Professional Documents

Culture Documents

Bomba Axial Sumergible - Estudio de Caso PDF

Uploaded by

Ángeles Rodríguez0 ratings0% found this document useful (0 votes)

9 views2 pagesOriginal Title

Bomba axial sumergible- Estudio de caso.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views2 pagesBomba Axial Sumergible - Estudio de Caso PDF

Uploaded by

Ángeles RodríguezCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Case study

Flygt submersible propeller pumps at

LaGuardia Airport, NY

Flygt submersible pumps eliminate flood damage concerns at LaGuardia airport

Hurricane Sandy paralyzed LaGuardia Airport as it rolled through the

Northeast in October 2012. After the airport’s five stormwater pump

stations lost power, an estimated 100 million gallons of water built up

to four feet deep at some points, including along the shuttle ramps

of this busy hub for Delta Airlines.

Scope

High water on an airfield always presents a problem, but in the

aftermath of the super storm, the Port Authority of New York &

New Jersey stepped up the planned replacement of the hydraulic

and electrical muscle of its Pump Stations #4 and #6, which drain

LaGuardia’s two runways. Installation of Flygt submersible pumps at

LaGuardia airport.

The Authority sought to replace the extended shaft propeller

End user: LaGuardia Airport, NY

pumps at Stations #4 and #6 with submersible pumps, which would

Client: LaGuardia Airport, NY

eliminate any concerns regarding conventional motor units being

Order date: 2013

damaged by flood waters. Submersible pump units have no above-

Completion: 2013

the-ground motors that can be damaged and taken out of service

due to impact.

Solution

To replace the existing pumping units, G. A. Fleet Associates, a

full-service Flygt factory representative located in Harrison, NY

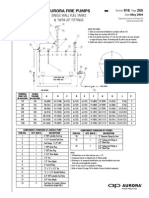

recommended Flygt brand PL-7101/300-hp electric submersible

Rated as explosion-proof for use in

hazardous locations, the Flygt axial

flow pumps are ideally suited for the

airside upgrade, where they will move

large volumes of water at low heads

(25 ft TDH).

propeller pumps which are designed to operate on the existing

4,160v power supply. Each of these units are mounted in 48-

inch diameter steel tubes, have a capacity of 33,000 gallons per

minute (gpm) and are of explosion-proof construction, approved

FCS123 • Flygt LaGuardia Airport, NY Case Study • 12/2013 • US

for use in hazardous locations due to the possibility of petroleum

products entering the wet-wells. The first two pumps were

installed at Runway Pump Station #6, and another seven pumps,

including one spare, await installation in Runway Pump Station #4,

following the completion of a new 5-kV substation.

The submersible design of the

nine identical Flygt propeller-type

pumps makes the motors inherently Flygt PL-7101/300-hp explosion-proof electric submers-

ible propeller pump unit awaiting installation.

invulnerable to submersion during Xylem, Inc.

high-water incidents. 14125 South Bridge Circle

Charlotte, NC 28273

Result Tel 704.409.9700

The replacement pumps function as an engineered system Fax 704.295.9080

that improves the airport’s stormwater control, flexibility, and www.xyleminc.com

operational efficiency. Flygt is a trademark of Xylem Inc. or one of its subsidiaries.

© 2013 Xylem, Inc. DEC 2013

The profile of the replacement pumps also adds clearance,

because the new pumps install completely within the collection

pit, unlike the taller vertical pumps that protruded approximately

10 feet above grade level. Adopting a standard primary www.youtube.com/flygtus

pump for the two runway stormwater stations also enables an

exchange with the spare pump in the event a unit is removed for

service.

The first two pumps are equipped with modular alarm

system panels that detect and identify the specific nature

of any malfunction. The alarm is transmitted via fiber-optic

communication line to a central station.

In addition to the turnkey engineering developed in

collaboration with a Flygt applications engineer, G.A. Fleet

Associates supplied the interface for the pump intakes, controls

and other components to facilitate the replacement by the

installation contractor. Flygt is a brand of Xylem Water Solutions

USA, Inc., which also supplied a number of smaller pumps for

the airport’s upgrade program.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Data Sheet Bluerov2Document2 pagesData Sheet Bluerov2Ángeles RodríguezNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- 2015-Intelligent Manager of Scientific Knowledge Based in Gamification (Gicci-Game)Document6 pages2015-Intelligent Manager of Scientific Knowledge Based in Gamification (Gicci-Game)Ángeles RodríguezNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Capital Cost AEO2020Document212 pagesCapital Cost AEO2020atiquegeeNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Capital Cost AEO2020Document212 pagesCapital Cost AEO2020atiquegeeNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Dimensionamiento de Ductouma1-Uma2 PDFDocument1 pageDimensionamiento de Ductouma1-Uma2 PDFÁngeles RodríguezNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Machinery FailureDocument4 pagesMachinery FailureÁngeles RodríguezNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Entrepiso (Plano-Difusores) PDFDocument1 pageEntrepiso (Plano-Difusores) PDFÁngeles RodríguezNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Entrepiso (Plano-Difusores) PDFDocument1 pageEntrepiso (Plano-Difusores) PDFÁngeles RodríguezNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Synthesis, Crystal Structure and Properties of Barium Coordination Compound Based On 1,3,5-Benzenetricarboxylic Acid Ligand PDFDocument8 pagesSynthesis, Crystal Structure and Properties of Barium Coordination Compound Based On 1,3,5-Benzenetricarboxylic Acid Ligand PDFÁngeles RodríguezNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- E Ductulator09Document9 pagesE Ductulator09josebolisNo ratings yet

