Professional Documents

Culture Documents

Buok Chapter 2

Uploaded by

Edmil Jhon AriquezCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Buok Chapter 2

Uploaded by

Edmil Jhon AriquezCopyright:

Available Formats

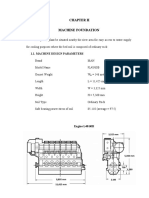

CHAPTER 2

DESIGN OF MACHINE FOUNDATION

GenSet Model: 9M25C Diesel Engine

Length of Engine: 8,125 mm

Height of Engine: 4,437 mm

Width of Engine: 1,700 mm

Weight of Engine and Generator: 54,000 kg

2.0 Solving for the Weight of the foundation, WF

The PME Code 2008 Edition Chapter2, Section 40, Article

4.1 B states that “the foundation mass should be 3 to 5 times

of the machinery it is supposed to support”. For safety-wise,

use 5 times of the machinery.

Thus,

𝑊𝐹 = 5𝑊𝑀

Where:

𝑊𝑀 =weight of the machine

𝑊𝐹 = weight of the foundation

Substituting,

𝑊𝐹 = 5(54,000𝑘𝑔)

Power Plant Engineering – Design of Diesel Power Plant 8

𝑾𝑭 = 𝟐𝟕𝟎, 𝟎𝟎𝟎𝒌𝒈

2.1 Dimension of Foundation

Upper Width, a, and Length, LF, of the Foundation:

Allow a clearance from the edge about one foot or

about 10% of the length of the bedplate

LL

b

2.1.1 Solving for length of the Foundation, LF

LF = 8,125 mm+2(0.10 x 8,125 mm)

LF = 9,750 mm or 9.750 m

Say use, 10 m

2.1.2 Solving for the width of the foundation, a

a

a = 1,700 mm+2(0.10 x 1,700 mm)

a = 2040 mm or 2.04 m

a = 2.10 m

b

2.1.3 Solving for Lower Width of the Foundation, b

WM +WF

Sb=

b(LF )

Where:

Sb= Safe Bearing Power of Soil

WM = Weight of the Machine

WF = Weight of the Foundation

Power Plant Engineering – Design of Diesel Power Plant 9

LF = Length of the Foundation

From Table 4-4 of PPE by Morse, p. 105, the safe bearing

power of soil is within the range of 19.5-58.5 tonnes/m2. For

safety design, the designers decided to use 58.5 tonnes/m2.

For safety machine foundation, the soil bearing capacity

should be ½ the allowance value.

Thus,

𝑆𝑏 WM +WF

=

2 b(LF )

2(𝑊𝑀 + 𝑊𝐹 )

𝑏=

𝑆𝑏 𝐿𝐹

2(270𝑡𝑜𝑛𝑛𝑒𝑠 + 540𝑡𝑜𝑛𝑛𝑒𝑠)

𝑏= 𝑡𝑜𝑛𝑛𝑒𝑠

(46.9 )(10𝑚)

𝑚2

𝑏 = 1.38𝑚

Say use, 𝒃 =1.40 m

Since the lower width “b” come out to be less than the

upper width “a”, it is customary to make “b” equal to “a”,

that is the foundation has rectangular cross-section.

𝒂 = 𝒃 = 𝟐, 𝟏𝟎𝟎 𝒎𝒎 = 𝟐. 𝟏𝟎 𝒎

2.1.4 Volume of the Rectangular Foundation, VF:

WF

VF =

PF

Where:

WF = Weight of the foundation

PF = Density of the concrete, 2406 kg/m3

Substituting,

Power Plant Engineering – Design of Diesel Power Plant 10

270,000 kg

VF = kg⁄

2,406 m3

VF = 112.22 m3

2.1.5 Height of the Rectangular Foundation, h:

VF

h=

LF x a

Where:

VF = Volume of the foundation

LF = Length of the foundation

Substituting,

112.22 m3

h=

10 m x 2.10 m

h = 5.4 m

2.1.6 Area of the Rectangular Foundation, AF:

AF = LF x a

Where:

AF = Length of the foundation

a = Upper width of the foundation

Substituting,

AF = 10 m x 2.10 m

AF = 21 m2

2.1.7 Net Weight Imposed by the Machine and Foundation on

Soil, Wnet:

Wnet= WM + WF

Where:

WM = Weight of the machine

WF = Weight of the foundation

Power Plant Engineering – Design of Diesel Power Plant 11

Substituting,

Wnet = 54 tonnes + 270 tonnes

Wnet= 324 tonnes

2.1.8 Pressure Exerted by the Machine and Foundation on

Soil,Si:

Wnet

Si =

AF

Where:

AF = Area of the foundation

Substituting,

324 tonnes

Si =

21 m2

Si = 15.42 tons⁄m2

2.1.9 Foundation Factor of Safety, FS:

Sb

FS=

Si

Where:

Sb = Safe soil bearing capacity

Si= Stress imposed by machine and

foundation on soil

Substituting,

58.5 tons⁄m2

FS=

(15.42 tons⁄m2 )

FS = 5.54

Based on the foregoing computation, the foundation is

concluded to be safe since its factor of safety exceeds the

allowable factor of safety discussed in PSME code, 2008

Edition, Chapter 2, Section 4.0, Article 4.1 which is 5.

Power Plant Engineering – Design of Diesel Power Plant 12

Dimensions of Machine Foundation

Foundation Geometrical Figure Rectangle

Height of foundation 5.4 m

Width of foundation 1.4 m

Length of foundation 10 m

Material Estimates for Machine Foundation

2.2 Determine the Amount of Cement, Sand and Stone in the

Foundation:

From PME Code, 2008 Edition, page 12, Section 4.2:

The foundation should be concrete, of 1 part cement, 2

parts sand and 4 parts broken stone or gravel (maximum of 50

mm; the entire foundation should be poured at one time, with

no interruption than are required for spading and ramming.

Table 4-1: DATA ON CONCRETE MIXES TO YIELD 1 CU M CONCRETE

(Power Plant Engineering by Frederick T. Morse)

Mixture Cement, Sand, Stone, Application Weight, Safe

Sacks yd3 yd3 t/m3 Comp.

Stress,

t/m2

1:2:4 4.8 0.44 0.88 R.C Floors, 2.66 328.10

Beams and

Columns

2.2.1Quantity of Cement, No. of Sacks, NSC:

NSC = VF x 7.8 sacks/m3

Where:

VF = Volume of foundation, 112.22 m3

Substituting,

NSC = 112.22 m3 x 7.8 sacks/m3

NSC = 875.316 sacks

NSC = 876 sacks/foundation

Power Plant Engineering – Design of Diesel Power Plant 13

NSC = 876 sacks (4 + 1 reserve)

NSC = 4,380 sacks

2.2.2 Quantity of Sand, Volume of Sand, VS:

VS = VF x 0.44 m3 sand

VS = 112.22 m3 x 0.44 sand

VS = 49.3768 m3 sand

VS = 50 m3 /foundation

VS = 50 m3(4+1 reserve)

VS = 250 m3 sand

2.2.3 Quantity of Stone, Volume of Stone, VST:

VST = VF x 0.88 m3 stone

VST = 112.22 m3 x 0.88 m3 stone

VST = 98.7536 m3stone

VST = 99 m3/foundation

VST = 99m3(4+1 reserve)

VST = 495 m3 stone

2.3 Steel Bar Reinforcement

2.3.1Weight of the Steel Bar Reinforcements, WSBR:

From PME Code, 2008 Edition, page 11, Section 4.1f:

“Concrete foundations should have steel bar

reinforcements placed both vertically and horizontally, to

avoid thermal cracking. Weight of reinforcing steel should be

from 0.5% to 1% of the weight of the foundation.”

For safety design, use the average which is 0.75%.

WSBR = 0.75% WF

WSBR = 0.0075 (270,000kg)

WSBR = 2025 kg

Power Plant Engineering – Design of Diesel Power Plant 14

2.3.2 Volume of the Steel Bar Reinforcements, VSBR:

From Kent’s Mechanical Engineering Handbook, Production

Volume, Page 6-02, the density of structural steel is equal

to 490 lb/ft3.

Weight of steel bar reinforcement

VSBR =

Density of steel

2025 kg x 2.2 lb⁄kg

VSBR =

lb (3.281)3 ft3

490 x

ft3 1m3

VSBR= 0.26 m3

2.3.3Volume of the Steel Bar Reinforcements per Piece, VRPP:

Say use, Standard size of steel bar reinforcements with

standard diameter equal to 16 mm and length of 6 m.

