Professional Documents

Culture Documents

Inside Digital Design 2018

Uploaded by

Dwane LweasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Inside Digital Design 2018

Uploaded by

Dwane LweasCopyright:

Available Formats

1 Inside digital designs, Draft-2018

CHAPTER 1

Introduction to digital design

Digital design revolution completely took over analogue designs, capturing major electronic design

industry. Besides other amazing features, design automation is well defined reasons for digital design

dominance. This chapter will introduce to amazing world of digital design, and travel through several

fundamental features to grasp state of art tools, hardware development; advancements and complex

digital design algorithms. First section will embark on basic terminology and concepts of digital design.

1-1 What is digital design?

Digital design is mapping of algorithms on silicon, where algorithm is defined as a function which

translates inputs to outputs. Figure 1-1 shows algorithm mapped on silicon, which generates outputs

based on inputs. Digital design deals with design of algorithms, methods to map them on silicon and

assure that they function properly.

Inputs Algorithm on the Outputs

silicon

Figure 1-1: Algorithm mapping inputs to outputs (This is what digital design is about,

designing algorithms and using automated techniques to map them on silicon)

Digital designer have to search for an optimal transfer function, which takes less area and provides high

performance. The goals of optimality are bounded by four criteria’s:

▪ Area, the design should consume as less area as possible.

▪ Performance, the design should work fast and delivers high performance.

▪ Power, the design should consume acceptable amount of power. So that it can sustain longer

period of time with battery and dissipate less heat.

Inside digital design, Draft 2018

2 Inside digital designs, Draft-2018

▪ Testability, the design should be testable after it is developed, so that faults can easily be traced.

In an ideal world design should utilize minimum area, provides high speed and performance, consumes

less power and should be fully testable after being manufactured.

1-1-1 Example of digital design algorithm:

Let’s start with a very simple example to understand what design mapping means? Consider a 2-bit

comparator in figure 1-2. The design can compare two inputs and assert ‘Cmp_EQ’ (if both inputs are

equal), ‘CMP_LT’ (if first input is less then second input), ‘CMP_GT’ (if first input is greater than second).

Cmp_EQ

Cmp_In1

Comparator2

Cmp_LT

Cmp_In2

Cmp_GT

Figure 1-2: Example of algorithm to be mapped on silicon, inputs and outputs are indicated

To figure out mapping between input and output conventional technique such as truth table and writing

Boolean equations can be used. Boolean equations are written for each output and are minimized using

K maps or Boolean reduction. Figure 1-3 shows truth table and possible Boolean equations.

Cmp_In1 Cmp_In2 Cmp_EQ Cmp_LT Cmp_GT

0 0 1 0 0

0 1 0 1 0

1 0 0 0 1

1 1 1 0 0

̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅

𝐶𝑚𝑝_𝐸𝑄 = 𝐶𝑚𝑝_𝐼𝑛1⋀𝐶𝑚𝑝_𝐼𝑛2

𝐶𝑚𝑝_𝐿𝑇 = ̅̅̅̅̅̅̅̅̅̅̅̅

𝐶𝑚𝑝_𝐼𝑛1& 𝐶𝑚𝑝_𝐼𝑛2

𝐶𝑚𝑝_𝐺𝑇 = 𝐶𝑚𝑝_𝐼𝑛1 & ̅̅̅̅̅̅̅̅̅̅̅̅

𝐶𝑚𝑝_𝐼𝑛2

Figure 1-3: Figuring out digital design algorithm

Inside digital design, Draft 2018

3 Inside digital designs, Draft-2018

Based on algorithm worked out in figure 1-3, the black box of figure 1-2 is filled. The result is a digital

design which transfers inputs to outputs. The circuit exactly defines, how each output will be shaped up

using each input. In other words, a combination of wires and logic elements defines a path from input to

output. The circuit elements are dictated by the functionality of digital design. In certain cases the

design may be twisted to satisfy the optimality goals.

