Professional Documents

Culture Documents

CHEM PDF A Approved

Uploaded by

Azhar KhanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CHEM PDF A Approved

Uploaded by

Azhar KhanCopyright:

Available Formats

Technical Datasheet

Chemical Seals Issue A

Chemical Seals

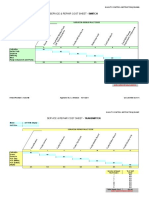

FLUSHING CONNECTION OPTION: GIVES ALL ‘ONE PIECE’ CONTRUCTION

THE ABILITY TO EMPTY THE FILLING FOR ½ “ MPT CONNECTION

MEDIUM WITHOUT REMOVING THE

PROCESS CONNECTION

ENLARGED SECTION SHOWING WELDED

DIAPHRAGM AND POSITION OF PTFE Product applications

SEAL:

Chemical Seals are suitable for a wide

range of applications in many Industry

sectors:

• Oil & Gas

PTFE SEAL

• Chemical

• Power Generation

• Pharmaceutical

• Food & Beverage

The choice of models available ensures

that the Chemical Seals are suitable for

• Stainless Steel Construction

use in:

• Screwed Connections • Corrosive atmospheres

• Flanged Connections • Resistant to chemical attack

• Various Wetted Parts (Stainless Steel, Tantalum)

• Welded Diaphragm How can we help you?

Delta Controls’ range of reliable

• Supplied with studs

pressure and temperature

• Direct or Remote Mount options

measurement instruments can be

• Maximum Working pressure up to 250 bar* customised to meet individual

requirements. For technical advice or to

*The MWP of the instrument and chemical seal assembly will be discuss your application please contact

equal to whichever of the two individual components is lowest. us on +44 (0) 20 8939 3500

TDS. ChemSeals0106 ISSUE A

How to order Chemical Seals

Typical Delta Model Number Consisting of 17 Characters

Characters 11,14,15,16 and 17 define the chemical seal as shown Material of

Wetted Process

Parts Connection

Type and P Max System Detail

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

Code

Standard CFS Code Mounting

1

<1.5 bar 00 Direct Mount

Standard CFS Capillary Lengths 1 metre to 9 metres in 1

2 01-09

>1.5 bar metre graduations

Non Standard

3

CFS <1.5 bar

Non Standard

4

CFS >1.5 bar

Note: Codes 3 & 4 are only used for non- Code Process Connection

standard CFSs that cannot be specified by

the options available on this datasheet 0 1/2” 150 lb RF ANSI

1 1” 150 lb RF ANSI

2 1 1/2” 150 lb RF ANSI

Process

Diaphragm 3 2” 150 lb RF ANSI

Code Connection Seal

Material 4 3” 150 lb RF ANSI

Material

F Stainless Steel Stainless Steel PTFE 5 1/2” 300 lb RF ANSI

6 1” 300 lb RF ANSI

M Monel Monel PTFE (NACE)

7 1 1/2” 300 lb RF ANSI

Monel Solution Annealed

V PTFE (NACE) 8 2” 300 lb RF ANSI

Stainless Steel

9 3” 300 lb RF ANSI

Tantalum Solution Annealed A Rc 1/4

W Stainless Steel PTFE (NACE)

F 1/4” NPTF

Y PTFE Overlay Stainless Steel PTFE J 1/2” NPTM

Z PTFE Overlay PTFE PTFE H 1/2” NPT Internal

K G1/2 B

Information Required at Quotation Stage:

Process Operating Limits: …………… °C To …………… °C

Ambient Temperature Range: …………… °C To …………… °C

Filling Medium Temperature Range Oxy Service + Chlorine

1 ST66 (Santotherm) +20 to +300°C N/A

2 SL 200/20 (Silicone) -50 to +200°C N/A

3 FLB (Flurolube) -20 to +100°C Yes

Options:

Capillary lengths over 9 metres

PVC Capillary cover

Flushing Connection

Material Certification / DIN 3.1B

Health and Safety Data Sheet

Alternative Process Connection

Alternative Materials

N.B. Please contact Delta-Controls for coding of these non-standard options

Delta Controls Limited

Island Farm Avenue, West Molesey, Surrey KT8 2UZ, UK.

