Professional Documents

Culture Documents

Role of Filler in The Enhancement of Properties of Bituminous Mixes: A Review

Uploaded by

IJRASETPublicationsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Role of Filler in The Enhancement of Properties of Bituminous Mixes: A Review

Uploaded by

IJRASETPublicationsCopyright:

Available Formats

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor:6.887

Volume 5 Issue VIII, August 2017- Available at www.ijraset.com

Role of Filler in the Enhancement of

Properties of Bituminous Mixes: A Review

Ankita Dhiman1, Ajay Kumar Duggal2

1 2

M.Tech Scholar, Professor, Civil Engineering Department, National Institute of Technical Teachers Training and Research

Chandigarh, India

Abstract—In this paper summary of the ongoing research papers concerning the effect of various fillers on bituminous mixes

was reviewed. Depending upon the particle size fines can act as filler or extender of bitumen binder. Filler particles should be

passed through 0.075mm sieve. Filler may be added in different range expectedly from 2% to 4% in bituminous concrete. When

the quantity of filler increases in the mix, the Marshall properties of the bitumen mix may also improve directly up to certain

limits. It was concluded that various fillers such as carbon black, fibres, rubbers, polymers, fly ash, silica or their combination

may have different effects on properties of mix that is rutting behaviour, ageing characteristics and stripping behaviour etc.

Filler makes mix stiffer, moisture resistant and durable etc.

Keywords— Fillers, Voids in Mineral Aggregates (VMA), Marshall Stability value, Marshall Flow value, Asphalt.

I. INTRODUCTION

India is the second largest country in the world which has largest development in case of economy. Government has started many

projects like Pradhan Mantri Gram Sadak Yojna (PMGSY) and National Highway Development Project (NHDP) for the

development of highway structures. Due to the increase in traffic, the load on pavement is increasing day by day. Due to this life of

bituminous pavement and quality of riding surface get decreased. Durability of roads also decreases if there is any change in

weather, rainfall intensity, terrain condition and properties of soil. Therefore, for increasing the pavement life, different types of

stabilizing additives like carbon black, fibres, rubbers, polymers, fly ash, artificial silica, and brick dust or a combination of these

materials and modifiers such as polymers and fibres can be used. So in present days, for enhancing the durability of roads, different

types of fillers are using in bituminous mix at very fast rate. Generally, bituminous concrete is used to construct the expressway or

NH or roads carrying heavy traffic. Therefore, material, grading and other requirements of bituminous concrete according to

MORTH is explained in this paper. Relevant papers related to effect of fillers on bituminous mixes has been presented in this review

paper. For coarse aggregates crushed rocks, gravel or other hard material retained on 2.36mm sieve may be used because its main

function is to bear loads due to wheels, resist wear due to abrasion. Crushed material or naturally occurring material or combination

of both passing through 2.36mm sieve and retained on 75 micron sieve shall be used as fine aggregates it should be hard, clean, and

dry and free from dust or other deleterious material. The function of fine aggregates is to fill the voids which remain in coarse

aggregates. Inert material may be used as filler, whole of which passes 600μm sieve, atleast 90% passing 150μm sieve & not less

than 70% passing 75μm sieve. It may be brick dust, stone dust, cement, limestone dust, fly ash or pond ash. As the name indicates

function of fillers is to fill up the voids. Bitumen is visco-elastic material which is used as a binder. Bitumen of suitable grade

should be selected from IS: 73.

II. MATERIAL USED IN BITUMINOUS MIXES

For coarse aggregates crushed rocks, gravel or other hard material retained on 2.36mm sieve may be used because its main function

is to bear loads due to wheels, resist wear due to abrasion. Crushed material or naturally occurring material or combination of both

passing through 2.36mm sieve and retained on 75 micron sieve shall be used as fine aggregates it should be hard, clean, and dry and

free from dust or other deleterious material. The function of fine aggregates is to fill the voids which remain in coarse aggregates.

Inert material may be used as filler, whole of which passes 600μm sieve, atleast 90% passing 150μm sieve & not less than 70%

passing 75μm sieve. It may be brick dust, stone dust, cement, limestone dust, fly ash or pond ash. As the name indicates function of

fillers is to fill up the voids. Bitumen is visco-elastic material which is used as a binder. Bitumen of suitable grade should be

selected from IS: 73.

©IJRASET (UGC Approved Journal): All Rights are Reserved 1150

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor:6.887

Volume 5 Issue VIII, August 2017- Available at www.ijraset.com

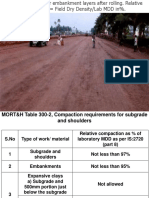

III. BITUMINOUS MIX DESIGN

Bituminous mix should be well designed so that it can withstand under the adverse conditions of traffic. Economy should be

maintained while designing the bituminous mix. The grading of materials in bituminous mix should be done in such a way so that

the resultant mix should satisfy the conditions like stability, Flow Value to meet traffic demand, sufficient bitumen content to ensure

proper binding and water proofing, voids to accommodate compaction due to traffic, sufficient workability for construction and

economical mix. Designing should be done by using Marshall Method. It involves determination of ratio in which aggregate should

be mixed to obtain the desired grading and optimum binder content. It should meet the requirements set out in Table 500-11 of

MORTH which is given in Table 1.