Cmp_In1 Cmp_EQ

Cmp_In2

Cmp_LT

Cmp_GT

Figure 1-4: The algorithm defines a mapping between input and output

1-1-3 Mapping design on silicon:

In this subsection, flow of mapping an algorithm on silicon will be explored. Figure 1-4 reflected a digital

circuit based on certain algorithm. Figure 1-5 shows flow of mapping algorithm to silicon; this means to

implement digital circuit on hardware and functionally verify it. First step of mapping is design

specification, which defines digital design. Such specification can be in form of formal document, code of

required design in some other language e.g. C++, or as verbal description. To design circuit correctly,

design specification must be clear and concise. Each module, associated ports, their sizes and

connections between modules should be properly indicated so that correct design could be

accomplished.

Once design specification is decided the digital design is simulated, mapped to hardware and

functionality is cross checked with required functionality as per required by design specification. The

implementation on hardware or mapping on silicon can be accomplished in different ways; depending

on the possible application and needs of hardware. The possible platforms and their scopes will be

discussed in coming sections. Functional verification is essential since it cross-checks design

implementation with required functionality. Testing the design for faults and verifying it against required

functionality are two different aspects and shouldn’t be confused. Testing means, that circuit is fault

free and is functioning without errors while verification means that if it matches required functionality.

Inside digital design, Draft 2018

4 Inside digital designs, Draft-2018

Figure 1-5 illustrate all steps of mapping, algorithm on silicon and cross validating it’s functionality.

Design

Specification

Mapping

algorithm on

silicon

Function

Verification

Verified

Figure 1-5: Design Flow of Digital Designs

1-1-4: Constraints of optimal digital design mapping:

The digital design becomes demanding because it is constrained by several design requirements. The

tradeoff between such requirements restricts designer to meet required parameters of performance,

area, power and testability at same time. Every end user wants fast systems, which are very reliable,

slim and consume less power. Yet trending and paced digital evolution and time to market a product

makes it even challenging. Delivering a cost-effective product with matching market trends before a

competitor does, is a demanding design regime. Never the less, there is no free lunch, and each of these

goals effect other parameters. For example, to achieve good performance, more area is required to be

spent which results in more power consumption of circuit. A very popular example to explain this effect

is ripple carry adder; each stage of 4-bit ripple carry adder consists of full adder. The carry is passed from

Inside digital design, Draft 2018

5 Inside digital designs, Draft-2018

previous stage, therefore full adders of next stage must wait until all previous stage manufactures carry

and forward it, as shown in figure 1-6. This means in 16-bit adder, last stage has to wait for 15 stages to

receive rippled carry, which reduces the design performance.

b[3] a[3] b[2] a[2] b[1] a[1] b[0] a[0]

Carry_out Carry_in

FA3 FA2 FA1 FA0

S[3] S[2] S[1] S[0]

Figure 1-6: Ripple carry adder, low performance with less area and power

The solution to this problem is carry look ahead, which generates carry in advance using propagate and

generate mechanism, as shown in figure 1-7. This speeds up the performance of circuit at cost of extra

area, hence to get more performance more area is required to be invested.

Carry Look Ahead Logic Calculator Cin

G[2]

G[2]

G[1]

P[2]

G[2]

P[2]

P[1]

P[2]

b[1] a[1] b[1] a[1] b[1] a[1] b[0] a[0]

FA3 FA2 FA1 FA0 Cin

S[3] S[2] S[1] S[0]

Inside digital design, Draft 2018

6 Inside digital designs, Draft-2018

Figure 1-7 : Better performance at cost of extra area and power consumption

Let’s try to reduce area of ripple carry adder and make it slim with the same functionality. Figure 1-8

shows a single full adder, whose output ‘COut’ is stored in d flip flop. This carry out is feedback to carry

in stage of adder. Two inputs are stored in two n-bit registers, which shifts single bit at every clock cycle,

finally the generated sum is also stored in shift register. This reduces hardware for any width of

numbers, but it can be easily figured out that it will require n clock cycle to sum up n-bit number. In this

case, power and area are reduced at the cost of performance.

COut FF

Cin ADDER D Q

X_in1 A

Sum

X_in2 B

Clk

X_in2

Figure 1-8: One full adder with shift registers and D-FF can produce N-bit adder, reduced

area with low performance

In similar way, to make design testable, an extra area must be spent to compensate testability logic

inside circuit. The main goals of testability are to provide a digital hardware in which fault diagnostics is

easy, it’s exact location can be spotted and if possible provides a repair or run time alternatives. The

least can be fault detection from outside of IC or digital design; obviously it can’t be achieved without

spending extra hardware.

