Professional Documents

Culture Documents

Jsa Micet Fyp

Uploaded by

Amirou RaizoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Jsa Micet Fyp

Uploaded by

Amirou RaizoCopyright:

Available Formats

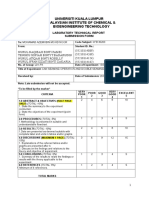

Reference Number-

JOB SAFETY / HAZARD ANALYSIS &

RISK ASSESSMENT FORM

UNIVERSITY OF KUALA LUMPUR

(MICET)

Safety data sheets for NEW chemicals used in your project (and NOT available in the

laboratory) need to be attached WITH this form.

Once this assessment has been signed by you, a technician, your project supervisor and

safety health officer; an assigned reference number will be given, please submit:

the original document of this assessment to be kept by you.

The copy of the document of this assessment to TECHNICIAN IN-CHARGED [TIC]

of main laboratory used; to be kept in the laboratory safety file.

If more than one laboratory used in this project, submit a copy of this document to

the TIC to be kept in the laboratory safety file.

Ensure this assessment is resubmitted for approval when work out of office hour.

Ensure this assessment is read and signed annually by all concerned.

Postgraduate student is required to submit After hours risk management procedure

together with this submission.

Ensure this assessment is reviewed annually by the project supervisor for posrgraduate.

Remember that anything that you put in this form you must follow!

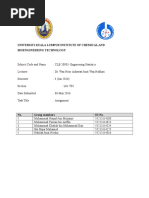

1. Title of Research Project

Preparation of Filter Medium from Sawdust Cellulose for Surface Water

2. Name of Supervisor

Supervisor Dr. Indok Nurul Hasyimah Binti Mohd Amin

Co supervisor

JSA FORM revision 8 ( Feb 2017) 1

3. Details information

Name Mohamad Nazrin Bin Rahmad

Researcher Identification No. Student ID: 55213115038

[Student ID – UniKL MICET or I/C No: 940504-14-5167

IC No – others]

Contact No. 0176415980

UniKL MICET (Program) PROCESS

External Researcher

( School/College/University/Company)

Fyp Starting Time Sem: 6 Year: 2018

Expiry Date Date: 2019

(Diploma – 1 semester;

Degree – 2 semester

Master – 2 years; PhD: 4 years

External – as specified in Letter of intention)

4. Methods / Procedures

Experimental procedure

4.1 Extraction Of Cellulose

4.1.1 Materials

a) Sawdust

b) Dimethyl Sulfoxide

4.1.2 Procedures

a) Preparation of sawdust

The Scaphium spp. wood sample can obtain from furnishing shop around Alor Gajah.

First, the sample needs to dry directly to sunlight and cut into a small piece. Next, the

small pieces of wood chips will ground into powder using a grinder. Then, the sawdust

will dry overnight in a vacuum oven at 100˚C before using.

b) Dissolution of wood

Prepare the Dimethyl Sulfoxide (DMSO) in liquid form and stir with the sawdust. In

dissolution process, prepare 5 different mass of sawdust which is 2g, 4g, 6g, 8g, and

10g. Then, all the samples will disperse with 190g of DMSO in 100ml beaker. Stir the

mixture with a magnetic stirrer on a hot plate at 50˚C in the open atmosphere with speed

of 3 about 1.5 hours. A dark and viscous wood suspension with about 5 wt% wood

concentration will obtain.

JSA FORM revision 8 ( Feb 2017) 2

c) The extraction of cellulose and lignin

After the dissolution process, all the samples will filter through filter paper to remove

undissolved residue which the cellulose-rich extract. The some of the extract and

undissolved residue will go through drying process overnight in a vacuum oven at

100˚C for later use. While the clear brownish liquid is lignin.

4.2 Preparation of Filter Medium

4.2.1 Materials

a) Cellulose with water content of 50 wt%

b) Chitosan from shrimp shell

c) Polyethylene glycol

d) Acetic acid (96 %)

e) Sulfuric acid (98 %)

4.2.2 Procedures

a) Purification of cellulose

Prepare the cellulose by acid hydrolysis of cellulose following the Sulfuric Acid

hydrolysis with minor modification. Hydrolyze the sludge with 63.5% Sulfuric Acid

for 104 minutes at 45˚C. The resulting undergo series of centrifugation, washing with

deionized water and sonication step to collect the cellulose in the supernatant. It will

neutralize by dialysis and store until further use in the form of aqueous suspensions.

Concentrate the cellulose by dialysis against Polyethylene Glycol (PEG) to a

concentration of 4.2 wt.% prior to use for membrane fabrication.

b) Preparation of membrane

Firstly, dissolve the chitosan in 2 wt.% Acetic Acid follow by addition of deionized

water to form a solution of 1 wt.%. Mix the cellulose with chitosan with a ratio of 9:1

and the total concentration of mixture is 2 wt.%. Pour the mixture of chitosan and

cellulose into petri plate and put into fume hoot for drying and solidify. Leave the

samples about 24 hours. Bring the sample for analysis.

4.3 Analysis

4.3.1 Chemical Characteristics (Fourier Transform Infrared Spectroscopy)

a) Scanning imulsion X will give one pattern of peak while scanning imulsion Y which

consist of imulsion X plus impurities will give another pattern of peak.

b) By substracting the peaks of sample, the remaining peaks are the pattern for the

impurities.

c) Searching this patern it can be determine the compounds in the impurities.

d) Using ATD is the best recommended for this final year project.

e) Next will be insert carefully ATD and ensure the source of light is turned on.

f) The instrument will scan the background and scan the sample X.

g) As a result, the data will be print and compare to identify the impurities by plotting

the graph.

JSA FORM revision 8 ( Feb 2017) 3

4.3.2 Porosity

Porosity is a method to identify the empty space in a material and defined as the pore

volume divided by the total volume of the membrane with a unit of percentage (%). Below

is the equation of porosity of membrane, P%

(𝑊𝑤 − 𝑊𝑑) × 𝐷𝑐

𝑃% = × 100%

(𝑊𝑤 − 𝑊𝑑) × 𝐷𝑐 + 𝑊𝑑 × 𝐷𝑖

Where :

Ww : Mass of wet membrane in Water

Wd : Mass of dry membrane (g)

Di : Water density (1.0 g/cm3)

Dc : Cellulose density (1.5 g/cm3)

From the equation, the process needs to identify the mass of filter membrane samples in

wet and dry state. All the mass value will insert to the equation above to find the value P%.