πDb 2 Lb

VRPP =

4

Where:

Db = diameter of steel bar

Lb = length of steel bar

Substituting,

π(0.016m)2 (6m)

VRPP =

4

VRPP = 0.001206 m3/piece

2.3.4 Total Number of Steel Bar Reinforcements, TSBR:

Volume of steel bar reinforcements

TSBR =

volume of steel bar reinforcements per piece

0.26 m3

TSBR = 3

0.001206 m ⁄piece

TSBR = 215.6 pieces

Power Plant Engineering – Design of Diesel Power Plant 15

TSBR = 216 pieces/foundation

TSBR = 216 pieces(4 units)

TSBR = 864 pieces

2.4 Anchor Bolts

2.4.1 Selection of Anchor Bolts:

From PME Code, 2008 Edition, page 13, Section 4.2:

“To prevent pulling out of the bolts when the nuts are

tightened, the length embedded in concrete shall be equal to

or more than thirty (30) times the bolt diameter.”

For Standard Specification of Anchor Bolts.

2.4.2 Diameter of anchor bolts, DAB:

Say use, DAB = 1 inch or 25.0 mm

2.4.3 Length of anchor bolt imbedded in concrete, LAB:

From PME Code 2008 Edition “the length embedded in

concrete shall be equal to or more than thirty (30) times the

bolt diameter”.

Standard length for 1-inch anchor bolt diameter is equal

to 36-inches

Therefore:

LAB = 36 inches

Power Plant Engineering – Design of Diesel Power Plant 16

Other dimensions of anchor bolt of 1-inch diameter.

Hook, C = 4 inches

Thread, T = 6 inches

2.4.4 Total Length of Anchor Bolts, LTAB:

LTAB = L + C

LTAB = 36 in + 4 in

LTAB = 40 inches

2.4.5 Quantity of Bolts, BQ:

Assuming that there are 3 bolts per meter of the bedplate.

Perimeter of Rectangular Foundation

𝑃 = 2𝐿 + 2𝑊

𝐵𝑄 = 𝑃 × 3 𝑏𝑜𝑙𝑡𝑠⁄𝑚𝑒𝑡𝑒𝑟

𝐵𝑄 = (2𝐿 + 2𝑊) × 3 𝑏𝑜𝑙𝑡𝑠⁄𝑚𝑒𝑡𝑒𝑟

Where:

W = width of bedplate

L = length of bedplate

Substituting,

BQ = [2(8.125m) + 2(1.7m)] × 1 bolts⁄meter

BQ = 20 bolts

BQ = 20 pcs/bedplate

BQ = 20 pcs(4 + 1 reserve)

BQ = 100 pieces

2.4.6 Diameter of Pipe Sleeves, DPS:

“the diameter of pipe sleeve should at least three (3)

times the diameter of anchor bolt”.

𝐷𝑃𝑆 = 3𝐷𝐴𝐵

𝐷𝑃𝑆 = 3(1𝑖𝑛)

𝑫𝑷𝑺 = 𝟑inches or 76 mm

Power Plant Engineering – Design of Diesel Power Plant 17

2.4.7 Length of Pipe Sleeve

“the total length of pipe sleeve is at least 18 times the

diameter of bolts”.

𝐿𝑃𝑆 = 18𝐷𝐴𝐵

𝐿𝑃𝑆 = 18(1𝑖𝑛)

𝑳𝑷𝑺 = 𝟏𝟖𝒊𝒏 or 457 mm

2.4.8 Total Length of Pipe Sleeve, LPS:

With the total number of bolts used in each foundation

bedplate, the total length of the pipe sleeve to be used will

be,

TLPS = length of pipe sleeve x BQ

Where:

BQ = total number of bolts

Substituting,

TLPS = 18 in (100 pcs)

0.0254𝑚

𝑇𝐿𝑃𝑆 = 6,480𝑖𝑛 ×

1𝑖𝑛

𝑻𝑳𝑷𝑺 = 𝟏𝟔𝟒. 𝟓𝟗𝟐𝒎

2.4.9 Quantity of Pipe Sleeve, PSQ:

Using the commercial standard pipe length which is 20

feet per piece.

total length of pipe sleeve

PSQ = standard length of pipe sleeve

3.281 ft

164.592 m ( )

1 m

PSQ = ft

20 ⁄pc

PSQ = 27pieces

2.5 Grouting

Machine should be leveled by driving wedges between the

machine’s base and the concrete foundation and with the aid

of a spirit level. Grout all spaces under the machine bed

with a thin mixture of one part cement and two parts of sand.

Power Plant Engineering – Design of Diesel Power Plant 18

The level wedges should be removed after the grout has

thoroughly set and fill wedges’ holes with grout.

