Professional Documents

Culture Documents

Torque sizing analysis chart and calculations for trunnion ball valves

Uploaded by

ibharOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Torque sizing analysis chart and calculations for trunnion ball valves

Uploaded by

ibharCopyright:

Available Formats

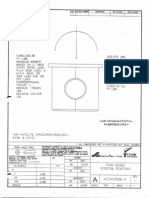

VALVE/ ACTUATOR TORQUE SIZING ANALYSIS CHART FOR TRUNNION BALL VALVES

PISTON STYLE SCOTCH YOKE ACTUATOR SIZING CALCULATIONS SHEET

LARGER ACTUATORS 2500NM TO 17000NM SPRING RETURN (SET SPRING TO CLOSE)

Valve Valve BTO Valve RTO Valve ETO Valve BTC Valve RTC Valve ETC MAST Maximum

Item

Size/Class (N-m) (N-m) (N-m) (N-m) (N-m) (N-m) (N-m) DELTA P

1 100NB 600CL 500 150.00 175 445 150.00 375 2850 9900 KPA

Actuator Actr BTO Actr RTO Actr ETO Actr BTC Actr RTC Actr ETC Actr BTO Air Supply

Model/Type (N-m) (N-m) (N-m) (N-m) (N-m) (N-m) (N-m) Pressure

1A HD722SR80 1346 673.00 807.60 1278.7 673.00 807.60 1346 5.5 BAR

Safety Factor 169% 349% 361% 187% 349% 115% -53%

NOTES

No safety factor has been allowed in any valve or actuator torques shown. All torques are nett.

Above Actuator is Complete with Bracket (ISO Mounting) and high tensile Adaptor

All Torque Values are theoretical, however where required we will torque test prior to despatch.

The real valve torque value can be higher depending upon the following listed factors as these factors can drastically increase (or decrease) the torque.

Please advise if any of the following factors are applicable. Approximate valve torque increases/ decreases (Apply safety factor accordingly) are:-

1) Fluid carrying dust, powder, abrasive particles (+50% to 125%). In extreme cases can be higher. i.e. Up to 200%

1a) Slurry, pulp, resins, paste (+50%) can be even higher in some cases

2) Dry service (Dry Gas) (+25%)

3) High or low temperature (consult us)

4) Infrequent use (+30-50%) *1 - *2

5) If a higher minimum air supply than shown above is available more torque will be produced in the air operation phase.

6) Torque is based on a maximum Delta P for class. If your actual working pressure is lower please advise as a smaller actuator may be possible.

7) Lubricated service (clean oil or other high lubricity fluid) (+15%)

*1 PTFE/RPTFE can require more torque to unseat after a period of time due to its fluidity & memory. For Devlon/ Nylon Seat the valve torque is higher and PEEK is even higher

(of course we have factored into torque of valve where applicable), however as these are harder materials (especially PEEK) infrequent use has a lesser effect on the increase in

torque.

*2 Where set fail closed, an additional infrequent use safety factor at least needs to be applied to spring stroke torques (especially the spring BTC if set fail closed or the spring BTO

if set fail open). Infrequent use:- Once per month +25%, once every 4 months +30%, once per month, over 4 months +40%

Abbreviations:-

BTO = Break to open (air stroke) BTC = Break to close (spring stroke) MAST = Max stem torque

RTO = Running to open (air stroke) RTC = Running to close (spring stroke)

ETO = End to open (air stroke) ETC = End to close (spring stroke)

You might also like

- 4r75e Ford TransmissionDocument5 pages4r75e Ford TransmissionDavid Prince71% (7)

- Automatic Transaxle (F4A51)Document194 pagesAutomatic Transaxle (F4A51)Dayro GeneyNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Pilatus Pc-Xii Initial Maintenance Training CourseDocument442 pagesPilatus Pc-Xii Initial Maintenance Training CourseSabrina GrasielaNo ratings yet

- S12R-Y1PTA-2 Mitsubishi Diesel Generator EngineDocument3 pagesS12R-Y1PTA-2 Mitsubishi Diesel Generator EnginealstomNo ratings yet

- PM Master Data Template v1Document72 pagesPM Master Data Template v1Naseer SultanNo ratings yet

- Expansion Joint CatalogDocument142 pagesExpansion Joint CatalogNicole Smith100% (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Design Criteria PDFDocument60 pagesDesign Criteria PDFMohmmad ShaikhNo ratings yet

- Steps For Charm ConfigurationDocument7 pagesSteps For Charm ConfigurationpoornasapNo ratings yet

- DbsDocument9 pagesDbsibharNo ratings yet

- Duct Static Pressure Loss Calculation-BF EAF-08 (T1)Document9 pagesDuct Static Pressure Loss Calculation-BF EAF-08 (T1)Sam SamNo ratings yet