Table 1

MORTH Requirements for Bituminous Concrete

Property Minimum value

Marshall Stability 9.0

Value, KN

Flow Value 2-4

Marshall quotient 2-5

(Stability/Flow)

Air Voids, % 3-5

Voids in Mineral

Aggregate (VMA),%

Grading-1 10-12

Grading-2 11-13

Voids Filled with 65-75

Bitumen (VFB),%

A. Gradation of Aggregates

The gradations of aggregates used should be as per Table: 500-17 of MORTH specifications given in Table 2.

Table 2 MORTH grading for Bituminous Concrete

BC Grading-1 Grading-2

Designation

Layer 50 30-40

Thickness, mm

Sieve Size, mm Cumulative % Cumulative %

by weight of by weight of

total aggregate total aggregate

passing passing

19.0 90-100 100

13.2 59-79 79-100

9.5 52-72 70-88

4.75 35-55 53-71

2.36 28-44 42-58

1.18 20-34 34-48

0.600 15-27 26-38

0.300 10-20 18-28

0.150 5-13 12-20

0.075 2-8 4-10

Bitumen Min 5.2% Min 5.4%

Content, %

©IJRASET (UGC Approved Journal): All Rights are Reserved 1151

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor:6.887

Volume 5 Issue VIII, August 2017- Available at www.ijraset.com

IV. FINDINGS FROM THE LITERATURE REVIEW

Byong Chol Bai, Dae-Wook Park, Hai Viet Vo, Samer Dessouky, and Ji Sun Im [1] studied the thermal properties of asphalt

mixtures modified with conductive fillers. Two different mixing processes were adopted to mould asphalt mixtures, dry- and wet-

mixing, and two conductive fillers were used in this study, graphite and carbon black. Evaluation of combination of conductive filler

with carbon fibre in asphalt mixture was done. The rheological properties of modified asphalt binders with conductive fillers were

measured using dynamic shear rheometer and bending beam rheometer at grade specific temperatures. On the basis of rheological

testing, the improvement in rutting resistance and decrease thermal cracking resistance on the addition of conductive fillers was

studied. Thermal testing indicated that graphite and carbon black improve the thermal properties of asphalt mixes and the combined

conductive fillers are more effective than the single filler. Therefore, graphite and carbon black have a potential to increase rutting

resistance but decrease thermal cracking resistance. The wet-mixing process provides a better distribution of conductive filler in

asphalt mixtures; however, the dry process can be performed more simply. Debashish Kar, Mahabir Panda and Jyoti Prakash Giri [2]

studied the influence of fly-ash as filler in bituminous mixes. Control mixes with cement and stone dust were made so for

comparison. For the purpose of mix design and evaluation of paving mix Marshall Test has been considered. Other performance

tests such as indirect tensile strength and retained stability has been carried out. It has been observed that the mixes in which fly ash

was added as filler show inferior properties compared to control mixes but satisfy desired criteria specified by a much higher margin.

Hence, recommendation was made to use fly ash wherever available, as it reduces the cost of execution and solve the fly ash

disposal problems. However it has been observed that at optimum bitumen content the mixes satisfy all the Marshall criteria but the

optimum bitumen content required in case of cement and stone dust were same while for fly ash, it was slightly higher. Farag

Khodary, M.S. Abd El-sadek, H.S. El-Sheshtawy [3] explained the mechanical properties of modified asphalt concrete mixtures

using Ca(OH)2 as nanoparticles. Ca (OH)2 nanoparticles were synthesized by sol.gel method and analyzed by XRD and TEM. The

results showed significant improvement on both physical and mechanical properties of modified asphalt concrete mixtures. When

5% Ca(OH)2 nanoparticles were added, there was decrease in the penetration grade of the blend nearly by 30%. Softening point was

increased by 15°C (45%) and the viscosity was decreased by 7%. The specimens without modification had the lowest value of

indirect tensile strength, while Ca(OH)2 nanoparticles modified asphalt concrete mixtures has the highest value of indirect tensile

strength specially at modification level 4%. Finally the use of modified asphalt concrete mixtures with Ca(OH)2 was preferred in hot

climate as well as in heavy traffic load area as it may improve road mechanical properties, including rutting resistance and enhance

bitumen performance to resist high traffic loads. Hossein Zalnezhad, Saeed Sadeghpour Galooyak, Hossein Farahani, Ahmad Goli [4]

investigated the effect of nano-silica on the specification of the sasobit warm mix asphalt. In this investigation, Nano-silica has been

added in three percentages of 2%, 4% and 6% to improve the physical, rheological and mechanical properties of warm mix asphalt

(WMA) containing 2% Sasobit. The results of investigations indicated that by increasing the percentage of Nano-silica, the quality

and functionality of the warm mix asphalt has been improved. Resilient modulus of WMA was slightly increased by increasing the

Nano-silica content. So, the pavement responded towards the traffic loading at 25oC well. Crack depth at a specified load cycles was

decreased dramatically by adding the Nano-silica to the Sasobit WMA. At the same time, the stiffness of modified samples was

much lower than control WMA. The results showed that the combination of Sasobit and Nano-silica improves the rutting resistance.

