soil

• Using grouting material

• Stabilizing the soil with chemicals

9. What are the different types of foundation?

Ans-Types of Foundation

Foundations are mainly two types.

1. Shallow Foundation, and

2. Deep Foundation.

1. Shallow Foundation

A shallow foundation is a type of foundation that transfers loads to the very near

the surface. Shallow foundations typically have a depth to width ratio of less than 1.

[Type here] civil4m [Type here]

CIVIL ENGINEERING INTERVIEW QUESTIONS & ANSWERS:

The shallow foundation itself can be various types.

Types of Shallow Foundation

Follow are the types of shallow foundation –

• Pad footing or column footing

• Cantilever or strap footings

• Mat/Raft footings

• Wall Footings

Pad Footing or Column Footing

This type of footing can be two types –

1. Isolated footing and

2. Combined footing.

10. Explain moment of inertia and its importance.

Ans-Inertia is the resistance of any physical object to any change in its state of motion; this

includes changes to its speed, direction, or state of rest. It is the tendency of objects to

keep moving in a straight line at constant velocity. The principle of inertia is one of the

fundamental principles of classical physics that are used to describe the motion of objects

and how they are affected by applied forces. Inertia comes from the Latin word, iners,

meaning idle, sluggish. Inertia is one of the primary manifestations of mass, which is a

quantitative property of physical systems. Isaac Newton defined inertia as his first law in his

Philosophiæ Naturalis Principia Mathematical.

11. How do we determine the specific gravity of a cement?

Specific Gravity = (W2-W1)/(W2-W1)-W3-W4)*.79

When: W1= weight of empty flask

W2= weight of flask+cement

W3= weight of flask +cement+kerosene

W4= weight of flask+kerosene

0.079=b specific gravity of kerosene

Specific Gravity Of cement= 3.15 g/cc

[Type here] civil4m [Type here]

CIVIL ENGINEERING INTERVIEW QUESTIONS & ANSWERS:

12. Density Of 1 Bag cement?

Ans-I believe the standard density of 1 cement bag is equal to 1440 kg/m3. Density = mass/volume

(ρ=m/V) So, V=m/ρ 50 kg ÷ 1440 kg/m3 = 0.0347 m3 = 1.23

13. What are the causes of the building collapse?

Ans-

1. Bad Design.

2. Faulty Construction.

3. Foundation Failure.

4. Extraordinary loads.

5. Unexpected Failure Modes.

6. Combination of Causes.

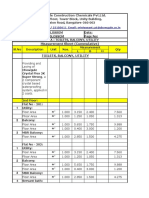

14. What is bar bending schedule (BBS) & how to prepare it?

Ans-

SL. Mem No Bar N Shape Cutt Spac Total Dia Unit wei Total Rem

NO ber of Ma o of Bar ing ing Lengt of Wei ght Weigh ark

Elem rks Len h(M) Bar ght (kg) t(kg)

ent gth (m (kg)

(M) m)

15. Why is concrete cube test carried out?

Ans-Concrete cube test is carried out for finding out the Characteristic

Compressive strength of Concrete.

The load at which the concrete block will fail in Compression Testing Machine. It will

give ultimate Load as well as compressive strength of concrete.

16. Why is concrete slump test carried out?

Ans-The concrete slump test measures the consistency of fresh concrete before it sets. It is

performed to check the workability of freshly made concrete, and therefore the ease with

which concrete flows. It can also be used as an indicator of an improperly mixed batch.

17. What is bleeding, segregation, honeycombing of concrete?

bleeding - when cement and watar come on the top and aggregate is settle down is

called bleeding this is due to specific gravity of material and improper placing.

segregation - it means separation of ingredients of concrete

[Type here] civil4m [Type here]

CIVIL ENGINEERING INTERVIEW QUESTIONS & ANSWERS:

honey combing - after removal of formwork from column beam there is hole Is

called honeycombing. it due to improper compaction of concrete.

18. a.What is pre-stressed concrete?

Ans-The principle behind prestressed concrete is that compressive stresses induced by

high-strength steel tendons in a concrete member before loads are applied will balance

the tensile stresses imposed in the member during service.

b. Which reinforcement is used in prestressed concrete?

(i) Spalling reinforcement

Spalling stresses are established behind the loaded area of anchor blocks and this causes

breaking away of surface concrete. These stresses are induced by strain incompatibility

with Poisson’s effects or by the shape of stress trajectories.

(ii) Equilibrium reinforcement

Equilibrium reinforcement is required where there are several anchorages in

which prestressing loads are applied sequentially.

