Professional Documents

Culture Documents

A Common Mistake in Design of Water Tank

Uploaded by

Khagesh AkreCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Common Mistake in Design of Water Tank

Uploaded by

Khagesh AkreCopyright:

Available Formats

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Index Copernicus Value (2015): 78.96 | Impact Factor (2015): 6.391

A Common Mistake in Design of Water Tank

Gajendra Verma

Rajiv Gandhi Technical University, Sri Aurobindo Institute of Technology, Indore Madhya Pradesh (India)

Abstract: In this paper a common mistake in calculating the thickness the wall and corresponding area of reinforcement in the water

tank by working stress method have been discussed. Due to water pressure, wall of the water tank is subjected to Tension and Bending

Moment. In most of the books, the thickness of the wall and area of reinforcement for bending moment is calculated by following

formulae considering cracked section

t= + effective cover and

Ast =

When the moment of resistance of wall section (which is the least moment of resistance of wall considering as cracked and uncracked

section) is calculated from the above values of “t” and “Ast”, it comes out less than the applied moment, hence design is not safe.

Therefore, it is necessary to determine thickness and corresponding area of reinforcement of wall section in such a manner so that it

remains safe in cracked as well as in uncracked condition. To overcome this problem, a simple procedure for calculating the thickness

the wall and area of reinforcement in the water tank by working stress method have been discussed. In this paper, the thickness of wall

is calculated considering it as an uncracked section ignoring area of reinforcement and area of reinforcement considering it as a

cracked section. At the end, effect on area of reinforcement due reduction in thickness of wall of tank have been also discussed.

Keywords: Working stress method, Area of reinforcement, Thickness of Wall, Cracked section, Uncracked section

1. Introduction j= Lever arm factor

R = Moment of resistance factor

The liquid retaining structures are used to store liquid like AT = Equivalent area of transformed Section.

water, diesel, petrol etc. A water tank is used to store water to IT = Equivalent moment of inertia transformed Section about

tide over the daily requirements. In general, water tanks can neutral axis

be classified under three heads: (i) tanks resting on ground Ast = Area of steel in tension

(ii) elevated tanks supported on staging, and (iii) M = Applied bending moment

underground tanks. From the shape point of view, water M.R. = Moment of resistance

tanks may be classified as Circular tank, Rectangular tank, Mcr = Moment of resistance of section considering cracked

Spherical tank and Intze tank. The liquid retaining structures section

are designed as a crack free structure and hence their Muncr = Moment of resistance of section considering

designed is different from others R.C.C. structures. For crack uncracked section

free structure, the tensile stresses in concrete calculated on

equivalent concrete section should be within permissible 3. Problem Formulation

limits as given in IS:3370-II-2009. In order to avoid leakage

and to impart impermeability to the concrete, concrete of A numerical problem is taken for discussion in which wall of

grade M-30 (M-25 for smaller tank up to capacity < 50 m3) the tank is designed by working stress method for a given

and above is recommended for liquid retaining structures bending moment using the procedure given in most of books.

according to IS: 3370-I-2009.The Indian standard code Then moment of resistance of wall section is determined

(IS:3370-I-2009) suggested minimum cement content 320 considering cracked and uncracked section. It is found that

kg/m3 in order to have impermeable concrete and to keep design fails as its moment of resistance comes out less than

shrinkage low. As per the provisions of the code (IS 3370-II- applied moment. A second approach is discussed for

2009), the water tanks may be designed by determining thickness and area of reinforcement in order to

Working stress method make it safe.

Limit State method

In the same numerical, area of reinforcement is calculated by

2. Symbols Used reducing the thickness as obtained in second approach.

b = Breadth of the section 4. Analysis and Design of Tank Wall

t = Overall thickness of the section

d= Effective depth of the section Let us design the wall of the water tank subjected to bending

σcbc = Permissible compressive stress in concrete due to moment 50 kNm using M-30 concrete and Fe-415 steel.

bending. First Approach: Following procedure is adopted to design

σcbt = Permissible tensile stress in concrete due to bending. the wall of the water tank in books -

σst = Permissible stress in steel in tension. Modular Ratio (m) = = 9.33

m = Modular ratio.

k = Neutral axis depth factor Neutral axis depth factor (k) = =

Volume 6 Issue 1, January 2017

www.ijsr.net

Licensed Under Creative Commons Attribution CC BY

Paper ID: ART20164696 2431

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Index Copernicus Value (2015): 78.96 | Impact Factor (2015): 6.391

= 0.418 Area of Transformed section

Lever arm factor (j) = 1- k/3 = 1- 0.418/3 = 0.861 (AT) = bD + (m-1) Ast

Moment of resistance factor (R) = = 1000*230 + ( 9.33 -1)* 2627.70

= 251888.74 mm2

= 1.8 N/mm2

Depth of neutral axis

Required effective depth of wall (d) = x=

=166.67 say 170 mm

=

Assume effective cover as 60 mm.