4.3.3 Mechanical Properties (Universal Testing Machine)

a) Perform start-up procedure.

b) Open the testing software on the computer.

c) Choose the method for testing and new file.

d) Click “Insert New Test Icon” and click the EZ & Plus Service.

e) Put the sample and press re-zero button on the control panel beside the equipment.

f) Press the start button and then check the parameter back. After that press OK to

start the test.

g) Repeat the steps from C for new sample with new parameter.

h) Repeat the steps from E for new sample with same sample.

i) After complete the test print-up all test result.

4.3.4 Flux Measurement (Stirred-Cell Membrane Filtration)

a) A dead-end stirred-cell membrane filtration system connected to an N2 gas cylinder

was used to evaluate flux performance with the capacity of 300 ml.

b) Place the stirred-cell membrane on magnetic stirrer to reduce solid cake build up on

the membrane surface.

c) The filter membrane needs to install into the holder to begin the process.

d) Set the operation condition with the pressure of 0.196 MPa in the system was

maintained by nitrogen gas.

e) Leave the filter membrane for one day prior to measurement of water flux.

f) Calculate water flux by observing the amount of solvent passing through the

membrane under applied pressure within a fixed time interval.

JSA FORM revision 8 ( Feb 2017) 4

5 Type of hazards identified in this project.

i. All hazards must be identified during sampling in & out the campus, performing the experiment in the laboratory and analyzing of results.

ii. If your experiment is going to be carried out at external laboratory, it is a requirement to do hazard identification at those laboratories.

Type of hazards Table to be completed Potential Hazards

Yes No

Physical hazards Please fill in table 5a

Biological hazards Please fill in table 5b

Chemical hazards Please fill in table 5c

5a Hazards that have potential to cause harm (potential hazard)

( Do not forget to include ergonomic hazards AND all the physical hazards)

Physical hazards identified Precautions / Emergency action

[at ALL sites; sampling site, laboratory etc]

1. Handle properly

Broken Glassware

2. Inform to person in charge if any incident happens.

1. Use the proper glove when using this type of equipment.

Handling with hot equipment

2. Get the First Aid for pretreatment and inform to person in-charge for further treatment.

1. Hand must be dry before handling the electrical appliance.

Electrical Shock

2. Switch off the electrical power supply and call the assistance instantly.

1. Wear safety shoes with non-skid sole and keep floor free from water.

Slips, trips and falls

2. Report to supervisor or technician any repair needed to nonslip tiling or products.

JSA FORM revision 8 ( Feb 2017) 5

5b Hazards that have potential to cause harm (potential hazard)

( All the biological hazards)

Biological hazards identified Precautions / Emergency action

[at ALL sites; sampling site, laboratory etc]

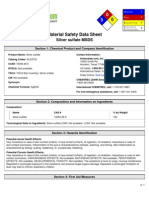

5c. Substances used which have potential to cause harm (potential hazard)

NB: This section is concerned with hazards inherent in the substances rather than the way they might be used in this procedure. All columns must be filled

according to Safety Data Sheet.

Substance Hazards identified EXPOSURE LIMIT Precautions in handling Emergency action

(e.g. toxic, flammable) (MEL or OEL) (if (if gloves required state type) in the event of spillage etc.

assigned- do not quote

LD50 etc.)

Dimethyl sulfoxide Potential Acute Health Not Avalable. Precautions: Eye Contact:

Effects: Keep away from heat. Keep Check for and remove any

Slightly hazardous in away from sources of ignition. contact lenses. Immediately

case of inhalation (lung Ground all equipment containing flush eyes with running water

irritant). Slightly material. Do not ingest. Do not for at least 15 minutes, keeping

hazardous in case of skin breathe gas/fumes/ vapor/spray. eyelids open. Cold water may

contact (irritant, Wear suitable protective be used. Get medical attention

permeator), of eye clothing. In case of insufficient if irritation occurs.

contact (irritant), of ventilation, wear suitable Skin Contact:

ingestion. respiratory equipment. If Wash with soap and water.

ingested, seek medical advice Cover the irritated skin with an

JSA FORM revision 8 ( Feb 2017) 6

Potential Chronic immediately and show the emollient. Get medical

Health Effects: container or the label. Keep attention if irritation develops.

Slightly hazardous in away from incompatibles such as Cold water may be used.

case of skin contact oxidizing agents. Serious Skin Contact: Not

(irritant, sensitizer, Storage: available.

permeator), of ingestion. Keep container in a cool, well- Inhalation:

CARCINOGENIC ventilated area. Keep container If inhaled, remove to fresh air.

EFFECTS: tightly closed and sealed until If not breathing, give artificial

Not available. ready for use. Avoid all possible respiration. If breathing is

MUTAGENIC sources of ignition (spark or difficult, give oxygen. Get

EFFECTS: Mutagenic flame). Hygroscopic. Sensitive medical attention.

for mammalian somatic to light. Store in light-resistant Serious Inhalation: Not

cells. Mutagenic for containers. available.

bacteria and/or yeast. Ingestion:

TERATOGENIC Do NOT induce vomiting

EFFECTS: Not available. unless directed to do so by

DEVELOPMENTAL medical personnel. Never give

TOXICITY: Not anything by mouth to an

available. The substance unconscious person. Loosen

may be toxic to tight clothing such as a collar,

blood, kidneys, liver, tie, belt or waistband. Get

mucous membranes, medical attention if symptoms

skin, eyes. Repeated or appear.

prolonged exposure to Serious Ingestion: Not

the substance can available.

produce target

organs damage.

