Professional Documents

Culture Documents

Role of Nano Zirconia Addition On Photodegradation of Lldpeldpeplablend Fil

Uploaded by

Ilhamdi AkmalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Role of Nano Zirconia Addition On Photodegradation of Lldpeldpeplablend Fil

Uploaded by

Ilhamdi AkmalCopyright:

Available Formats

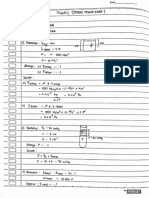

trial Chem

us i

Dubey et al., Ind Chem 2016, 2:3

Ind

st

Industrial Chemistry

ry

DOI: 10.4172/2469-9764.1000121

ISSN: 2469-9764

Research Article

Research Article Open

OpenAccess

Access

Role of Nano Zirconia Addition on Photodegradation of LLDPE/LDPE/PLA

Blend Films

Priti Dubey1*, Smita Mathur1, Navin Chand2 and Pradeep Upadhyaya1

1

Central Institute of Plastic Engineering and Technology, Lucknow, Uttar Pradesh, India

2

CSIR - Advanced Materials and Processes Research Institute (AMPRI), Bhopal, Madhya Pradesh, India

Abstract

In this present study observed the effect of nano filler (titanate coupling agent treated nano-zirconia) on

degradation behavior of PLA filled LLDPE/LDPE/MA-g-PE modified blend. Blown Films were exposed to UV light by

using an accelerated weather meter (QUV). Results show that with the loading of nano-zirconia in the LLDPE/LDPE/

PLA/MA-g-PE blend, tensile strength reduced to 47-54% before total rupture. Nano composite films lose weight

by 4 to 6% in 144 hrs. However, without the addition of nano filler, blends lose their weight only 0.76%. Thermal

behavior of degraded nano composite blown films was studied by using Differential Scanning Calorimetry (DSC).

The morphological changes were observed by the Scanning Electron Microscope (SEM). FTIR was used for change

in functional group study.

Keywords: Nano-filler; Zirconia; FTIR; DSC; MA-g-PE study effect of nanofiller zirconium oxide on photodegradation of MA-

g-PE compatibilized LLDPE/LDPE/PLA blown film in accelerated

Introduction weatherometer has been studied. From the results, it was observed that

with an increase of nanofiller amount support the degradation rate.

It is difficult for polymers to be treated after use due to their

Physical changes, weight loss, mechanical, thermal and morphological

resistance to the environment. When polymers are disposed of in a

properties with degradation rate. By the FTIR analysis changes in

natural environment, they remain for a long time without degradation.

functional groups during the photodegradation were also analyzed.

It is frequently asserted by environmental pressure groups that the

polyolefins can not biodegrade since the molecular weight must be Materials and Methods

less than 500 for this to occur. Due to low cost and good mechanical

properties as compare to other commodity plastics polyethylene’s are Materials

world’s most extensively used commodity plastic of the 21st century [1-

Blown films used in this study were developed earlier and provided

4]. Among the applications in all plastics, polyethylene consumption is

for this study [24]. Blown film grade Butene-linear low density

64% in packaging and bottles area [4]. In the packaging area, carry bags

polyethylene (trade name: Sabic LLDPE 118W; Density=0.918 g/cm3,

are regularly used product and are most visible [5]. For easy disposal

MFI=1.0 g/10 min at 190°C and 2.16 kg) was supplied by M/S Saudi

of polymers naturally in an environment, photodegradable and

Basic Industries Corporation, Saudi Arabia. General purpose film grade

biodegradable plastics in packaging materials are the best combination low density polyethylene (trade name: Relene 24FS040; Density=0.922

to decrease the accumulation of packaging waste in the environment g/cm3, MFI=4.0 g/10 min at 190°C and 2.16 kg) produced by M/s Reliance

[6]. Many authors reported that degradation rate of polyethylene polymers, India. Sheet extrusion grade Poly lactic acid (trade name:

is slow [7,8]. Biodegradable and photodegradable films may be the Revode 101, Density=1.250 g/cm3, MFI=2-10 g/10 min at 190°C and 2.16

solution of visual pollution; these polymers broke into small pieces kg) was obtained from M/s Zhejiang Hisun Biomaterials Co. Ltd., China.

and reduce into low molecular weight. Natural photodegradation of Maleic anhydride grafted polyethylene (MFI- 1.5 g/10 min, MAH content

polyolefin is a very slow process; however, many research papers have 0.5-0.8% and Density - 0.953 g/cm3) was supplied by M/s Plus polymers,

reported use of transition metals, which act as pro-oxidant. Addition India. Nano-Zirconia (surface area- 30 m/g, and bulk density - 0.42 g/cm)

of these pro-oxidants can promote the oxidation of polyolefin in the was supplied by M/s Zirox technologies, India. Titanate coupling agent

presence of oxygen and exposure to light/heat. Many pro-oxidant used (EB-1019A) was purchased by M/s IPMC, Pune, India [24].

with plastics include oxide or stearates of metals such as manganese

iron, zinc, zirconium, cerium, titanium and cobalt [9-16]. Photodegradation analysis

In past few research articles the idea of increasing biodegradability Nanocomposite formulations are listed in Table 1. PLA filled

achieved by adding natural biopolymer such as starch along with pro- and unfilled LLDPE/LDPE/MA-g-PE blend with and without nano

oxidant in the presence of compatibilizer [17-19]. Further issues were

raised regarding the toxicity of transition metals and accumulation of

Nickel was inconsiderable [20]. Zirconium as a ceramic biomaterial *Corresponding author: Priti Dubey, Central Institute of Plastic Engineering

and biocompatibility with polyethylene has been reported [21,22]. and Technology, Lucknow, Uttar Pradesh, India, Tel: +91-8765923053; E-mail:

Earlier research papers report the enhanced mechanical, thermal and priticipet14@gmail.com

optical properties of films processed from the materials LLDPE /LDPE/ Received August 23, 2016; Accepted September 08, 2016; Published September

PLA/MA-g-PE and LLDPE/LDPE/PLA/MA-g-PE/nano zirconia 09, 2016

blend [23,24]. The role of inorganic fillers on thermal, mechanical and Citation: Dubey P, Mathur S, Chand N, Upadhyaya P (2016) Role of Nano Zirconia

degradation properties was also reported with many blends [17,18,25]. Addition on Photodegradation of LLDPE/LDPE/PLA Blend Films. Ind Chem 2: 121.