(iii) Bursting Reinforcement

Tensile stresses are induced during prestressing operation and the maximum bursting

stress occurs where the stress trajectories are concave towards the line of action of the

load. Reinforcement is needed to resist these lateral tensile forces.

19. What is the ratio of steel and concrete to use in slabs, beams, columns?

For Slab-arround 75 kgs/Cum steel will consume.

ie Vol=Mass/Density

=75/7850

= .0095

For one Cum includes (Concrete and Steel)

ie =1-.0095

=.99 (Concrete)

Then ratio=.0095/.99

=.00955 X 100

=.95 (Ratio between concrete and steel)

For Beam-arround 130 kgs/Cum steel will consume.

ie Vol=Mass/Density

=130/7850

= .0165

For one Cum includes (Concrete and Steel)

ie =1-.0165

=.983 (Concrete)

Then ratio=.0165/.983

=.0167 X 100

=1.67 (Ratio between concrete and steel)

[Type here] civil4m [Type here]

CIVIL ENGINEERING INTERVIEW QUESTIONS & ANSWERS:

For Beam-arround 150 kgs/Cum steel will consume.

ie Vol=Mass/Density

=150/7850

= .0191

For one Cum includes (Concrete and Steel)

ie =1-.0165

=.98 (Concrete)

Then ratio=.0191/.98

=.0194 X 100

=1.94 (Ratio between concrete and steel)

20. Difference between pre-tensioning and post-tensioning?

Pre tensioning :

1. In this method the concrete is prestressed with tendons before it is placing in position.

2. This method is developed due to bonding between the concrete and steel tendons .

3. Pre tensioning is preferred when the structural element is small and easy

to transported.

4. In this method similar prestressed members are prepared .

Post - tensioning

1. In this method prestressing is done after the concrete attains it's strength

2. This method is developed due to bearing

3. Post tensioning is preferred when the structural element is heavy

4. In this method products are changed according to structure

21. What are the weights of 16mm, 12mm, 20mm, 25mm, 8mm Dia. Bars

Ans- D^2/162 kg

(D- Dia of Bar)

22. What is the minimum Propping Period of Beams and Slabs of

various Spans?

In the normal condition, formwork shall be removed

1) For slab props left under 3 days, it is usually removed after 12 to 24 hours.

2) For sides of beam formwork shall be removed after 24 hours.

3) For verticak member, it shall be removed 24 to 48 hours as may be decided by

the engineer in charge.

4) Bam soffits (props left under)7 days

5) Removal of props to slabs (Spanning upto 4.5 m)-7 days

6) Removal of props to slabs (Spanning over 4.5 m)-14 days

7) Removal of props to beams and arches (Spanning upto 6 m)-14 days

8) Removal of props to beams and arches (Spanning over 6 m)21 days

[Type here] civil4m [Type here]

CIVIL ENGINEERING INTERVIEW QUESTIONS & ANSWERS:

23. What are the advantages of Prestressed Concrete over R.C.C?

Longevity of prestressed structure is greater than rcc structure because the reinforcement

stays unaffected from outer agencies. High compressive strength of concrete and high

tensile strength of steel are used for prestressing that makes it more economical.

24. Quantity of materials required for different works.

Depend on materials

25. Which is stronger solid steel rod or hollow steel pipe?

Believe it or not, a hollow steel pipe is generally stronger than a solid steel rod, at least for

two shafts of the same length and the same an equal weight of steel. Variations in length

and type of steel will of course have an impact on the strength of the rod/pipe.

This is primarily due to the fact that most of the strength of a cylinder comes from its outer

portion; hence even though it is hollow in the center it still has its strength. This results in a

better strength to weight ratio for a hollow pipe than a solid rod. It also make the hollow

pipe better apt to take more weight and is less likely to bend under that weight. A hollow

steep pipe is also less likely to buckle in axial compression.

26. Initial & final setting time of concrete?

Initial setting time of cement is not less than 30 minitues—minimum.

Final setting time of cement is not to be more than of 600 minutes-maximum.

27. why we use steel reinforcement in concrete for construction?

Steel, which has high tensile strength, is used with concrete in order to counteract the

concrete's low tensile strength and ductility. The main purpose of inclusion of steel is

resist tensile stress in particular regions of the concrete that may cause structural failure or

cracking.

28. Is brick strength more or concrete block?

Room on dairy

29. How to Calculate Number of Bricks Per Square Foot?

4.5 bricks per square foot

[Type here] civil4m [Type here]

CIVIL ENGINEERING INTERVIEW QUESTIONS & ANSWERS:

30. 28 days compressive strength of concrete in PSI?