Acetic acid Potential Acute Health Precautions: Eye Contact:

Effects: TWA: 10 ppm (25 mg/m3) Keep away from heat. Keep Check for and remove any

Very hazardous in case away from sources of ignition. contact lenses. In case of

of skin contact (irritant), Ground all equipment containing contact, immediately flush

of eye contact (irritant), material. Do not ingest. Do not eyes with plenty of water for at

of ingestion, of breathe gas/fumes/ vapor/spray. least 15 minutes. Cold water

inhalation. Hazardous in Never add water to this product.

JSA FORM revision 8 ( Feb 2017) 7

case of skin contact In case of insufficient may be used. Get medical

(corrosive, permeator), of ventilation, wear suitable attention immediately.

eye contact (corrosive). respiratory equipment. If Skin Contact:

Liquid or spray mist may ingested, seek medical advice In case of contact, immediately

produce tissue damage immediately and show the flush skin with plenty of water

particularly on mucous container or the label. Avoid for at least 15 minutes while

membranes of eyes, contact with skin and eyes. Keep removing contaminated

mouth and respiratory away from incompatibles such as clothing and shoes. Cover the

tract. Skin contact may oxidizing agents, reducing irritated skin with an emollient.

produce burns. Inhalation agents, metals, acids, alkalis. Cold water may be used. Wash

of the spray mist may Storage: clothing before reuse.

produce severe irritation Store in a segregated and Thoroughly clean shoes before

of respiratory tract, approved area. Keep container in reuse. Get medical attention

characterized by a cool, well-ventilated area. immediately.

coughing, choking, or Keep container tightly closed Serious Skin Contact:

shortness of breath. and sealed until ready for use. Wash with a disinfectant soap

Inflammation of the eye Avoid all possible sources of and cover the contaminated

is characterized by ignition (spark or flame). skin with an anti-bacterial

redness, watering, and cream. Seek immediate

itching. Skin medical attention.

inflammation is Inhalation:

characterized by itching, If inhaled, remove to fresh air.

scaling, reddening, or, If not breathing, give artificial

occasionally, blistering. respiration. If breathing is

Potential Chronic difficult, give oxygen. Get

Health Effects: medical attention immediately.

Hazardous in case of skin Serious Inhalation:

contact (irritant), of Evacuate the victim to a safe

ingestion, of inhalation. area as soon as possible.

CARCINOGENIC Loosen tight clothing such as a

EFFECTS: Not available. collar, tie, belt or waistband. If

MUTAGENIC breathing is difficult,

EFFECTS: Mutagenic administer oxygen. If the

for mammalian somatic victim is not breathing,

JSA FORM revision 8 ( Feb 2017) 8

cells. Mutagenic for perform mouth-to-mouth

bacteria and/or yeast. resuscitation. WARNING: It

TERATOGENIC may be hazardous to the

EFFECTS: Not available. person providing aid to give

DEVELOPMENTAL mouth-to-mouth resuscitation

TOXICITY: Not when the inhaled material is

available. The substance toxic, infectious or corrosive.

may be toxic to kidneys, Seek immediate medical

mucous membranes, attention.

skin, teeth. Repeated or Ingestion:

prolonged exposure to Do NOT induce vomiting

the substance can unless directed to do so by

produce target organs medical personnel. Never give

damage. Repeated p. 2 anything by mouth to an

or prolonged contact with unconscious person. Loosen

spray mist may produce tight clothing such as a collar,

chronic eye irritation and tie, belt or waistband. Get

severe skin irritation. medical attention if symptoms

Repeated or prolonged appear. Serious Ingestion: Not

exposure to spray mist available.

may produce respiratory

tract irritation leading to

frequent attacks of

bronchial infection.

Glutaraldehyde Potential Acute Health Precautions: Eye Contact:

Effects: TWA: 0.2 ppm (0.82 mg/m3) Keep locked up. Do not ingest. Check for and remove any

Hazardous in case of skin Do not breathe gas/fumes/ contact lenses. In case of

contact (irritant), of eye vapor/spray. Wear suitable contact, immediately flush

contact (irritant), of protective clothing. In case of eyes with plenty of water for at

ingestion, of inhalation insufficient ventilation, wear least 15 minutes. Cold water

(lung irritant, lung suitable respiratory equipment. If may be used. Get medical

sensitizer). Slightly ingested, seek medical advice attention immediately.

hazardous in case of skin immediately and show the Skin Contact:

JSA FORM revision 8 ( Feb 2017) 9

contact (sensitizer, container or the label. Avoid In case of contact, immediately

permeator). contact with skin and eyes. Keep flush skin with plenty of water.

Potential Chronic away from incompatibles such as Cover the irritated skin with an

Health Effects: oxidizing agents, alkalis. emollient. Remove

CARCINOGENIC Storage: contaminated clothing and

EFFECTS: Classified A4 Light Sensitive. Refrigerate. shoes. Cold water may be

(Not classifiable for Store in light-resistant used.Wash clothing before

human or animal.) by containers. Keep containers reuse. Thoroughly clean shoes

ACGIH tightly closed. Keep containers before reuse. Get medical

[Glutaraldehyde]. in a cool, well ventilated attention.

MUTAGENIC area. Serious Skin Contact:

EFFECTS: Mutagenic Wash with a disinfectant soap

for mammalian somatic and cover the contaminated

cells. [Glutaraldehyde]. skin with an anti-bacterial

Mutagenic for bacteria cream. Seek immediate

and/or yeast. medical attention.

[Glutaraldehyde]. Inhalation:

TERATOGENIC If inhaled, remove to fresh air.

EFFECTS: Not available. If not breathing, give artificial

respiration. If breathing is

difficult, give oxygen. Get

medical attention immediately.

Serious Inhalation:

Evacuate the victim to a safe

area as soon as possible.

Loosen tight clothing such as a

collar, tie, belt or waistband. If

breathing is difficult,

administer oxygen. If the

victim is not breathing,

perform mouth-to-mouth

resuscitation. WARNING: It

may be hazardous to the

person providing aid to give

JSA FORM revision 8 ( Feb 2017) 10

mouth-to-mouth resuscitation

when the inhaled material is

toxic, infectious or corrosive.

Seek immediate medical

attention.

Ingestion:

If swallowed, do not induce

vomiting unless directed to do

so by medical personnel.

Never give anything by mouth

to an unconscious person.