Wheel track test implied that asphalt concrete with modified binders are less temperature susceptible and have less rut depth and

permanent deformation. K.B. Raghuram& Venkaiah Chowdary[5] studied the performance evaluation of stone matrix asphalt using

low cost fibres. Cellulose fibre has been used to reduce the drain down of asphalt from SMA mixes. Stability & the resistance to

rutting were evaluated. It was done by standard Marshall Procedure. By using wheel track test setup depth of rutting was checked

where rut depth achieved after 20,000 repetitions, was used to evaluate the performance of SMA mixes. SMA mixes stabilized with

FERP showed lower draindown than the SMA mixes with other fibres. FERP & jute fibres resulted in higher stability values,

resisting the permanent deformation when compared to other fibres which might replace the high cost cellulose fibres in SMA

Mix.Lt. Gen. A.K. Nanda & Lt. Col. Manoj Gupta [6] studied the performance characteristics of modified bitumen with respect to its

physical and rheological properties. In order to enhance the performance of bitumen, polymers were added. The rheological study

and characterization of bitumen was done by dynamic shear rheometer. The change in physical & rheological properties by addition

of ethylene vinyl acetate (EVA), a plastomer, linear styrene butadiene styrene (SBS), an elastomer & crumb rubber (CR) were

discussed in the paper to some extent. There was improvement in the response of binder to the loading at service temperatures after

polymer addition. Complex modulus of modified bitumen is higher as compared to neat bitumen. For low cost roads CRMB can be

used because it is cheapest binder. At high temperatures/low frequencies PMB has better performance. The addition of polymer and

CR in binder may increase its initial cost of construction but it will provide better and long lasting roads which reduces its life cycle

©IJRASET (UGC Approved Journal): All Rights are Reserved 1152

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor:6.887

Volume 5 Issue VIII, August 2017- Available at www.ijraset.com

cost, which makes it economical. Mohd Ezree Abdullah, Kemas Ahmad Zamhari, Rosnawati Buhari, Norhidayah Abdul Hassan [7]

gave review on the exploration of nanomaterials application in pavement engineering. This paper described the theory of

nanotechnology and its historical development including the method used by the researchers. The effect of different types of

nanoparticles, their suitable dosages, modifying procedures, problems and benefits on binder and mixture were explained. In

flexible pavement application, researchers focused on the modification of binder using nanoclay, nano-hydrated lime and carbon

nanoparticles. The physical property like penetration and ductility has been decreased by nanomaterials and increase softening point

value. The rheological properties such as performance grade, rutting resistance, low-temperature cracking resistance and aging

resistance also showed better improvements. There was improvement in engineering properties like stiffness, rutting resistance,

indirect tensile strength and resilient modulus. When nano-TiO2 as modifier is applied in rigid pavement it also gave positive effects.

Nano-TiO2 showed higher compressive strength when added into concrete which indicates higher abrasion resistance, higher fatigue

life as compared to controlled concrete. The use of TiO2 coating as a photocatalytic compound would also provide acceptable

durability and wear resistance. M.S. Ranadive and Honne Gowda S. [8] studied the enhancing stability of flexible pavements using

plastic waste and fly ash. To evaluate the strength and deformation Marshall Stability value and flow value was determined. Mix

with fly ash and plastic waste gave better result than mix with fly ash. AT 5% fly ash maximum stability value recorded on Marshall

test apparatus was 1560 kg and the values of flow, Percentage air voids, VMA & VFB was 2.3, 4.2%, 13.4% and 68.2%

respectively. Also bituminous mix with addition of 5% fly ash & 2% plastic gave higher value of stability 1700 kg & the values of

flow, percentage air voids, VMA & VFB is 2.4, 3.9%, 13.1% & 70.0% respectively, which were within the limits of specifications

given by MORTH.M Satyakumar, R. Satheeshchandran& K.C. Wilson [9] determined the texture depth for sand mix asphalt

modified with sulphur, slurry & fly-ash. This paper deals with the texture depth contribution to tire pavement contact. Three tests

stretches of length 275m was made for study by adding mineral fillers such as fly-ash, slurry & sulphur with beach sand & bitumen

at different combination. The analysis was made to check the effect of properties such as percentage of air voids, flow value & unit

weight on the texture depth of the experimental surface mixtures along with the skid resistance. The result of investigation showed

that it gave superior surface characteristics compared to conventional dense mix. M. Veerendra Kumar, R. Muralidhara & Divya J.

Nair [10] did the comparative study of wet and dry blending of plastic modified bituminous mix used in road pavements. In this study

engineering properties of wet mix & dry mix is evaluated. The optimum binder content observed by Marshall Test was 4.98%.

There was increase in the performance at 8% partial replacement by waste plastic in both WM & DM. DM gave better performance

in terms of fatigue, strength, stiffness by utilization of waste plastics than WM. From this waste disposal problem of plastic waste is

solved and economy in pavement construction may be achieved. P.Vilvakumar, N.Senthil, S.Lakshmi, C.Kamaraj, S.Gangopadhyay

[11]

studied the performance of sugarcane fibre in stone matrix asphalt. In this study the dosage of fibres were 3g, 5g, 7g and 10g by

weight of mix i.e. 0.26%, 0.43%, 0.6% and 0.86% by weight of mix respectively. The SMA mix of 50mm thickness made as per

MORTH specification showed good stone contact. The VMA and air voids observed were17% & 4% respectively. The drain down

values was in the range of 0.04% to 0.17% by weight of mix. 0.6% was the optimum dosage of sugarcane bagasse by weight of mix.

The range of permanent deformation was 1-2 mm & samples compacted at 160o C showed that the samples are resistant to rutting.

Ravindra Tomar, R K Jain and M K Kostha [12] studied the effect of filler on paving mix. This project stressed on the mix design

considerations. It has been observed that bituminous mixes with the non-conventional fillers such as brick, dust and silica fume gave

satisfactory result in terms of Marshall Properties & the problem of waste disposal can be solved in making bituminous concrete.