Thickness of wall (t) = 170 + 60 = 230 mm = 119.78 mm

Moment of inertia of Transformed section about N.A.

Required area of reinforcement (Ast) =

= 2627.70 mm2 IT = + + (m-1) Ast (d-x) 2

Now let us calculate the moment carrying capacity of wall

section = +

The moment carrying capacity of wall is calculated by + (9.33 – 1)*2627.70( 170 – 119.78)2

considering following two cases and lesser is adopted as = 1074376263 mm4

moment carrying capacity of the section. Moment considering cracked section

Muncr = σcbt

Case-I: Considering cracked section

= *2

= 19.50*10^6 N-mm = 19.50 kNm --- (ii)

Hence moment carrying capacity

= Least in (i) and (ii)

= 19.50 kNm < Applied moment (=50 kNm)

Hence design is not safe.

Second Approach: To overcome this problem, the thickness

of wall of tank is calculated from theory of uncracked section

and then amount of reinforcement is calculated using theory

of cracked section. Moment of resistance of a uncracked

section ignoring the area of reinforcement is calculated by

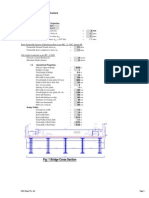

Figure 1: Cross section of cracked section following formula-

Depth of neutral axis

b x x/2 = m Ast (d-x)

1000* x2/2 = 9.33*2627.70 * (170 - x) where I = M.I.of the section about N.A. ignoring area of

x = 70.02 mm reinforcement

Depth of critical neutral axis

xc = k*d = 0.418 * 170 = 71.06 mm

Since x < xc, hence section is under reinforced.

ymax = Distance of extreme tension fibre from N.A. = t/2

Moment considering cracked section

σcbt = Permissible tensile stress in concrete in bending

(Mcr) = Ast*σst * (d - )

= 2 N/mm2 for M-30

= 2627.70*130*(170 – 70.02/3)

= 50.10 * 10^6 Nmm = 50.10 kNm----(i)

Case-II: Considering uncracked section

OR t = =

= 387.29 mm say 390 mm

Assume effective cover as 60 mm.

Available effective depth (d) = 390 – 60 = 330 mm

Required area of reinforcement (Ast) =

= 1353.66 mm2

Moment of resistance of cracked section

= 53.41 kNm --------- (i)

Moment of resistance of uncracked section

= 53.80 kNm ----- (ii)

Hence moment carrying capacity

= Least in (i) and (ii)

Figure 2: Cross section of uncracked section = 53.41 kNm > Applied moment (=50 kNm)

Hence design is safe.

Volume 6 Issue 1, January 2017

www.ijsr.net

Licensed Under Creative Commons Attribution CC BY

Paper ID: ART20164696 2432

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Index Copernicus Value (2015): 78.96 | Impact Factor (2015): 6.391

5. Effect on Area of Reinforcement due to Table 2: Area of reinforcement in wall section

Bending Thickness Effective Required area % %

Reduction in Thickness of Wall Moment of wall (t) depth of of decrease increase

(M) wall(d) reinforcement in in area of

Let us see the effect on area of reinforcement due to (Ast) thickness reinforce

reduction in thickness of wall as calculated in second of wall -ment

approach. kN-m mm mm mm2

50 390 330 1353.66

Assume thickness of wall as 370 mm. 50 370 310 2115 5.13 56.24

Effective depth (d) 370 – 60 = 310 mm 50 360 300 3495 7.69 158.19

Required area of reinforcement (Ast) = 50 350 290 5030 10.26 271.59

= 1440.99 mm2

Moment of resistance of cracked section

= 53.15 kNm (i)

Moment of resistance of uncracked section

= 48.63 kNm (ii)

Hence moment carrying capacity

= Least in (i) and (ii)

= 48.63 kNm < Applied moment (=50 kNm)

Hence design is not safe.