Loosen tight clothing such as a

collar, tie, belt or waistband.

Get medical attention

immediately. Serious

Ingestion: Not available.

Polyethylene glycol Potential Acute Health Precautions: Eye Contact:

Effects: TWA: 10 mg/m3 Keep away from heat. Keep Check for and remove any

Slightly hazardous in away from sources of ignition. contact lenses. In case of

case of skin contact Ground all equipment containing contact, immediately flush

(irritant, permeator), of material. Do not ingest. Do not eyes with plenty of water for at

eye contact (irritant), of breathe gas/fumes/ vapor/spray. least 15 minutes. Cold water

ingestion, of inhalation. Wear suitable protective may be used. Get medical

Potential Chronic clothing. If ingested, seek attention if irritation occurs.

Health Effects: medical advice immediately and Skin Contact:

CARCINOGENIC show the container or the label. Wash with soap and water.

EFFECTS: Not available. Keep away from incompatibles Cover the irritated skin with an

MUTAGENIC such as oxidizing agents, acids, emollient. Get medical

EFFECTS: Not available. alkalis. attention if irritation develops.

TERATOGENIC Storage: Cold water may be used.

EFFECTS: Not available. Keep container tightly closed. Serious Skin Contact: Not

DEVELOPMENTAL Keep container in a cool, well- available.

TOXICITY: Not ventilated area. Inhalation:

available. Repeated or

JSA FORM revision 8 ( Feb 2017) 11

prolonged exposure is If inhaled, remove to fresh air.

not known to aggravate If not breathing, give artificial

medical condition. respiration. If breathing is

difficult, give oxygen. Get

medical attention.

Serious Inhalation: Not

available.

Ingestion:

Do NOT induce vomiting

unless directed to do so by

medical personnel. Never give

anything by mouth to an

unconscious person. If large

quantities of this material are

swallowed, call a physician

immediately. Loosen tight

clothing such as a collar,

tie, belt or waistband.

Serious Ingestion: Not

available.

Sulfuric acid Potential Acute Health Precautions: Eye Contact:

Effects: TWA: 3 mg/m3 Keep locked up. Keep container Check for and remove any

Very hazardous in case dry. Do not ingest. Do not contact lenses. In case of

of skin contact breathe gas/fumes/ vapor/spray. contact, immediately flush

(corrosive, irritant, Never add water to this product. eyes with plenty of water for at

permeator), of eye In case of insufficient least 15 minutes. Cold water

contact (irritant, ventilation, wear suitable may be used. Get medical

corrosive), of ingestion, respiratory equipment. If attention immediately.

of inhalation. Liquid or ingested, seek medical advice Skin Contact:

spray mist may produce immediately and show In case of contact, immediately

tissue damage the container or the label. Avoid flush skin with plenty of water

particularly on mucous contact with skin and eyes. for at least 15 minutes while

membranes of eyes, Storage: removing contaminated

mouth and respiratory clothing and shoes. Cover the

JSA FORM revision 8 ( Feb 2017) 12

tract. Skin contact may Hygroscopic. Reacts. violently irritated skin with an emollient.

produce burns. Inhalation with water. Keep container Cold water may be used.Wash

of the spray mist may tightly closed. Keep container in clothing before reuse.

produce severe irritation a cool, well-ventilated area. Do Thoroughly clean shoes before

of respiratory tract, not store above 23°C (73.4°F). reuse. Get medical attention

characterized by immediately. Serious Skin

coughing, choking, or Contact:

shortness of breath. Wash with a disinfectant soap

Potential Chronic and cover the contaminated

Health Effects: skin with an anti-bacterial

CARCINOGENIC cream. Seek immediate

EFFECTS: Classified 1 medical attention.

(Proven for human.) by Inhalation:

IARC, + (Proven.) by If inhaled, remove to fresh air.

OSHA. Classified A2 If not breathing, give artificial

(Suspected for respiration. If breathing is

human.) by ACGIH. difficult, give oxygen. Get

MUTAGENIC medical attention immediately.

EFFECTS: Not available. Serious Inhalation:

TERATOGENIC Evacuate the victim to a safe

EFFECTS: Not available. area as soon as possible.

DEVELOPMENTAL Loosen tight clothing such as a

TOXICITY: Not collar, tie, belt or waistband. If

available. The substance breathing is difficult,

may be toxic to kidneys, administer oxygen. If the

lungs, heart, victim is not breathing,

cardiovascular system, perform mouth-to-mouth

upper respiratory tract, resuscitation. WARNING: It

eyes, teeth. may be hazardous to the

person providing aid to give

mouth-to-mouth resuscitation

when the inhaled material is

toxic, infectious or corrosive.

JSA FORM revision 8 ( Feb 2017) 13

Seek immediate medical

attention.

Ingestion:

Do NOT induce vomiting

unless directed to do so by

medical personnel. Never give

anything by mouth to an

unconscious person. Loosen

tight clothing such as a collar,

tie, belt or waistband. Get

medical attention if symptoms

appear.

Serious Ingestion: Not

available.

Skin Contact – Flush with copious amounts of water for at least 15 minutes. Remove contaminated clothing and wash before reuse. Unless contact has been

slight obtain medical attention.

Inhalation – Remove to fresh air, rest and keep warm. If breathing is difficult give artificial respiration and obtain medical attention.

Eye contact – Irrigate with copious amounts of eye wash or water for at least 15 minutes. Assure adequate flushing by separating the eyelids with fingers.

Obtain medical attention

Ingestion – Do not induce vomiting. If conscious provide water for person to thoroughly wash out mouth (and sip if required). Obtain medical attention.

Full safety data sheets for the above chemicals must available in file at the laboratory in use.

Please ensure data sheets for any previously unused chemical are added to the laboratory's safety file.

Nomenclature

CoSHH: Control of Substances Hazardous to Health MEL: Maximum exposure limit TWA: Time weighted average

SDS : Safety Data Sheet [or the old term is called OEL: Occupational exposure limit TLV: Threshold limit value

CSDS-CHEMICAL SAFETY DATA SHEET or

MSDS-MATERIAL SAFETY DATA SHEET

JSA FORM revision 8 ( Feb 2017) 14

5d. Equipment used in the procedure which may cause harm

NB: This section is concerned with hazards inherent in the equipment rather than the way it might

be used in this procedure.