The digital designer must find an optimal trade off while mapping algorithm onto silicon considering

required application and requirements of design. Most of current designs are power and performance

critical, this effectively means that digital designers have extra liberty to use larger chip areas due to

availability of high transistor densities for enhance performance. The area of design is less critical then

the performance itself, however using larger chip area effects in larger power consumption which

should be restricted. Higher power consumption means lower time for battery held devices and high

heat dissipation. Besides testability has gained almost mandatory place in almost all type of digital

Inside digital design, Draft 2018

7 Inside digital designs, Draft-2018

designs. This makes digital designing more challenging and demanding and to meet these constraint

dimension of research are wide open.

1-1-4 Level of digital design

The algorithm can be designed and thought at different level of abstraction. Ultimately the design is to

be translated into silicon, and things will proceed into transistors. The transistors are manufactured

using metal interconnects and semiconductors materials, however, it seems dauntingly different to

think mammoth designs on physical layout level. Therefore, other levels of abstraction are introduced to

make life of digital designer easy and tools are provided to link different levels of abstraction. The

section will cover following levels RTL (register transfer level), gate level, schematics/switch level and

layout/physical level.

1-1-5-1: RTL(register transfer level)

RTL is highest level of abstraction where design is represented by so called black boxes. The design is

shown at highest level of abstraction where only blocks, its I/O and their widths are indicated. The

system is shown as integration of such boxes. A standard routing is shown between them and data is

meant to flow between certain registers of the design hence deriving name, register transfer level.

Additionally , brief functional description of each block is also provided to show a top level design

model. Mostly design specifications are provided at register transfer level.

1-1-5-2 Gate level

The second way of representing logic is gate level; symbolical gates are used to represent circuit. Mostly

standard gates are used to reflect certain logic; however more specialized gate can also be included in

design. Gate level representation is mostly used for small designs, as for larger designs it is hard to

maintain and draw so many gates. Most of synthesis tools also translate the design at gate level know as

gate net list.

1-1-5-3 Schematics/ switch level

Schematic level or switch level involves representation of circuits using transistors. It is not difficult to

imagine that representing or thinking circuits at transistor level will become a tedious job. Although

some AMS(analogue mix signal) or microwave circuits are still sketched at transistor level however, it is

not popular way for digital designs. Transformation of gate level into schematic is natural procedure

since gates symbols under the hood uses transistors.

Inside digital design, Draft 2018

8 Inside digital designs, Draft-2018

1-1-5-4 Layout/physical level

For the chip manufacturing industry or the physical FPGA board, physical level layout is the last level of

abstraction. Physical level involves silicon wells, metal interconnects and other device level details.

Although, each transistor eventually boils down to physical layers, however, it is not practical to hand or

tool craft millions of transistors for given application. Therefore, most of the sub steps above uses

specialized tool chains and set of tool to translate between different layer of abstraction.

1-2 Digital design automation

Before electronic design automation designs were hand crafted, team of designers used to sit on a big

sheet of paper and draw schematics with their hands, and IC’s were fabricated using these designs. This

is possible for few thousand transistors however, for larger designs with multibillion transistor truth

tables isn’t viable way to design circuits. In mid 70’s part of the process was automated, and place and

route was done using automated tools. As the transistor size grew, things became harder to manage

using schematics and handcrafting techniques. The growth in memory sizes, demand to operate at high

clock speeds and dense transistor density demanded innovation in IC design industry. The ground

breaking development was done with language based hardware construction in early 1980’s. Advent of

language based hardware description immediately improved the performance and capability of IC

design industry. The design and simulation of hardware became much faster and reliable. In 1981 US

defense department started a project called VHDL to pursue effort for language based hardware

construction. The first commercial success in this regard was achieved by gateway automation in 1985,

and this was start of new era of rapid IC design growth. Since then IC fabrication industry has

revolutionized every year and device size has grown many times smaller. This means that now ICs can

support larger number of transistors on the same device as they used to support some 40 years back.