- Atos Fuel SDocument133 pagesAtos Fuel Singenieriaelectronic100% (1)

- Appliance ShipmentsDocument10 pagesAppliance ShipmentsnNo ratings yet

- Introduction To Oracle GroovyDocument53 pagesIntroduction To Oracle GroovyDeepak BhagatNo ratings yet

- TLB840R Hydraulic Testing GuideDocument13 pagesTLB840R Hydraulic Testing GuideLuisAntonioVegaParangueo100% (1)

- Hydraulic Drifter: General SpecificationDocument2 pagesHydraulic Drifter: General Specification牛千No ratings yet

- Solomons Organic Chemistry Solution Manual - Chapter 3Document12 pagesSolomons Organic Chemistry Solution Manual - Chapter 3Imanghh25% (4)

- Generator Parts Specification and DrawingsDocument30 pagesGenerator Parts Specification and DrawingsAnindra Ahmad Farras100% (2)

- Operational Guidelines For VlsfoDocument2 pagesOperational Guidelines For VlsfoИгорьNo ratings yet

- Valve/ Actuator Torque Sizing Analysis Chart For Trunnion Ball ValvesDocument1 pageValve/ Actuator Torque Sizing Analysis Chart For Trunnion Ball ValvesagrovadoNo ratings yet

- Actuator Pneumatic Sizing Programme Torque CalculationDocument1 pageActuator Pneumatic Sizing Programme Torque CalculationDan CanoNo ratings yet

- Transmision A5hf Hyundai PDFDocument152 pagesTransmision A5hf Hyundai PDFIongornistuNo ratings yet

- Manual GruaDocument14 pagesManual Gruaantuan551No ratings yet

- Pressure Reducing, Pilot Operated Spool Type: Common Cavity, Size 10Document2 pagesPressure Reducing, Pilot Operated Spool Type: Common Cavity, Size 10tecnicomanelNo ratings yet

- Model DDV Deluge Valve FeaturesDocument15 pagesModel DDV Deluge Valve FeaturesCoordinador TecnicoNo ratings yet

- Vc34 Kompend Mds eDocument4 pagesVc34 Kompend Mds eSafetyjoe2No ratings yet

- Actuadores Compuertas Hoja de DatosDocument1 pageActuadores Compuertas Hoja de DatosAlberto NunciraNo ratings yet

- Counterbalance, Relief Compensated Poppet Type Differential Area, Counterclockwise AdjustmentDocument2 pagesCounterbalance, Relief Compensated Poppet Type Differential Area, Counterclockwise AdjustmenttecnicomanelNo ratings yet

- Picanol Omni Plus 800 Machine Specification and Working PrincipleDocument55 pagesPicanol Omni Plus 800 Machine Specification and Working Principlefarshad behroziNo ratings yet

- Actuator InformationDocument4 pagesActuator InformationFajar DwikurniaNo ratings yet

- RC 750Document7 pagesRC 750ahmetNo ratings yet

- 30 300 G7028SR3Document1 page30 300 G7028SR3ERASMO PEREZ IZQUIERDONo ratings yet

- Rating ChartsDocument133 pagesRating Chartsjuanchocazon780% (1)

- Pressure Reducing and Relieving, Direct Acting Spool Damped TypeDocument2 pagesPressure Reducing and Relieving, Direct Acting Spool Damped TypetecnicomanelNo ratings yet

- Aerzen TurboDocument3 pagesAerzen Turbocarlangas77No ratings yet

- Trane RTAF DataDocument1 pageTrane RTAF DatadheerajdorlikarNo ratings yet

- March Pump Manual 7 Plastic 0155 0046 1000 Rev32Document2 pagesMarch Pump Manual 7 Plastic 0155 0046 1000 Rev32Asima Jaya TamaNo ratings yet

- Bilge Pump Performance CurveDocument91 pagesBilge Pump Performance CurveИгорь КлимовNo ratings yet

- Pneumatic / Electro Pneumatic Positioner: Specialists in Process Efficiency and Energy ConservationDocument2 pagesPneumatic / Electro Pneumatic Positioner: Specialists in Process Efficiency and Energy ConservationAntonio HerreraNo ratings yet

- Technical Service Guide CT LB TWM Uv VH 6990005 EnUS TSG 09-11Document244 pagesTechnical Service Guide CT LB TWM Uv VH 6990005 EnUS TSG 09-11Henry HuayhuaNo ratings yet

- Specification Sheet: Centrifuge For Petrol and Mineral OilsDocument3 pagesSpecification Sheet: Centrifuge For Petrol and Mineral Oilsh8pb8jzyhgNo ratings yet

- Spam Relay Settings in DRPDocument3 pagesSpam Relay Settings in DRPchandanhatwarNo ratings yet

- DS Linear Motors P10-70x320U-BD-SSCDocument21 pagesDS Linear Motors P10-70x320U-BD-SSCArturo GomezNo ratings yet

