Professional Documents

Culture Documents

16.3 Dpi

Uploaded by

Adhe Iermha Suryanie0 ratings0% found this document useful (0 votes)

23 views1 pagedesain produkindustri

Original Title

16.3 DPI

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentdesain produkindustri

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

23 views1 page16.3 Dpi

Uploaded by

Adhe Iermha Suryaniedesain produkindustri

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 1

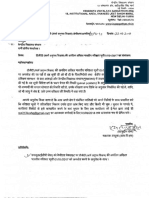

Materials, Process/Manufacturing, and

Product Technologies for Configured

Consumer Products

Sorbent Dialysis

At most hemodialysis centers, the rich dialysate from the hemodialysis devices is not regenerated and recycled,

but disposed of through drains and replaced by freshly diluted solution. This process, known as single-pass

dialysis, requires large volumes of ultra-pure water, typically prepared using reverse osmosis, activated carbon,

deionization, and the like. The necessary equipment and holding tanks are expensive and require much space

and, consequently, are not well suited for home hemodialysis products. In the Allient 1 Sorbent Hemodialysis

System (see the Sorbent Dialysis Primer and History of Sorbent Dialysis Web sites), the spent dialysate is

chemically regenerated by passing through a disposable cartridge containing layers of activated carbon, the

urease enzyme, and ionexchange membranes. A small amount of makeup solution, called the infusate,

replenishes any essential ions lost in the filter. Thanks to this regeneration process, only 6 L are required for

each treatment session, compared with greater than 120 L for single-pass dialysis. In addition to removing urea

from the dialysate, the cartridge removes bacteria, heavy metals, and other contaminants from ordinary tap

water, eliminating the need for water-treatment equipment. New devices are completely portable, requiring only

a source of electricity (see the Sorbent Dialysis Primer Web site). The first sorbent dialysis system was

developed in the early 1970s and was sold under the REDY 1 brand name (for REcirculating DYalysis). Its use

continued throughout the 1980s and, in 1993, a portable device was created. FDA approval for this device was

not completed, however, and production was suspended until 1999, when SORB Technology, Inc., obtained the

REDY 1 brand and renewed interest in sorbent dialysis. After merging with Renal Solutions, Inc., in 2001, they

began to develop a system for home use. Renal Solutions, Inc., recently obtained FDA approval to market their

product, the Allient Sorbent Dialysis System, for both in-center and home treatment (see the History of Sorbent

Dialysis Web site). As shown in Figure 16.23, the used dialysate from the hemodialysis unit enters a purification

layer, consisting of activated carbon, to remove particulate matter, heavy metals, etc. Next, the dialysate passes

through a layer of the urease enzyme, which converts urea to ammonium and carbonate ions, that is, ammonium

carbonate. It next passes through a zirconium phosphate layer (cation exchanger), where the dangerous

ammonium ions are exchanged for hydrogen and sodium. A layer of zirconium oxide (anion exchanger) binds

fluorides and phosphates that have been removed from the blood. Because the urease enzyme can break down

unlimited amounts of urea, the main limitation of the cartridge is its capacity to bind ammonia. Current

cartridges (known as SORB TM and HISORB TM ) can process 20–30 g of urea nitrogen before losing their

ability to bind ammonia. A breakthrough of ammonia, when its concentration exceeds 1 TM 2 wt%, indicates that

the capacity has been exceeded and the cartridge must be changed (see the Sorbent Dialysis Primer Web site,

page 6).

b. Technology Protection To protect their technology, prior to designing a new home hemodialysis

product, product-development teams need to be aware of existing patents. In July 2007, an advanced Google

patent search for the term ‘‘home hemodialysis’’ returned 37 patents. The breakdown by decade is as follows:

As seen, far more patents were issued in the 1990s than in the other decades. Many of the inventors cited the

low percentage of patients undergoing dialysis at home and offered solutions they believed would increase the

popularity of this treatment. The following categories were well represented in the search results: On the basis

of this search, it seems clear that the principal technologies associated with the hemodialysis device and the

sorbent dialysis cartridge have been identified (U.S. Patents 3,865,726; 4,276,173; D282,578; 5,783,124;

3,669,878; 4,473,449; 6,878,283; 4,148,314; 6,804,991). Before initiating the design of the home hemodialysis

product in Section 17.3, a more specific search should be carried out for patents associated with devices to

improve safety and for machine disinfection. When significant technologies are located, they can be added to the

innovation map. Other references on hemodialysis devices, in general, include Misra (2005) and Shapiro (2004).