But the bitumen content needed was high. Saeed Sadeghpour Galooyak, Massoud Palassi, Hosein Zanjirani Farahani, Ahmad Goli

[13]

studied the effect of carbon nanotube on the rheological properties of bitumen. In this, carbon nanotubes of different contents

were used for the modification of the conventional bitumen. It was observed that the agglomerated Nano-materials were peeled off

and uniformly dispersed in bitumen in ultrasonic mixture. The rheological tests were done by using Dynamic Shear Rheometer & x-

ray analysis was done on the modified bitumen. Master curves were plotted, and the results showed that addition of 1.2 % by weight

of carbon nanotubes to the bitumen increased the stiffness and reduced the phase angle of base bitumen. So, the carbon nanotubes

improved the classical properties (softening point, penetration, etc.) and performance of modified bitumen compared to base binder.

S.B Patil, A.K. Vyas, A.B. Gupta, A.N. Arora, Pawan Kalla[14]studied the influence of imperial smelting furnace slag aggregate on

properties of bituminous mixes. In DBM and BC the replacement of natural aggregates was done by ISF slag from 5% to 25%, at

different binder contents. The properties of these mixes such as bulk density, stability, void content, void in mineral aggregate and

voids filled with bitumen were determined. On bituminous mixes containing ISF slag, Leachate analysis was done. 20% fine

aggregates replacement by ISF slag in BC and DBM satisfied all the criteria of MORTH Specifications. For crushing broken fine

stone aggregates economy was achieved for saving fuel, electricity, mechanical energy etc. The problem of disposal of waste can be

reduced in an environmentally acceptable manner. Y.C. Tewari& R.S. Bharadwaj[15]studied the role of nanotechnology in highway

©IJRASET (UGC Approved Journal): All Rights are Reserved 1153

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor:6.887

Volume 5 Issue VIII, August 2017- Available at www.ijraset.com

engineering. It deals with understanding, controlling & manipulating matter at the level of individual atoms & molecules in the

range of 0.1-100nm & creating materials, devices & system with new properties and functions. In this study nanotechnology and its

effects on highway engineering was explained. When nano material like carbon nano tube is added to cement it may improve its

performance. In asphalt nano material addition may enhance its mechanical performance, durability, reflectivity & skid resistance,

better binding, quicker curing, better maintenance & sustainability. Although the cost of nanotechnology is high, this may hinder

their application for highway engineering. But the benefits drawn from nanotechnology are more which can justify the additional

cost. But inappropriate vision and lack of knowledge may also affect its use in highway engineering.

V. CONCLUSIONS

After going through the studies carried out by different authors it may be concluded that use of fillers in the bituminous mixes result

in enhancement of performance of bituminous mix in one or other way. It also helps to utilize the waste material, as disposal of such

material may adversely affect the atmosphere. If graphite and carbon black are used together as filler in bituminous mix, it will

increase the rutting resistance but decrease thermal cracking resistance. Use of fly ash as filler is economical but the mix having fly

ash had inferior properties as compared to controlled mix. If cheap and non-conventional fillers are added in the mix then high

bitumen content is needed. But non-conventional fillers give economical mix and satisfy all the specified criteria. Use of nano

particles may improve the properties of mix but it may make mix uneconomical as cost of nanotechnology is presently very high.

However, since the high performing and long lasting pavements are the need of the hour, it becomes imperative to work out overall

economy on the basis of higher life and performance. Evidently use of nano particles or similar fillers may reduce the maintenance

cost of roads and increase its durability.

REFERENCES

[1] Byong Chol Bai, Dae-Wook Park, Hai Viet Vo, Samer Dessouky, and Ji Sun Im, The thermal properties of asphalt mixtures modified with conductive fillers

(Journal of Nano Material, May, 2015).

[2] Debashish Kar, Mahabir Panda and Jyoti Prakash Giri, The influence of fly-ash as filler in bituminous mixes (ARPN Journal of Engineering & Applied Sciences,

June, 2014).

[3] Farag Khodary, M.S. Abd El-sadek, H.S. El-Sheshtawy, Effect of Ca(OH)2 as nanoparticle on mechanical properties of modified asphalt concrete mixtures

(International Journal of Civil Engineering & Technology (IJCIET, May, 2014).

[4] Hossein Zalnezhad, Saeed Sadeghpour Galooyak, Hossein Farahani, Ahmad Goli, The effect of nano-silica on the specification of the sasobit warm mix asphalt

(Petroleum & Coal, ISSN 1337-7027, Nov, 2015).

[5] K.B. Raghuram& Venkaiah Chowdary, The performance evaluation of stone matrix asphalt using low cost fibres (Journal of the Indian Road Congress, July-

September, 2013).

[6] Lt. Gen.A.K. Nanda & Lt. Col. Manoj Gupta, The performance characteristics of modified bitumen with respect to its physical and rheological properties

(Indian Highways, May, 2010).

[7] Mohd Ezree Abdullah, Kemas Ahmad Zamhari, Rosnawati Buhari, Norhidayah Abdul Hassan, Review on the exploration of nanomaterials application in

pavement engineering (Journal Technology, January, 2015).

[8] M.S. Ranadive and Honne Gowda S., Enhancing stability of flexible pavements using plastic waste and fly ash (Indian Highways, Oct, 2011).

[9] M. Satyakumar, R. Satheeshchandran& K.C. Wilson, Texture depth determination for sand mix asphalt modified with sulphur, slurry & flyash (Indian

Highways, Sept, 2013).

[10] M. Veerendra Kumar, R. Muralidhara & Divya J. Nair, Comparative study of wet and dry blending of plastic modified bituminous mix used in road pavements

(Indian Highways, Dec, 2013).