Equipment Nature of hazard Precautions to be taken

Electrical shock : Make sure

Electrical shock

work area and hand is dry.

Hot surface

Fume Hot surface : Ware the proper

Oven glove in handling the hot

equipment.

Fume : Ware the mask while

opening and closing the oven.

Hot surface : Ware the proper

Hot surface

glove in handling the hot

Electrical shock equipment.

Splashing of hazardous material

Electrical shock : Ensure that

Magnetic Stirrer

work area and hand is dry.

Splashing of hazardous

material : Waring the lab cot to

cover skin.

Ensure the spectrometer is

Electrical shock

properly grounded and all the

Fourier Transform Infrared cables are properly insulated.

Spectroscopy Check that the area around is

clean and dry before operating

the spectrometer.

Electrical shock : Check that

Electrical shock

area around the meachine clean

Mechanical exposure and dry before start the operation

Universal Testing Machine

Mechanical exposure : Keep

distance safely while the machine

is operate.

Take the fresh air. Get the

Asphyxiant

medical attention immediately if

Stirred-Cell Membrane Filtration Expose to nitrogen gas getting worse.

NOTE:

ALL EQUIPMENTS USED ELECTRICAL POWER WILL HAVE ELECTRICAL HAZARDS.

6. Laboratories required

PILOT PLANT

LAB 15 (Polymer Processing Testing & Analysis)

LAB 2B (Analytical Chemistry)

LAB 2C (Analytical Chemistry)

JSA FORM revision 8 ( Feb 2017) 15

6a. First Aid & Fire Fighting Equipment (FAFFE) Available

LABORATORY: LABORATORY: LABORATORY: LABORATORY:

FAFFE

PILOT PLANT LAB 15 LAB 2B LAB 2C

Eye wash & Model: Haw’s Model: Haw’s Model: Haw’s Model: Haw’s

emergency Coperation 8300 Coperation 8300 Coperation 8300 Coperation 8300

shower

Last date checked: Last date Last date Last date

19/2/2018 checked: checked: checked:

14/2/2018 19/2/2018 19/2/2018

Condition:

GOOD Condition: Condition: Condition:

GOOD GOOD GOOD

Antiseptic

Expire: 10/2020 Expire: 7/2018 Expire: 10/2020 Expire: 10/2020

cream

Dressing Cotton Bud Natural Cotton Tweezers Tweezers

Triangular Triangular Plaster Strip Plaster Strip

Bandage Bandage (handy plass) (handy plass)

Elastic Gauze Bandage Safety Pin Safety Pin

Comforming

Bandage

Gauze Swabs Gauze Swabs W.O.W Bandage W.O.W Bandage

Cosmoplast Melolin Wooden Splint Wooden Splint

Plaster

Elastic Crepe Thermometer Cotton Bud Cotton Bud

Bandage

W.O.W. Bandage Wooden Splint Alcohol Swab Alcohol Swab

Wooden Splint Scissors Scissors

Gauze Swab Gauze Swab

Triangular Triangular

Bandage Bandage

Surgical Tape Surgical Tape

Eyemo Not Available Not Available Not Available Not Available

Yellow lotion Expire: 8/2017 Not Available Expire: 1/2018 Expire: 1/2018

Dettol Expire: Not Expire: 1/2020 Expire: 1/2020 Expire: 1/2020

Available

Chemical

Available Available Available Available

spill kit

Fire Checked on: Checked on: Checked on: Checked on:

Extinguisher 19/2/2018 14/2/2018 19/2/2018 19/2/2018

Next checking on: Next checking on: Next checking on: Next checking on:

13/12/2018 29/12/2018 20/9/2018 20/9/2018

JSA FORM revision 8 ( Feb 2017) 16

FAFFE LABORATORY: Lab 1C

Eye wash & emergency Model: Haw’s Coperation

shower 8300

Last date checked:

7/2/2018

Condition: GOOD

Antiseptic cream Expire: 10/2020

Dressing Surgical Tape

Gauze Bandage

Elastic Comforming

Bandage

Fabric Strip

Alcohol Pads

Crepe Bandage

Eyemo Not Available

Yellow lotion Expire: 8/2017

Dettol Expire: 1/2020

Chemical spill kit Available

Fire Extinguisher Checked on: 17/3/2018

Next checking on:

28/11/2018

JSA FORM revision 8 ( Feb 2017) 17

7. Disposal routes for waste materials

Tick [ ] or complete appropriate box for each category of waste WITH reference to FIRST

SCHEDULE of ENVIRONMENTAL QUALITY (SCHEDULED WASTES) REGULATIONS 2005.

Route for disposal:

Nature of Black Solvent drum Sharps Other

Black

waste: Sink bin (e.g. (SW311; route

bag SW322; SW323) bin

SW410) (specify)

Dissolved lignin (SW 3)

Cellulose waste (SW 3)

Tissue, glove,

face mask, filter

(SW 410)

paper

Used sawdust

cellulose filter

(SW 4)

membrane

NOTE:The following list of scheduled wastes are not exhausted, the above regulation must be

referred to complete this section.

SW109 Waste containing mercury or its compound

SW206 Spent inorganic acids

SW311 Waste of oil or oily sludge

SW322 Waste of non-halogenated organic solvents

SW323 Waste of halogenated organic solvents

SW421 Rags, plastics, papers or filters contaminated with scheduled wastes

NOTE:

PLEASE SPECIFY YOUR BIOHAZARD WASTE - ROUTE OF DISPOSAL

8. Specific risk assessment for procedure and precautions to be

taken

During handling the machine, lab equipment, lab apparatus and etc, make sure that personal

protective equipment (PPE) must be wear appropriately according to the equipment that will be

handle and all precaution in table 5a, 5c and 5d must be followed. In preparation of cellulose, there

is a LOW risk of contact with hazardous chemicals. Waring the right glove when handling the hot

equipment. Ensure hand are dried when handling the electrical equipment. Before start the

experiment, make sure all the apparatus in good condition, dried and clean workplace and proper

wiring for electrical equipment. Thus, during the experiment ensure take extra care in handling

apparatus and chemical to avoid broke and chemical spillage. Make sure that student fully

understands the standard operating procedure when using the machine and lab equipment. During

handling acid, alkali and hazardous chemical, workplace must be well-ventilated area and know

where the FAFFE is placed. In cellulose filter process, there is a MINOR risk of contact with the

hazardous chemical. Waring proper PPE will avoid any injury during handling this process. During

the analysis, there is LOW risk of contact with hazardous chemicals because it will become filter

medium in a dried condition. After following all above preparations the overall risk assessment for

this procedure is LOW.