Several publications have been published on the effect of transition doi: 10.4172/2469-9764.1000121

metals on photodegradation [9-11,14-16]. Copyright: © 2016 Dubey P, et al. This is an open-access article distributed under

the terms of the Creative Commons Attribution License, which permits unrestricted

There is no literature based on the role of nano zirconia addition use, distribution, and reproduction in any medium, provided the original author and

on photodegradation in LLDPE/LDPE/PLA blend films. In this present source are credited.

Ind Chem, an open access journal

ISSN: 2469-9764 Volume 2 • Issue 3 • 1000121

Citation: Dubey P, Mathur S, Chand N, Upadhyaya P (2016) Role of Nano Zirconia Addition on Photodegradation of LLDPE/LDPE/PLA Blend Films.

Ind Chem 2: 121. doi: 10.4172/2469-9764.1000121

Page 2 of 6

zirconia blown films were cut into rectangular shaped samples of

dimension 15 × 2.5 cm2. Blends were UV irradiated using an accelerated LnZ0 LnZ1 LnZ2 LnZ3

weathering tester (Model-Q-Lab QUV/Spray with solar eye irradiance 30

control) following ASTM D-5208: standard practice for Operating

Fluorescent Light Apparatus for UV exposer of nonmetallic materials, 25

Tensile Strength (MPa)

using irradiance of 0.66 W/m2 for 8 hrs. Irradiance cycle and 8 hrs.

20

Condensation cycle. The samples were exposed upto 144 hrs.

Weight loss 15

Percent weight loss of nano zirconia filled and unfilled LLDPE/ 10

LDPE/ PLA/MA-g-PE blend blown films were determined as:

5

Initial wt. before UV exposure -Final wt. after UV exposure

%Weight Loss ×100 0

Initial wt. before UV exposure 0 24 48 72 96 120 144

Time (hrs)

Mechanical testing

Figure 1: Variation in tensile strength with time after UV exposure of various

Nano zirconia filled and unfilled LLDPE/LDPE/ PLA/MA-g- LLDPE/LDPE/PLA/MA-g-PE blend and its nano composites.

PE blend blown films were tested using universal testing machine

(INSTRON) used to test the tensile strength of the developed

LnZ0 LnZ1 LnZ2 LnZ3

specimens. The tensile test was carried out according to ASTMD-882. 700

The rectangular shaped samples had the dimensions 2.5 cm in width

and 15 cm in length were tested. Tensile strength was calculated in 600

Flongation at break (%)

machine direction. The average of 5 tested samples was reported in the 500

present research paper.

400

Thermal studies

300

LLDPE/LDPE/PLA/MA-g-PE blends modified with nanofillers

200

blown films were tested on Differential Scanning Calorimetric (DSC),

Perkin Elmer, which was used to find the thermal transitions in 100

prepared blown film samples. DSC analysis was carried out from 50 to

0

200°C at heating rate of 10°C /min. The percentage of crystallinity was 0 24 48 72 96 120 144

calculated from DSC result using the following relation. Hf for purely Time (hrs)

crystalline polyethylene is 276 J/g according to Da Costa and Ramos [26].

Figure 2: Variation in elongation at break (%) with time after UV exposure of

∆H f (observed) various LLDPE/LDPE/PLA/MA-g-PE blend and its nano-composites.

%

= Crystallinity × 100

∆H f (100% crystalline )

works [27,28]. The result also indicate that higher degradation rate

was found in 1.5 phr containing nano zirconia (LnZ3) composite due

Fourier Transforms Infrared (FTIR) spectroscopy

to good dispersion in matrix. This effect can be explained in terms

PLA filled and unfilled LLDPE/LDPE/ MA-g-PE blend blown films of the crystallinity increase observed by DSC, with the formation of

were analyzed for functional group analysis and change in intensities new crystals.

of functional groups by using Fourier Transforms Infrared (FTIR)

spectroscopy (Perkin Elmer). Differential Scanning Calorimetry (DSC) screening

The Differential Scanning Calorimetry (DSC) results for the UV

Morphological studies

Exposed and unexposed LLDPE/LDPE/PLA/MA-g-PE blend and their

Surface morphology and compatibility of blends prepared from nanocomposites are described in Table 4 and Figure 3 for all the samples,

LLDPE/LDPE/PLA/MAgPE and its nanocomposites blown films were crystallinity (a property that gives improving the stiffness and thermal

observed by using SEM Model ELU 430. stability of the material) increased after 96 hrs. Of UV exposure. The DSC

analysis was carried out in order to study the various temperature transitions

Results and Discussion of the prepared nanocomposites. Endothermic curves of DSC scan gives

Mechanical properties information about melting temperature and degree of crystallinity. The

DSC scans of samples containing zirconia oxide, for treated and untreated

The Figures 1 and 2 illustrate the tensile strength and percentage samples, are plotted in Figure 3 and the related data are summarized in Table

elongation at break of the films. It is noted that the LLDPE/LDPE/ 4 and Figure 3 showed that the melting temperatures of both pure samples

PLA/MA-g-PE and the LLDPE/LDPE/PLA/MA-g-PE/zirconia and LnZ3 samples underwent reduction after 96 hours of UV exposure.

followed similar trends in the change in tensile properties over time. However, samples containing prooxidant melting temperature (Tm) show

However, the degradation of tensile properties was 47% to 54% for the higher reduction than without nanofiller samples after treatment. The

nanocomposites after 48 hrs before ruptured and for LLDPE/LDPE/ reduction of Tm could be due to the breakdown of LLDPE/LDPE blend

PLA/MA-g-PE blend was 50.2% after 144 hrs. And Tables 2 and 3 chains and molecular weight reduction. As reported by Colom et al. [29]

indicates that the presence of the nanofiller accelerates the degradation the decrease of the decomposition and melting temperatures is associated

of the blend material, a fact that has also been observed in previous with breaking of polymeric chains leads to lower thermal stability of the

Ind Chem, an open access journal

ISSN: 2469-9764 Volume 2 • Issue 3 • 1000121

Citation: Dubey P, Mathur S, Chand N, Upadhyaya P (2016) Role of Nano Zirconia Addition on Photodegradation of LLDPE/LDPE/PLA Blend Films.