[11] P.Vilvakumar, N.Senthil, S.Lakshmi, C.Kamaraj, S.Gangopadhyay, A study on the performance of sugarcane fibre in stone matrix asphalt (Indian Highways,

June, 2013).

[12] Ravindra Tomar, R K Jain and M K Kostha, The effect of filler on paving mix (International Journal of Engineering Research & Science & Technology

(IJERST), Nov, 2013).

[13] Saeed Sadeghpour Galooyak, Massoud Palassi, Hosein Zanjirani Farahani, Ahmad Goli, The effect of carbon nanotube on the rheological properties of bitumen

(Petroleum & Coal, ISSN 1337-7027, Nov, 2015).

[14] S.B Patil, A.K. Vyas, A.B. Gupta, A.N. Arora, Pawan Kalla, The influence of imperial smelting furnace slag aggregate on properties of bituminous mixes

(Indian Highways, Feb, 2009).

[15] Y.C. Tewari& R.S. Bharadwaj, Nanotechnology in highway engineering (Indian Highways, March, 2013).

[16] Ministry of Road Transport and Highways, Specifications for Road and Bridge Works, Fifth Revision, Published by IRC New Delhi, 2013.

©IJRASET (UGC Approved Journal): All Rights are Reserved 1154

You might also like

- A Review On Performance of Bituminous Mix Using E-Waste and Fly-Ash For The Flexible Pavement-IJAERDV04I0241658Document5 pagesA Review On Performance of Bituminous Mix Using E-Waste and Fly-Ash For The Flexible Pavement-IJAERDV04I0241658Editor IJAERDNo ratings yet

- Review Paper On Effect of Various Fillers On Bituminous MixesDocument5 pagesReview Paper On Effect of Various Fillers On Bituminous MixesSulaiman Musa MuhammadNo ratings yet

- Reclaimed Asphalt Pavement RapDocument10 pagesReclaimed Asphalt Pavement RapkomalNo ratings yet

- Bitumen Concrete Mix Design Using Cement and Phosphogypsum As Filler MaterialsDocument5 pagesBitumen Concrete Mix Design Using Cement and Phosphogypsum As Filler MaterialsIJAERS JOURNALNo ratings yet

- QA in Highway Sector-Part-4Document10 pagesQA in Highway Sector-Part-4boomiNo ratings yet

- Mix Design For Wearing Course of Flexible Road Pavement by Marshall MethodDocument6 pagesMix Design For Wearing Course of Flexible Road Pavement by Marshall MethodVenkat Ramana reddyNo ratings yet

- JETIR1904A26Document7 pagesJETIR1904A26mrshukla699No ratings yet

- Marshall Mix Design MethodDocument21 pagesMarshall Mix Design MethodAltaf HossainNo ratings yet

- Comparing Properties of Bituminous Concrete Mixes Prepared Using Morth and Superpave GradationsDocument8 pagesComparing Properties of Bituminous Concrete Mixes Prepared Using Morth and Superpave Gradationsmots02No ratings yet

- Module 4Document91 pagesModule 4Nitesh ShahNo ratings yet

- 001 effect-of-fillers-on-bituminous-paving-mixes-IJERTV8IS050070Document5 pages001 effect-of-fillers-on-bituminous-paving-mixes-IJERTV8IS050070Sulaiman Musa MuhammadNo ratings yet

- Basic SpecificationDocument5 pagesBasic SpecificationArunpandiyanNo ratings yet

- Bituminous Mix Design IitrDocument43 pagesBituminous Mix Design IitrSamarth Garg100% (2)

- International Journal of Scientific Eng and Tech Research - Flakiness IndexDocument8 pagesInternational Journal of Scientific Eng and Tech Research - Flakiness IndexrealchicNo ratings yet

- Experimental Investigation On Bituminous Mix Using Coconut CoirDocument8 pagesExperimental Investigation On Bituminous Mix Using Coconut CoirTJPRC PublicationsNo ratings yet

- Use of Industrial Wastes in The Construction of Flexible PavementsDocument6 pagesUse of Industrial Wastes in The Construction of Flexible Pavementssai venkateshNo ratings yet

- Effect of Varying Mixing & Compaction Temperature On Marshall Properties of Bituminous Concrete MixDocument44 pagesEffect of Varying Mixing & Compaction Temperature On Marshall Properties of Bituminous Concrete Mixshiva5059100% (1)

- Study and Experimental Analysis On BitumenDocument7 pagesStudy and Experimental Analysis On BitumenIJRASETPublicationsNo ratings yet

- Dry Mix DesignDocument7 pagesDry Mix DesignNeeraj ChaubeyNo ratings yet

- DO - 013 - S2013 Generic Specs For SmaDocument7 pagesDO - 013 - S2013 Generic Specs For SmaAndrei AlidoNo ratings yet

- 8.6.4 Coated MacadamsDocument4 pages8.6.4 Coated MacadamsFebrinaDianKurniasariNo ratings yet

- Evaluating of Rutting in Highways & Providing Its Solution in Terms of Stone Matrix Asphalt.Document7 pagesEvaluating of Rutting in Highways & Providing Its Solution in Terms of Stone Matrix Asphalt.IJRASETPublications100% (1)

- Dense Bituminous Macadam-DbmDocument14 pagesDense Bituminous Macadam-DbmCheng Engi50% (2)

- Asphalt Concrete Wearing Course RequirementsDocument29 pagesAsphalt Concrete Wearing Course RequirementsTj TalhaNo ratings yet