Foundation should be isolated from floor slabs or

building footings by at least 25 mm around its perimeter to

eliminate transmission of vibration.

“Grouting is a process of filling a small clearance

between the machine and the foundation with a hardening

mixture. Grout is usually made of a 2:1 mixture of sand and

cement, mixed wet enough to be fully fluid.”, from PPE by

Frederick T. Morse, Page 112.

2.5.1 Volume of the Grout, VG:

Using a standard thickness of the grout to be 25 mm.

VG = grout thickness x AF

Where:

AF = area of foundation

Substituting,

VG = 0.025m x 34.52m2

VG = 0.863 m3/foundation

VG = 0.863 m3 (4 + 1 reserve)

VG = 4.315 m3

2.6 Quantity of Tire Wire (G.I wire)

From Architectural and Cons. data by G. Salvan and S.

Thapa, Pg. 657, Estimate Guide for Lay-out and

Scaffoldings.

“For the tie wire, multiply the horizontal bar to the

number of vertical bars, this gives the number of connections.

Then multiply by 0.40 to get the total length of G.I. wire.

Then divide by 126 to get the number of G.I. wire.

2.6.1 For the Number of Connection,

Power Plant Engineering – Design of Diesel Power Plant 19

Number of connection = Vertical bars x Horizontal bars

3.041 11.352

Number of connection = 0.5 × 0.5

3.28 3.28

Number of connection = 1,486 connections

2.6.2 Total Length of G.I. wire,

Total Length of G.I. wire = 1,486 (0.4)

Total Length of G.I. wire = 595 m

2.6.3 Total Weight of G.I. wire,

595m

Total Weight of G.I. wire = 126m/kg

Total Weight of G.I. wire = 4.72kgs

Say use, Total Weight of G.I. wire = 4.75kgs

2.7 Quantity of Plywood to be used in Foundation

2.7.1 Solving for the Surface Area of the Machine Foundation

where the plywood would serve as a guide of foundation.

SAMF = 2(b × hf ) + 2(hf × Lf )

SAMF = 2(3.041m × 3.25m) + 2(3.25m × 11.352m)

𝐒𝐀 𝐌𝐅 = 𝟗𝟑. 𝟓𝟓𝟒𝟓𝒎𝟐 𝑜𝑟 (𝟏, 𝟎𝟎𝟔. 𝟓𝒇𝒕𝟐 )

2.7.2 Area of Plywood

𝐴𝑝 = 4𝑓𝑡 × 8𝑓𝑡

𝑨𝑷 = 𝟑𝟐𝒇𝒕𝟐 (2.974𝒎𝟐 )

From Architectural and Construction Data by G. Salvan and

S. Thapa, p.657, Estimate Guide for Layout and Scaffoldings

1 Surface Area of Foundation

No. of Pcs. of 2 in. Plywood = Area of Plywood

Power Plant Engineering – Design of Diesel Power Plant 20

1 1,006.5𝑓𝑡 2

No. of Pcs. of 2 in. Plywood = 32𝑓𝑡 2

1

No. of Pcs. of 2 in. Plywood = 31.45

Say use, No. of Pcs. Of 1/2 in. Plywood = 32 pieces

2.8 QUANTITY OF REINFORCED LUMBER

2.8.1 For Scaffoldings use: 2”×3” ×12’

From Architectural and Construction Data by G. Salvan and

S. Thapa, p.657,it is stated that, to get the board feet of

2”×3” of lumber, multiply the total area of plywood in 60%

Thus,

Total board feet of 2” × 3” lumber = 1,006.5𝑓𝑡 2 (0.6)

Total board feet of 2” × 3” lumber = 603.9𝑓𝑡 2

Therefore, the quantity of 2” ×3” × 12′ lumber required

603.9𝑓𝑡 2

= 6board feet/𝑝𝑐𝑠

= 101 pieces

2.9 QUANTITY OF NAILS REQUIRED

2.9.1 Quantity of Nails for Plywood

As recommended by Salvan and Thapa Architectural and

Construction Data, p. 657

Total area of plywood(m2 )

No. of kegs of 2"C. W. nails = 2303

Where:

1kegs= 45.5 kg of nails

93.5545𝑚2

No. of kegs of 2"C. W. nails = 2303

No. of kegs ofNo. of kegs of 2"C. W. nails = 0.040623kegs

45.5kg

No. of kegs of 2"C. W. nails = 0.040623kegs × 1kegs

No. of kegs of 2"C. W. nails = 1.85kg

Say use, 2 kilograms of #2 nails

Power Plant Engineering – Design of Diesel Power Plant 21

2.9.2 Quantity of Nails for Lumber

Total Board Foot of Lumber

No. of kegs ofNo. of kegs of 4"C. W. nails = 2800

603.9𝑓𝑡 2

No. of kegs ofNo. of kegs of 4"C. W. nails = 2800

45.5kg

No. of kegs ofNo. of kegs of 4"C. W. nails = 0.2157kegs × 1keg

No. of kegs ofNo. of kegs of 4"C. W. nails = 9.81kg

Say use, 10 kilograms of #4 nails

Power Plant Engineering – Design of Diesel Power Plant 22

You might also like

- Machine FoundationDocument6 pagesMachine FoundationJohn Nolan Sagun67% (3)

- Designing A Machine Foundation For A 10Document5 pagesDesigning A Machine Foundation For A 10frexis11100% (2)

- Designing a Diesel Generator FoundationDocument18 pagesDesigning a Diesel Generator FoundationjomilanNo ratings yet

- Machine Foundation Design Computation v1Document16 pagesMachine Foundation Design Computation v1Lloyd CruzetNo ratings yet

- MDM Method ExcelDocument22 pagesMDM Method ExcelJonathan Q CorpinNo ratings yet

- Machine FoundationDocument5 pagesMachine FoundationVon Eric DamirezNo ratings yet

- Juan Martin Garcia System Dynamics ExercisesDocument294 pagesJuan Martin Garcia System Dynamics ExercisesxumucleNo ratings yet

- Machine Foundation of Diesel Power PlantDocument9 pagesMachine Foundation of Diesel Power PlantLorenzo Lacorte100% (1)

- Machine FoundationDocument9 pagesMachine FoundationMarc Graham Nacua0% (2)

- Genset Foundation ComputationDocument7 pagesGenset Foundation ComputationJan Felix DonsalNo ratings yet

- Nikola Tesla Was Murdered by Otto Skorzeny.Document12 pagesNikola Tesla Was Murdered by Otto Skorzeny.Jason Lamb50% (2)

- Internal Audit ChecklistDocument18 pagesInternal Audit ChecklistAkhilesh Kumar75% (4)

- FP-XH PGRG eDocument936 pagesFP-XH PGRG ebvladimirov85No ratings yet

- Foundation ComputationDocument10 pagesFoundation ComputationCris TopperNo ratings yet

- Foundation For Agricultural MachinesDocument22 pagesFoundation For Agricultural MachinesMac allan ramosNo ratings yet

- Design of FoundationDocument8 pagesDesign of FoundationNIVRA CALUYONo ratings yet

- Iv. Machinery Foundation Learning Outcome: I. Definition of FoundationDocument11 pagesIv. Machinery Foundation Learning Outcome: I. Definition of FoundationRab Bel As J.No ratings yet

- Machine FoundationDocument12 pagesMachine FoundationEdward Razorhands100% (1)

- Foundation Design ComputationDocument1 pageFoundation Design ComputationMark Kevin BechaydaNo ratings yet

- Structural Design of FootingsDocument82 pagesStructural Design of FootingsRafi Sulaiman100% (1)

- Bolted Connection Design & Analysis MethodsDocument3 pagesBolted Connection Design & Analysis MethodsJohn Philip NuñezNo ratings yet

- Buok Chapter 3Document44 pagesBuok Chapter 3Edmil Jhon AriquezNo ratings yet

- Shear Strength TheoryDocument32 pagesShear Strength TheoryChikkanna TNo ratings yet

- Machine FoundationDocument24 pagesMachine FoundationMASILAMANI T100% (1)

- Assignment 2Document5 pagesAssignment 2Noraishah Syahirah Azhar100% (1)

- Undamped Forced VibrationDocument10 pagesUndamped Forced VibrationnadineNo ratings yet

- Tensile Compressive Strength DeterminationDocument7 pagesTensile Compressive Strength DeterminationSleepy SpettoNo ratings yet

- EQUAKEDocument64 pagesEQUAKERouvelle TanyagNo ratings yet

- 5.clock, Variation and Progression PDFDocument17 pages5.clock, Variation and Progression PDFAmpolNo ratings yet

- Thermo Solutions - Part7 PDFDocument1 pageThermo Solutions - Part7 PDFLiz ArfinNo ratings yet

- APARTMENT SLAB DESIGN CALCULATIONSDocument9 pagesAPARTMENT SLAB DESIGN CALCULATIONSApple Grace S. ValenciaNo ratings yet