Today Giga hertz speeds, Giga bytes storages and many million transistor counts are norm. This all is

blessed by electronic design automation and invention of reliable tools to construct digital hardware.

Advent of multimedia devices like hand held phones, digital cameras, MP3 players etc. tested the design

capabilities of engineers. The demand for implementation of complex algorithms in speech signal

processing required complex silicon implementation, modulation schemes, IFFT cores, compression

algorithms, adaptive equalizers and RF signal processing required demanding designs for digital

Inside digital design, Draft 2018

9 Inside digital designs, Draft-2018

designers. The mixed signal designs have included designs on single chip mostly used in smart phones.

This effectively means advance digital design products in market using electronic design

automation(EDA).

1-2-1 EDA (Electronic design automation):

In 1965 Gordon Moore predicted the possible rapid growth in IC design as shown in figure 1-9, and IC

design industry has religiously followed the curve. This was only enabled due to rapid development of

technology in IC design and IC manufacturing industry.

Figure 1-9: Moore’s Law, transistor count will double every year

Innovations were made in electronic design automation (EDA). The birth of tool based development

allowed IC designer to handled complex algorithms and digital design using state of the art tools. One of

the innovation was programming based hardware development, this means effectively to invent a

language which can model hardware also known as HDL (hardware descriptive language. Initially,

purpose of Verilog HDL was to support simulation of hardware, but latter additional feature of

manufacturing hardware (synthesis) was incorporated. This modifies digital design philosophy, and

extends the definition to mapping of algorithms on to silicon using electronic design automation. Figure

1-5 is redrawn to extend the idea; mapping algorithm into silicon is replaced based HDL coding of the

design. Functional verification /testing of design are automated through use of software and verified

design can be synthesized into functional hardware. The reflection of digital design using automated

techniques is shown in figure 1-10.

Inside digital design, Draft 2018

10 Inside digital designs, Draft-2018

Design

Design

specifications

Specification

Simulation

HDL code for

Simulation

Function

Verification using

Test Bench

Synthesis of

Synthesis

Digital Design

list

Gate net

Post Synthesis

Simulation

Figure 1-10: Design flow of digital designs using EDA

First step remains the same, and starts with design specifications. Once design specifications are frozen,

Verilog HDL coding is done considering simulation of design. Third step , loops back between Verilog

HDL code and test bench until the code is functionally correct and matches design specifications.

Once design become functionally and logically correct it’s transformed to gate level netlist or transistor

level schematics. Most synthesis tools involve library cell driven synthesis, therefore post synthesis

simulation is performed to check if the synthesized circuit is functionally correct. EDA industry has

Inside digital design, Draft 2018

11 Inside digital designs, Draft-2018

defined four types of synthesis schemes:

High Level Synthesis: Use high level languages e.g. C++ and converts it into RTL.

Logic synthesis: Use RTL description mostly in Verilog HDL or VHDL and converts it into gate level netlist.

Schematic Capture: Use standard cells, and transform given logic using standard cell logic.

Layout: usually called schematic driven layout, where schematic level logic is directly transformed into

physical layouts.

Also simulation can be done at several levels, which are given below:

Logic Simulation: Digital simulation of an RTL design or gate net list after synthesis is done.

Schematic Simulation: Low level transistor simulation or schematic or physical layout, accurate at device

level. Such simulations are not subject of this text – book.

Hardware Emulation: It is done by after manufacturing of chip, using specialized in circuit system built in

the chip itself. Sometimes, special purpose registers or interfaces are provided for in circuit emulation.

1-2-3 HDL’s and their progress

To stay in touch with the demanding Moore’s law and high chip densities with current multibillion

transistors and feature size less then 22nm, HDL’s extended several new features. IEEE standardized

Verilog in 2001 to support new requirements; this was emergence of Verilog 2001. After standardization

a consortiums of IC design industries and other stack holders got together to extend HDL’s to support

next generation IC designs. The result was two standard i.e. Verilog 2005 and System C 2005 to

accommodate new aspects of HDL.