- Test Report: Consulting Engineers Group LTDDocument9 pagesTest Report: Consulting Engineers Group LTDImran Khan100% (1)

- Sand Replaced by Stone Dust in ConcreteDocument9 pagesSand Replaced by Stone Dust in Concreteabhishek KumarNo ratings yet

- An Experimental Study of Bituminous Mixes Using A Natural FibreDocument3 pagesAn Experimental Study of Bituminous Mixes Using A Natural FibreEditor IJTSRDNo ratings yet

- JETIR1812571Document6 pagesJETIR181257159 Vikas KumarNo ratings yet

- Use of Waste Plastic in Bituminous Concrete MixDocument51 pagesUse of Waste Plastic in Bituminous Concrete MixRahul KumarNo ratings yet

- 114-Article Text-304-1-10-20181231Document7 pages114-Article Text-304-1-10-20181231Vikas RavekarNo ratings yet

- Published PaperDocument6 pagesPublished Papersaurabh jawlekarNo ratings yet

- SDBC Design CalculationsDocument30 pagesSDBC Design Calculationsakst1976200095% (19)

- Experimental Study of Bituminous Mixes Using Natural Fibre-Ijaerdv04i0236381Document6 pagesExperimental Study of Bituminous Mixes Using Natural Fibre-Ijaerdv04i0236381Editor IJAERDNo ratings yet

- Ijciet: ©iaemeDocument6 pagesIjciet: ©iaemefndsfsbskbNo ratings yet

- Testing of Sand Quality at Construction Site For ConcreteDocument6 pagesTesting of Sand Quality at Construction Site For ConcreteHussamAlmustafaNo ratings yet

- Bitumen Concrete Mix Design Using Cement and Phosphogypsum As Filler MaterialDocument6 pagesBitumen Concrete Mix Design Using Cement and Phosphogypsum As Filler MaterialGhulam JailanNo ratings yet

- A Comparative Study On Effect of Different Fillerson Stone Matrix Asphalt MixDocument6 pagesA Comparative Study On Effect of Different Fillerson Stone Matrix Asphalt MixAdvanced Research PublicationsNo ratings yet

- Specification For Additional Asphalt 302ADocument11 pagesSpecification For Additional Asphalt 302Amelinda bulosNo ratings yet

- Design and Estimate of Modified With Pla PDFDocument13 pagesDesign and Estimate of Modified With Pla PDFshaurya sharmaNo ratings yet

- The International Journal of Science & TechnoledgeDocument7 pagesThe International Journal of Science & TechnoledgescegtsNo ratings yet

- Cement: A) Brand 2. Aggregates: A) Fine Aggregate B) Coarse Aggregate The Characteristics of Materials Are Given in Table 1 To 3Document7 pagesCement: A) Brand 2. Aggregates: A) Fine Aggregate B) Coarse Aggregate The Characteristics of Materials Are Given in Table 1 To 3Praneeth KumarNo ratings yet

- Marshall Mix Design and AnalysisDocument38 pagesMarshall Mix Design and AnalysisMoidin AfsanNo ratings yet

- Effect of Zeolite On Marshall Properties of SDBC MixDocument5 pagesEffect of Zeolite On Marshall Properties of SDBC MixIJRASETPublicationsNo ratings yet

- Experimental Investigation On Waste Utilization Ofmarble Dust in Concrete With Partially Replacement of CementDocument7 pagesExperimental Investigation On Waste Utilization Ofmarble Dust in Concrete With Partially Replacement of CementIJRASETPublicationsNo ratings yet

- Design Mix m40Document4 pagesDesign Mix m40SOIGNE ENGINEERING CONSULTANTSNo ratings yet

- Pengaruh Bahan Tambahan Anti Stripping Pada Campuran Aspal Panas Hot Rolled Sheet Wearing Course Yang Menggunakan Agregat LokalDocument11 pagesPengaruh Bahan Tambahan Anti Stripping Pada Campuran Aspal Panas Hot Rolled Sheet Wearing Course Yang Menggunakan Agregat LokalNuel RumbararNo ratings yet

- Effect of Bitumen Wax On Asphalt Mixture PerformanceDocument10 pagesEffect of Bitumen Wax On Asphalt Mixture PerformanceTomás Ignacio Nieto FloresNo ratings yet

- Experimental Investigation On The Use of Sugarcane Bagasse Ash Granite Waste As Fine Aggregate in ConcreteDocument11 pagesExperimental Investigation On The Use of Sugarcane Bagasse Ash Granite Waste As Fine Aggregate in ConcreteIJRASETPublicationsNo ratings yet

- Shafi Ullah PaperDocument5 pagesShafi Ullah PaperRawid KhanNo ratings yet

- BREN DBM Grade-IIDocument12 pagesBREN DBM Grade-IIJoydeep NeogiNo ratings yet

- Laboratory Simulation of Compaction of Bituminous Concrete Mix For Refusal Density CriteriaDocument10 pagesLaboratory Simulation of Compaction of Bituminous Concrete Mix For Refusal Density CriteriaMuhammad Maad RazaNo ratings yet

- Studies On Strength and Durability of Concrete Made With Manufactured SandDocument5 pagesStudies On Strength and Durability of Concrete Made With Manufactured SandEditor IJTSRDNo ratings yet

- Section 6. Specs. Part E. Surface CourseDocument6 pagesSection 6. Specs. Part E. Surface CourseJerosalem ParaanNo ratings yet