- Case StudyDocument10 pagesCase StudyKristoffer VillegasNo ratings yet

- Ppe MorseDocument413 pagesPpe MorseNakanakanaknak100% (2)

- Module 4. Lesson 1 Properties of FuelsDocument6 pagesModule 4. Lesson 1 Properties of FuelsVJ CarbonellNo ratings yet

- Mechanics (Dynamics)Document2 pagesMechanics (Dynamics)Earl JennNo ratings yet

- Steel Design Handout Chapters 1 3Document119 pagesSteel Design Handout Chapters 1 3Hannan Sarrondo VitugNo ratings yet

- MODULE V Draft SystemDocument12 pagesMODULE V Draft SystemRyan Calica100% (1)

- PROBLEM 2.93: SolutionDocument41 pagesPROBLEM 2.93: SolutionCharbel Abou KhalilNo ratings yet

- From Table AT7 - Design of Machine Elements of Faires For AISI C1045 - S 96 Ksi - S 59 Ksi - E 30 x10 Psi A) Based On Ultimate StrengthDocument4 pagesFrom Table AT7 - Design of Machine Elements of Faires For AISI C1045 - S 96 Ksi - S 59 Ksi - E 30 x10 Psi A) Based On Ultimate StrengthMark AgusNo ratings yet

- POWER PlantDocument26 pagesPOWER PlantChincel G. ANINo ratings yet

- Designing Bevel Gears for a Speed ReducerDocument17 pagesDesigning Bevel Gears for a Speed ReducerherrerafaridNo ratings yet

- Bulk Modulus of Elasticity ProblemsDocument1 pageBulk Modulus of Elasticity ProblemsEdbert TulipasNo ratings yet

- Power Plant UpgradeDocument39 pagesPower Plant UpgradeNathaniel Baguio100% (1)

- Wf-Section Compression Strength LRFD Method Per NSCP 2015 Edition (S.I. Units) Developed By: Joel M. Regino, CE, RMPDocument1 pageWf-Section Compression Strength LRFD Method Per NSCP 2015 Edition (S.I. Units) Developed By: Joel M. Regino, CE, RMPjoel reginoNo ratings yet

- Thin-Walled - Thick Walled Pressure VesselDocument16 pagesThin-Walled - Thick Walled Pressure VesselMark Niño JavierNo ratings yet

- KONTRAKCH2Document4 pagesKONTRAKCH2Mark Laurence Recio100% (1)

- ME 518-PlatesDocument13 pagesME 518-PlatesGraceeNo ratings yet

- 476304-Power Plant Engineering by Morse PDFDocument637 pages476304-Power Plant Engineering by Morse PDFRv PilongoNo ratings yet

- Buok Chapter 4Document21 pagesBuok Chapter 4Edmil Jhon AriquezNo ratings yet

- Strength Materials: Modular RatioDocument9 pagesStrength Materials: Modular RatioSuraj KumarNo ratings yet

- Entrance Exam2Document13 pagesEntrance Exam2Shrinath Singanamalli100% (1)

- Sample Problems:: SG 0.90 SG 0.0Document1 pageSample Problems:: SG 0.90 SG 0.0Jessa San PedroNo ratings yet

- Theorem PappusDocument59 pagesTheorem PappusArijit SantraNo ratings yet

- ESAS - Sample Problems in Statics and MechanicsDocument3 pagesESAS - Sample Problems in Statics and MechanicsKYLE LEIGHZANDER VICENTE100% (1)

- Module 3 - Lubrication & Journal Bearings: Isat U Me - Me 413A Machine Design 2 - Lecture Notes OnlyDocument6 pagesModule 3 - Lubrication & Journal Bearings: Isat U Me - Me 413A Machine Design 2 - Lecture Notes OnlyGeoffrey GolbequeNo ratings yet

- Genset FoundationDocument1 pageGenset FoundationAshish MNo ratings yet

- Chapter 3Document8 pagesChapter 3Jerome CansadoNo ratings yet

- Block ShearDocument6 pagesBlock ShearVermuch CasioNo ratings yet

- Lyka Chapter 2 DieselDocument17 pagesLyka Chapter 2 DieselRuby Jane LuchingNo ratings yet

- Design of Pile FoundationDocument16 pagesDesign of Pile FoundationJagal Udaya100% (3)

- BS5950 End Plate DesignDocument4 pagesBS5950 End Plate DesignSimon Lsm67% (3)