- Catalogo de Difusores Serie 5000Document8 pagesCatalogo de Difusores Serie 5000Ángeles RodríguezNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- 1) - Small-Town Taxi Operates One Vehicle During The 9:00 A.M. To 5:00 P.M. PeriodDocument2 pages1) - Small-Town Taxi Operates One Vehicle During The 9:00 A.M. To 5:00 P.M. PeriodWaqas50% (2)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Iron and Steel MakingDocument90 pagesIron and Steel MakingTanzil ZaidiNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Phoenix Petroleum PhilippineDocument2 pagesPhoenix Petroleum PhilippinetwometersNo ratings yet

- DD2 MaintenanceDocument168 pagesDD2 MaintenanceCiprian RaileanuNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Lecture (1) Properties of Fluids: LecturerDocument28 pagesLecture (1) Properties of Fluids: LecturerILAYAPERUMAL KNo ratings yet

- Chapter 2: Heat Exchangers Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallDocument85 pagesChapter 2: Heat Exchangers Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallNadirah RahmanNo ratings yet

- 250D-7E Shop ManualDocument431 pages250D-7E Shop ManualChung ChungNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Greenstar Gas Combi Boilers Technical and Specification InformationDocument68 pagesGreenstar Gas Combi Boilers Technical and Specification InformationUmut ArslanNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Centrifugal PumpDocument166 pagesCentrifugal PumpvenkeekuNo ratings yet

- 5 Basic Rules of Pump PipingDocument2 pages5 Basic Rules of Pump PipingChotiwan Rattanasatien100% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- GE Frame 5 Gas Turbine MaintenanceDocument4 pagesGE Frame 5 Gas Turbine MaintenanceMohamed Nawar100% (2)

- 1WallTank NFPADocument1 page1WallTank NFPAshimrozkhanNo ratings yet

- Joost Van Bennekom - Glycerol 1Document221 pagesJoost Van Bennekom - Glycerol 1russell_mahmoodNo ratings yet

- Ethylene ExperimentDocument3 pagesEthylene ExperimentLexzyrie Sybelle S. TolarbaNo ratings yet

- 13 Relevant Costs For Decision MakingDocument87 pages13 Relevant Costs For Decision MakingEunice Jade Cresino100% (1)

- Compressors - Working and CharacteristicsDocument7 pagesCompressors - Working and CharacteristicsibnuharyNo ratings yet

- Metric and Inch (Sae) Fasteners: All ModelsDocument22 pagesMetric and Inch (Sae) Fasteners: All ModelsMONTACARGAS AVSNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Direct Injection: o o o oDocument7 pagesDirect Injection: o o o opardeep4372No ratings yet

- Reciprocating Compressor IIDocument59 pagesReciprocating Compressor IIAbdussalamElhanashi50% (2)

- New Text DocumentDocument18 pagesNew Text DocumentSpook SpooksenNo ratings yet

- Pumps Compressors / Fans / Blowers Vessels Miscellaneous Equipment Miscellaneous EquipmentDocument1 pagePumps Compressors / Fans / Blowers Vessels Miscellaneous Equipment Miscellaneous EquipmentHernan Humberto Castañeda MendozaNo ratings yet

- List Vendor CatalogDocument54 pagesList Vendor CatalogNugrawan Satria100% (2)

- IDT Imageprospekt 2012 Web enDocument46 pagesIDT Imageprospekt 2012 Web enjbharghavNo ratings yet

- Asia Merchant Hydrogen Plants Jan 2016Document3 pagesAsia Merchant Hydrogen Plants Jan 2016totpityiNo ratings yet

- ORG LAB Extraction2009Document10 pagesORG LAB Extraction2009Ivan Markus KiranaNo ratings yet

- API 12B Comparison PDFDocument6 pagesAPI 12B Comparison PDFgst ajahNo ratings yet

- FAT ProcedureDocument6 pagesFAT Procedurebmanojkumar16100% (2)

- Hydro Electric Power Plants-GovernorDocument19 pagesHydro Electric Power Plants-GovernorAnonymous PvzeJ38Y8No ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Ums OperationDocument27 pagesUms OperationSwarg Vibha0% (1)

- Manrose Ventilation Fan Catalogue PDFDocument108 pagesManrose Ventilation Fan Catalogue PDFRendani VeleNo ratings yet