Professional Documents

Culture Documents

Technical Data Sheet Technical Data Sheet Technical Data Sheet Technical Data Sheet Brazetec S Brazetec S Brazetec S Brazetec S 5 5 5 5

Uploaded by

IonutCiobanuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Data Sheet Technical Data Sheet Technical Data Sheet Technical Data Sheet Brazetec S Brazetec S Brazetec S Brazetec S 5 5 5 5

Uploaded by

IonutCiobanuCopyright:

Available Formats

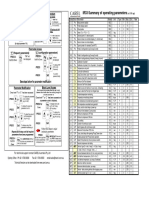

Technical Data Sheet

BrazeTec S 5

TD BT 0603 E.02

Inhalt

Standard

DIN EN 1044 CP 104 (L-Ag5P acc. DIN 8513)

ISO 3677 B-Cu89PAg-645/815

Nominal composition [wt.-%]

wt.-%] Cu remainder; Ag 5; P 6

Permitted impurities max. [wt.-%] Al 0,01; Bi 0,030; Cd 0,01; Pb 0,025; Zn 0,05; Zn + Cd 0,05

Max. impurities [wt.-%] 0,25

Technical data

Melting range approx. 645 - 815 °C (DIN EN 1044)

Working temperature approx. 710 °C (DIN EN 1044)

Density approx. 8,2 g/cm³

Tensile strength acc. DIN EN 12797 approx. 250 MPa with Cu

Elongation approx. 8 %

Electrical Conductivity approx. 5,0 m/

2

Ωmm

Operating temp. of brazed joint max. 150 °C (without loss in strength)

Standard delivery forms *

Wire: 1,0 - 1,5 - 2,0 mm Ø

Rods: 1,0 - 1,5 - 2,0 mm Ø, 500 mm length

Ribbon: 0,1/ 0,2/ 0,3/ 0,4 mm thickness and 70 mm width

Preforms: rings, shaped parts, sections, stamped and shaped parts,

lamina, discs, perforated plates

*Other delivery forms upon request

Applications

BrazeTec S 5 is a phosphorous-containing brazing alloy with excellent flow characteristics . The

brazing alloy is suitable for joining copper to copper or copper -based materials. Due to its

phosphorous content, you have not to use an additioal flux for brazing only copper to copper . This

brazing alloy is not allowed to be used if sulfur containing medias may have contact with the joint

during operating. Further it is not allowed to use this alloy for joining steels (Fe) or materials containing

iron,

nickel cobaltas it will be formed brittle phases in the joint .

In refrigeration and air conditioning industries BrazeTec S 5 can be used for service temperatures

down to -50°C.

It can be used for brazing with flame, with induction heating and in a furnace under protective

atmospheres.

Typical applications are found e.g. in the electric industry and for the refrigeration and air conditioning

industry.

Our information about our products and equipment as well as our systems and procedures are based on comprehensive

research and application technological experience. We communicate these results, but take no liability for respective single

contracts that are exceeding thereof. We reserve the right to make technical changes in the process of product development in

27.01.2012 --- TD BT 0603 E.02 - Umicore vertraulich - Dokument nur am Tag des Ausdrucks gültig --- Seite 1

You might also like

- BT Silfos 15 ENDocument1 pageBT Silfos 15 ENIonutCiobanuNo ratings yet

- TD BrazeTec s15 EDocument1 pageTD BrazeTec s15 EIonutCiobanuNo ratings yet

- Show TD BrazeTec S15 enDocument1 pageShow TD BrazeTec S15 enIñakiNo ratings yet

- Phoenix SH Ni 2 K 80 PDFDocument1 pagePhoenix SH Ni 2 K 80 PDFPrakash RajNo ratings yet

- Data Sheet A-12Document7 pagesData Sheet A-12anon_928750560No ratings yet

- 02.CARBO - RC 3 Blau eDocument1 page02.CARBO - RC 3 Blau eMario CastilloNo ratings yet

- Material No. EN Symbol (Short) Aisi/Sae UNS Afnor B.S. Alloy Registered Work's Label StandardsDocument1 pageMaterial No. EN Symbol (Short) Aisi/Sae UNS Afnor B.S. Alloy Registered Work's Label StandardschetanNo ratings yet

- UTP Brazing Filler MetalsDocument8 pagesUTP Brazing Filler MetalsIvan Dulic100% (1)

- FCAW - Flux Coredpowder Cored WiredDocument40 pagesFCAW - Flux Coredpowder Cored WiredGabor VatoNo ratings yet