JSA FORM revision 8 ( Feb 2017) 18

9. Level of supervision required and suitability for out-of-hours work

Please mark box [ ] to indicate appropriate supervision category for this procedure.

work may not be carried out except under the direct supervision of a

Category A specified member of staff who is present continuously

work may not be started without the supervisor's advice and approval, some

Category B additional training and initial direct supervision

work may not be started without the supervisor's advice and approval and

Category C some additional training - no direct supervision required

although extra care must be observed, workers should already be competent

Category D

and adequately-trained for this task

risks are insignificant and supervision unnecessary

Category E

9a. Is this procedure authorised for out-of-hours work?

YES :___ NO:

[TO BE FILLED FOR WORK TO BE DONE OUT OF OFFICE HOURS ]

Date and time Supervisor Approval HOS Approval SHO Approval

10. Emergency Contact

No NAME CONTACT NO

1. Security Guard 06-5512054

2. Safety Executive 016-6459211

Name: MOHD NAQUIB BIN

MOHAMMAD

3. Safety and Health Officer 019-2436965

Name: NOR AINI BTE BUROK

4. Supervisor 012-6447422

Name: Dr. Indok Nurul Hasyimah Binti

Mohd Amin

5. Co-supervisor (if any)

Name:

Note:

Supervisor is required to make hourly phone calls to check on students when they work out of office

hour

JSA FORM revision 8 ( Feb 2017) 19

11. Signature of technician involved in the project.

Form Checked By Mohd Zamzuri Bin Ismail Signature

(Technician):- (Date)

Form Checked By Ahmad Faiz Bin Daud Signature

(Technician):- (Date)

Form Checked By Mohd Fadil Bin Mohd Amin Signature

(Technician):- (Date)

Form Checked By Mohd Sukri Bin Rahmat Signature

(Technician):- (Date)

12. Signature of academic supervisor and co supervisor

Note that this assessment needs to be reviewed and signed annually to take into account any developments of the procedure [if the project is

more than one year, eg postgraduate].

Supervisor (Name): Dr. Indok Nurul Hasyimah Binti Signature

Mohd Amin (Date)

Co-Supervisor (Name): Signature

(Date)

13. Signature of authorised signatory for JSA approval

Signature Name

Date

JSA FORM revision 8 ( Feb 2017) 20

14. Signature and contact number of workers involved with this procedure

Please sign annually to say you have read the attached document and understood it.

# Name of other student Signature & # Name of other student Signature &

involved Contact No. involved Contact No.

(Date) (Date)

1 2

3 4

5 6

7 8

9 10

11 12

JSA reference number of other JSA reference number

student involved of other student involved

JSA FORM revision 8 ( Feb 2017) 21

Review Section [TO BE FILLED BY POSTGRADUATE ONLY].

15. Signature of the reviewer/s

Note that this assessment needs to be reviewed and signed ANNUALLY to take into account any developments of the procedure

(This section should be signed by the technician/s in charge of the areas where the work is to be done)

Signature Could any less Signature Could any less

(Date) hazardous substance or (Date) hazardous substance or

procedure be used? procedure be used?

JSA FORM revision 8 ( Feb 2017) 22

You might also like

- The Many Benefits of Hydrogen PeroxideDocument11 pagesThe Many Benefits of Hydrogen PeroxideJustiniano DelfinNo ratings yet

- Full Report Practical 1Document12 pagesFull Report Practical 1Meck LotfiNo ratings yet

- Lab 04 - Simple Difference, A Not A, Simple Paired Comparison TestDocument13 pagesLab 04 - Simple Difference, A Not A, Simple Paired Comparison TestEdison SutionoNo ratings yet

- D 4442 - 15 Standard Test Methods For Direct Moisture Content Measurement of Wood and Wood-Based MaterialsDocument6 pagesD 4442 - 15 Standard Test Methods For Direct Moisture Content Measurement of Wood and Wood-Based MaterialsshgsuhermanNo ratings yet

- LR-Practical 2 (AAS Ashing)Document12 pagesLR-Practical 2 (AAS Ashing)najwaNo ratings yet

- LR-Practical 8 (Texture)Document12 pagesLR-Practical 8 (Texture)najwaNo ratings yet

- Lab Report Full MargerinDocument11 pagesLab Report Full Margerinainnor100% (1)

- Suggested Answer - Tutorial 3 Chm510 (Mac2017)Document5 pagesSuggested Answer - Tutorial 3 Chm510 (Mac2017)Mark Sullivan100% (2)

- Environment Monitoring, Result Evaluation and Common Contaminants Study of Vaccine Manufacturing FacilityDocument12 pagesEnvironment Monitoring, Result Evaluation and Common Contaminants Study of Vaccine Manufacturing FacilityIJRASETPublicationsNo ratings yet

- Lab 8 Che506Document17 pagesLab 8 Che506Aeyrul KhairulNo ratings yet

- Silt Control GuideDocument32 pagesSilt Control GuidePcEngNo ratings yet

- Practical 2: Determination of Viscosity of Food Products Using A ViscometerDocument9 pagesPractical 2: Determination of Viscosity of Food Products Using A ViscometernajwaNo ratings yet

- QGL-CE-001Guidelines For Corridors and Corridor CrossingsRev2Document29 pagesQGL-CE-001Guidelines For Corridors and Corridor CrossingsRev2tomNo ratings yet