Ind Chem 2: 121. doi: 10.4172/2469-9764.1000121

Page 3 of 6

MA-g-PE Titanate coupling

Formulation Blend code LLDPE (wt %) LDPE (wt %) PLA (phr) Nano ZrO2 (phr)

(phr) agent (phr)

LLDPE/LDPE/PLA/MA-g-PE/nano ZrO2 LnZ0 85 15 10 4 0 0

LLDPE/LDPE/PLA/MA-g-PE/nano ZrO2 LnZ1 85 15 10 4 0.5 1

LLDPE/LDPE/PLA/MA-g-PE/nano ZrO2 LnZ2 85 15 10 4 1.0 1

LLDPE/LDPE/PLA/MA-g-PE/nano ZrO2 LnZ3 85 15 10 4 1.5 1

Table 1: Nano composite films formulation.

12 123.55 After Degradiation

Before Degradiation

10

127.48

8

LnZ3

6

4

121.09

117.34

2

LnZ0

118.02 122.11

0

-2

80 85 90 95 100 105 110 115 120 125 130 135 140

Temperature (°C)

Figure 3: DSC thermogram of LnZ0 and LnZ3 before and after 96 hrs. UV exposure.

Blend Change in Tensile strength (MPa) on different Time (hrs) prepared films. The crystallinity of without nanofiller samples increased

Code 0 24 48 72 96 120 144 around 1%, from 10.8 to 11.4, whereas with nanofiller LnZ3 samples

LnZ0 22.5 20.3 18.7 15.1 12.8 12.5 11.2 underwent higher increase, about 8%, from 21.74 to 29.7 after 96 hours

LnZ1 22.56 13.48 12.23 F F F F of UV exposure (Table 4). The increase of crystallinity is probably due to

LnZ2 23.68 12.67 10.9 F F F F increased nucleation in the amorphous regions. The chain scission allowed

LnZ3 26.85 12.53 F F F F F the small segments resulted to crystallize. The increase of crystallinity could

contribute in degradation products which possessed the lower Tm than

Table 2: Change in tensile strength (MPa) of LLDPE/LDPE/PLA/MA-g-PE blend

with nanozirconia before and after UV exposure at various time intervals. before UV exposed samples. Furthermore, the increase of crystallinity,

particularly LnZ3 samples, gives supporting evidence on the role of zirconia

Change in Elongation break (%) on different Time (hrs)

nanofiller in accelerating degradation process on UV exposure.

Blend Code

0 24 48 72 96 120 144 FTIR

LnZ0 520 517 190.4 150.98 78.85 61.0 50.8

LnZ1 510 308 82.7 F F F F The Figure 4 illustrates Comparison spectra of LLDPE/LDPE /

LnZ2 580 145.7 52.5 F F F F PLA/MA-g-PE and LLDPE/LDPE /PLA/MA-g-PE/zirconia before and

LnZ3 625 35 F F F F F after UV exposure and characteristic peak (wave number) are given

F – Fragmented in Table 5. Chain broadening was observed in LnZ3 at 1190-1090 cm-1

(O-C=O stretching) and in LnZ0 chain broadening was not observed.

Table 3: Change in elongation at break (%) of LLDPE/LDPE/PLA/MA-g-PE blend

with nanozirconia before and after UV exposure at various time intervals.

Chain broadening was due to the presence of more than one oxidation

product which can be clearly observed in Figure 4 after 96 hrs UV

exposure. Change in intensities of zirconia containing nanocomposite

Before UV exposure

Sample Code Crystallinity shows noticeable change at 2901 cm-1 and 2915 cm-1 (C-H stretching),

Tm °C ∆ Hf J/g

1756-1744 cm-1 (Ester carbonyl group), 1460 cm-1 (CH2 bending), and

LnZ0 122.11 29.35 10.8

722 cm-1 (Skelton vibration of CH2) whereas without nanofiller blend

LnZ3 127.48 60.01 21.74

in LnZ0 showed slight changes in intensities which reveals autoxidation

After UV exposure

Sample Code Crystallinity of LLDPE/LDPE/PLA/MA-g-PE blend in presence of metal oxide.

Tm °C ∆ Hf J/g

LnZ0 121.09 31.49 11.41 SEM

LnZ3 123.56 81.9 29.7

The Figures 5A and 5B shows the image for the LLDPE/LDPE/

Tm: Melting point (peak), °C; ∆Hf, heat of fusion, J/g; Crystallinity: crystallinity index (%)

PLA/MA-g-PE (Figure 5a) and its nano-composite containing 1.5 phr

Table 4: Melting temperature and crystallinity of samples before and after 96 hours

zirconia (LnZ3) after 96 hrs UV exposure. The morphological changes

of UV exposure.

Ind Chem, an open access journal

ISSN: 2469-9764 Volume 2 • Issue 3 • 1000121

Citation: Dubey P, Mathur S, Chand N, Upadhyaya P (2016) Role of Nano Zirconia Addition on Photodegradation of LLDPE/LDPE/PLA Blend Films.