In order to make it safe, area of reinforcement must be

increased. There is no direct approach for calculating the

area of reinforcement in uncracked theory. It may be

calculated by trial and error by using the following formulae Graph 1: Variation in area of rainforcement

–

AT = bD + (m-1) Ast

x=

IT = + + (m-1) Ast (d-x) 2

M= σcbt

Required area of reinforcement (Ast) = 2115 mm2

Moment of resistance of cracked section

= 76.45 kNm (i)

Moment of resistance of uncracked section

= 50.01 kNm (ii)

Hence moment carrying capacity

= Least in (i) and (ii) Graph 2: Variation in area of rainforcement

= 50.01 kNm > Applied moment (=50 kNm)

Hence design is safe. From table -2, it is clear that if thickness is reduced by 5.13

Similarly area of reinforcement is calculated for other %, the area of reinforcement increases by 56.24 %.Similarly,

thickness 360 mm and 350 mm and tabulated in Table-2 If the thickness is reduced by 7.69 % and 10.26 %, the

corresponding increase in area of reinforcement is 158.19 %

6. Discussion and 271.59 % respectively. Also, it is clear from Graph-2 that

rate of % increase in area of reinforcement increases rapidly

The results of first and second approach are given in as thickness of wall goes on reducing. Hence, a small

Table – 1 decrease in thickness requires large amount of reinforcement

which makes the design uneconomical.

TABLE – 1 (Moment of Resistance of wall section)

M t Ast Muncr Mcr M.R.

(kN-m) mm) (mm2) (kN-m) (kN-m) (kN-m)

7. Conclusion

First 50 230 2627.70 19.50 50.10 19.50

Approach From the above results, following conclusions are extracted-

Second 50 390 1353.66 53.80 53.41 53.41 1) The second approach is logically correct.

Approach 2) The thickness of wall of water tank should be selected

carefully otherwise section may be uneconomical

It is clear from table-1 that second approach is correct as

moment of resistance obtained is more than the applied References

moment.

[1] Dayaratnam P. Design of Reinforced Concrete Structures.

New Delhi. Oxford & IBH publication.2000

Volume 6 Issue 1, January 2017

www.ijsr.net

Licensed Under Creative Commons Attribution CC BY

Paper ID: ART20164696 2433

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Index Copernicus Value (2015): 78.96 | Impact Factor (2015): 6.391

[2] Vazirani & Ratwani. Concrete Structures. New Delhi.

Khanna Publishers.1990.

[3] Sayal & Goel .Reinforced Concrete Structures. New

Delhi. S.Chand publication.2004.

[4] N.Krishna Raju, Advanced Reinforced Concrete

Structures , CBS Publishers New Delhi CBS

Publishers 2013

[5] Bhavikatti.V, Advanced Reinforced Concrete Design

(vol-II), New age international, 2nd edition, 2009..

[6] O.P Jain and Jai Krishna Plain and reinforced Concrete

Volume-II.

[7] Dr. B.C.Punmia, et al, Comprehensive R.C.C. Desings,

Laxmi Pub. 1998.

[8] IS : 3370 ( Part I )- 2009, Code of Practice for Concrete

Structures for the Storage of Liquids

[9] IS : 3370 ( Part II )- 2009, Code of Practice for Concrete

Structures for the Storage of Liquids

Author Profile

Gajendra Verma obtained the Bachelor degree in

Civil Engineering and Master Degree in Structural

Engineering from Government Engineering College,

Ujjain, Madhya Pradesh (India) in 1987 and 2010

respectively. He served the various Engineering Colleges. Currently

he is working as an Associate Professor and HOD in the

Department of Civil Engineering, Aurobindo Institute of

Technology, Indore Madhya Pradesh (India). He has over two

decades of teaching experience. His research interest is in the area

of Structural designs. He is also a Member of Institute of Engineers

and Indian Society for Technical Education.