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- CMM 25-11-466529430584234180428Document288 pagesCMM 25-11-466529430584234180428Radmanovic Uros MrmyNo ratings yet

- Crichton, Michael - NextDocument351 pagesCrichton, Michael - NextrtarakNo ratings yet

- Intro To Computing SyllabusDocument7 pagesIntro To Computing SyllabusAireen Rose Rabino ManguiranNo ratings yet

- 4 Absorber Stripper d3Document3 pages4 Absorber Stripper d3Adhe Iermha SuryanieNo ratings yet

- New Doc 2018-05-26 PDFDocument3 pagesNew Doc 2018-05-26 PDFAdhe Iermha SuryanieNo ratings yet

- Pemisahan DiffusionalDocument3 pagesPemisahan DiffusionalAdhe Iermha SuryanieNo ratings yet

- Anaerobic Digestion Basics: Lide Chen and Howard NeiblingDocument4 pagesAnaerobic Digestion Basics: Lide Chen and Howard NeiblingAdhe Iermha SuryanieNo ratings yet

- TDS LF-361Document2 pagesTDS LF-361ofershochetNo ratings yet

- Checkpoint R65 QoS Admin GuideDocument220 pagesCheckpoint R65 QoS Admin GuidePradeep_KNVPNo ratings yet

- Svcet: Unit IV Traveling Waves On Transmission LineDocument21 pagesSvcet: Unit IV Traveling Waves On Transmission LineDeepak CoolNo ratings yet

- ANSI-IEEE, NEMA and UL Requirements For SwitchgearDocument4 pagesANSI-IEEE, NEMA and UL Requirements For Switchgearefmartin21No ratings yet

- RoundingDocument65 pagesRoundingSourav Kumar100% (1)

- Lecture 1 - Course IntroductionDocument46 pagesLecture 1 - Course IntroductionRifaqat ZaheerNo ratings yet

- Logitech Mouse M505 ManualDocument2 pagesLogitech Mouse M505 ManualbmmanualsNo ratings yet

- Exp 0002Document28 pagesExp 0002nag_gvnrNo ratings yet

- PGPX 2008 09 Placement BrochureDocument60 pagesPGPX 2008 09 Placement BrochureTom JerryNo ratings yet

- BOXER NH TC35DA TC40DA TC45DA Mount Instructions PDFDocument16 pagesBOXER NH TC35DA TC40DA TC45DA Mount Instructions PDFjwdNo ratings yet

- Standing Seam Installation-23-11-21Document35 pagesStanding Seam Installation-23-11-21Gokulnath TgNo ratings yet

- Dodge Ram Truck 2015 Hitch Plate Prep Parts DiagramDocument4 pagesDodge Ram Truck 2015 Hitch Plate Prep Parts DiagramStephen RivettNo ratings yet

- DORP Action PlanDocument3 pagesDORP Action PlanSantisas Zai100% (3)

- Accreditation ScopeDocument19 pagesAccreditation ScopeTrainer 01No ratings yet

- 17118Document5 pages17118hairilmasonNo ratings yet

- Apache Derby DatabaseDocument4 pagesApache Derby DatabaseJohn KrcmarikNo ratings yet

- Technics Su-7200 SMDocument21 pagesTechnics Su-7200 SMF_E_TermanNo ratings yet

- BC-5800 Liquid SystemDocument114 pagesBC-5800 Liquid SystemДмитрийNo ratings yet

- Ann (02) 23 08 2018Document73 pagesAnn (02) 23 08 2018Paul RajNo ratings yet

- CP R77.20 EndpointSecurity AdminGuideDocument168 pagesCP R77.20 EndpointSecurity AdminGuideMSNo ratings yet

- Information Leaflet: 1. Introduction To PieasDocument4 pagesInformation Leaflet: 1. Introduction To Pieascensored126No ratings yet

- Types and Construction of Biogas PlantDocument36 pagesTypes and Construction of Biogas Plantadeel_jamel100% (3)

- UHP Water Jetting Unit: Ultrabar 10 ECDocument1 pageUHP Water Jetting Unit: Ultrabar 10 ECFrederik CañabiNo ratings yet

- No More FTP White PaperDocument11 pagesNo More FTP White PaperrlogieNo ratings yet

- YUI 2.7 Cheat Sheets ConcatenatedDocument41 pagesYUI 2.7 Cheat Sheets Concatenatedcron112No ratings yet

- McQuay PFS C Installation Manual EngDocument17 pagesMcQuay PFS C Installation Manual EngAnbarasan Nagarajan100% (1)

- Norphonic VoIP D10003Document2 pagesNorphonic VoIP D10003Topcom Toki-VokiNo ratings yet