- IFS Stancor SEW50 DatasheetDocument2 pagesIFS Stancor SEW50 DatasheetMaruRojaNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document1 pageS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)LIONN SOFTWARESNo ratings yet

- Platform 2100Document4 pagesPlatform 2100Eduardo MxlNo ratings yet

- AC RTP Nutrunner - US - FINALDocument3 pagesAC RTP Nutrunner - US - FINALManish MohananNo ratings yet

- RXQ 54Document1 pageRXQ 54Surya LiemNo ratings yet

- Atlas Copco ToolsDocument4 pagesAtlas Copco ToolsnotengofffNo ratings yet

- Valvulas 2 y 3 inDocument65 pagesValvulas 2 y 3 inGabo Montaño MendozaNo ratings yet

- HIGH FLOW PULSE VALVESDocument4 pagesHIGH FLOW PULSE VALVESFelipe SalvatierraNo ratings yet

- MPSA56/MMBTA56/PZTA56 PNP General Purpose Amplifier: DescriptionDocument15 pagesMPSA56/MMBTA56/PZTA56 PNP General Purpose Amplifier: DescriptionloebazzzNo ratings yet

- Lmsection E2x040Document2 pagesLmsection E2x040Jhon MontenegroNo ratings yet

- I. Model PC-12, Normal Category, Approved July 15, 1994Document12 pagesI. Model PC-12, Normal Category, Approved July 15, 1994Juan2323petisNo ratings yet

- Tooling ListDocument4 pagesTooling ListPiyushNo ratings yet

- YTWDocument2 pagesYTWwpt_meNo ratings yet

- Hindle 4.2.2 Torque Characteristics PDFDocument6 pagesHindle 4.2.2 Torque Characteristics PDFpandit1010No ratings yet

- E2b060series Overcenter ParkerDocument11 pagesE2b060series Overcenter ParkerElisabet Carreras MarcosNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document1 pageS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)LIONN TESTE2021No ratings yet

- Hitachi Zunoh 3100fDocument3 pagesHitachi Zunoh 3100fmehNo ratings yet

- Bosch Rexroth - Datasheet - Counterbalance ValvesDocument2 pagesBosch Rexroth - Datasheet - Counterbalance ValvesDiogo LuisNo ratings yet

- Metering SatamDocument3 pagesMetering SatamYohanes AzzisNo ratings yet

- Httplequoc vnuploadsuserfiles38AE PDFDocument6 pagesHttplequoc vnuploadsuserfiles38AE PDFnam nguyenNo ratings yet

- Superelevation ENGLISH V5 - 3 (C. Pillar 2-04-05)Document19 pagesSuperelevation ENGLISH V5 - 3 (C. Pillar 2-04-05)Yohannes GirmaNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document1 pageS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)BaytolgaNo ratings yet

- 2014 NSFMWDocument13 pages2014 NSFMWibharNo ratings yet

- 2014 NSFMWDocument13 pages2014 NSFMWibharNo ratings yet

- 2013 NSFMWDocument22 pages2013 NSFMWibharNo ratings yet

- 4268538Document196 pages4268538ibharNo ratings yet

- DFDFDocument2 pagesDFDFibharNo ratings yet

- Standard Materials of Construction: Venturi Fire Pump Test MetersDocument1 pageStandard Materials of Construction: Venturi Fire Pump Test MetersibharNo ratings yet

- NSFMW Paper Prod Alloc Depoly From Concept To Ops Final 181027 PDFDocument12 pagesNSFMW Paper Prod Alloc Depoly From Concept To Ops Final 181027 PDFibharNo ratings yet

- Global Fire Pump Model Numbers PDFDocument2 pagesGlobal Fire Pump Model Numbers PDFibharNo ratings yet

- Ex 7 400 4 Product Sheet WCM 1Document4 pagesEx 7 400 4 Product Sheet WCM 1ibharNo ratings yet

- B&PV Secc III 2007 NH PDFDocument28 pagesB&PV Secc III 2007 NH PDFibharNo ratings yet

- SPEC0Document2 pagesSPEC0ibharNo ratings yet

- Control Valves 91000Document16 pagesControl Valves 91000ibharNo ratings yet

- The Basics of Uninterruptible Power Supplies: Electrical Construction and MaintenanceDocument9 pagesThe Basics of Uninterruptible Power Supplies: Electrical Construction and MaintenanceibharNo ratings yet

- DP Level Configuration AssistantDocument2 pagesDP Level Configuration AssistantibharNo ratings yet

- Uninterruptible Power SuppliesDocument5 pagesUninterruptible Power SuppliesibharNo ratings yet

- EREDocument27 pagesEREibharNo ratings yet

- Firestop: B-Line Series Cable Tray Systems EatonDocument6 pagesFirestop: B-Line Series Cable Tray Systems EatonibharNo ratings yet