Volume 6 Issue 1, January 2017

www.ijsr.net

Licensed Under Creative Commons Attribution CC BY

Paper ID: ART20164696 2434

You might also like

- Glass Balustrade DesignDocument18 pagesGlass Balustrade Designveereshan100% (1)

- Slab-Top Moment SpanDocument14 pagesSlab-Top Moment SpanRohit PhadatareNo ratings yet

- AISC Seismic Design-Module2-Moment Resistant Frames-V2Document233 pagesAISC Seismic Design-Module2-Moment Resistant Frames-V2Shantonu DeyNo ratings yet

- BW - Calculation Sheet - Rev01Document15 pagesBW - Calculation Sheet - Rev01Ernest NavarroNo ratings yet

- Structural Glass Design-CP3Document5 pagesStructural Glass Design-CP3msiddiq1No ratings yet

- Design Sheet: DPWH DesignedDocument5 pagesDesign Sheet: DPWH DesignedEdward Albert Mendoza BañagaNo ratings yet

- RC2009 University of HongKong Reinforced Concrete DesignDocument29 pagesRC2009 University of HongKong Reinforced Concrete DesignApril IngramNo ratings yet

- RCD 02 Flexural Analysis of BeamDocument13 pagesRCD 02 Flexural Analysis of BeamJohn Kenneth RuizNo ratings yet

- Design and Drawing of RC Structures: Dr. G.S.SureshDocument40 pagesDesign and Drawing of RC Structures: Dr. G.S.SureshKanhaiya BhagatNo ratings yet

- Design Calculations For Aluminium Profile 13794Document14 pagesDesign Calculations For Aluminium Profile 13794Wilson PesantezNo ratings yet

- Design of Formwork For Column R0 - 3.7 MTRDocument5 pagesDesign of Formwork For Column R0 - 3.7 MTRrahul1433No ratings yet

- Design Concrete SheetDocument14 pagesDesign Concrete SheetIan Roderick JafferyNo ratings yet

- Bridge-Ch-5-Example On Slab Bridge EDITEDFINALDocument15 pagesBridge-Ch-5-Example On Slab Bridge EDITEDFINALkassahun kebede100% (1)

- Annexure-2 (Section Design Calcs)Document107 pagesAnnexure-2 (Section Design Calcs)blisscutest beagleNo ratings yet

- RCD 02 Flexural Analysis of BeamDocument13 pagesRCD 02 Flexural Analysis of BeamJohn Kenneth RuizNo ratings yet

- Structural Glass Design-BS6399Document6 pagesStructural Glass Design-BS6399msiddiq1100% (2)

- 4.beam Design Singly and DoublyDocument10 pages4.beam Design Singly and DoublyReuben James BangaoilNo ratings yet

- Design of SlabDocument9 pagesDesign of SlabPrakash Singh Rawal100% (1)

- Crack Width Check BS5400 4Document6 pagesCrack Width Check BS5400 4amirNo ratings yet

- Bicycle Design ProjectDocument12 pagesBicycle Design Projectjabirp27No ratings yet

- Tanks Edge SettlementDocument19 pagesTanks Edge Settlementalinor_tn100% (1)

- Beam SlabDocument66 pagesBeam Slabmadkik100% (1)

- Mechanic of Solid and Shells PDFDocument521 pagesMechanic of Solid and Shells PDFKomarudinNo ratings yet

- Refractories For Cement IndustryDocument246 pagesRefractories For Cement IndustryDang Do Minh100% (3)

- Airy StressFunctionDocument7 pagesAiry StressFunctionManoj RamNo ratings yet

- Structural Design of Raft Foundation Based On Geotechnical AnalysisDocument6 pagesStructural Design of Raft Foundation Based On Geotechnical AnalysisNaresh KumarNo ratings yet

- Crack Width Check BS5400 4Document6 pagesCrack Width Check BS5400 4Parthiban ArivazhaganNo ratings yet

- Slab-Top Moment Support at Column FaceDocument19 pagesSlab-Top Moment Support at Column FaceRohit PhadatareNo ratings yet

- Mathcad - Bridge (8mx18m) Deck Slab DesignDocument16 pagesMathcad - Bridge (8mx18m) Deck Slab DesignSreyleap NhetNo ratings yet

- CRJGR Aayu STS Inf S2.0 CNS RTW 00004C CC 22 11 PDFDocument28 pagesCRJGR Aayu STS Inf S2.0 CNS RTW 00004C CC 22 11 PDFHazim AffendiNo ratings yet

- Crackwidth (Gergely & Lutz)Document61 pagesCrackwidth (Gergely & Lutz)Medianna Novita100% (1)

- Slab-Bottom Moment SpanDocument13 pagesSlab-Bottom Moment SpanRohit PhadatareNo ratings yet

- Handout CE415 DeflectionDocument30 pagesHandout CE415 DeflectionbilalNo ratings yet

- FCE 411 - Geotechnical Engineering II 2019-2020-1Document58 pagesFCE 411 - Geotechnical Engineering II 2019-2020-1Dennis OG100% (1)