- DESIGN OF CIRCULAR WATER TANK USING GFRP BARSDocument35 pagesDESIGN OF CIRCULAR WATER TANK USING GFRP BARSmohammed samiNo ratings yet

- Design of Pile FoundationDocument16 pagesDesign of Pile FoundationHani AboobackerNo ratings yet

- Micropile design for run-off basin tensionDocument12 pagesMicropile design for run-off basin tensionqsultan100% (1)

- Result: QX P X 1 X 1Document1 pageResult: QX P X 1 X 1Aaron Nah ColliNo ratings yet

- Sugarcane Processing GuideDocument7 pagesSugarcane Processing GuideYogendra JaiswalNo ratings yet

- A Simple Method To Solve Quartic Equations: June 2012Document7 pagesA Simple Method To Solve Quartic Equations: June 2012Edmil Jhon AriquezNo ratings yet

- Edmil Jhon B. Ariques, ME: MembershipDocument2 pagesEdmil Jhon B. Ariques, ME: MembershipEdmil Jhon AriquezNo ratings yet

- Edmil Jhon B. Ariques, ME: MembershipDocument3 pagesEdmil Jhon B. Ariques, ME: MembershipEdmil Jhon AriquezNo ratings yet

- Result: QX P X 1 X 1Document1 pageResult: QX P X 1 X 1Aaron Nah ColliNo ratings yet

- Fil7 PDFDocument1 pageFil7 PDFEdmil Jhon AriquezNo ratings yet

- Edmil Jhon B. Ariques, ME: MembershipDocument2 pagesEdmil Jhon B. Ariques, ME: MembershipEdmil Jhon AriquezNo ratings yet

- Verification of Board RatingsDocument1 pageVerification of Board RatingsEdmil Jhon AriquezNo ratings yet

- Laws of ThermodynamicsDocument6 pagesLaws of ThermodynamicsEdmil Jhon AriquezNo ratings yet

- Edmil Jhon B. Ariques, ME: MembershipDocument2 pagesEdmil Jhon B. Ariques, ME: MembershipEdmil Jhon AriquezNo ratings yet

- Heavy Equipment Safety Training HandbookDocument22 pagesHeavy Equipment Safety Training HandbookFajrin M. Natsir100% (1)

- Curriculum VitaeDocument2 pagesCurriculum VitaeEdmil Jhon AriquezNo ratings yet

- ResumeDocument2 pagesResumeEdmil Jhon AriquezNo ratings yet

- Lecture 3-Rubber Processing-Ch14Document41 pagesLecture 3-Rubber Processing-Ch14Mohit Kohli100% (2)

- Merry Christmas YeahDocument1 pageMerry Christmas YeahEdmil Jhon AriquezNo ratings yet

- Electric Force and ColoumbDocument1 pageElectric Force and ColoumbEdmil Jhon AriquezNo ratings yet

- Remittance Advice - EMILY BANO ARIQUEZ PDFDocument1 pageRemittance Advice - EMILY BANO ARIQUEZ PDFEdmil Jhon AriquezNo ratings yet

- Introduction To Plastics Processing.Document55 pagesIntroduction To Plastics Processing.Edmil Jhon AriquezNo ratings yet

- 14 Tips To Make Your Monitor More Healthy For The EyesDocument38 pages14 Tips To Make Your Monitor More Healthy For The Eyestavdeash238No ratings yet

- Ohm's Law and Resistance ExplainedDocument3 pagesOhm's Law and Resistance ExplainedEdmil Jhon AriquezNo ratings yet

- Laws of ThermodynamicsDocument6 pagesLaws of ThermodynamicsEdmil Jhon AriquezNo ratings yet

- Rotary dryer most common dryer usedDocument352 pagesRotary dryer most common dryer usedWati KaNo ratings yet

- Remittance Advice - EMILY BANO ARIQUEZ PDFDocument1 pageRemittance Advice - EMILY BANO ARIQUEZ PDFEdmil Jhon AriquezNo ratings yet

- BIRForm PD R590912 A646001 732784 Apr-04-04-54-48Document1 pageBIRForm PD R590912 A646001 732784 Apr-04-04-54-48Edmil Jhon AriquezNo ratings yet

- Remittance Advice - Emily Bano AriquezDocument1 pageRemittance Advice - Emily Bano AriquezEdmil Jhon AriquezNo ratings yet

- BIRForm PD R590912 A646001 732784 Apr-04-04-54-48Document1 pageBIRForm PD R590912 A646001 732784 Apr-04-04-54-48Edmil Jhon AriquezNo ratings yet