Ind Chem 2: 121. doi: 10.4172/2469-9764.1000121

Page 4 of 6

Before UV exposure After UV exposure

LnZ3

% Transmittance

% Transmittance

LnZ0

3500 3000 2500 2000 1500 1000 500 3500 3000 2500 2000 1500 1000 500

Wave number (cm ) -1

Wave number (cm ) -1

Figure 4: FTIR of LnZ0 and LnZ3 before and after 96 hrs. UV exposure.

B

Figure 5: SEM images A) LnZ0 before and after 96 hrs. UV exposure and B) LnZ3 before and after 96 hrs. UV exposure.

Ind Chem, an open access journal

ISSN: 2469-9764 Volume 2 • Issue 3 • 1000121

Citation: Dubey P, Mathur S, Chand N, Upadhyaya P (2016) Role of Nano Zirconia Addition on Photodegradation of LLDPE/LDPE/PLA Blend Films.

Ind Chem 2: 121. doi: 10.4172/2469-9764.1000121

Page 5 of 6

observed in LLDPE/LDPE/PLA/MA-g-PE (LnZ0) and its nanocomposite

LnZ0 LnZ1 LnZ2 LnZ3

after exposure to the UV light, and observed that number of voids together 7

with extended cracks running in-between and around the dispersed 6

particles in nanofiller filled blend (Figure 5b). The formation of a large

number of voids and cracks in the nanocomposite suggests that LLDPE/ 5

Weight loss (%)

LDPE/PLA/MA-g-PE degradation begins at the interface between the 4

polymer matrix and the nanofiller particles. As a result, we can assume

that a well-dispersed filler, which results in an increased interface region 3

between matrix and filler and enhances degradation. 2

Physical changes 1

Physical and weight changes shown in Figures 6 and 7 and observed 0

that samples were become brittle in nature and weight loss seen after 0 24 8 72 96 120 144

Time (hrs)

the exposure of UV. With and without filler weight loss was 4% to 6.4%,

0.92% respectively after 144 hrs UV Exposure. Figure 7: Weight loss (%) after UV exposure.

Conclusion 3. The FTIR spectra show changes in intensities, especially in

The influence of UV-irradiation on with and without nano the carbonyl (1756-1749 cm-1), 1190 -1090 cm-1 (O-C=O

zirconia filled LLDPE/LDPE/PLA/MA g PE blend blown films shows stretching) and bands at 721 cm-1 and 1461 cm-1 corresponding

tremendous optimistic results. Which was supported by various to vibrations of -CH2 groups and bending vibrations of -CH2

techniques such as FTIR, SEM and DSC. bonds respectively on UV exposure. The change in intensity of

these peaks is a result of the fracture of the polyethylene chain

The following conclusions can be drawn from above experiments: after UV exposure.

1. After UV exposure, the highest reduction in tensile and 4. Surface cracks and voids were enhanced by addition of nano

elongation at break properties was observed in the blend filler nano zirconia. It was clearly seen by SEM analysis at 1.5

containing 1.5 phr nano zirconia in LLDPE/LDPE/PLA/MA g phr containing nano zirconia LLDPE/LDPE/MA g PE blend

PE blend by 54% and 90.7% after 48 hrs before ruptured and in (LnZ3) shows more cracks and voids than LLDPE/LDPE/MA

LLDPE/LDPE/PLA/MA-g-PE blend by 50.2% and 90.2% after g PE blend (LnZ0) after 96 hrs. UV exposure.

144 hrs UV exposure.

5. Weight loss 6.4% in LLDPE/LDPE/PLA/MAgPE/nano zirconia

2. Degradation of LLDPE/LDPE/PLA/MA g PE blend with nano nanocomposite (LnZ3) and 0.92% in LLDPE/LDPE/PLA/MA-

zirconia had occurred leading to crystallization. g-PE blend (LnZ0) and physical changes were observed after

UV exposure.

Peak Position (cm-1) Characteristic group

2914- 2905, 28 cm-1 CH symmetric and asymmetric stretching

Acknowledgements

1461cm -1

CH2 bending The authors would like to acknowledge for FTIR analysis to Mr. Deepak Sharma

720 cm-1 vibration of CH2 from CDRI (Central Drug Research Institute), Lucknow, Uttar Pradesh, India.

1756-1744 cm-1 Ester carbonyl group References

1190-1090 cm-1 O-C=O stretching

1. Hakkarainen M, Khabbaz F, Albertsson AC (2005) Biodegradation of polyethylene

1024 C-O stretching followed by assimilation of degradation products. Biopolymers Online.

1639-1600 cm-1 C=C bond

2. Eggins HO, Mills J, Hol TA, Scott G (1971) Biodeterioration and biodegradation

Table 5: Data obtained from FTIR spectra. of synthetic polymers. Soc Appl Bacteriol Symp Ser, pp: 267-279.

3. Galli P, Vecellio G (2004) Polyolefins: the most promising large‐volume

materials for the 21st century. Journal of Polymer Science Part A: Polymer

Time (hrs.) Chemistry 42: 396-415.

0

4. Sudhakar M, Doble M, Murthy PS, Venkatesan R (2008) Marine microbe-

mediated biodegradation of low-and high-density polyethylenes. International

Biodeterioration & Biodegradation 61: 203-213.

5. Scott G (1999) Polymers and the Environment. Royal Society of Chemistry.

48

6. Botelho G, Queiros A, Machado A, Frangiosa P, Ferreira J (2004)

Enhancement of the thermooxidative degradability of polystyrene by chemical

modification. Polymer degradation and stability 86: 493-497.

96 7. Albertsson AC (1977) Studies on Mineralization of 14C Labelled Polyethylenes

in Aerobic Biodegradation and Aqueous Aging. Royal Institute of Technology.

8. Albertsson AC (1978) Biodegradation of synthetic polymers. II. A limited

microbial conversion of 14C in polyethylene to 14CO2 by some soil fungi.

Journal of Applied Polymer Science 22: 3419-3433.