- Dos II - Lecture NotesDocument71 pagesDos II - Lecture NotesSajee SweetNo ratings yet

- RCC 2 MarksDocument27 pagesRCC 2 MarksWilliam WhaiteNo ratings yet

- Crack Width Check BS5400 4Document4 pagesCrack Width Check BS5400 4fontec.info2023No ratings yet

- Design of Trade Off III Precast ConcreteDocument9 pagesDesign of Trade Off III Precast ConcretemateojullieanneNo ratings yet

- Comparative Study of Slab Culvert Design Using IRC 112:2011 and IRC 21:2000Document4 pagesComparative Study of Slab Culvert Design Using IRC 112:2011 and IRC 21:2000Darshan ShahNo ratings yet

- Hgiel 1129 Dve 9 HW 291+100 Fly DN 02Document189 pagesHgiel 1129 Dve 9 HW 291+100 Fly DN 02Chandan SharmaNo ratings yet

- ACS Unit 001Document9 pagesACS Unit 001sarifnNo ratings yet

- Calculations XavierDocument35 pagesCalculations XavierAlexo NgendaNo ratings yet

- UNIT Dfty57Document8 pagesUNIT Dfty57JPDGLNo ratings yet

- Design of Doubly Rectangular BeamDocument14 pagesDesign of Doubly Rectangular BeamAhmad HusnainNo ratings yet

- Design and Drawing of RC Structures: Dr. G.S.SureshDocument40 pagesDesign and Drawing of RC Structures: Dr. G.S.SureshvipinNo ratings yet

- PT Hollow Box (BR 18m X 20m) Girder Design-Rev FINALDocument25 pagesPT Hollow Box (BR 18m X 20m) Girder Design-Rev FINALlyty WUNo ratings yet

- Design and Drawing of RC Structures: Dr. G.S.SureshDocument40 pagesDesign and Drawing of RC Structures: Dr. G.S.SureshkannanNo ratings yet

- Notes On Serviceability LimitsDocument9 pagesNotes On Serviceability LimitsOsama DabbasNo ratings yet

- Item Date Checker Contact Email Crack Width 10-May-07 Tayeb KazemiDocument8 pagesItem Date Checker Contact Email Crack Width 10-May-07 Tayeb KazemipradeeshNo ratings yet

- RCC Lab Report - 2Document15 pagesRCC Lab Report - 2Razn NhemaphukiNo ratings yet

- Design of SlabDocument33 pagesDesign of SlabFun JinNo ratings yet

- Singly Reinforced Beam DesignDocument7 pagesSingly Reinforced Beam Designravi1214No ratings yet

- Usab Feed Tanks 09092015Document16 pagesUsab Feed Tanks 09092015DenishmakvanaNo ratings yet

- Module-IV - Rectangular Water TanksDocument61 pagesModule-IV - Rectangular Water TanksChinkuNo ratings yet

- Seismic Masonry Guide 2nd Edition Oct 2018 R1 Split 4Document71 pagesSeismic Masonry Guide 2nd Edition Oct 2018 R1 Split 4Eduardo Martinez CaleroNo ratings yet

- Concrete CalculationDocument10 pagesConcrete CalculationKaye Ibañez CastilloNo ratings yet

- Design of Two Way Slab (Continuous) : Given DataDocument3 pagesDesign of Two Way Slab (Continuous) : Given DataParwan ExceltechNo ratings yet

- Total Mark 40: CON4338 Structures and Tall Buildings Assignment 3Document2 pagesTotal Mark 40: CON4338 Structures and Tall Buildings Assignment 3Ho JamesNo ratings yet

- Crack Width Check BS5400 4 4Document6 pagesCrack Width Check BS5400 4 4Marvin MalicdemNo ratings yet

- Oil SumpDocument4 pagesOil SumpSuchitra PandaNo ratings yet

- Example-Fully Restrained BeamDocument5 pagesExample-Fully Restrained BeamF.a.AlfredThom100% (1)

- CIV3506 2022 Assign2 Exemplary2Document33 pagesCIV3506 2022 Assign2 Exemplary2Neil WayneNo ratings yet

- Do It Yourself 1Document63 pagesDo It Yourself 1Nguyen Duc CuongNo ratings yet

- Crack Width Check BS5400 4Document6 pagesCrack Width Check BS5400 4Dushyant GuptaNo ratings yet

