Professional Documents

Culture Documents

Sampling Program in Hydrocarbon Processing Infographic

Uploaded by

scribd_alphaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sampling Program in Hydrocarbon Processing Infographic

Uploaded by

scribd_alphaCopyright:

Available Formats

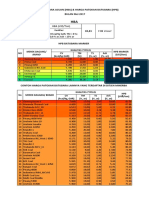

Sampling Program in Hydrocarbon Processing

Sample Integrity Process Monitoring Sampling Uptime

Avoid human bias and contamination by Avoid Lock-out, Tag-out of poorly designed Keep sample panels in peak performance

collecting samples with reliable sample sample panels. Ensure uninterrupted with regular inspections and replacement of

panels engineered specifically for each monitoring of processes to proactively wear parts. Ensure uptime with preventative

application. protect plant equipment from corrosion. maintenance specific to your application.

Only Sentry can handle all types

of hydrocarbon sampling

Gas Liquid Solid Steam

Crude Desulfurization

Amines Caustic Desalter Amines Catalysts Caustic

Feedstock Resid Condensate Fuel Gas

Recovered Oil Sour Water Sulfur

Cracking (FCCU)

Catalysts Heavy Oils Reforming

Key

Light Oils Sour Water Aromatics Butane Methane

Naphtha Propane

Hydrotreating

Amines Condensate Hydrogen Alkylation & Isomerization

Naphtha Product Sour Water Applications Acids Butane Condensate

Finish Product Coking

Asphalt Diesel Gasoline Amines Ammonia Caustic Coke

Jet Fuel Kerosene LPG Condensate Lube Oils Resid Sour Water

Key Management Issues

Operator and Product Quality Regulatory Compliance

Environmental Safety Trust your product quality testing results Sampling equipment made by suppliers

A low-emission, closed-loop sampling with samples collected by sample panels with an ISO 9001 certification and designed

approach protects the operator from volatile engineered specifically to handle the to meet ASME, NACE, HAXLOC and/or CRN,

and/or toxic exposure while preventing temperatures, pressures and corrosiveness CE, PED and ATEX standards are important

spills into the environment. found in Hydrocarbon processing. to meeting health and safety regulations.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Oman PR-1159 - Commissioning and Start-UpDocument116 pagesOman PR-1159 - Commissioning and Start-Upscribd_alpha100% (2)

- Fast Pyrolysis and Bio Oil Upgrading Presentation)Document46 pagesFast Pyrolysis and Bio Oil Upgrading Presentation)api-3799861100% (3)

- Argus Biofuels (2023!08!08)Document11 pagesArgus Biofuels (2023!08!08)Pitipat LeeNo ratings yet

- Column PipingDocument25 pagesColumn Pipingscribd_alphaNo ratings yet

- API RP 530-2009 Data BookDocument120 pagesAPI RP 530-2009 Data Bookscribd_alphaNo ratings yet

- API RP 530-2009 Data BookDocument120 pagesAPI RP 530-2009 Data Bookscribd_alphaNo ratings yet

- Unit Iii Fuels and CombustionDocument30 pagesUnit Iii Fuels and CombustionKKiranKumarNo ratings yet

- Home Automation Projects With Arduino - Ebook PDFDocument190 pagesHome Automation Projects With Arduino - Ebook PDFscribd_alpha100% (6)

- DME Haldor Topsoe BroshurDocument2 pagesDME Haldor Topsoe BroshurPloychompoo HanyanuwatNo ratings yet

- VmgsimDocument65 pagesVmgsimObatarhe Ogra100% (1)

- Calculation For Vacuum CondenserDocument0 pagesCalculation For Vacuum Condenserraden_aditiya39No ratings yet

- CM Model 5 Coalescer Cartridges PDFDocument2 pagesCM Model 5 Coalescer Cartridges PDFscribd_alphaNo ratings yet

- TS-2014 PDFDocument4 pagesTS-2014 PDFscribd_alphaNo ratings yet

- C1.0 Series Absolute Rated Vapor Phase ElementsDocument1 pageC1.0 Series Absolute Rated Vapor Phase Elementsscribd_alphaNo ratings yet

- Roles and Responsibilities of Plant Commissioning Rev 3 PDFDocument15 pagesRoles and Responsibilities of Plant Commissioning Rev 3 PDFNavpreet SinghNo ratings yet

- Process Sampling 101Document10 pagesProcess Sampling 101scribd_alphaNo ratings yet

- Carbonyl PDFDocument7 pagesCarbonyl PDFscribd_alphaNo ratings yet

- PyroGreen October 2017 UnconfidentialDocument14 pagesPyroGreen October 2017 Unconfidentialscribd_alphaNo ratings yet

- Condenser Hpi 1708Document9 pagesCondenser Hpi 1708scribd_alphaNo ratings yet

- Predifined Eagle LayersDocument1 pagePredifined Eagle Layersscribd_alphaNo ratings yet

- TCM809/TCM810: 3-Pin Microcontroller Reset MonitorsDocument16 pagesTCM809/TCM810: 3-Pin Microcontroller Reset Monitorsscribd_alphaNo ratings yet

- 611 3001 1 PB PDFDocument6 pages611 3001 1 PB PDFscribd_alphaNo ratings yet

- Gas RotametersDocument3 pagesGas Rotametersscribd_alpha100% (1)

- Klinger Catalogue 2013Document296 pagesKlinger Catalogue 2013pandiangvNo ratings yet