T+44 (0)20 8939 3500 F+44 (0)20 8783 1163 E sales@delta-controls.com W www.delta-controls.com

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Staff Survey - Covid MeasuresDocument1 pageStaff Survey - Covid MeasuresAzhar KhanNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Design MethodologyDocument10 pagesDesign MethodologyEt GilewNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Resinlab - EP1340 TDSDocument3 pagesResinlab - EP1340 TDSAzhar KhanNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- PC 28Document3 pagesPC 28Azhar KhanNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Cooper - Intrinsic Safety GuideDocument20 pagesCooper - Intrinsic Safety Guidetkdrt2166100% (2)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Diff Between EN50021 Vs EN60079-15Document1 pageDiff Between EN50021 Vs EN60079-15Azhar KhanNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Service & Repair Cost Sheet - Switch: D P Ar Ts Te M S E NC Lo Su Re Au LT Ith M Ec H TW Ith R An Ge NT C Om Po Ne NT SDocument3 pagesService & Repair Cost Sheet - Switch: D P Ar Ts Te M S E NC Lo Su Re Au LT Ith M Ec H TW Ith R An Ge NT C Om Po Ne NT SAzhar KhanNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Design of LeversDocument21 pagesDesign of Leverssbkulk90% (10)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Variseal enDocument88 pagesVariseal enAzhar KhanNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Mechanical Properties of Fasteners Made of Carbon Steel and Alloy SteelDocument1 pageMechanical Properties of Fasteners Made of Carbon Steel and Alloy SteelAzhar KhanNo ratings yet

- RS210SEAH3XX00BKCDocument1 pageRS210SEAH3XX00BKCAzhar KhanNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- ATEXExd SentryDocument2 pagesATEXExd SentryAzhar KhanNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Design Guide For Surface Coating 05 v18 72dpiDocument54 pagesDesign Guide For Surface Coating 05 v18 72dpifunluaslan100% (2)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Application Form - IP Testing (TypeIP1) Iss2 1008Document1 pageApplication Form - IP Testing (TypeIP1) Iss2 1008Azhar KhanNo ratings yet

- Habia Wire - DatasheetDocument1 pageHabia Wire - DatasheetAzhar KhanNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- What Are End of Line Resistors and Do I Need ThemDocument3 pagesWhat Are End of Line Resistors and Do I Need ThemAzhar KhanNo ratings yet

- Flash TestDocument1 pageFlash TestAzhar KhanNo ratings yet

- 28FD01Document2 pages28FD01Azhar KhanNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- SRD 387Document1 pageSRD 387Azhar KhanNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Corrosion Resistance PlatingDocument1 pageCorrosion Resistance PlatingAzhar KhanNo ratings yet

- Fera Activity Listing - Hydrogen - March 06Document4 pagesFera Activity Listing - Hydrogen - March 06cdkeni23No ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Engineering Drawings IntrodroductionDocument39 pagesEngineering Drawings Introdroductionadnan100% (3)

- Design Guide For Surface Coating 05 v18 72dpiDocument54 pagesDesign Guide For Surface Coating 05 v18 72dpifunluaslan100% (2)

- 213Document14 pages213Azhar KhanNo ratings yet

- Differential Geometry of Curves and Surfaces 3. Regular SurfacesDocument16 pagesDifferential Geometry of Curves and Surfaces 3. Regular SurfacesyrodroNo ratings yet

- Resumen C37 010 Aplicacion de Breaker Disenados IC Simetrica PDFDocument9 pagesResumen C37 010 Aplicacion de Breaker Disenados IC Simetrica PDFglendathais100% (1)

- Prawn ProcessingDocument21 pagesPrawn ProcessingKrishnaNo ratings yet

- Full Download Short Term Financial Management 3rd Edition Maness Test BankDocument35 pagesFull Download Short Term Financial Management 3rd Edition Maness Test Bankcimanfavoriw100% (31)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Mini Project 1 - 1Document9 pagesMini Project 1 - 1Sameer BaraNo ratings yet

- ASCE Snow Loads On Solar-Paneled RoofsDocument61 pagesASCE Snow Loads On Solar-Paneled RoofsBen100% (1)

