Professional Documents

Culture Documents

St1 & 2000 Service Manual

Uploaded by

danielbouwmeesterCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

St1 & 2000 Service Manual

Uploaded by

danielbouwmeesterCopyright:

Available Formats

ST1000+ and ST2000+

D3390-1

Z323 ST1000+ and Z324 ST2000+ Autopilot Service Procedures

ST1000+ and ST2000+ Service Manual 83130-1 1

ST1000+ and ST2000+

CE MARKING OF EQUIPMENT/REPLACEMENT PARTS

WARNING

If the Autohelm equipment under repair, test, calibration, installation or setting to

work carries the European CE mark, only parts and components supplied or

approved for such use by Autohelm should be used in order to maintain compli-

ance with the relevant CE requirements.

Incorporation, use or attachment, by any means, of parts or components not

supplied for or not approved for such use by Autohelm or, if supplied or approved

for use by Autohelm, not properly fitted in accordance with instructions published,

provided or recommended by Autohelm, may cause the equipment to malfunc-

tion and, in particular, to become unsafe or to no longer meet the relevant CE

requirements. In these circumstances, Raytheon Marine Europe Ltd excludes

liability to the fullest extent permissible in law for any loss or damage including any

liability for its contribution to such loss or damage by its negligent acts or

omissions .

2 ST1000+ and ST2000+ Service Manual 83130-1

ST1000+ and ST2000+

Contents

1. Description ............................................................................................ 5

2. Operation .............................................................................................. 5

3. Disassembly and Assembly ................................................................ 6

3.1 Upper Case Removal ....................................................................... 6

3.2 PCB Removal................................................................................... 6

3.3 Display Assembly ............................................................................. 8

3.4 Drive Module Removal ..................................................................... 9

3.5 Drive Motor Replacement ................................................................ 9

3.6 Fluxgate Compass Removal and Installation ................................. 10

3.7 Drive Module Assembly ................................................................. 10

3.8 PCB Installation ............................................................................. 11

3.9 Upper Case Refitting ...................................................................... 11

4. Special Functions ............................................................................... 12

4.1 Changing the Operating Sense ...................................................... 12

4.2 Display Test .................................................................................... 12

4.3 Autopilot Type Selection ................................................................. 12

4.4 Display of Software Code ............................................................... 12

4.5 Calibration Lockout ........................................................................ 13

5. Functional Test ................................................................................... 14

5.1 Overall Test .................................................................................... 14

5.2 SeaTalk and NMEA Tests ............................................................... 15

5.3 Keypad ........................................................................................... 15

5.4 Display ........................................................................................... 15

5.5 Drive Assembly .............................................................................. 16

5.6 Fluxgate Compass Assembly......................................................... 16

6. Block Diagram and Signal Tables ..................................................... 17

Main Cable Connectors ................................................................... 17

Fluxgate Compass Connector (SKT1) ............................................. 17

7. Software History ................................................................................. 19

8. Spares numbers ................................................................................. 19

ST1000+ and ST2000+ Service Manual 83130-1 3

ST1000+ and ST2000+

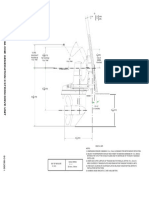

9. Circuit Diagram and PCB Layout ...................................................... 20

10. PCB Components List ..................................................................... 22

Contents

Figure 1. Exploded View ............................................................................ 7

Figure 2. Display Assembly ....................................................................... 8

Figure 3. Gearbox Assembly ..................................................................... 9

Figure 4. Cable Routing........................................................................... 10

Figure 5. Spade Terminal Connections to PCB ....................................... 11

Figure 6. Test Equipment ......................................................................... 14

Figure 7. Fluxgate Electrical Connections ............................................... 16

Figure 8. Block Diagram .......................................................................... 18

Figure 9. PCB Layout .............................................................................. 20

Figure 10. PCB Layout ............................................................................ 21

4 ST1000+ and ST2000+ Service Manual 83130-1

ST1000+ and ST2000+

1. Description

This section of the Service Manual details the Servicing Procedures for the

Autohelm ST1000+ Tiller Autopilot, Catalogue Number Z323 and Autohelm

ST2000+ Tiller Autopilot, Catalogue Number Z324.