- CPB 20104 Mass Transfer 2 UniKL MICET Experiment 2: Tray Dryer Full Lab ReportDocument9 pagesCPB 20104 Mass Transfer 2 UniKL MICET Experiment 2: Tray Dryer Full Lab ReportSiti Hajar MohamedNo ratings yet

- Experiment 2: Different Types of Drying Method A. Dehydration Using Cabinet DrierDocument5 pagesExperiment 2: Different Types of Drying Method A. Dehydration Using Cabinet DriernajwaNo ratings yet

- Plumbing Key AnswerDocument7 pagesPlumbing Key AnswerStanley Scott ArroyoNo ratings yet

- Adulteration Lab ReportDocument8 pagesAdulteration Lab ReportchromeNo ratings yet

- CPB30303 Oil and Fat Process Technology UniKL MICET Experiment 4: Lab Scale Soap Production Full Lab ReportDocument15 pagesCPB30303 Oil and Fat Process Technology UniKL MICET Experiment 4: Lab Scale Soap Production Full Lab ReportSiti Hajar MohamedNo ratings yet

- JSA Example Final Year ProjectDocument33 pagesJSA Example Final Year ProjectnasuhaNo ratings yet

- Exp 4 Heat Sterilization of Canned Chicken in Prepared SauceDocument4 pagesExp 4 Heat Sterilization of Canned Chicken in Prepared SauceNurul Syafiqah0% (1)

- Assignment FSG471Document7 pagesAssignment FSG471NurSyazaHaniNo ratings yet

- Inno Full ReportDocument18 pagesInno Full ReportAhmad KhalidNo ratings yet

- Lab Report Food AnalysisDocument2 pagesLab Report Food AnalysisAlimah Azeli100% (1)

- CPB30303 Oil and Fat Process Technology UniKL MICET Experiment 1: Physical Refining of Crude Palm Oil Full Lab ReportDocument28 pagesCPB30303 Oil and Fat Process Technology UniKL MICET Experiment 1: Physical Refining of Crude Palm Oil Full Lab ReportSiti Hajar Mohamed100% (8)

- Sensory Evaluation - Lab Report 1Document6 pagesSensory Evaluation - Lab Report 1api-383535959No ratings yet

- FULL PRACTICAL 5 NadopodDocument5 pagesFULL PRACTICAL 5 NadopodBatrisyia IlhamNo ratings yet

- CPB 30103 Biochemical Engineering UniKL MICET Experiment 4: Determination of Bacterial Loads Viable Cell Counts Full Lab ReportDocument12 pagesCPB 30103 Biochemical Engineering UniKL MICET Experiment 4: Determination of Bacterial Loads Viable Cell Counts Full Lab ReportSiti Hajar Mohamed100% (2)

- Exp 4 Batch Evaporative Crystallization PDFDocument9 pagesExp 4 Batch Evaporative Crystallization PDFmirza farhanNo ratings yet

- Ex7 Effect of Prepanoic Acid To Shelf Life of BreadDocument5 pagesEx7 Effect of Prepanoic Acid To Shelf Life of BreadnajwaNo ratings yet

- FST568 - Practical 1 TasteDocument3 pagesFST568 - Practical 1 Tastenur syaza haniNo ratings yet

- Lab Report Experiment 1Document10 pagesLab Report Experiment 1Arieanna AsyiqinNo ratings yet

- LR Ex 4 SaponificationDocument13 pagesLR Ex 4 SaponificationFarrah DiyanaNo ratings yet

- Exp 3 Lab Scale Margarine ProductionDocument11 pagesExp 3 Lab Scale Margarine Productionaffeena100% (2)

- Exp 1 Unit OperationDocument5 pagesExp 1 Unit Operationenieynaz0% (1)

- CPB 30103 Biochemical Engineering UniKL MICET Experiment 1: Preparation of Buffer Solution Full Lab ReportDocument10 pagesCPB 30103 Biochemical Engineering UniKL MICET Experiment 1: Preparation of Buffer Solution Full Lab ReportSiti Hajar Mohamed0% (1)

- Faculty of Applied Sciences Laboratory Report Food Preservation and Manufacturing Labarotary FST 528Document9 pagesFaculty of Applied Sciences Laboratory Report Food Preservation and Manufacturing Labarotary FST 528nur syaza haniNo ratings yet

- Lab FST306 MoistureDocument34 pagesLab FST306 MoistureAishah LatepNo ratings yet

- Exp 6 QCDocument9 pagesExp 6 QCainsyuhadaazizNo ratings yet

- Double Seaming ExperimentDocument7 pagesDouble Seaming ExperimentNurul Naqibah33% (3)

- Experiment 1 Optimization of Flow Rate and Column Temperature (Method Development)Document7 pagesExperiment 1 Optimization of Flow Rate and Column Temperature (Method Development)NUR IZZATI OTHMAN BASRINo ratings yet

- Food (Preservatives) Regulation, 2019 - Sri LankaDocument11 pagesFood (Preservatives) Regulation, 2019 - Sri LankaKapithas KNo ratings yet

- Result & Discussion CanningDocument2 pagesResult & Discussion CanningSuganya Nair100% (1)

- Exp 8Document5 pagesExp 8Lyani FaraNo ratings yet

- ConclusionDocument1 pageConclusionenieynaz0% (1)

- Proposal Innovation Management 2020 (BAYMAX SCANNER)Document23 pagesProposal Innovation Management 2020 (BAYMAX SCANNER)Muhamad Afham RosdiNo ratings yet

- Manual Lab CMT450 - Unit OperationDocument17 pagesManual Lab CMT450 - Unit OperationNur Hafikah MustaphaNo ratings yet

- Lab 6 - Growth Kinetics Study of Microorganism in Shake Flask PDFDocument7 pagesLab 6 - Growth Kinetics Study of Microorganism in Shake Flask PDFJaymacNo ratings yet

- EXPERIMENT 1 Food ChemistryDocument9 pagesEXPERIMENT 1 Food ChemistryNabila Husna100% (2)

- EXP2 BIOCHEM Analyzing and Determine Sugars and Starch in Plant Tissues.Document10 pagesEXP2 BIOCHEM Analyzing and Determine Sugars and Starch in Plant Tissues.NUR AMALIA BINTI MAZLEE STUDENTNo ratings yet