- BraizingDocument1 pageBraizingMusic NetNo ratings yet

- Nickel-Iron For Cast Iron: Data SheetDocument3 pagesNickel-Iron For Cast Iron: Data SheetSandro ChiliquingaNo ratings yet

- D-70 Cupronickel Rev 06Document3 pagesD-70 Cupronickel Rev 06Luis Gustavo AndradeNo ratings yet

- Brazing & Soldering of Solar PanelsDocument9 pagesBrazing & Soldering of Solar Panelskamals55No ratings yet

- Description:: AWS A5.4 E308-16 JIS Z3221 ES308-16 EN 1600 E 19 9 R 1 2 Covered Electrodes For Stainless SteelDocument1 pageDescription:: AWS A5.4 E308-16 JIS Z3221 ES308-16 EN 1600 E 19 9 R 1 2 Covered Electrodes For Stainless Steel13421301508No ratings yet

- Rtds and Thermistors: Resistance Temperature SensingDocument2 pagesRtds and Thermistors: Resistance Temperature Sensingicaro89No ratings yet

- Chromecore-430-G Er430Document1 pageChromecore-430-G Er430peymanNo ratings yet

- Avesta 2205 AC DCDocument1 pageAvesta 2205 AC DCpipedown456No ratings yet

- Material No. EN Symbol (Short) Aisi/Sae UNS Afnor B.S. Alloy Registered Work's Label StandardsDocument1 pageMaterial No. EN Symbol (Short) Aisi/Sae UNS Afnor B.S. Alloy Registered Work's Label Standards周学锋No ratings yet

- TriMark Metalloy 80N1Document2 pagesTriMark Metalloy 80N1Claudia MmsNo ratings yet

- Bohler Fox DMV 83 KB - SmawDocument1 pageBohler Fox DMV 83 KB - Smawsoft4gsmNo ratings yet

- Boehler CM2-UPDocument1 pageBoehler CM2-UPdiahNo ratings yet

- s543b - Electrozi Basic 7018 Info ENGDocument2 pagess543b - Electrozi Basic 7018 Info ENGVlad AdrianNo ratings yet

- Pressure & Temperature Switch RT SeriesDocument4 pagesPressure & Temperature Switch RT SeriesVivek Vous AimeNo ratings yet

- Metrode E2209 (B-60) ElectrodeDocument6 pagesMetrode E2209 (B-60) ElectrodeClaudia MmsNo ratings yet

- TDS - ER80S-B6.GTAW Rev1Document1 pageTDS - ER80S-B6.GTAW Rev1Erick VazquezNo ratings yet

- 02112015000000B - Boehler FOX CM 5 KB - CeDocument1 page02112015000000B - Boehler FOX CM 5 KB - CejaroNo ratings yet

- Официальный дистрибьютор ЗАО «Ресурс» т/ф 8 (383) 363-26-24, 291-93-02 630020 Россия г.Новосибирс ул.Объединения д.9 e-mail: resurszao@Document1 pageОфициальный дистрибьютор ЗАО «Ресурс» т/ф 8 (383) 363-26-24, 291-93-02 630020 Россия г.Новосибирс ул.Объединения д.9 e-mail: resurszao@brayanNo ratings yet

- RTD and ThermistorsDocument13 pagesRTD and ThermistorsEliasNo ratings yet

- High Perf Metals Brochure v1Document5 pagesHigh Perf Metals Brochure v1arianaseriNo ratings yet

- MIP - Bohler - Welding - Austria 65 PDFDocument1 pageMIP - Bohler - Welding - Austria 65 PDFAdmir TalicNo ratings yet

- Böhler CM 5-Ig: TIG Rod, High-Alloyed, Creep ResistantDocument1 pageBöhler CM 5-Ig: TIG Rod, High-Alloyed, Creep Resistantwesley59No ratings yet

- Mild Steel 490mpa High Tensile Strength SteelDocument38 pagesMild Steel 490mpa High Tensile Strength SteelCarlos PadillaNo ratings yet

- E 7016 Product-SheetDocument1 pageE 7016 Product-SheetAlireza TakrimiNo ratings yet

- Technical Datasheet Forged Carbon Steel A105n Gate Valve Trim8 Class800 NPTDocument5 pagesTechnical Datasheet Forged Carbon Steel A105n Gate Valve Trim8 Class800 NPTBenny 37No ratings yet

- TD UMICORE BrazeTec 3076U ENDocument1 pageTD UMICORE BrazeTec 3076U ENkmNo ratings yet