- Influence - of - Marble - Dust - Filler - On - Marshal - Properties - of - Hot - Mix - Asphalt - IJRASET-with-cover-page-v2Document11 pagesInfluence - of - Marble - Dust - Filler - On - Marshal - Properties - of - Hot - Mix - Asphalt - IJRASET-with-cover-page-v2revnaal444No ratings yet

- Exercise HighwayDocument7 pagesExercise HighwayOmar AbdelnabyNo ratings yet

- Asphalt Concrete Ingredient, Design, Production and LayingDocument17 pagesAsphalt Concrete Ingredient, Design, Production and LayingKali Bahadur ShahiNo ratings yet

- 2018 Baltic Journal of Road and Bridge EngineeringDocument10 pages2018 Baltic Journal of Road and Bridge EngineeringAbhinay KumarNo ratings yet

- QA in Highway Sector-Part-3Document10 pagesQA in Highway Sector-Part-3boomiNo ratings yet

- Use of Waste Polyethylene in Flexible Pavement - PPT ThesisDocument32 pagesUse of Waste Polyethylene in Flexible Pavement - PPT ThesisUday ThanganNo ratings yet

- Design and Analysis of Components in Off-Road VehicleDocument23 pagesDesign and Analysis of Components in Off-Road VehicleIJRASETPublicationsNo ratings yet

- Design and Analysis of Fixed-Segment Carrier at Carbon Thrust BearingDocument10 pagesDesign and Analysis of Fixed-Segment Carrier at Carbon Thrust BearingIJRASETPublicationsNo ratings yet

- Advanced Wireless Multipurpose Mine Detection RobotDocument7 pagesAdvanced Wireless Multipurpose Mine Detection RobotIJRASETPublicationsNo ratings yet

- IoT-Based Smart Medicine DispenserDocument8 pagesIoT-Based Smart Medicine DispenserIJRASETPublications100% (1)

- 11 V May 2023Document34 pages11 V May 2023IJRASETPublicationsNo ratings yet

- Air Conditioning Heat Load Analysis of A CabinDocument9 pagesAir Conditioning Heat Load Analysis of A CabinIJRASETPublicationsNo ratings yet

- BIM Data Analysis and Visualization WorkflowDocument7 pagesBIM Data Analysis and Visualization WorkflowIJRASETPublicationsNo ratings yet

- TNP Portal Using Web Development and Machine LearningDocument9 pagesTNP Portal Using Web Development and Machine LearningIJRASETPublicationsNo ratings yet

- Controlled Hand Gestures Using Python and OpenCVDocument7 pagesControlled Hand Gestures Using Python and OpenCVIJRASETPublicationsNo ratings yet

- Real Time Human Body Posture Analysis Using Deep LearningDocument7 pagesReal Time Human Body Posture Analysis Using Deep LearningIJRASETPublications100% (1)

- A Review On Speech Emotion Classification Using Linear Predictive Coding and Neural NetworksDocument5 pagesA Review On Speech Emotion Classification Using Linear Predictive Coding and Neural NetworksIJRASETPublicationsNo ratings yet

- Design and Development of Cost-Effective 3D-PrinterDocument7 pagesDesign and Development of Cost-Effective 3D-PrinterIJRASETPublicationsNo ratings yet

- Skill Verification System Using Blockchain SkillVioDocument6 pagesSkill Verification System Using Blockchain SkillVioIJRASETPublicationsNo ratings yet

- Design and Analysis of Fixed Brake Caliper Using Additive ManufacturingDocument9 pagesDesign and Analysis of Fixed Brake Caliper Using Additive ManufacturingIJRASETPublicationsNo ratings yet

- Skin Lesions Detection Using Deep Learning TechniquesDocument5 pagesSkin Lesions Detection Using Deep Learning TechniquesIJRASETPublicationsNo ratings yet

- Comparative in Vivo Study On Quality Analysis On Bisacodyl of Different BrandsDocument17 pagesComparative in Vivo Study On Quality Analysis On Bisacodyl of Different BrandsIJRASETPublicationsNo ratings yet

- Credit Card Fraud Detection Using Machine Learning and BlockchainDocument9 pagesCredit Card Fraud Detection Using Machine Learning and BlockchainIJRASETPublications100% (1)

- A Blockchain and Edge-Computing-Based Secure Framework For Government Tender AllocationDocument10 pagesA Blockchain and Edge-Computing-Based Secure Framework For Government Tender AllocationIJRASETPublicationsNo ratings yet

- Real-Time Video Violence Detection Using CNNDocument7 pagesReal-Time Video Violence Detection Using CNNIJRASETPublicationsNo ratings yet

- Low Cost Scada System For Micro IndustryDocument5 pagesLow Cost Scada System For Micro IndustryIJRASETPublicationsNo ratings yet

- An Automatic Driver's Drowsiness Alert SystemDocument7 pagesAn Automatic Driver's Drowsiness Alert SystemIJRASETPublications100% (1)

- Smart Video Surveillance Using YOLO Algorithm and OpenCVDocument8 pagesSmart Video Surveillance Using YOLO Algorithm and OpenCVIJRASETPublications100% (1)

- Literature Review For Study of Characteristics of Traffic FlowDocument10 pagesLiterature Review For Study of Characteristics of Traffic FlowIJRASETPublicationsNo ratings yet

- CryptoDrive A Decentralized Car Sharing SystemDocument9 pagesCryptoDrive A Decentralized Car Sharing SystemIJRASETPublications100% (1)

- Experimental Study of Partial Replacement of Cement by Pozzolanic MaterialsDocument9 pagesExperimental Study of Partial Replacement of Cement by Pozzolanic MaterialsIJRASETPublicationsNo ratings yet