2. Operation

Full details of operation and calibration are given in the User Handbook,

Publication Number 81130-1

ST1000+ and ST2000+ Service Manual 83130-1 5

ST1000+ and ST2000+

3. Disassembly and Assembly

Before dismantling the autopilot, check the operating sense (port/starboard), if

the PCB condition allows. All new PCBs are factory set to starboard operating

sense. A replacement PCB in a unit set up for port operation must be set to port

operation.

The autopilot may be calibrated to suit a particular vessel. Note the calibration

settings and set up the new PCB if required.

If the spares PCB contains software of a higher issue than the PCB it replaces,

the relevant Operating Supplement(s) must be included when the equipment is

returned to the customer.

Replacement PCBs are set up as ST1000+.

Component identification numbers refer to Figure 1, Exploded View, unless a

detail figure is identified at the start of a section.

3.1 Upper Case Removal

1. Ensure the drive unit is fully retracted

2. Remove the case securing screws (10, 8 off)

3. Lift off the upper case (1)

Do not run the actuator assembly with the upper case removed and the PCB in

place. There is insufficient clearance between the guide bridge and the PCB and

damage to PCB components may result.

If it is required to run the actuator the PCB should be unscrewed and lifted slightly.

3.2 PCB Removal

All work on the PCB should be carried out taking normal static precautions.

1. Remove the upper case (1)

2. Remove the screws (19, 3 off) securing the PCB

3. Lift the PCB off its support pillars and disconnect the Fluxgate flexible circuit

(16) from connector SK1. Disconnect the power, data, screen, NMEA +,

NMEA- and motor spade connectors (22, 23, 24) from the PCB.

Replacement PCBs are supplied without an LCD. If changing the PCB refer to

section 3.3 for instructions to remove and transfer the display assembly to a

replacement PCB.

6 ST1000+ and ST2000+ Service Manual 83130-1

22 24

23

Figure 1. Exploded View

ST1000+ and ST2000+

3

19

4

1. Upper Case

18

2. Case Seal

3. Motor/Gearbox Assembly

(see Figure 2 for detail)

5 4. Pivot Pin

17 5. Pivot Seal

6. Main Cable

16 6 7. Cable Cutout

1

6 8. Lower Case

15

9. Cable Channel

10. Case Securing Screw (8 off)

11. Drive Unit Support Web

14

12. Fluxgate Assembly

13 13. End Cap

14. Ram Tube

21 20 15. End Plate/Seal

16. Fluxgate Flexible Circuit

17. PCB

12

18. LCD Assembly

(see Figure 1 for detail)

11

19. PCB Retaining Screws (3 off)

20. Gimbal Support Location Screw (2 off)

21. Gimbal Support (2 off)

22. Power and SeaTalk Spade Connectors

23. NMEA Spade Connectors

10

9 8 7 24. Motor Spade Connectors

D3386-1

ST1000+ and ST2000+ Service Manual 83130-1 7

ST1000+ and ST2000+

3.3 Display Assembly

Refer to Figure 2.

The display assembly is a snap fit which is retained on the PCB by four moulded

lugs (2). The backlight diffuser (6) clips into the display bezel (1) and retains the

LCD and its elastomer connector (3).

1. Bezel

1

2. Bezel Fixing Lug

3. Elastomer

2

4. Spring Lug

5. LCD

6. Diffuser

D3381-1

Figure 2. Display Assembly

The display is back lit via the diffuser by two green LEDs which are mounted

directly on the PCB.

Removal

1. Unclip the bezel lugs (2) from the PCB (Upper pair first then lower pair)

2. Ease the complete display assembly from the board.

Installation

If fitting a new LCD the marked protective film must be removed.