144 Films broken in to small pieces

9. Amin M (1974) Photo-initiated oxidation of polyethylene effect of photo-

LnZ0 LnZ1 LnZ2 LnZ3

sensitizers. European Polymer Journal 10: 1019-1028.

Figure 6: Physical changes after UV exposure of various LLDPE/LDPE/PLA/ 10. Osawa Z, Kurisu N, Nagashima K, Nakano K (1979) The effect of transition

MAgPE blend and its nanocomposites. metal stearates on the photodegradation of polyethylene. Journal of Applied

polymer science 23: 3583-3590.

Ind Chem, an open access journal

ISSN: 2469-9764 Volume 2 • Issue 3 • 1000121

Citation: Dubey P, Mathur S, Chand N, Upadhyaya P (2016) Role of Nano Zirconia Addition on Photodegradation of LLDPE/LDPE/PLA Blend Films.

Ind Chem 2: 121. doi: 10.4172/2469-9764.1000121

Page 6 of 6

11. Roy PK, Hakkarainen M, Varma IK, Albertsson AC (2011) Degradable polyethylene: 22. Garvie RC, Nicholson PS (1972) Structure and Thermomechanical Properties

fantasy or reality. Environmental science & technology 45: 4217-4227. of Partially Stabilized Zirconia in the CaO‐ZrO2 System. Journal of the American

Ceramic Society 55: 152-157.

12. Chiellini E, Corti A, D'antone S, Baciu R (2006) Oxo-biodegradable carbon

backbone polymers–oxidative degradation of polyethylene under accelerated 23. Singh O, Upadhyaya P, Chand N, Mishra TK (2012) Mechanical and optical

test conditions. Polymer Degradation and Stability 91: 2739-2747. properties of Poly Lactic Acid modified Linear-Low Density Polyethylene/Low

13. Roy PK, Surekha P, Rajagopal C, Chatterjee SN, Choudhary V (2007) Studies Density Polyethylene (LLDPE/LDPE) blend blown film. International Journal of

on the photo-oxidative degradation of LDPE films in the presence of oxidised Mechanical and Industrial Engineering 2: 11-14.

polyethylene. Polymer degradation and stability 92: 1151-1160.

24. Kumar R, Upadhyaya P, CHAND N (2014) Effect of Chemically Modified

14. Scott G, Islam S (1999) Polymer-bound UV activators for polyolefins. Polymer Nano Zirconia Addition on Properties of LLDPE/LDPE/PLA/MA-g-PE Bio-

degradation and stability 63: 61-64. nanocomposite Blown Films for Packaging Applications.International Journal

of Chemical and Physical Sciences 3:65-76

15. Jakubowicz I (2003) Evaluation of degradability of biodegradable polyethylene

(PE) Polymer Degradation and Stability 80: 39-43. 25. Jongsomjit B, Panpranot J, Okada M, Shiono T, Praserthdam P (2006)

Characteristics of LLDPE/ZrO~ 2 Nanocomposite Synthesized by In-situ

16. Jakubowicz I, Yarahmadi N, Petersen H (2006) Evaluation of the rate of abiotic

Polymerization using a Zirconocene/MAO Catalyst. Iranian Polymer Journal

degradation of biodegradable polyethylene in various environments. Polymer

15: 433-439.

degradation and stability 91: 1556-1562.

17. Griffin GJL (1974) Advances in chemistry series, 134. Fillers and Reinforcements 26. Da Costa HM, Ramos VD (2008) Analysis of thermal properties and rheological

for Plastics, p: 159. behavior of LLDPE/EPDM and LLDPE/EPDM/SRT mixtures. Polymer

Testing 27: 27-34.

18. Griffin GJL (1980) Synthetic polymers and the living environment. Pure and

Applied Chemistry 52: 399-407. 27. Kontou E, Georgiopoulos P, Niaounakis M (2012) The role of nanofillers on

the degradation behavior of polylactic acid. Polymer Composites 33: 282-294.

19. Griffin GJL (1994) Starch polymer blends. Polymer degradation and stability

45: 241-247. 28. Morlat-Therias S, Fanton E, Gardette JL, Peeterbroeck S, Alexandre M, et

al. (2007) Polymer/carbon nanotube nanocomposites: influence of carbon

20. Wolfe DW, Bache CA, Lisk DJ (1990) Analysis of dithiocarbamate and nickel nanotubes on EVA photodegradation. Polymer Degradation and Stability 92:

residues in lettuce and peppers grown in soil containing photodegradable

1873-1882.

plastic mulch. Journal of Food Safety 10: 281-286.

21. Helmer JD, Driskell TD (1969) Research on bioceramics. In Symp. On use 29. Colom X, Canavate J, Sunol JJ, Saurina J, Carrasco F (2003) Natural and

of ceramics as surgical implants. South Carolina (USA): Clemson University. artificial aging of polypropylene–polyethylene copolymers. Journal of applied

polymer science 87: 1685-1692.

Ind Chem, an open access journal

ISSN: 2469-9764 Volume 2 • Issue 3 • 1000121

You might also like

- Setiawan - 2021 - IOP - Conf. - Ser. - Mater. - Sci. - Eng. - 1034 - 012069Document8 pagesSetiawan - 2021 - IOP - Conf. - Ser. - Mater. - Sci. - Eng. - 1034 - 012069JOSENo ratings yet

- Effect of Ultraviolet Light On The Degradation of Low-Density and High PDFDocument7 pagesEffect of Ultraviolet Light On The Degradation of Low-Density and High PDFUlises RomanNo ratings yet

- Polymer Testing: Material BehaviourDocument6 pagesPolymer Testing: Material BehaviourRoshni PattanayakNo ratings yet

- IOP Conference Series: Materials Science and Engineering - Structure and Properties of Organically Modified Poly(butylene adipate-co-terephthalate) NanocompositesDocument13 pagesIOP Conference Series: Materials Science and Engineering - Structure and Properties of Organically Modified Poly(butylene adipate-co-terephthalate) NanocompositesKwanchaiBuaksuntearNo ratings yet