- CecDocument9 pagesCecYulNo ratings yet

- Crude FiberDocument5 pagesCrude FiberMichelle_Rose__9036100% (3)

- BIO 462 Experiment 2Document6 pagesBIO 462 Experiment 2Nurul Farhah RadzuwanNo ratings yet

- (Lab Report Operation Unit) Experiment 7Document4 pages(Lab Report Operation Unit) Experiment 7Fazsroul33% (3)

- Laboratory Report of Instrumental Analysis of Food (FST 606)Document18 pagesLaboratory Report of Instrumental Analysis of Food (FST 606)biokimia 2018No ratings yet

- Lab CHM 420 Exp 2Document4 pagesLab CHM 420 Exp 2nana izzNo ratings yet

- FST 559 Unit Operation 9 & 10Document9 pagesFST 559 Unit Operation 9 & 10Ahmad ZienNo ratings yet

- Mic531 Lab Report 1Document6 pagesMic531 Lab Report 1Ahmad Nur AqmalNo ratings yet

- CLB 20903 Engineering Statistics UniKL MICET Assignment (Question 5) : Linear Regression AnalysisDocument7 pagesCLB 20903 Engineering Statistics UniKL MICET Assignment (Question 5) : Linear Regression AnalysisSiti Hajar MohamedNo ratings yet

- Full Report Ish Chemical RegistrationDocument17 pagesFull Report Ish Chemical RegistrationAyub KasyfiNo ratings yet

- Microscopic Examination of FoodDocument7 pagesMicroscopic Examination of FoodNurul Najwa0% (1)

- Effect of Varying Concentrations of Clarifying Enzyme On The Yield and Quality of Watermelon JuiceDocument10 pagesEffect of Varying Concentrations of Clarifying Enzyme On The Yield and Quality of Watermelon JuiceRashneveNo ratings yet

- PHASE EQUILIBRIUM - Freezing Point Depression and Molar Mass DeterminationDocument9 pagesPHASE EQUILIBRIUM - Freezing Point Depression and Molar Mass DeterminationNurulNo ratings yet

- Fst359 Experiment 3 Rice FlourDocument11 pagesFst359 Experiment 3 Rice Flourfatin umairahNo ratings yet

- Bioprocess Engg. Practical ManualDocument29 pagesBioprocess Engg. Practical ManualRam Verma60% (5)

- Binder Content Centrifuge Extractor Issue 5Document10 pagesBinder Content Centrifuge Extractor Issue 5Mansueta StefanusNo ratings yet

- Rainwater Harvesting 101 - Your How-To Collect Rainwater GuideDocument13 pagesRainwater Harvesting 101 - Your How-To Collect Rainwater GuideNitheesh KumarNo ratings yet

- Mobil 600 W Super Cylinder OilDocument10 pagesMobil 600 W Super Cylinder Oilluis carlos Mendoza AriasNo ratings yet

- Marine Boilers 25Document99 pagesMarine Boilers 25Anjaana PrashantNo ratings yet

- Introduction 2Document12 pagesIntroduction 2Jean Denis TavoueNo ratings yet

- MTWD HistoryDocument8 pagesMTWD HistoryVernie SaluconNo ratings yet

- Feeding Distillers' Grains - Watch Sulfer ContentDocument4 pagesFeeding Distillers' Grains - Watch Sulfer ContentAlejandro CalderónNo ratings yet

- Material and Energy BalanceDocument26 pagesMaterial and Energy Balancem9m2070No ratings yet

- Evaluation of ShampoosDocument3 pagesEvaluation of ShampoosprinceamitNo ratings yet

- Generation of Overland FlowDocument4 pagesGeneration of Overland FlowLesly Ann Pauline ManaoatNo ratings yet

- Alternative Deconstruct and Design TaskDocument5 pagesAlternative Deconstruct and Design Taskapi-321385393No ratings yet

- MASTERSEAL SP120 v3Document2 pagesMASTERSEAL SP120 v3Rajesh KumarNo ratings yet

- Water Saving Irrigation Tech., R.LampayanDocument39 pagesWater Saving Irrigation Tech., R.LampayanThe Finest TeamNo ratings yet

- Ag SO4Document5 pagesAg SO4ptnamhoangNo ratings yet

- Is Drinking 8 Glasses A DayDocument2 pagesIs Drinking 8 Glasses A DayJin ChuaNo ratings yet

- Self - Priming Centrifugal Pumps: MotorDocument2 pagesSelf - Priming Centrifugal Pumps: MotorbheemsinghsainiNo ratings yet

- Agua Ing PDFDocument29 pagesAgua Ing PDFbenabdallah131No ratings yet

- Lab Report Specific HeatDocument5 pagesLab Report Specific HeatAhmad Shahir ShakriNo ratings yet

- Feasibility of Coastal Reservoir To Harness Godavari River Surplus WatersDocument8 pagesFeasibility of Coastal Reservoir To Harness Godavari River Surplus WatersN. SasidharNo ratings yet

- Water Cycle Atomospheric ConditionsDocument26 pagesWater Cycle Atomospheric ConditionsEUNICE CORREANo ratings yet

- Polyisobutylene SuccinicamideDocument9 pagesPolyisobutylene Succinicamideperqs BeautyisjoyNo ratings yet

- Premi Test Tips and TricksDocument28 pagesPremi Test Tips and TricksReza WahyudiNo ratings yet

- Ultrasonic InterferometerDocument22 pagesUltrasonic InterferometerakshatguptaNo ratings yet

- Big Performance! The New Range of Kärcher Pumps.: Professional Pump Systems For The House and GardenDocument28 pagesBig Performance! The New Range of Kärcher Pumps.: Professional Pump Systems For The House and GardenAromaBox AromakozmetikaNo ratings yet

- Nitrogen RemovalDocument80 pagesNitrogen RemovalJoy Das MahapatraNo ratings yet

- Plumbing SymbolsDocument6 pagesPlumbing SymbolsFrancisco Jr DelasalaNo ratings yet