1. Place the LCD (5) into the bezel (1) (note orientation)

2. Place the elastomer connector (3) on top of the LCD connection strip (note

orientation)

3. Insert the diffuser (6) into the bezel so that the two spring lugs (4) locate into

the display bezel

4. Press the display assembly on to the PCB ensuring all four bezel lugs (2)

locate correctly.

8 ST1000+ and ST2000+ Service Manual 83130-1

ST1000+ and ST2000+

3.4 Drive Module Removal

1. Remove the PCB

2. Lift out the drive assembly and ease the ram tube (14) from the case seal (2).

3.5 Drive Motor Replacement

Refer to Figure 3.

1. Remove the drive module

2. Remove the gearbox securing screws (10, 4 off)

3. Separate the support plates (7, 2 off)

4. Remove the motor securing screws (8, 2 off) from the rear plate.

The motor can now be lifted away and a replacement fitted.

Replacement is a reversal of the removal procedure. After securing the gearbox

ensure both belts (9, 2 off) are fitted correctly by hand turning the leadscrew drive

pulley (4) and observing correct belt tracking.

1 2 3 4 7 5 6

1. Support Bridge

2. Guide Rod

3. Lead Screw

4. Lead Screw Drive Pulley

5. Motor

6. Motor Cables

7. Gearbox Support Plate

8. Motor Securing Screws (x2)

9. Drive Belts

10. Gearbox Securing Screws (x4)

11. Drive Nut

12 11 10 7 9 8 12. Ram Tube

D3382-1

Figure 3. Gearbox Assembly

ST1000+ and ST2000+ Service Manual 83130-1 9

ST1000+ and ST2000+

3.6 Fluxgate Compass Removal and Installation

1. Remove the drive module

2. Remove the gimbal supports (21, 2 off)

3. Lift out the fluxgate assembly (12).

Replacement is a reversal of the removal procedure. Note the orientation of the

flexible circuit tail (16).

The tail of the fluxgate can be easily damaged and care should be taken not to

fold or bend it sharply.

3.7 Drive Module Assembly

1. Locate the main cable (6) and red and black motor leads in the channel (9) at

the side of the lower case (8)

2. Enter the ram tube (14) into the case seal (2).

3. Lay the drive module into the lower case making sure the cables pass through

the cutout (7) in the gearbox support plates as shown in Figure 3

4. Lay the case seal (2) in the outer groove around the perimeter of the lower

case.

D3383-1

Figure 4. Cable Routing

10 ST1000+ and ST2000+ Service Manual 83130-1

ST1000+ and ST2000+

3.8 PCB Installation

Before refitting the PCB check that the drive assembly is fully retracted. Failure to

do this results in damage to the PCB at installation.

Check the PCB to ensure that the four FET drive transistors are mounted verti-

cally and not bent over at an angle.

1. Remove the display assembly from the old PCB and fit to the new board (see

section 3.3)

2. Connect the main cable and motor cable wires to the PCB tags. Ensure

correct connection. Refer to Figure 4.

+12V, Brown

M1, Red

NMEA IN --, Green 0V, Blue

M2, Black

NMEA IN +, White SeaTalk Data, Yellow

Motor Cable

Main Cable

Connector tags viewed from Component Side of PCB D3388-1

Figure 5. Spade Terminal Connections to PCB

3. Connect the fluxgate flexible circuit tail (16) into PCB socket SKT1. (Ensure

correct orientation. Refer to Figure 8)

4. Lower the PCB onto the location pillars

5. Lock in place with the securing screws (19, 3 off)

6. Power up the unit and confirm display operation by momentarily pressing the -

1 and +10 degree keys. The display should count up from 0 to 9 on all four

characters, then display all other annotations. Observe the display and

confirm all segments are switching on.