As a conclusive argument, Verilog HDL is powerful hardware description language, which can generate

hardware’s using coding techniques. Besides, hardware implementation it also facilitates testing using

software. But naturally HDLs aren’t like ordinary software languages; they are designed to model

hardware. The HDL’s are made technology independent, so that they are reusable and portable. A single

HDL code can be switched on over 30,000 of FPGAs and CPLDs or on ASICs. The digital design approach

is made systematic, it starts with design specification (what to design), HDL implementations are done

and transformed into hardware (called synthesis). This HDL code can be mapped on FPGA or ASIC may

be the target. This is beauty of digital design, that it allows using similar HDL code for over 50,000

programmable devices with no modification. Once a code is written it can be reused anywhere and

moreover HDLs can be managed as project cycle. The digital designs are thought in logical way, rather

than talking about boolean algebra and K maps. The logic reduction of digital designs is done by making

use of EDA tools rather than thinking of reduction of gates and transistor.

Inside digital design, Draft 2018

12 Inside digital designs, Draft-2018

1-3 Embedded system fabrics and programming platforms

There are several options to implement any given embedded design including microcontrollers, DSP

Processors, FPGAs and ASICs. Each one of them are useful at different level of developments and

applications. For example, ASICs are fast and application specific however, they have high fabrication

cost, on the other hand, microcontrollers are cheap and cost effective with more generic architecture.

Most of complex digital circuits have microcontroller, DSPs and FPGAs mounted on single chip. For

example, system on chip (SOCs) offers variable type of embedded systems fabricated on single chip.

They have even analogue systems along with digital components, with variable clock speed. This section

will address basic fabric of FPGA, and their comparison with other embedded platforms.

1-3-1 Fabric of FPGA

FPGAs are reprogrammable platforms which are so designed that any logic can be mapped on it. Before

addressing on how Verilog HDL is mapped inside FPGAs, the basic architecture of FPGA is dissected. The

main essence of FPGA is that it can implement any logic function. To start with FPGA fabric Multiplexer

function mapping is discussed in Example 1-1.

Design Example 1-1: Understanding versatility of Multiplexer

Implement F(A,B,C)=∑(1,2,4,5)using 4x1 Multiplexer.

Step-1- Make the truth table of the logic function above

A B C F

0 0 0 0

0 0 1 1

0 1 0 1

0 1 1 0

1 0 0 1

1 0 1 1

1 1 0 0

1 1 1 0

Step-2- Make the truth table of the logic function above

Inside digital design, Draft 2018

13 Inside digital designs, Draft-2018

A B C F Mux inputs

0 0 0 0 C

0 0 1 1

0 1 0 1 C’

0 1 1 0

1 0 0 1 1

1 0 1 1

1 1 0 0 0

1 1 1 0

Because it is 4x1 multiplexer this means that we need four inputs therefore we will group three inputs

in pair and use A and B inputs from Selection.

Step-3-Implement the design by applying all four inputs of multiplexer with C, C’, 1 and 0. And apply A

and B for controlling which input will be selected to the output.

C I0

I1 MUX 4x1

Y

1

I2

0 I3 S0 S1

If the multiplexer in Example 1-1 was 8x1 then we do not need any pairing. C is directly applied on the

input of Multiplexer directly. For example, 1-2 a XOR logic gate is implemented. The two inputs A and B

Inside digital design, Draft 2018

14 Inside digital designs, Draft-2018

are used as selection line and the output of the truth table is applied at the inputs. It just like storing the

output and then selecting them using inputs.

Design Example 1-2:XOR using Multiplexer

A B F

0 0 0 F0=0

0 1 1 F1=1 MUX 4x1 Y

1 0 1 F2=1

1 1 0 F3=0

A

B

This means that if a buffer for inputs and the buffer are connected to multiplier then multiplexer will be

reconfigurable by copying different data in the buffers and then applying these inputs to multiplexer.

Figure 1-11 has Multiplexer, Look up Table (LUT) and D Flip Flop. As described above that Multiplexer

can be reshaped in any form if inputs are changed Multiplexer can have any function. The new values

are stored in LUTs which is directly connected to multiplexer. The output of the Multiplexer is stored in

the DFF and hence the value is retained. This block of LUT, MUX and DFF is called complex logic

block(CLB). CLBs are basic building blocks of FPGAs , which allow flexible reconfigurability to device.