A typical concrete compressive strength specification requires 4,000 to 5,000 psi at 28 days

31. How to calculate the unit weight of steel bars?

Ans- 21 Qns

32. What is Plinth Level and Sill Level?

Sill levels are raised from few centimeters upto one meter above the floor levels or even

more. Plinth is the level of your lowest slab or floor. Sill is the bottom of window

level. Plinth level is the carpet level of ground floor of the building

33. What is Brest Wall?

a wall that is built to resist lateral pressure (especially a wall built to prevent the advance of

a mass of earth)

34. What is Brick crushing strength(PSI)?

Crushing strength of the brick depends on the design requirements. But minimum strength

is abut 3.5N/mm2 for non bearing walls or partition walls but for bearing walls or walls

which receives loads may tall even from 10N/mm2 to 14N/mm2

35. How many Types of Joints are in Concrete Pavement?

Ans-

36. How can cracks in concrete be avoided?

1. One of the primary cause of cracks in concrete is bleeding of water from concrete

mix means the excess water in the fresh mix. When the excess water evaporates,

the concrete will shrink, and you found the surface cracks in concrete.

2. After finishing of concrete, cement starts to react internally. If you do not

provide the moisture (Starting of curing) at the time of drying of concrete, the heat

of hydration accelerates the process of drying of concrete which ultimately leads to

the cracks in concrete.

3. At last, faulty construction practice and use of bad quality materials also lead

to the cracks in concrete.

37. How many types Of Damp proofing in construction?+

1. Intergral damp proofing.

2. Cavity wall Construction..

3. Gunting.

4. Membrane damp proofing.

[Type here] civil4m [Type here]

CIVIL ENGINEERING INTERVIEW QUESTIONS & ANSWERS:

5.Surface treatment of damp proofing.

38.. 28 Days Strength of Concrete (1:2:4)?

The compressive strength for concrete cylinder (300mm x 150 mm) after 28 days for

the ratio of 1:2:4. It is evident that the compressive strength is gradually decrease as

the quantity of powder sand is increased from 1: (2+0) :4 to 1: (0.5) :4 from a value of

22.04 MPa to 19.4 MPa and then increase for 1: (0+2) :4 is 21.05 MPa.

39. How many types of slabs are there & how to design it?

The slab may be supported by walls, by reinforced concrete beams usually cast

monolithically with the slab, by structural steel beams, by columns, or by the ground.

Slabs are classified into 16 types. There are 16 different types of Slabs in

Construction.

40. How much is the cover for the slab?

Clear cover for slab varies with the exposure condition of the slab. Generally clear coverof 15

mm is provided in normal situation. Originally Answered: How much is the cover of a slab?

Hi, The minimum cover for slab will be 25mm and it will go up to 30mm .

41.Maximum % of Steel in columns and beams?

In columns, maximum percentage of steel is 6%( without lapping) and 4%( with

lapping).In doubly reinforced beams it is 4% for both the steel in tension and

compression side and a total of 8% gross area. In beams,slabs maximum

percentage steel is 4% of gross area

42. What is fineness modulus?

The Fineness modulus (FM) is an empirical figure obtained by adding the total

percentage of the sample of an aggregate retained on each of a specified series

of sieves, and dividing the sum by 100.

43. What is Packing Factor?

In crystallography, atomic packing factor (APF),packing efficiency

or packing fraction is the fraction of volume in a crystal structure that is occupied

by constituent particles. It is a dimensionless quantity and always less than unity.

44. Difference between one-way slab & two-way slab?

In one way slab the slabs are supported by the beams on the two opposite sides.

In two way slabthe slabs are supported on all the four sides. ... Inone way slab the

ratio of Longer span to shorter span is equal or greater than 2. (i.e l/b ≥ 2).

[Type here] civil4m [Type here]

CIVIL ENGINEERING INTERVIEW QUESTIONS & ANSWERS:

45Difference between QA & QC?

Quality Assurance Is Not Quality Control. ... The difference is that QA is process

oriented and QC is product oriented. Testing, therefore is product oriented and thus

is in the QC domain. Testing for quality isn't assuring quality, it's controlling it.