- Food Biotechnology in Ethical PerspectiveDocument340 pagesFood Biotechnology in Ethical Perspectivemojtaba2500100% (2)

- Trawl Master Present A TieDocument19 pagesTrawl Master Present A Tieapi-3719203No ratings yet

- Accuity: High Speed Automated 2D & 3D Optical Gauging Single Click Setup and InspectionDocument4 pagesAccuity: High Speed Automated 2D & 3D Optical Gauging Single Click Setup and InspectionAPPLENo ratings yet

- Modified Phosphate and Silica Waste in Pigment PaintDocument12 pagesModified Phosphate and Silica Waste in Pigment PaintDani M RamdhaniNo ratings yet

- History and Philo of ScienceDocument5 pagesHistory and Philo of ScienceJan Oliver YaresNo ratings yet

- Viscous Fluid Flow Frank M White Third Edition - Compress PDFDocument4 pagesViscous Fluid Flow Frank M White Third Edition - Compress PDFDenielNo ratings yet

- DEEP ECOLOGY - An Intro - McLaughlinDocument5 pagesDEEP ECOLOGY - An Intro - McLaughlinCarlo MagcamitNo ratings yet

- DS Ltch00601daa0 R05Document4 pagesDS Ltch00601daa0 R05rajareddy235No ratings yet

- Communication Guide: For Vita 62 Compliant VPX Power SuppliesDocument8 pagesCommunication Guide: For Vita 62 Compliant VPX Power Suppliesk.saikumarNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Calibration of Force ReductionDocument36 pagesCalibration of Force Reductionvincenzo_12613735No ratings yet

- Module in Pe 103Document79 pagesModule in Pe 103Kym Dacudao100% (1)

- L2 Biostatistics ProbabilityDocument84 pagesL2 Biostatistics ProbabilityAaron CiudadNo ratings yet

- Material Requirement Planning (MRP)Document55 pagesMaterial Requirement Planning (MRP)Lisa CarlsonNo ratings yet

- Yadea User Manual For e Scooter 1546004910Document44 pagesYadea User Manual For e Scooter 1546004910Danthe ThenadNo ratings yet

- PEDocument12 pagesPEMae Ann Base RicafortNo ratings yet

- Abnormalities of Placenta, Amniotic Fluid and Cord: Prepared By, B. Ezhilarasi, Nursing TutorDocument21 pagesAbnormalities of Placenta, Amniotic Fluid and Cord: Prepared By, B. Ezhilarasi, Nursing TutorGopala KrishnanNo ratings yet

- Recycling Mind MapDocument2 pagesRecycling Mind Mapmsole124100% (1)

- Intel Stratix 10 Avalon - MM Interface For PCI Express Solutions User GuideDocument173 pagesIntel Stratix 10 Avalon - MM Interface For PCI Express Solutions User Guideenoch richardNo ratings yet

- Index PDFDocument159 pagesIndex PDFHüseyin IşlakNo ratings yet

- Apcotide 1000 pc2782Document1 pageApcotide 1000 pc2782hellmanyaNo ratings yet

- Convection Concentric Annulus Vertical Cylinders Filling Porous MediaDocument17 pagesConvection Concentric Annulus Vertical Cylinders Filling Porous MediakarthikeyanNo ratings yet

- Sudip Praposal - 1Document20 pagesSudip Praposal - 1Usha BbattaNo ratings yet

- 09 Passport 7K 15K Performance Guidelines PCR 3 0Document44 pages09 Passport 7K 15K Performance Guidelines PCR 3 0thed719No ratings yet

- MiscanthusDocument27 pagesMiscanthusJacob GuerraNo ratings yet

- Periodic Tales: A Cultural History of the Elements, from Arsenic to ZincFrom EverandPeriodic Tales: A Cultural History of the Elements, from Arsenic to ZincRating: 3.5 out of 5 stars3.5/5 (137)

- Monkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeFrom EverandMonkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeRating: 4 out of 5 stars4/5 (1)

- Is That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeFrom EverandIs That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeRating: 5 out of 5 stars5/5 (4)

- The Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsFrom EverandThe Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsRating: 4 out of 5 stars4/5 (146)