- Construction and Building Materials: Shanshan LV, Xiaojing Liu, Jiyou Gu, Yang Jiang, Haiyan Tan, Yanhua ZhangDocument7 pagesConstruction and Building Materials: Shanshan LV, Xiaojing Liu, Jiyou Gu, Yang Jiang, Haiyan Tan, Yanhua ZhangEstudiante2346No ratings yet

- D Hats Hana Murthi 2017Document7 pagesD Hats Hana Murthi 2017Ichsan MaulanaNo ratings yet

- Effect of Nano Zno On The Phase Mixing of Polyurethane Hybrid DispersionsDocument9 pagesEffect of Nano Zno On The Phase Mixing of Polyurethane Hybrid DispersionsKvsn RajuNo ratings yet

- Materials Today: Proceedings: S. Krishna Satya, P.S. Rama SreekanthDocument5 pagesMaterials Today: Proceedings: S. Krishna Satya, P.S. Rama SreekanthGuilherme Dos Santos MoreiraNo ratings yet

- Polymeric Waste CDDocument9 pagesPolymeric Waste CDJessica MuroNo ratings yet

- Rheological and Rutting Evaluation of Composite Nanosilica:Polyethylene Modified BitumenDocument7 pagesRheological and Rutting Evaluation of Composite Nanosilica:Polyethylene Modified BitumenManglemnganba LaishramNo ratings yet

- Liu 2005Document10 pagesLiu 2005ainmnrhNo ratings yet

- A Review On Starch Based Nanocomposites For Bioplastic MaterialsDocument7 pagesA Review On Starch Based Nanocomposites For Bioplastic MaterialsMike Anthony GocotanoNo ratings yet

- Impact of ZnO Nanoparticles Morphology On Relaxation and Transport Properties of PLADocument10 pagesImpact of ZnO Nanoparticles Morphology On Relaxation and Transport Properties of PLAEdwin WahidNo ratings yet

- Qasim 2019 - Soil Burial Degradation of Polypropylene Starch BlendDocument7 pagesQasim 2019 - Soil Burial Degradation of Polypropylene Starch BlendDibe DivolorNo ratings yet

- Polylactic Acidgraphene Nanocomposite ConsolidatedDocument12 pagesPolylactic Acidgraphene Nanocomposite ConsolidatedAyoub BNo ratings yet

- Bacillus Subtilis Biodegrades PETDocument4 pagesBacillus Subtilis Biodegrades PETAntuanet ToledoNo ratings yet

- Vervoort Et Al-2017-Polymer Engineering ScienceDocument7 pagesVervoort Et Al-2017-Polymer Engineering ScienceDemir YurdakulNo ratings yet

- Enhancing The Impact and Flexural Strength of PP by Taguchi MethodologyDocument9 pagesEnhancing The Impact and Flexural Strength of PP by Taguchi Methodologyamit motwaniNo ratings yet

- Research ProposalDocument14 pagesResearch ProposalFathima RumanaNo ratings yet

- Graphene-Based Polymer Nanocomposites: Materials For Future RevolutionDocument5 pagesGraphene-Based Polymer Nanocomposites: Materials For Future RevolutionMadhab BeraNo ratings yet

- Open Access Proceedings Journal of Physics - Conference SeriesDocument8 pagesOpen Access Proceedings Journal of Physics - Conference SeriesPranavi YeruvaNo ratings yet

- Polymers 14 03344 v2Document21 pagesPolymers 14 03344 v2Cășeriu BiancaNo ratings yet

- Preparation of Dimer Acid Based Polyamide Film by Solution Casting Method and Its Properties OptimizationDocument12 pagesPreparation of Dimer Acid Based Polyamide Film by Solution Casting Method and Its Properties OptimizationMuhammad AdeelNo ratings yet

- OSP-PP Polymer - Composites PDFDocument8 pagesOSP-PP Polymer - Composites PDFAtta Ur Rehman Shah MENo ratings yet

- Bacillus Subtilis Biodegrades Poly(Ethylene TerephthalateDocument4 pagesBacillus Subtilis Biodegrades Poly(Ethylene TerephthalateExon PerezNo ratings yet

- The Castor Oil Based Water Borne Polyurethane Dispersion Effect of - NCO/OH Content: Synthesis, Characterization and PropertiesDocument11 pagesThe Castor Oil Based Water Borne Polyurethane Dispersion Effect of - NCO/OH Content: Synthesis, Characterization and PropertiesÖzlem YılmazNo ratings yet

- Polymer Degradation and Stability Study Reveals Mechanism of Novel Oxo-Biodegradable PolypropylenesDocument8 pagesPolymer Degradation and Stability Study Reveals Mechanism of Novel Oxo-Biodegradable Polypropylenesrizky mutiara adithamaNo ratings yet

- Catalysts 12 01630 v2Document13 pagesCatalysts 12 01630 v2mylover huNo ratings yet

- A Comparative Study of ZnO-PVP and ZnO-PEG Nanoparticles ActivityDocument8 pagesA Comparative Study of ZnO-PVP and ZnO-PEG Nanoparticles ActivityVũ Hải NamNo ratings yet

- Green SolventsDocument16 pagesGreen SolventsChristian AranaNo ratings yet

- Graphene-Based Polymer Nanocomposites: Materials For Future RevolutionDocument5 pagesGraphene-Based Polymer Nanocomposites: Materials For Future RevolutionMadhab BeraNo ratings yet

- Chemical Engineering Journal: February 2018Document9 pagesChemical Engineering Journal: February 2018saeasdNo ratings yet

- Assessment of Mechanical Properties of Recycled HDDocument8 pagesAssessment of Mechanical Properties of Recycled HDjulian casanovaNo ratings yet

- Articles No 2Document11 pagesArticles No 2Benzarti NejiNo ratings yet

- Himmah - 2019 - IOP - Conf. - Ser. - Mater. - Sci. - Eng. - 515 - 012084Document11 pagesHimmah - 2019 - IOP - Conf. - Ser. - Mater. - Sci. - Eng. - 515 - 012084Blue StarNo ratings yet