46. What do you mean by Fe415?

This Reinforced steels are made of Cold worked High Yield Strength Deformed i.e

Cold Twisted and Deformed (CTD) to reach High Strength. The common Steels are

Fe415 and Fe 500. Fe means Iron. 415 means Minimum yield stress of 415 in MPa

47. What are the functions of a column in a building?

A column is used to support the weight of the roof and also in the upper floors. Now

a days, many columns are used for decorative purposes

48. How many feet are in 4 square yards?

4*12=36 sqfeet

49. What is the average density of soil?

Bulk density is dependent on soil organic matter, soil texture, the density of soil

mineral (sand, silt, and clay) and their packing arrangement. As a rule of thumb,

most rocks have a density of 2.65 g/cm3 so ideally, a silt loam soil has 50% pore

space and a bulk density of 1.33 g/cm3

50. What is the ratio of Grades M5, M7.5, M10, M15, M20, M25,

M30, M35, M40?

M5 - 1:5:10. M7.5 - 1:4:8. M10 - 1:3:6. M15 - 1:2:4. M20 - 1:1.5:3. M25 -

1:1:2. M30,M35,M40 - Design Mix Followed ...

51. Why foundation is provided?

The second purpose of a foundation is to tie the different parts of the building

together so that it does not sink unevenly and crack. Finally, foundations anchor the

building to prevent its moving sideways when, for example, it is built on sloping

ground

52. The concrete slump recommended for beams and slabs;

The concrete slump recommended for beams and slabs is 30-125mm

[Type here] civil4m [Type here]

CIVIL ENGINEERING INTERVIEW QUESTIONS & ANSWERS:

53. What is the meaning of soil reinforcement?

Two common examples are:1) Mixing a soil amendment such as lime into weak

clayey soil and recompacting to improve soil bearing capacity (often done under the

road base in highway construction)2) Installing plastic or composite webbing layers

(called geogrid material) alternating with compacted soil to produce a

54. . What is the different type of slump test indications?

Slump tests are performed to empirically measure the workability of fresh concrete.

... They are as follows: > True Slump > Shear Slump >

Collapse SlumpTrue Slump: This type of slump is characterized by the general

drop of the concrete mass evenly without visible signs of deterioration or

disintegration

55. What is buckling or crippling load?

Crippling is just like buckling, but it happens in the web of a beam when it is

being compressed. It often occurs at the supports of a beam, where the bottom

flange is resting on a support, and the top flange is holding up the load, such as on

a bridge abutment.

56..Define slenderness ratio. What is its effect on the design of compression member?

Slenderness ratio is the ratio of the length of a column and the least radius of gyration of its

cross section. ... It is used extensively for finding out the design load as well as in classifying

various columns in short/intermediate/long.

57.Shear force and BM diagrams for different types of loadings on beams.

Shear force and bending moment diagrams for different beamssubjected to

concentrated loads, uniformly distributed load, (UDL) uniformly varying load (UVL) and

couple for different types ofbeams

58.Difference between mild steel and HYSD bars?

High Yield strength deformed bars is the steel used in reinforcements. It has higher carbon

content .Higher tensile strength. ... HYSD is a special quality steel with much higher tensile

strength than the mild steel (30 to 40% stronger than mild steel) . It is costlier , more strong

& more hard than mild steel.

59.What is meant by 80/100 grade bitumen?

Bitumen Penetration Grade 80/100 is a standard penetration grade Bitumen usually used as

a PavingGrade Bitumen suitable for road construction and for the production of asphalt

pavements with superior properties. ... Penetration Grade bitumens are specified by the

penetration and softening point test

[Type here] civil4m [Type here]

CIVIL ENGINEERING INTERVIEW QUESTIONS & ANSWERS:

60.What is differential settlement?

Differential or uneven settlement occurs when the soil beneath a structure can not bear the

weights imposed. The settlement of a structure is the amount that the structure will “sink”

during and after construction. Differential settlements become a big problem when the

foundation settles unevenly

61.What does 33,43 and 53-grades of cement mean?

33 43 53 are the three grades of cement very widely used in the Construction industry. The

characteristic compressive strength of the three grades of cementafter careful curing for

28days should not be less than 33MPa 43 MPa and 53 MPa

62.How do you construct a 25 storey building with no columns?

No

63.Types of loads on structure?

Types of loads acting on a structure are:

Dead loads.

Imposed loads.

Wind loads.

Snow loads.

Earthquake loads.

Special loads.

64.Difference between pre-tensioning and post-tensioning?

In pre-tensioning the stressing wires or tendons are stressed prior to placing concrete as

shown below. Inpost-tensioning the wires or tendons are stressed and each end is anchored

to concrete section after has been cast and has attained sufficient strength to safely withstand

the prestressing force, as shown below.

65.What is the L/D ratio of a cantilever beam?