- Crack Width Check BS5400 4Document6 pagesCrack Width Check BS5400 4Anonymous 1HFV185Sl4No ratings yet

- Instructional Materials Principles of Reinforced Conrete Cien 30183Document251 pagesInstructional Materials Principles of Reinforced Conrete Cien 30183Aichelle Ann BersabeNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Standing Tall: Taylor Solutions For High-Rise StructuresDocument6 pagesStanding Tall: Taylor Solutions For High-Rise StructuresKhagesh AkreNo ratings yet

- ETABS-Time History Analysis-DetailedDocument4 pagesETABS-Time History Analysis-DetailedhasanalharisalaydrusNo ratings yet

- Is.3861.2002 Method of Measurement of Plinth, Carpet and Rentable Areas of BuildingsDocument10 pagesIs.3861.2002 Method of Measurement of Plinth, Carpet and Rentable Areas of Buildingsvijay2528No ratings yet

- I Scheme Syllabus Fifth Semester Civil EngineeringCE CR CS Part 1Document48 pagesI Scheme Syllabus Fifth Semester Civil EngineeringCE CR CS Part 1Khagesh AkreNo ratings yet

- Journal of Alloys and Compounds: Flow Stress Modeling of AZ91 Magnesium Alloys at Elevated TemperatureDocument7 pagesJournal of Alloys and Compounds: Flow Stress Modeling of AZ91 Magnesium Alloys at Elevated TemperatureChetan PrakashNo ratings yet

- 1.1 Introduction of Chassis FrameDocument53 pages1.1 Introduction of Chassis FramegadhireddyNo ratings yet

- Time Based Thermal StressDocument7 pagesTime Based Thermal StressFilipNo ratings yet

- Henkel Elastomeric GuideDocument2 pagesHenkel Elastomeric GuideFerdinand A AlbarNo ratings yet

- StructAeroBeamsPart2 PDFDocument93 pagesStructAeroBeamsPart2 PDFAlem LoajnerNo ratings yet

- Analysis of Reinforced Concrete Maluos BDocument67 pagesAnalysis of Reinforced Concrete Maluos BAl Patrick Dela CalzadaNo ratings yet

- Symmetric Bending of Beams: Learning ObjectivesDocument0 pagesSymmetric Bending of Beams: Learning ObjectivesWijayanto BekasiNo ratings yet

- 1 s2.0 0045794993902389 Main PDFDocument14 pages1 s2.0 0045794993902389 Main PDFAhmed MohammedNo ratings yet

- Test 1 Mec630Document1 pageTest 1 Mec630Aziful AimanNo ratings yet

- Student Assignment Cover SheetDocument11 pagesStudent Assignment Cover SheetAhmed AdelNo ratings yet

- Chapter7 Rock Mechanics InteractionsDocument7 pagesChapter7 Rock Mechanics InteractionsGirma FikreNo ratings yet

- Shafts Subjected To LoadDocument27 pagesShafts Subjected To LoadMaria MeharNo ratings yet

- Extended Abstract - David Simavorian (66007)Document17 pagesExtended Abstract - David Simavorian (66007)Relu MititeluNo ratings yet

- Kisssoft 03/2017 - Tutorial 6: Shaft EditorDocument15 pagesKisssoft 03/2017 - Tutorial 6: Shaft EditorNguyễnVănLăngNo ratings yet

- Stress - StrainDocument92 pagesStress - StrainMrßmárt KillerNo ratings yet

- Degennes 1996Document4 pagesDegennes 1996Abdul NaseerNo ratings yet

- Static Equilibrium and ElasticityDocument26 pagesStatic Equilibrium and ElasticitydeeparNo ratings yet

- Dashti - Out Plane Response - 2Document33 pagesDashti - Out Plane Response - 2Melo PereiraNo ratings yet

- Department of Civil and Environmental Engineering - MITDocument72 pagesDepartment of Civil and Environmental Engineering - MITPatrick DavisNo ratings yet

- General Theory of Elastic StabilityDocument12 pagesGeneral Theory of Elastic Stabilitygirma kebedeNo ratings yet

- Material Selection For Optimal Environmental Impact in Fizzy Drink Container Based On Ashby's ChartDocument7 pagesMaterial Selection For Optimal Environmental Impact in Fizzy Drink Container Based On Ashby's ChartAnand BhiseNo ratings yet

- Dr. Y. M. Ghugal BiodataDocument21 pagesDr. Y. M. Ghugal BiodataGirish DeshmukhNo ratings yet