- A Construction Engineers Guide To Selecting The Right Type of Electrical Raceway - Metallic Conduit OptionsDocument3 pagesA Construction Engineers Guide To Selecting The Right Type of Electrical Raceway - Metallic Conduit OptionsibharNo ratings yet

- SDFDocument3 pagesSDFibharNo ratings yet

- Basics Uninterruptible PoDocument9 pagesBasics Uninterruptible PoibharNo ratings yet

- DerDocument60 pagesDeribharNo ratings yet

- Conduit Anoxidable Tablas PDFDocument32 pagesConduit Anoxidable Tablas PDFibharNo ratings yet

- How To Pipe and Cable Locate UndergroundDocument46 pagesHow To Pipe and Cable Locate Undergroundengineersupply100% (5)

- Controls and Flowmeters PDFDocument40 pagesControls and Flowmeters PDFibharNo ratings yet

- Torque sizing analysis chart and calculations for trunnion ball valvesDocument1 pageTorque sizing analysis chart and calculations for trunnion ball valvesibharNo ratings yet

- JointDocument62 pagesJointibharNo ratings yet

- 9 ExpansionJointDocument22 pages9 ExpansionJointJohnson V. JamesNo ratings yet

- Superconductivity in RH S and PD Se: A Comparative StudyDocument5 pagesSuperconductivity in RH S and PD Se: A Comparative StudyChithra ArulmozhiNo ratings yet

- ISCOM HT803 DatasheetDocument2 pagesISCOM HT803 Datasheetnmc79No ratings yet

- Gallium Nitride Materials and Devices IV: Proceedings of SpieDocument16 pagesGallium Nitride Materials and Devices IV: Proceedings of SpieBatiriMichaelNo ratings yet

- Valve Actuator Data SheetDocument1 pageValve Actuator Data SheetRob StorrowNo ratings yet

- Kalayaan Elementary SchoolDocument3 pagesKalayaan Elementary SchoolEmmanuel MejiaNo ratings yet

- Superalloy Brochure PDFDocument16 pagesSuperalloy Brochure PDFDaren NeradNo ratings yet

- Pumps - IntroductionDocument31 pagesPumps - IntroductionSuresh Thangarajan100% (1)

- MITRES 6 002S08 Chapter2Document87 pagesMITRES 6 002S08 Chapter2shalvinNo ratings yet

- Lecture 2 Principle of EMRDocument33 pagesLecture 2 Principle of EMRizhar engkuNo ratings yet

- Digital Logic Design - Switch Logic & Basic GatesDocument27 pagesDigital Logic Design - Switch Logic & Basic GatesTroon SoonNo ratings yet

- 98 99 Anti Lock BrakesDocument101 pages98 99 Anti Lock BrakestrialnaqueraNo ratings yet

- e-GP System User Manual - Tender Evaluation Committee UserDocument82 pagese-GP System User Manual - Tender Evaluation Committee UserMd. Jakaria ApuNo ratings yet

- QAF10A200S TheTimkenCompany 2DSalesDrawing 03 06 2023Document1 pageQAF10A200S TheTimkenCompany 2DSalesDrawing 03 06 2023LeroyNo ratings yet

- Apriori AlgorithmDocument13 pagesApriori AlgorithmKiran JoshiNo ratings yet

- Die Science - Developing Forming Dies - Part I - The FabricatorDocument6 pagesDie Science - Developing Forming Dies - Part I - The FabricatorSIMONENo ratings yet

- UG WeibullDocument776 pagesUG WeibullCharles GuzmanNo ratings yet

- 0001981572-JAR Resources in JNLP File Are Not Signed by Same CertificateDocument13 pages0001981572-JAR Resources in JNLP File Are Not Signed by Same CertificateAnonymous AZGp1KNo ratings yet

- c1Document19 pagesc1vgnagaNo ratings yet

- F (X, Y) Sin (Xy) + X LN (Y) Find F at (0, )Document9 pagesF (X, Y) Sin (Xy) + X LN (Y) Find F at (0, )muhammad abrarNo ratings yet

- 3BSE079234 - en 800xa 6.0 ReleasedDocument7 pages3BSE079234 - en 800xa 6.0 ReleasedFormat_CNo ratings yet

- PTP - Level MethodsDocument23 pagesPTP - Level Methodssasikiran mNo ratings yet

- 10th Term Exams Computer Science PaperDocument2 pages10th Term Exams Computer Science PaperMohammad Tariq JavaidNo ratings yet

- VRV A 12 PDFDocument1 pageVRV A 12 PDFMoe Thiri ZunNo ratings yet

- Haidarali-MR-2011-PhD-Thesis 01 PDFDocument378 pagesHaidarali-MR-2011-PhD-Thesis 01 PDFIbrahim KhanNo ratings yet