In case of limit state of serviceability, excessive deflection of structural elements are

contained by limiting the “l/d” ratio. That is the ratio of effective length to effective depth of the

member. IS 456: 2000 prescribed a limiting value of 'l/d'=7, for can

tilever beams for spans up to 10m.

66.What is camber?

Camber is the angle between vertical wheel allignment and the angle perpendicular to the surface

67.What is batching?

the quantity of material prepared or required for one operation

68.Difference between volume and weight batching?

Weigh Batching vs Volume Batching. Once mix design is established, the first task is to

batch materials.Batching is the process of measuring and combining required ingredients of

concrete by either by weight or by volume as per the mix design and introducing them into a

mixture to produce a uniform quality of concrete

[Type here] civil4m [Type here]

CIVIL ENGINEERING INTERVIEW QUESTIONS & ANSWERS:

69.How is a theodolite leveled?

A theodolite works by combining optical plummets (or plumb bobs), a spirit (bubble level), and

graduated circles to find vertical and horizontal angles in surveying. An optical plummet

ensures the theodolite is placed as close to exactly vertical

above the survey point.

70.What is a benchmark? Name the different types.

There are four primary types of benchmarking: internal, competitive, functional, and generic.

Internal benchmarking is a comparison of a business process to a similar process inside the

organization. Competitive benchmarking is a direct competitor-to-competitor comparison of

a product, service, process, or method.

71.Types of admixtures?

Following are the types of concrete admixtures:

Air entraining concrete admixture.

Water reducing admixture.

Retarding concrete admixture.

Accelerating concrete admixture.

Calcium chloride.

72.What are the CAD softwares you have used?

CAD (computer-aided design) software is used by architects, engineers, drafters, artists,

and others to create precision drawings or technical illustrations. CAD software can be used

to create two-dimensional (2-D) drawings or three-dimensional (3-D) models.

Interpret a strss vs strain curve.

Low carbon steel generally exhibits a very linear stress–strain relationship up to a well

defined yield point (Fig.2). The linear portion of the curve is the elastic region and the slope is

the modulus of elasticity or Young's Modulus ( Young's Modulus is the ratio of the compressive

stress to the longitudinal strain).

73.Define modulus of elasticity.

the ratio of the stress in a body to the corresponding strain (as in bulk modulus, shear modulus,

and Young's modulus) — called also coefficient of elasticity, elastic modulus.

74.What are the chemical compositions of cement?

Portland cement consists essentially of compounds of lime (calcium oxide, CaO) mixed with

silica (silicon dioxide, SiO2) and alumina (aluminum oxide, Al2O3). The lime is obtained from a

calcareous (lime-containing) raw material, and the other oxides are derived from an

argillaceous (clayey) material.

75.What is creep & shrinkage of concrete?

Creep and shrinkage of concrete are two physical properties of concrete. The creep of

concrete, which originates from the calcium silicate hydrates (C-S-H) in the hardened Portland

cement paste (which is the binder of mineral aggregates), is fundamentally different from the

creep of metals and polymers

[Type here] civil4m [Type here]

CIVIL ENGINEERING INTERVIEW QUESTIONS & ANSWERS:

[Type here] civil4m [Type here]

You might also like

- Civil Engineering Interview Question & AnswerDocument9 pagesCivil Engineering Interview Question & Answeranbusudhan100% (1)

- Civil Interview QuestionsDocument6 pagesCivil Interview QuestionsSonam Rinchen BhutiaNo ratings yet

- Civil Engineering Interview QuestionsDocument12 pagesCivil Engineering Interview Questionsjadgug100% (1)

- Questions Civil EngineeringDocument5 pagesQuestions Civil Engineeringraghu4unitNo ratings yet

- Civil Engineering Interview QuestionsDocument17 pagesCivil Engineering Interview Questionsgaza man100% (1)

- 75 Civil Engineering Interview QuestionsDocument2 pages75 Civil Engineering Interview QuestionsZakir AliNo ratings yet

- Civil engineering 250 Civil Engineer Interview Questions and Answers asked in Top CompaniesDocument35 pagesCivil engineering 250 Civil Engineer Interview Questions and Answers asked in Top CompaniesSrikanth SrikanthNo ratings yet

- Top Civil Engineering Interview QuestionsDocument6 pagesTop Civil Engineering Interview QuestionsSaddaqatNo ratings yet

- Qa QC Interview QuestionsDocument17 pagesQa QC Interview QuestionsAjin Sharma100% (1)