- GDKDocument17 pagesGDKscribd_alphaNo ratings yet

- 470 FLOW Report - INFLUENCE OF THERMODYNAMIC CALCULATIONS ON THE FLOW RATE OF SONIC NOZZLESDocument12 pages470 FLOW Report - INFLUENCE OF THERMODYNAMIC CALCULATIONS ON THE FLOW RATE OF SONIC NOZZLESscribd_alphaNo ratings yet

- TCM809/TCM810: 3-Pin Microcontroller Reset MonitorsDocument16 pagesTCM809/TCM810: 3-Pin Microcontroller Reset Monitorsscribd_alphaNo ratings yet

- TLV431x Low-Voltage Adjustable Precision Shunt Regulator: 1 Features 2 ApplicationsDocument52 pagesTLV431x Low-Voltage Adjustable Precision Shunt Regulator: 1 Features 2 Applicationsscribd_alphaNo ratings yet

- Bombas de Vacío Sihi LPH - Pac EnglishDocument11 pagesBombas de Vacío Sihi LPH - Pac EnglishGENRRYCURONo ratings yet

- 07 07 2017Document1 page07 07 2017scribd_alphaNo ratings yet

- MTOMR2016Document127 pagesMTOMR2016scribd_alphaNo ratings yet

- Tutorial ChemsepDocument333 pagesTutorial ChemsepJosé Luis Lustau Álvarez-Cienfuegos100% (1)

- TI - TAS5086-5186V6EVM Application Reportslea054Document39 pagesTI - TAS5086-5186V6EVM Application Reportslea054scribd_alphaNo ratings yet

- Bref-General Principle of Monitoring PDFDocument123 pagesBref-General Principle of Monitoring PDFscribd_alphaNo ratings yet

- The Utilization of Banana Peels To Produce BriquettesDocument7 pagesThe Utilization of Banana Peels To Produce BriquettesEarl Joy EJ DalaganNo ratings yet

- S.No. 34. Petrol Interceptor Approved DrawingDocument1 pageS.No. 34. Petrol Interceptor Approved DrawingJOv ElNo ratings yet

- DPP2 - Combustion and FlameDocument2 pagesDPP2 - Combustion and FlameAnanya ShrivastavaNo ratings yet

- BioGasoline PDFDocument19 pagesBioGasoline PDFSyed Ahmed FlareNo ratings yet

- SR.N o Party Name Location/ District Contacted Through Sourc eDocument4 pagesSR.N o Party Name Location/ District Contacted Through Sourc eRounakNo ratings yet

- Liquid FuelsDocument26 pagesLiquid FuelsSHANE MABUGAYNo ratings yet

- Petroleum Geology MCQsDocument7 pagesPetroleum Geology MCQsOxaLic Acid100% (1)

- 4.1 Properties of LPG As Engine Fuel: Prepared By:-Prajwal WaghmareDocument3 pages4.1 Properties of LPG As Engine Fuel: Prepared By:-Prajwal WaghmareAniket DhoneNo ratings yet

- 25-Fuel SystemDocument21 pages25-Fuel SystemПавелNo ratings yet

- Prices Effective Dated December 01 2013Document41 pagesPrices Effective Dated December 01 2013Ayyaz ShadNo ratings yet

- Unit 3 Checkpoint 1 AssignmentDocument5 pagesUnit 3 Checkpoint 1 AssignmentAndrew MNo ratings yet

- BaluDocument18 pagesBaluAlexiaa RahmaaNo ratings yet

- Ul Valvula Impacto EmcoDocument1 pageUl Valvula Impacto EmcolunaNo ratings yet

- Soo-Young No: Article InfoDocument9 pagesSoo-Young No: Article InfoAlexander VovaNo ratings yet

- BP Tank Wash Guide - New2006Document1 pageBP Tank Wash Guide - New2006nivasmarineNo ratings yet

- 8th Science CBSE Test Paper Solved Chapter 5 Coal and PetroleumDocument4 pages8th Science CBSE Test Paper Solved Chapter 5 Coal and PetroleumManash SinghaNo ratings yet

- Quality and Coal Resources of PakistanDocument2 pagesQuality and Coal Resources of PakistanProcess EngineerNo ratings yet

- Harga Batubara Acuan (Hba) & Harga Patokan Batubara (HPB) BULAN Mei 2017Document4 pagesHarga Batubara Acuan (Hba) & Harga Patokan Batubara (HPB) BULAN Mei 2017Dans RohmanNo ratings yet

- Alternate Fules Report-HariDocument20 pagesAlternate Fules Report-Hari18-331 YUGANDHARNo ratings yet

- Birquttes SantoiDocument21 pagesBirquttes SantoiEdward UyNo ratings yet

- Prices Effective Dated April 01 2016Document13 pagesPrices Effective Dated April 01 2016Adnan AkhtarNo ratings yet

- Fuels PptsDocument39 pagesFuels Pptspranay639No ratings yet

- Production of MTBE (Methyl Tertiary Butyl Ether) From Methanol and Butylene by Catalytic ConversionDocument11 pagesProduction of MTBE (Methyl Tertiary Butyl Ether) From Methanol and Butylene by Catalytic ConversionAsim RafiqueNo ratings yet

- Jurnal BioavturDocument53 pagesJurnal BioavturAvra ZNo ratings yet

- SMR Hydrogen Generators-Technologies and Producers 2009Document28 pagesSMR Hydrogen Generators-Technologies and Producers 2009Zoran JuricNo ratings yet