- Tetra V 309L-G: Technical Data Sheet Cored Welding WireDocument1 pageTetra V 309L-G: Technical Data Sheet Cored Welding WireawNo ratings yet

- 347 Stainless Steel: 1.4541 1.4543/1.4561/1.4550 1.4552 (Cast)Document4 pages347 Stainless Steel: 1.4541 1.4543/1.4561/1.4550 1.4552 (Cast)Prem NautiyalNo ratings yet

- Eutectrode 6666: Manual Arc Welding ElectrodeDocument1 pageEutectrode 6666: Manual Arc Welding ElectrodemortezaheidarianNo ratings yet

- Duplex Stainless SteelsDocument25 pagesDuplex Stainless Steelspym1506gmail.comNo ratings yet

- Material No. EN Symbol (Short) Aisi/Sae UNS Afnor BS Alloy Registered Work's Label StandardsDocument1 pageMaterial No. EN Symbol (Short) Aisi/Sae UNS Afnor BS Alloy Registered Work's Label StandardschetanNo ratings yet

- A-23 WB36 Rev 03 15NiCuMoNb5 MicrostructureDocument4 pagesA-23 WB36 Rev 03 15NiCuMoNb5 Microstructuremavis16No ratings yet

- Ag 34 SNDocument1 pageAg 34 SNkmNo ratings yet

- Fontargen A 101Document1 pageFontargen A 101Kara WhiteNo ratings yet

- item22-LNT 502Document1 pageitem22-LNT 502VVan TanNo ratings yet

- 17 4 PHDocument2 pages17 4 PHzaranrajputNo ratings yet

- Technical Datasheet Forged Carbon Steel A105n Gate Valve Trim8 Class800 SWDocument5 pagesTechnical Datasheet Forged Carbon Steel A105n Gate Valve Trim8 Class800 SWBenny 37No ratings yet

- Welding Consumables For Cast Iron MaterialsDocument4 pagesWelding Consumables For Cast Iron MaterialsskidanjeNo ratings yet

- XAR 450 (WB 710) EnglischDocument3 pagesXAR 450 (WB 710) EnglischMario MoranNo ratings yet

- Welding Consumables For Hydro Power StationsDocument16 pagesWelding Consumables For Hydro Power StationsMohamed FaragNo ratings yet

- Böhler Fox CM 5 KB: Classifi CationsDocument1 pageBöhler Fox CM 5 KB: Classifi CationsBranko FerenčakNo ratings yet

- 1 - UTP 614 KBDocument1 page1 - UTP 614 KBKrishna VachaNo ratings yet

- AFM Bronze AlloysDocument15 pagesAFM Bronze AlloysbrunizzaNo ratings yet

- Inertfil 308lsi: MIG-MAG Wires Stainless and Heat Resistant SteelsDocument1 pageInertfil 308lsi: MIG-MAG Wires Stainless and Heat Resistant SteelsEdison CheongNo ratings yet

- NF372 TB GlobalDocument2 pagesNF372 TB GlobalFuzail AhmadNo ratings yet

- Welding Consumables For The Offshore IndustryDocument24 pagesWelding Consumables For The Offshore IndustryLuis DuarteNo ratings yet

- Diaphragm - Type Diaphragm SealType L990.10Document4 pagesDiaphragm - Type Diaphragm SealType L990.10harglugurNo ratings yet

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Carel Ir33 Programming Guide PDFDocument2 pagesCarel Ir33 Programming Guide PDFIonutCiobanuNo ratings yet

- Controler Elliwel E37Document3 pagesControler Elliwel E37IonutCiobanuNo ratings yet

- k65 Fittings - UnlockedDocument4 pagesk65 Fittings - UnlockedIonutCiobanuNo ratings yet

- Model: ZF13K4E-TFD: Technical DataDocument6 pagesModel: ZF13K4E-TFD: Technical DataIonutCiobanuNo ratings yet

- Riello 40 Gs Series Package Gas BurnerDocument6 pagesRiello 40 Gs Series Package Gas BurnerIonutCiobanuNo ratings yet

- Traxoil OM3 - OM4Document5 pagesTraxoil OM3 - OM4IonutCiobanuNo ratings yet

- Outdoor Condensing UnitDocument27 pagesOutdoor Condensing UnitIonutCiobanuNo ratings yet

- Indoor Air Quality TraneDocument45 pagesIndoor Air Quality TraneMuhammad Faheem ShahbazNo ratings yet