- Pile Dia and Minimum ReinforcementDocument1 pagePile Dia and Minimum ReinforcementMAHTAB HOSSAIN100% (1)

- CIVIL ENGINEERING TECHNICAL QUESTIONS AND ANSWERS - Ebook - ConstructionPlacementsDocument46 pagesCIVIL ENGINEERING TECHNICAL QUESTIONS AND ANSWERS - Ebook - ConstructionPlacementsKunal DashNo ratings yet

- Road Project Steps and Interview QuestionsDocument54 pagesRoad Project Steps and Interview QuestionsaamirNo ratings yet

- Method Statement For Installation of Strip Seal/ Modular Strip Seal Expansion Joints InstallationDocument2 pagesMethod Statement For Installation of Strip Seal/ Modular Strip Seal Expansion Joints Installationajit karandikarNo ratings yet

- Top 50+ Civil Engineering Interview Questions and Answers 2021Document9 pagesTop 50+ Civil Engineering Interview Questions and Answers 2021Irfan AwanNo ratings yet

- Civil Engineering Interview QuestionsDocument19 pagesCivil Engineering Interview QuestionsSrivardhanSrbNo ratings yet

- 300+ (UPDATED) Civil Engineering Interview Questions and AnswersDocument11 pages300+ (UPDATED) Civil Engineering Interview Questions and AnswersIrfan AwanNo ratings yet

- Civil Engineering Interview QuestionsDocument4 pagesCivil Engineering Interview QuestionsDivyang PatelNo ratings yet

- IS 1893: 2002,2016 - CRITERIA For Earthquake Resistant Design of StructuresDocument29 pagesIS 1893: 2002,2016 - CRITERIA For Earthquake Resistant Design of Structuresparam2189No ratings yet

- AASHTO PC Girder Post Tensioning MethodologyDocument16 pagesAASHTO PC Girder Post Tensioning MethodologyKiryaki FrancisNo ratings yet

- 6 Pavement Quality Concrete PPT by Deepak ThamanDocument6 pages6 Pavement Quality Concrete PPT by Deepak ThamanThaman Thaman100% (1)

- 100 Civil Interview QuestionsDocument6 pages100 Civil Interview QuestionsWei LeeNo ratings yet

- JacketIngDocument28 pagesJacketIngVelmurugan Balasubramanian0% (1)

- Continuously Reinforced Concrete PavementDocument21 pagesContinuously Reinforced Concrete PavementAnastasios Karahalios100% (1)

- JNTU Civil Engineering Viva QuestionsDocument13 pagesJNTU Civil Engineering Viva QuestionsHema PenmatsaNo ratings yet

- Rubble Masonry Foundation WallDocument3 pagesRubble Masonry Foundation WallMalith De Silva100% (2)

- 150 Interview Qs For Fresh CIVIL EngineersDocument18 pages150 Interview Qs For Fresh CIVIL EngineersKashif Khan100% (2)

- Nirman SahayakDocument32 pagesNirman SahayakRoti100% (1)

- 10262-2009 (Is Code For Concrete Mix Design)Document18 pages10262-2009 (Is Code For Concrete Mix Design)krishna kumar100% (2)

- Civil Engineering Interview QuestionsDocument5 pagesCivil Engineering Interview QuestionsKwando Zulu100% (1)

- Most Asked 92 Civil Engineering Interview Questions With Answers PDFDocument12 pagesMost Asked 92 Civil Engineering Interview Questions With Answers PDFMohammed Hamed75% (12)

- Mivan - A Versatile Aluminum Formwork Construction Technique"Document27 pagesMivan - A Versatile Aluminum Formwork Construction Technique"Anirban MazumderNo ratings yet

- Concrete Testing-11Document32 pagesConcrete Testing-11kamal hameed tayy75% (8)

- Reinforcement Detailing of RCC SlabsDocument6 pagesReinforcement Detailing of RCC SlabsGani AnosaNo ratings yet

- Guide to designing RCC structural componentsDocument19 pagesGuide to designing RCC structural componentshamz786No ratings yet

- 18 Top Civil Engineering Interview QuestionsDocument3 pages18 Top Civil Engineering Interview QuestionsSrinivas P100% (1)

- Design of Sub Structures NotesDocument40 pagesDesign of Sub Structures NotesIlakkiya Dharmalingam100% (1)

- 100 Imp PointsDocument18 pages100 Imp Pointsfarhan poya100% (1)

- PRESTRESSED GIRDER STRESSINGDocument16 pagesPRESTRESSED GIRDER STRESSINGd_ko_alam2169100% (3)