- A.3 J Materials Science - 2022Document26 pagesA.3 J Materials Science - 2022Hamdan UIN WalisongoNo ratings yet

- International Biodeterioration & BiodegradationDocument9 pagesInternational Biodeterioration & BiodegradationAmarjit KumarNo ratings yet

- Awang_2018_IOP_Conf._Ser.__Mater._Sci._Eng._342_012046Document8 pagesAwang_2018_IOP_Conf._Ser.__Mater._Sci._Eng._342_012046Omkar NathNo ratings yet

- The_effect_of_pH_temperature_on_plasticDocument7 pagesThe_effect_of_pH_temperature_on_plasticw1wy.leoNo ratings yet

- Thin Films From Hydrophilic Poly (N, N-Dimethyl Acrylamide) Copolymers As Optical Indicators For HumidityDocument7 pagesThin Films From Hydrophilic Poly (N, N-Dimethyl Acrylamide) Copolymers As Optical Indicators For HumiditySwandiva WendradiNo ratings yet

- EPL 0006286 ArticleDocument11 pagesEPL 0006286 Articlekevin tayoNo ratings yet

- Silver-Loaded HDPE/Clay Nanocomposites With Antibacterial Property: A Potential Replacement For Commodity Polyethylene PlasticDocument12 pagesSilver-Loaded HDPE/Clay Nanocomposites With Antibacterial Property: A Potential Replacement For Commodity Polyethylene PlasticAna-Marya Radion0% (1)

- Study and Characterization of Virgin and Recycled LDPE/PP BlendsDocument10 pagesStudy and Characterization of Virgin and Recycled LDPE/PP BlendsOumaima BenNo ratings yet

- Publicatie Powdercoating 2017Document72 pagesPublicatie Powdercoating 2017Milagros MorantesNo ratings yet

- Polymers 14 02194Document19 pagesPolymers 14 02194aymene oujadiNo ratings yet

- Indones. J. Chem., 2019, 19 (3), 545 - 555: AbstractDocument11 pagesIndones. J. Chem., 2019, 19 (3), 545 - 555: Abstractt3guhku2hNo ratings yet

- Mechanical Color and Barrier Properties of Biodegradable Nanocomposites Polylactic Acidnanoclay 2155 6199 1000455Document5 pagesMechanical Color and Barrier Properties of Biodegradable Nanocomposites Polylactic Acidnanoclay 2155 6199 1000455yurinnelNo ratings yet

- Polymers 14 01626 v3Document44 pagesPolymers 14 01626 v3Pablo RaimondaNo ratings yet

- Synthesis of Nano Cellulose Fibers and Effect On Thermoplastics Starch Based FilmsDocument6 pagesSynthesis of Nano Cellulose Fibers and Effect On Thermoplastics Starch Based FilmsrummanNo ratings yet

- A Polilactic PDFDocument10 pagesA Polilactic PDFAdrian ChivuNo ratings yet

- Cashew Nut Shell Liquid Terminated Self-Healable Polyurethane As An Effective Anticorrosive Coating With Biodegradable Attribute PDFDocument11 pagesCashew Nut Shell Liquid Terminated Self-Healable Polyurethane As An Effective Anticorrosive Coating With Biodegradable Attribute PDFDaniela J. TitusNo ratings yet

- Hikmah 2018 IOP Conf. Ser. Mater. Sci. Eng. 333 012076Document8 pagesHikmah 2018 IOP Conf. Ser. Mater. Sci. Eng. 333 012076Artini PangastutiNo ratings yet

- Iscience: Complete Photocatalytic Mineralization of Microplastic On Tio Nanoparticle FilmDocument40 pagesIscience: Complete Photocatalytic Mineralization of Microplastic On Tio Nanoparticle Filmkamesh_che009No ratings yet

- WPFRC 6Document9 pagesWPFRC 6Tesema LegeseNo ratings yet

- Photocatalytic Degradation Study of Rhodamine-B by Green Synthesized Nano Tio2Document6 pagesPhotocatalytic Degradation Study of Rhodamine-B by Green Synthesized Nano Tio2Nguyễn Quang ThanhNo ratings yet

- Polymers: Biodegradable Mulching Films Based On Polycaprolactone and Its Porous Structure ConstructionDocument11 pagesPolymers: Biodegradable Mulching Films Based On Polycaprolactone and Its Porous Structure ConstructionNohemy LFNo ratings yet

- Strategic Possibility Routes of Recycled PET: Polymers May 2021Document36 pagesStrategic Possibility Routes of Recycled PET: Polymers May 2021yuppeNo ratings yet

- Paper 2Document10 pagesPaper 2kamalugarba93No ratings yet

- EPL-0007910 ArticleDocument14 pagesEPL-0007910 ArticleAna Claudia AlmeidaNo ratings yet

- A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessFrom EverandA Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessNo ratings yet

- Levofloxacin 500 mg/100 mL Solution Validation Protocol and Transfer of Related Substances (DPDocument62 pagesLevofloxacin 500 mg/100 mL Solution Validation Protocol and Transfer of Related Substances (DPIlhamdi AkmalNo ratings yet

- P00533e Background Document On Neodecanoic Acid - Ethenyl EsterDocument28 pagesP00533e Background Document On Neodecanoic Acid - Ethenyl EsterIlhamdi AkmalNo ratings yet

- Pei 2016Document17 pagesPei 2016Ilhamdi AkmalNo ratings yet

- Yamamoto Dan Higashitani 2007Document11 pagesYamamoto Dan Higashitani 2007Ilhamdi AkmalNo ratings yet

- Oct 8, Doc 2-CompressedDocument3 pagesOct 8, Doc 2-CompressedIlhamdi AkmalNo ratings yet