- Remittance Advice - Emily Bano AriquezDocument1 pageRemittance Advice - Emily Bano AriquezEdmil Jhon AriquezNo ratings yet

- Grade 8 Student Performance Word Games Assessment Tool Test ScoresDocument1 pageGrade 8 Student Performance Word Games Assessment Tool Test ScoresEdmil Jhon AriquezNo ratings yet

- Remittance Advice - Emily Bano AriquezDocument1 pageRemittance Advice - Emily Bano AriquezEdmil Jhon AriquezNo ratings yet

- BCP-8000 User's ManualDocument36 pagesBCP-8000 User's ManualAsad PatelNo ratings yet

- Diia Specification: Dali Part 252 - Energy ReportingDocument15 pagesDiia Specification: Dali Part 252 - Energy Reportingtufta tuftaNo ratings yet

- 7890 Parts-Guide APDocument4 pages7890 Parts-Guide APZia HaqNo ratings yet

- 07.03.09 Chest Physiotherapy PDFDocument9 pages07.03.09 Chest Physiotherapy PDFRakesh KumarNo ratings yet

- T9001 T9002 T9003 T9004: Tecn# Originator Title Aging Status of TecnDocument2 pagesT9001 T9002 T9003 T9004: Tecn# Originator Title Aging Status of TecnThanalachmy GopiNo ratings yet

- Direct From: 1St Quarter 2020Document23 pagesDirect From: 1St Quarter 2020JeanNo ratings yet

- Introduction To Finite Element Methods (2001) (En) (489s)Document489 pagesIntroduction To Finite Element Methods (2001) (En) (489s)green77parkNo ratings yet

- Clean Milk ProductionDocument19 pagesClean Milk ProductionMohammad Ashraf Paul100% (3)

- CP 343-1Document23 pagesCP 343-1Yahya AdamNo ratings yet

- Maintenance Handbook On Compressors (Of Under Slung AC Coaches) PDFDocument39 pagesMaintenance Handbook On Compressors (Of Under Slung AC Coaches) PDFSandeepNo ratings yet

- DNB Paper - IDocument7 pagesDNB Paper - Isushil chaudhari100% (7)

- Pioneer XC-L11Document52 pagesPioneer XC-L11adriangtamas1983No ratings yet

- 1"a Study On Employee Retention in Amara Raja Power Systems LTDDocument81 pages1"a Study On Employee Retention in Amara Raja Power Systems LTDJerome Samuel100% (1)

- VT6050 VT6010 QuickGuide ENDocument19 pagesVT6050 VT6010 QuickGuide ENPriyank KumarNo ratings yet

- Stability Calculation of Embedded Bolts For Drop Arm Arrangement For ACC Location Inside TunnelDocument7 pagesStability Calculation of Embedded Bolts For Drop Arm Arrangement For ACC Location Inside TunnelSamwailNo ratings yet

- مقدمةDocument5 pagesمقدمةMahmoud MadanyNo ratings yet

- SOIL ASSESSMENT AND PLANT PROPAGATION OF BELL PEPPERS (Capsicum Annuum)Document35 pagesSOIL ASSESSMENT AND PLANT PROPAGATION OF BELL PEPPERS (Capsicum Annuum)Audrey Desiderio100% (1)

- What Is DSP BuilderDocument3 pagesWhat Is DSP BuilderĐỗ ToànNo ratings yet

- Seed SavingDocument21 pagesSeed SavingElectroPig Von FökkenGrüüven100% (2)

- Lightwave Maya 3D TutorialsDocument8 pagesLightwave Maya 3D TutorialsrandfranNo ratings yet

- Reinforced Concrete Beam DesignDocument13 pagesReinforced Concrete Beam Designmike smithNo ratings yet

- Laser Surface Treatment ProcessesDocument63 pagesLaser Surface Treatment ProcessesDIPAK VINAYAK SHIRBHATENo ratings yet

- Handouts For TLG 3 1Document5 pagesHandouts For TLG 3 1Daniela CapisnonNo ratings yet

- Sri Radhakrishna SwamijiDocument43 pagesSri Radhakrishna SwamijiNarayana IyengarNo ratings yet

- Reflective Essay 4Document1 pageReflective Essay 4Thirdy AngelesNo ratings yet

- Transport of OxygenDocument13 pagesTransport of OxygenSiti Nurkhaulah JamaluddinNo ratings yet