- Stone Column PPT AbhiDocument94 pagesStone Column PPT Abhiakdce01No ratings yet

- Dcs 1Document12 pagesDcs 1Sai PrintersNo ratings yet

- Venkat FlexiblePavements ConstructionDocument110 pagesVenkat FlexiblePavements ConstructionVamsiKrishna100% (2)

- Dynamic Prestress Technical Guidelines PDFDocument8 pagesDynamic Prestress Technical Guidelines PDFdhopat kalpesh100% (1)

- Maintenance of PSC GirdersDocument10 pagesMaintenance of PSC GirdersradhakrishnangNo ratings yet

- Morth 2900 Pipe CulvertsDocument5 pagesMorth 2900 Pipe CulvertsRamesh100% (3)

- Bored Cast In-Situ Pile Method StatementDocument10 pagesBored Cast In-Situ Pile Method StatementVijay JamadarNo ratings yet

- Design of Reinforced Concrete Elements QuestionsDocument16 pagesDesign of Reinforced Concrete Elements QuestionsbalabhaiNo ratings yet

- BBS Retaining WallDocument7 pagesBBS Retaining WallRoushan Rai50% (2)

- Voided Salb MenthodologyDocument4 pagesVoided Salb Menthodologyu2asad0% (1)

- CE6702: PRESTRESSED CONCRETE STRUCTURES QUESTION BANKDocument12 pagesCE6702: PRESTRESSED CONCRETE STRUCTURES QUESTION BANKChockalingamNo ratings yet

- Civil Engineer Interview Questions & AnswersDocument16 pagesCivil Engineer Interview Questions & AnswersVictor OmotoriogunNo ratings yet

- UNDER-REAMED PILES: KEY FACTS ABOUT CONSTRUCTION AND DESIGNDocument7 pagesUNDER-REAMED PILES: KEY FACTS ABOUT CONSTRUCTION AND DESIGNAnonymous nwByj9LNo ratings yet

- Failure Investigation of Microwave Towers During Cyclones - A Case StudyDocument11 pagesFailure Investigation of Microwave Towers During Cyclones - A Case StudyMahaveer Janapala100% (2)

- Pavement Quality Concrete (PQC)Document28 pagesPavement Quality Concrete (PQC)Sailesh Kumar100% (8)

- Top 30 Design of Steel Structures Design Interview Questions and Answers PDF - MCQs Preparation For Engineering Competitive ExamsDocument3 pagesTop 30 Design of Steel Structures Design Interview Questions and Answers PDF - MCQs Preparation For Engineering Competitive ExamsMEBIN GEORGE MATHEW100% (1)

- Bridge BookDocument76 pagesBridge BookSunkara Hemanth KumarNo ratings yet

- Civil Engineering Interview QuestionsDocument8 pagesCivil Engineering Interview QuestionsMuthamsetty Shyam SundarNo ratings yet

- Prestressing of H.T.S Strands: Cable Fabrication & LayingDocument3 pagesPrestressing of H.T.S Strands: Cable Fabrication & LayingAnish Panchal100% (1)

- Measures To Prevent Damages in Black Cotton Soil AreasDocument6 pagesMeasures To Prevent Damages in Black Cotton Soil AreasSabyasachi Naik (Zico)100% (1)

- Quality Control of Rigid Pavements 1Document58 pagesQuality Control of Rigid Pavements 1pranjpatil100% (1)

- 21 Technical Interview Questions For Civil Engineer JobDocument6 pages21 Technical Interview Questions For Civil Engineer Jobasad karimNo ratings yet

- Checklist for Hindu Site Pooja CeremonyDocument3 pagesChecklist for Hindu Site Pooja CeremonyanilNo ratings yet

- 8 Day Step by Step Construction Sequence For Alluminium ShutteringDocument3 pages8 Day Step by Step Construction Sequence For Alluminium ShutteringanilNo ratings yet

- 8 Day Step by Step Construction Sequence For Alluminium ShutteringDocument3 pages8 Day Step by Step Construction Sequence For Alluminium ShutteringanilNo ratings yet

- 8-day aluminium shuttering cycle planDocument1 page8-day aluminium shuttering cycle plananilNo ratings yet

- 8-day aluminium shuttering cycle planDocument1 page8-day aluminium shuttering cycle plananilNo ratings yet

- Roll Grade PDFDocument1 pageRoll Grade PDFVicente GarcíaNo ratings yet

- IR Unified Standard Schedule of Rates - 2021Document10 pagesIR Unified Standard Schedule of Rates - 2021Vinod KumarNo ratings yet