LUT

I0

MUX

4x1

I1 DFF

I2

I3

Sel0

Sel1

CLK

Inside digital design, Draft 2018

15 Inside digital designs, Draft-2018

Figure 1-11: Basic Structure of CLB

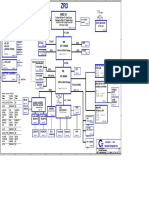

FPGAs has seas of such CLBS, allowed reprogram ability and reconfigurability. Blocks of CLBs are

connected through reprogrammable interconnects known as routing channels as shown in figure 1-12.

Each logic block consists of CLBs which can host any logic, while interconnection between them is

controlled by routing channels. Finally I/O pads and blocks are used to interconnect external world to

the logic inside device.

Figure 1-12: FPGA Fabric

FPGAs are reprogrammable therefore they offer very high speed, with reasonable cost. They doesn’t

incur high manufacturing costs like ASIC and yet provides high level of flexibility. Unlike, microcontrollers

there is no fixed instruction set, limited I/O operations, restricted set of registers etc. However, they

have generally more upfront costs then microcontrollers. Most of modern FPGAs allow soft processor

cores, which can be reconfigured on the fly. Nevertheless, with or without soft processor cores they suit

versatile performance critical applications where microcontroller can’t work.

1-3-2 Comparison of different embedded system platforms

Inside digital design, Draft 2018

16 Inside digital designs, Draft-2018

The first platform which comes to mind while thinking about any embedded system are

microcontrollers. There are tons of them, offering different capabilities, suiting variety of applications,

and supporting a large community of embedded developers. However, microcontrollers are ASICs which

process the code sequentially by loading it from ROM or Flash. Although, some powerful

microcontrollers are multicore these days, and process logics in parallel however, essentially, they are

sequential in nature. Microcontrollers may suit several application models, but where high speed is the

basic requirement things might turn into favor of FPGAs. They are based on parallel execution model

offering performance enhancements to many folds.

As said before, FPGAs are giant pile of logic which can be electronically reprogrammed to host any

circuit at high speed, while microcontroller are low cost predefined fixed architecture devices. Most of

the time embedded systems deploy both to them in same device to serve different layer of functionality

in system. Another popular device, when it comes to digital signal processing is DSP processors, which

have high end multiplication accumulation units (MACs). DSP processors suit tasks with high

performance requirements, with real time constraints. They mostly require multiplications and additions

at very high rate in parallel, and this is very common use case. Modern day system on chip (SOCs) use

DSP processors, microcontrollers, FPGAs and some ASICs all on one chip, interconnected via busses and

glue logic. It’s very common to buy intellectual property IPs cores from different vendors and put them

together in one packaging. For example, ARM sells IP core for microcontrollers, QUALCOMM offers

communication IP cores, and so on. Most of these IP cores are complaint to standard IP core principals

and connecting them together is concern of minor glue logic. These systems may communicate through

some bus architecture, or commercial bus architectures such as AMBA bus, However, since processor

scaling has sort of halted, multicore processor has become a computation culture. In company of several

processing cores, shared memories and abundance of core buses have sort of performance bottle neck

in modern day communication. Network on chip (NOC) borrows concepts from conventional networks

and provide a high-speed network inside chip. It contains routers, routing protocols, topologies and

other conventional networking inside chip to provide high speed communication capabilities to SOCs

with many dozen IP cores contained.

Rest of the book will take you to digital design journey focusing on core ideas of thinking in terms of

efficient architectures. Chapter 2, will discover Verilog HDL, the powerful language to model and

synthesize hardware. Chapter 3, and 4 will focus on algorithmic state machine ASMD, and Store

programmed machine SPM approaches to conquer larger designs. Once through basic design principals,

Inside digital design, Draft 2018

17 Inside digital designs, Draft-2018

the next chapter will address synthesis of digital design and considering the actual piece of hardware.

Chapter 6 lays foundation of DSP components which are further discussed in Chapter-11 as digital signal

processing components. Chapter 7 to 10 will look into optimized and high-performance designs by

taking pipelining, high level synthesis, network on chip (NOC) and design for testability into

consideration repectively.