- Structural Design of Underwater Drone Using Brushless DC MotorDocument9 pagesStructural Design of Underwater Drone Using Brushless DC MotorIJRASETPublicationsNo ratings yet

- Vehicles Exhaust Smoke Detection and Location TrackingDocument8 pagesVehicles Exhaust Smoke Detection and Location TrackingIJRASETPublications100% (1)

- Application For Road Accident RescueDocument18 pagesApplication For Road Accident RescueIJRASETPublications100% (1)

- Achieving Maximum Power Point Tracking With Partial ShadingDocument10 pagesAchieving Maximum Power Point Tracking With Partial ShadingIJRASETPublicationsNo ratings yet

- Preparation of Herbal Hair DyeDocument12 pagesPreparation of Herbal Hair DyeIJRASETPublications100% (1)

- Construction of Elevated Corridor in Deesa On NH-27 (KM 565+850 To KM 569+600) Dist: Banaskantha, GujaratDocument7 pagesConstruction of Elevated Corridor in Deesa On NH-27 (KM 565+850 To KM 569+600) Dist: Banaskantha, Gujaratsat palNo ratings yet

- PA&D Lec 1Document69 pagesPA&D Lec 1ZC47No ratings yet

- Irc SP 042 2014Document148 pagesIrc SP 042 2014roshanrsv100% (6)

- Final Survey ReportDocument119 pagesFinal Survey Reportbrunda gc100% (1)

- Highway Design Manual Qatar PDFDocument254 pagesHighway Design Manual Qatar PDFJazper YdioNo ratings yet

- Asset Management Manual A Guide For Practitioners: ApplicationsDocument36 pagesAsset Management Manual A Guide For Practitioners: Applicationsjorge GUILLENNo ratings yet

- Material Transfer VehiclesDocument16 pagesMaterial Transfer VehiclesEliezerChirinos100% (1)

- Los Angeles Abrasion Test On Aggregates - Values For Pavements and RoadsDocument4 pagesLos Angeles Abrasion Test On Aggregates - Values For Pavements and RoadsCarlo Dela CruzNo ratings yet

- APRG-TN13-03 Moisture Control PDFDocument2 pagesAPRG-TN13-03 Moisture Control PDFyasNo ratings yet

- 4 - 389 3M CaseDocument17 pages4 - 389 3M CaseSanjeev RanjanNo ratings yet

- TX IgDocument12 pagesTX Igpatrick mahlathiNo ratings yet

- Manipal School of Architecture and Planning, Mahe Arc 2101: Architectural Design & Detailing - Iii B. Arch: II Year/III SemesterDocument6 pagesManipal School of Architecture and Planning, Mahe Arc 2101: Architectural Design & Detailing - Iii B. Arch: II Year/III SemesterBhuvan ANo ratings yet

- Chemical AditiveDocument149 pagesChemical AditiveSamara LujanNo ratings yet

- Illinois Tollway Authority Materials SpecDocument5 pagesIllinois Tollway Authority Materials SpecBella ZakariaNo ratings yet

- Concrete Pavement:: Selection of Concrete MaterialsDocument40 pagesConcrete Pavement:: Selection of Concrete MaterialsKISHANNo ratings yet

- Urci RoadDocument10 pagesUrci Roadoche664740No ratings yet

- Transporting, Deposition, Curing and Finishing of ConcreteDocument29 pagesTransporting, Deposition, Curing and Finishing of ConcreteSathish SelvaNo ratings yet

- 8 Pavement EvaluationDocument22 pages8 Pavement EvaluationCynthiaSinagaNo ratings yet

- AMWP Form Biliran Status Report 2nd QuarterDocument23 pagesAMWP Form Biliran Status Report 2nd QuarterMico ParilNo ratings yet

- Airport Pavement Management-Enhancements To Micro PaverDocument8 pagesAirport Pavement Management-Enhancements To Micro PaverMichelfoersterNo ratings yet

- T Proc Notices Notices 040 K Notice Doc 38582 757114055Document19 pagesT Proc Notices Notices 040 K Notice Doc 38582 757114055Hawa KadiriNo ratings yet

- BA 42-96 (The Design of Integral Bridges)Document16 pagesBA 42-96 (The Design of Integral Bridges)djfeghaliNo ratings yet

- 210040117-Roller Compacted ConcreteDocument5 pages210040117-Roller Compacted Concretesahilbarbade.ee101No ratings yet

- Rsto 12Document56 pagesRsto 12Faisal AminNo ratings yet

- Plastic Roads-Seminar ReportDocument18 pagesPlastic Roads-Seminar ReportSooraj Surya78% (18)

- Viscosity Testing of Asphalt and Experience With Viscosity Graded Specifications STP532-EB.29769Document129 pagesViscosity Testing of Asphalt and Experience With Viscosity Graded Specifications STP532-EB.29769Sri RamyaNo ratings yet

- Pavement Design University of Western Australia CIVL 4121Document46 pagesPavement Design University of Western Australia CIVL 4121April IngramNo ratings yet

- User Guide: Sub-Saharan Africa Transport Policy ProgramDocument67 pagesUser Guide: Sub-Saharan Africa Transport Policy ProgramHenrique RibeiroNo ratings yet

- Dynamic Load AllowanceDocument10 pagesDynamic Load AllowanceAnNo ratings yet

- Spellnumber10m Bulo-NawoyDocument186 pagesSpellnumber10m Bulo-NawoyBeverly Nicole Dugao CutiNo ratings yet