- Ultrox EPN Conc Liquid Lit Revision 2Document2 pagesUltrox EPN Conc Liquid Lit Revision 2AliMuhammadNo ratings yet

- Processing, Properties and Applications of Highly Porous Geopolymers A ReviewDocument16 pagesProcessing, Properties and Applications of Highly Porous Geopolymers A ReviewGustavo SoaresNo ratings yet

- Influence of Heat Treatment On Resistance of Wear and Mechanical Properties of Die Steel Kind D3Document8 pagesInfluence of Heat Treatment On Resistance of Wear and Mechanical Properties of Die Steel Kind D3sardinetaNo ratings yet

- Ilcpa 39 234Document30 pagesIlcpa 39 234DoreamonNo ratings yet

- Reaction Notes-ChemistryDocument19 pagesReaction Notes-ChemistrySirupyEwe GamerNo ratings yet

- Owo Ewp ST DRW X B6 10 0300Document1 pageOwo Ewp ST DRW X B6 10 0300Anonymous qEPNPwANo ratings yet

- Essex Furukawa Datasheet GPMR 200 HD ENDocument1 pageEssex Furukawa Datasheet GPMR 200 HD ENdayan_ghdNo ratings yet

- Chemistry 2000 Paper 1+ansDocument13 pagesChemistry 2000 Paper 1+ansapi-38240030% (2)

- MMA Crack Sealer TDSDocument2 pagesMMA Crack Sealer TDSCarlos GuerraNo ratings yet

- Best Aluminium Pro Le Manufacturers in IndiaDocument4 pagesBest Aluminium Pro Le Manufacturers in IndiaDigitalprajapatiNo ratings yet

- English/Metric Gas Flow Rate Conversion ChartDocument1 pageEnglish/Metric Gas Flow Rate Conversion Chartjena_skNo ratings yet

- Balance Doc 1Document7 pagesBalance Doc 1Alexa AnguloNo ratings yet

- SI1285F Non-Destructive TestingDocument3 pagesSI1285F Non-Destructive TestingAngelina MatutinaNo ratings yet

- Ionic and Covalent Compound - 121125Document12 pagesIonic and Covalent Compound - 121125Xandria SabrosoNo ratings yet

- Diamond Like CoatingsDocument24 pagesDiamond Like CoatingscecilchifticaNo ratings yet

- Materials Booklet Gabbro PrecisionDocument16 pagesMaterials Booklet Gabbro Precisionphilip vargheseNo ratings yet

- Know All About Jewelry Maki NG Jewelry Desi Gni NG and Metal Worki NG PDFDocument116 pagesKnow All About Jewelry Maki NG Jewelry Desi Gni NG and Metal Worki NG PDFhung garul100% (2)

- GU-629 Application and Selection of Standard Pipe Supports (Formerly SP1187)Document48 pagesGU-629 Application and Selection of Standard Pipe Supports (Formerly SP1187)Ibrahim Naguib100% (1)

- March Bill1Document38 pagesMarch Bill1ShakthivelNo ratings yet

- Catalyst Acid-Base Properties Impact Glycerol DehydrationDocument7 pagesCatalyst Acid-Base Properties Impact Glycerol DehydrationnayarapradoNo ratings yet

- Ferrocement Construction MethodsDocument24 pagesFerrocement Construction MethodsRafael CuaNo ratings yet

- RW Ti Pds Prorox WM 960 Astm IndiaDocument1 pageRW Ti Pds Prorox WM 960 Astm IndiaLee Kok RoyNo ratings yet

- Data Sheet: Valid From: 5/7/21Document2 pagesData Sheet: Valid From: 5/7/21Omar GuillenNo ratings yet

- Gate Valves Options: Two-Piece Stem Housing Single Stem ExtensionsDocument2 pagesGate Valves Options: Two-Piece Stem Housing Single Stem Extensionsmykel_dpNo ratings yet

- Saic Q 1007Document2 pagesSaic Q 1007Hussain Nasser Al- NowiesserNo ratings yet

- Retrofitting of 6-Storey Paulino HospitalDocument36 pagesRetrofitting of 6-Storey Paulino HospitalRhea Marie AlabatNo ratings yet

- Chemical Bonding Agents and MortarsDocument14 pagesChemical Bonding Agents and MortarsakurilNo ratings yet

- Welding Solutions For Oil & Gas Downstream (EN)Document32 pagesWelding Solutions For Oil & Gas Downstream (EN)Kara WhiteNo ratings yet