- 8229-Oil Well PDFDocument32 pages8229-Oil Well PDFShweta MahajanNo ratings yet

- UNITEN ICCBT 08 Mechanical Properties of Foamed ConcreteDocument10 pagesUNITEN ICCBT 08 Mechanical Properties of Foamed ConcreteLim Han JianNo ratings yet

- Basics - of - Civil & Mechanical Eng.Document7 pagesBasics - of - Civil & Mechanical Eng.Rahul J.RNo ratings yet

- Henkel Loctite AdesiveDocument60 pagesHenkel Loctite Adesive69x4No ratings yet

- Ice Making Plant Visit ReportDocument8 pagesIce Making Plant Visit ReportAnis Badshah33% (3)

- Eng 5Document21 pagesEng 5MushtaqElahiShaikNo ratings yet

- Sample Load ComputationDocument2 pagesSample Load ComputationABCD EFGNo ratings yet

- Phil Green Building Code Presentation by RMCARINGAL v2Document74 pagesPhil Green Building Code Presentation by RMCARINGAL v2Micah San JuanNo ratings yet

- Mathcad - BASEPLATE DESIGN - 10 PDFDocument6 pagesMathcad - BASEPLATE DESIGN - 10 PDFMonotobo X MakinaNo ratings yet

- TEKIRO TOOLS - WeldingDocument3 pagesTEKIRO TOOLS - WeldingAnya RumeserNo ratings yet

- Splice Design - LRFDDocument22 pagesSplice Design - LRFDkalpanaadhiNo ratings yet

- Sustainable Materialization of Responsive ArchitectureDocument20 pagesSustainable Materialization of Responsive ArchitectureAlexander TeohNo ratings yet

- Automatic Fire Extinguishing Systems For Commercial Cookingfire Extinguishing Systems For Commercial CookingDocument63 pagesAutomatic Fire Extinguishing Systems For Commercial Cookingfire Extinguishing Systems For Commercial CookingAlex Chin0% (1)

- BROAN HD997I Notice Mode Emploi Guide ManuelDocument24 pagesBROAN HD997I Notice Mode Emploi Guide ManuelbobmoranefrNo ratings yet

- Sbsfid 12858 DifDocument20 pagesSbsfid 12858 DifYIBELTAL EBABU100% (2)

- Zambelis Catálogo 2021-2022 NewDocument369 pagesZambelis Catálogo 2021-2022 NewVEMATELNo ratings yet

- Polymer ConcreteDocument25 pagesPolymer ConcreteLalithya100% (2)

- Production Methods of Aluminium Foam A Brief ReviewDocument4 pagesProduction Methods of Aluminium Foam A Brief ReviewJuan SarmientoNo ratings yet

- Daøhv Osq Fy, Eksvs O Eghu Feykok Fof'Kf"V: HKKJRH EkudDocument21 pagesDaøhv Osq Fy, Eksvs O Eghu Feykok Fof'Kf"V: HKKJRH EkudParmar RashmikaNo ratings yet

- Writing A Process DiagramDocument2 pagesWriting A Process Diagramdeathnote lNo ratings yet

- New Cements For The 21st Century The Pursuit of An Alternative To Portland CementDocument14 pagesNew Cements For The 21st Century The Pursuit of An Alternative To Portland CementPopovac NetNo ratings yet

- Fence Engineering ManualDocument30 pagesFence Engineering ManualvklsNo ratings yet

- Design of Pipe SupportsDocument8 pagesDesign of Pipe SupportsSushil WadiyeNo ratings yet

- 4.design of FootingDocument34 pages4.design of FootingGladys LeonorNo ratings yet

- Mokka Tips: Create A Unique Tactile Experience With Sappi's Touch Collection Release PapersDocument2 pagesMokka Tips: Create A Unique Tactile Experience With Sappi's Touch Collection Release Papersmanish singhalNo ratings yet

- Flat Slab BW 2Document14 pagesFlat Slab BW 2Kuladeep YalamanchiliNo ratings yet

- Numerical Simulation of Low Pressure Die-Casting Aluminum WheelDocument5 pagesNumerical Simulation of Low Pressure Die-Casting Aluminum WheelMostafaNo ratings yet

- Gate of Creation - Architectural Case StudyDocument28 pagesGate of Creation - Architectural Case StudyJoyal NellisseryNo ratings yet

- Past Exams Matrix and Solns 1516Document35 pagesPast Exams Matrix and Solns 1516Sam100% (2)