- Dieter Urban - Polymer Dispersion and Their Industrial Applications - 2002 PDFDocument417 pagesDieter Urban - Polymer Dispersion and Their Industrial Applications - 2002 PDFNop Pirom100% (2)

- Pressure Relief Valve Engineering HandbookDocument93 pagesPressure Relief Valve Engineering Handbookakrouti92% (12)

- Journal of The Mechanical Behavior of Biomedical MaterialsDocument9 pagesJournal of The Mechanical Behavior of Biomedical MaterialsIlhamdi AkmalNo ratings yet

- Hydrophobic Coreshell Particles Via Miniemulsion PDocument140 pagesHydrophobic Coreshell Particles Via Miniemulsion PIlhamdi AkmalNo ratings yet

- Technical Data Sheet: Latex Emulsion PaintsDocument2 pagesTechnical Data Sheet: Latex Emulsion PaintsAaron Chris Gonzales100% (1)

- Result and Discussion: 3.3. Biodiesel PropertiesDocument5 pagesResult and Discussion: 3.3. Biodiesel PropertiesIlhamdi AkmalNo ratings yet

- Msds Monomero de Estireno EspanolDocument14 pagesMsds Monomero de Estireno EspanolIlhamdi AkmalNo ratings yet

- Abstrak JurnalDocument1 pageAbstrak JurnalIlhamdi AkmalNo ratings yet

- SubhanallahDocument19 pagesSubhanallahfrenNo ratings yet

- Flow Rate (In Chromatography)Document1 pageFlow Rate (In Chromatography)Ilhamdi AkmalNo ratings yet

- 13 Neicheva 313-316Document4 pages13 Neicheva 313-316Dian MustikasariNo ratings yet

- Polymers: Types & ProcessingDocument55 pagesPolymers: Types & ProcessingCJNo ratings yet

- 2020 Trash Packet Somerset, Massachusetts (Searchable)Document10 pages2020 Trash Packet Somerset, Massachusetts (Searchable)James P. Burke100% (1)

- Pharmaceutical Packaging: United StatesDocument4 pagesPharmaceutical Packaging: United StatesMichael WarnerNo ratings yet

- ASTM Plastics Standards - 2014-08-21Document49 pagesASTM Plastics Standards - 2014-08-21jeneveuxpas0% (3)

- Amazing Plastic Dyes Its Vast Applications and PropertiesDocument2 pagesAmazing Plastic Dyes Its Vast Applications and PropertiesRoyceintlNo ratings yet

- Molding Design GuideDocument11 pagesMolding Design GuideMichael ZhangNo ratings yet

- Mushroom Growers Handbook 1 Mushworld Com Chapter 3 1 2Document2 pagesMushroom Growers Handbook 1 Mushworld Com Chapter 3 1 2NathanielDarko100% (1)

- PE Lecture 3Document53 pagesPE Lecture 3Fauzaan KhanNo ratings yet

- Manufacturing of Plastic ComponentsDocument50 pagesManufacturing of Plastic ComponentsrameshwarmaNo ratings yet

- Investigatory ProjectDocument7 pagesInvestigatory ProjectEstelaBegildoNo ratings yet

- Sustainable SportswearDocument18 pagesSustainable SportswearAnushkaNo ratings yet

- Natural and Organic Cosmetics Definition and ConceptsDocument9 pagesNatural and Organic Cosmetics Definition and ConceptsNgân Kim0% (1)

- Reading Plastic PlanetDocument1 pageReading Plastic PlanetXavy MuñozNo ratings yet

- Pitampur - Indore Industrial Company ListDocument13 pagesPitampur - Indore Industrial Company Listanon_769009642100% (5)

- Dow Corning Silicone Encapsulant Product InformationzDocument10 pagesDow Corning Silicone Encapsulant Product Informationzrickje1234No ratings yet

- Ministry Housing Council Construction WorksDocument29 pagesMinistry Housing Council Construction WorksMohd Arrif YusufNo ratings yet

- Classification and Management of Household WasteDocument27 pagesClassification and Management of Household Wasteangelrom33% (3)

- The Sourcing Continuum - Article by Dave WolskiDocument4 pagesThe Sourcing Continuum - Article by Dave WolskiDavid WolskiNo ratings yet

- Panchal Plastic Machinery PVT LTDDocument28 pagesPanchal Plastic Machinery PVT LTDsan dipNo ratings yet

- Automatik-P-USG en 20120718 PDFDocument8 pagesAutomatik-P-USG en 20120718 PDFCesar Guevara GamarraNo ratings yet

- Wood Plastic CompositesDocument12 pagesWood Plastic CompositesMadhusudhan SrinivasNo ratings yet

- Organic Building and Building MaterialsDocument3 pagesOrganic Building and Building MaterialsMalak BenattiaNo ratings yet

- Metacognitive Viewing ReportDocument3 pagesMetacognitive Viewing ReportImperial Ma LizaNo ratings yet

- Monitoring Microplastics in Drinking Water An Interlaboratory Study To Inform Effective Methods For Quantifying and Characterizing MicroplasticsDocument8 pagesMonitoring Microplastics in Drinking Water An Interlaboratory Study To Inform Effective Methods For Quantifying and Characterizing MicroplasticsSERGIONo ratings yet

- Life 2e BrE Pre-Inter SB U05 (C, D, E, F, Review)Document43 pagesLife 2e BrE Pre-Inter SB U05 (C, D, E, F, Review)sally hoNo ratings yet

- Plant Propagation StructuresDocument4 pagesPlant Propagation StructuresJaskiratNo ratings yet

- Viking Pump Product Selection GuideDocument32 pagesViking Pump Product Selection GuideEduardo EstradaNo ratings yet

- Oral SummaryDocument3 pagesOral SummaryNatasha ParkNo ratings yet

- Coffee Cups from Coffee GroundsDocument9 pagesCoffee Cups from Coffee Groundsaldira jasmineNo ratings yet

- Finding Plastic EverywhereDocument16 pagesFinding Plastic Everywherecarrie929ukNo ratings yet