Inside digital design, Draft 2018

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Electrical Engineering Hand BookDocument22 pagesElectrical Engineering Hand Bookjicksonjohn100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Manual Do Automation Studio - ProfissionalDocument20 pagesManual Do Automation Studio - Profissionalmarcelocrqr100% (2)

- Answer: Q1Document46 pagesAnswer: Q1amar2k904100% (3)

- Clock Gating MethodologyDocument71 pagesClock Gating MethodologyGirish BabuNo ratings yet

- MR-96A Service Manual V3.0 enDocument57 pagesMR-96A Service Manual V3.0 enHussain Amir Ali0% (1)

- Acer Aspire 3050, 5050 Quanta ZR3 DA0ZR3MB6E0 DA0ZR3MB6C1Document31 pagesAcer Aspire 3050, 5050 Quanta ZR3 DA0ZR3MB6E0 DA0ZR3MB6C1essemirNo ratings yet

- Microprocessors 1: The 8051 Instruction SetDocument28 pagesMicroprocessors 1: The 8051 Instruction SetnagasaikiranNo ratings yet

- DCK 255Document27 pagesDCK 255Opris ManuelNo ratings yet

- 15A04802 Low Power VLSI Circuits & SystemsDocument1 page15A04802 Low Power VLSI Circuits & SystemsContent for all CreatorNo ratings yet

- Ut163 Usb ControllerDocument32 pagesUt163 Usb Controllerelcomandante100% (8)

- Ateml AT90USB162 DatasheetDocument306 pagesAteml AT90USB162 DatasheetComputer GuruNo ratings yet

- Cadence Tutorial PDFDocument61 pagesCadence Tutorial PDFJinesh Kb100% (1)

- Flash Stock Rom No LG K5 - Ultimate GuideDocument9 pagesFlash Stock Rom No LG K5 - Ultimate GuideCristóvão RodriguesNo ratings yet

- BiosDocument27 pagesBiosDrift GeeNo ratings yet

- Use of Digital Technologies in EducationDocument5 pagesUse of Digital Technologies in EducationOpen Access JournalNo ratings yet

- Computer Hardwares and Its FunctionDocument5 pagesComputer Hardwares and Its FunctionAmirul ShamNo ratings yet

- Simulation Set 2Document4 pagesSimulation Set 2Harsh ThakurNo ratings yet

- Types of Computers Based On Principles of OperationDocument6 pagesTypes of Computers Based On Principles of OperationMayank Jain NeerNo ratings yet

- IHI0024C Amba Apb Protocol SpecDocument28 pagesIHI0024C Amba Apb Protocol SpecAnil KumarNo ratings yet

- What Is A Computer BHS enDocument2 pagesWhat Is A Computer BHS enCrimson SilverNo ratings yet

- CJ2 - Basic Prog - PPT (Compatibility Mode)Document85 pagesCJ2 - Basic Prog - PPT (Compatibility Mode)Choirull HidayatNo ratings yet

- Clock Generator 8284Document14 pagesClock Generator 8284Faiz Ahmed100% (1)

- What Is Video RAMDocument2 pagesWhat Is Video RAMrks12345No ratings yet

- Implementation of 1-Bit Full Adder Circuit Using Pass Transistor LogicDocument11 pagesImplementation of 1-Bit Full Adder Circuit Using Pass Transistor LogicIJRASETPublicationsNo ratings yet

- Input Output OrganizationDocument30 pagesInput Output OrganizationGiri Saranu100% (22)

- Experiment 1Document7 pagesExperiment 1ydsrajuNo ratings yet

- The CMOS Inverter ExplainedDocument4 pagesThe CMOS Inverter ExplainedVidhya DsNo ratings yet

- Laboratory Manual: Digital System DesignDocument37 pagesLaboratory Manual: Digital System DesignArshad RasheedNo ratings yet

- Datasheet 74HCT04 PDFDocument4 pagesDatasheet 74HCT04 PDFCarlos RamirezNo ratings yet

- YBM 1200 ManualDocument31 pagesYBM 1200 Manualmartinaleguzzo100% (1)