3.9 Upper Case Refitting

1. Clean the LCD and the window in the upper moulding with a lint free anti static

wipe

2. Ensure the case seal is seated correctly in the outer groove around the

perimeter of the lower case

3. Ensure the O ring seal (5) is located around the pivot pin (4)

4. Lower the upper case onto the assembly and locate with the securing screws

(10, 8 off). Do not over tighten (8 in Ibs max.).

ST1000+ and ST2000+ Service Manual 83130-1 11

ST1000+ and ST2000+

4. Special Functions

4.1 Changing the Operating Sense

All units are supplied from the factory set up as Starboard.

The operating sense of the autopilot can be reversed by pressing the +1° and -1°

course change keys together for 5 seconds

The unit should beep for 10 seconds to confirm change over and the display

should show the new setting, either Port or Starboard.

4.2 Display Test

A special display test feature in the ST1000/200+ software checks that the

display assembly is fitted correctly after changing the PCB. Display test is

switched on by momentarily pressing the -1° and +10° keys together.

The display should scroll all four characters through from 0 to 9 and then display

each annotation. This sequence continues until the Standby or Auto key is

pressed or the unit is powered down.

4.3 Autopilot Type Selection

The ST1000+ and ST2000+ autopilots use the same PCB (Q218), but gears in

the ST1000+ and ST2000+ drive modules are different, so each pilot runs a

different program. Both sets of software are contained within the same chip.

To select the correct program:

1. Press the -10° and +1° keys until the display shows the pilot type number,

2000 or 1000 (approx. 5 seconds)

2. Press the -10° and +1° keys again until the display flashes the pilot type

number (approx. 5 seconds)

3. Select the correct pilot type using the +1° and -1° keys

4. Save the setting by pressing the -10° and +1° keys until the normal Standby

display appears (approx. 2 seconds)

Changing Autopilot type clears all calibration setting/compass linearisation and

returns the unit to factory setting.

4.4 Display of Software Code

The software code of the pilot can be displayed by switching the pilot to standby

mode and pressing the Standby key until the display shows P followed by a

number (approx. 10 seconds).

The number indicates the version of software fitted, for example, P 0 6 indicates

Version 6 software.

12 ST1000+ and ST2000+ Service Manual 83130-1

ST1000+ and ST2000+

4.5 Calibration Lockout

Access to the compass linearisation and calibration functions on the ST1000+/

2000+ autopilots can be prevented. This can be a useful feature, for example, to

charter boat operators who spend a lot of time tuning the pilot to the boat, only to

find a customer alters the settings at a later date.

Any attempt to linearise the compass or enter calibration when the lockout

function is enabled results in the display showing Cal Off. The user cannot then

change any settings.

To disable calibration:

1. Press and hold the -1° and Standby keys for 10 seconds until the display

shows CAL ON

2. Toggle calibration access between ON and OFF using the -1° and +1° keys

3. Store the selected setting by pressing the -1° and Standby keys for 10

seconds.

ST1000+ and ST2000+ Service Manual 83130-1 13

ST1000+ and ST2000+

5. Functional Test

Supply 0v Navigator

NMEA- or Wind

3

Instrument

4

2

with NMEA

Output

5

1

6

NMEA+

Fuse Red Screen Yellow

Supply +12V

D3384-1

Figure 6. Test Equipment

5.1 Overall Test

APPLY POWER TO UNIT

CHECK UNIT BEEPS, FLASHES

C AND FINALLY DISPLAYS

A MAGNETIC HEADING

NO CHANGE PCB

OK

RESTART

YES

PRESS & HOLD +10 KEY

CHECK MOTOR RUNS

NO

OK

YES

PRESS & HOLD -10 KEY

CHECK MOTOR RUNS

NO

OK

DISCONNECT POWER &

REMOVE DRIVE MODULE

YES DISCONNECT MOTOR SPADE

TERMINALS & APPLY 10V DC

PRESS AUTO & CHECK TO MOTOR TERMINALS

DISPLAY SHOWS A CHECK MOTOR RUNS

NO CHANGE PCB NO

OK OK CHANGE MOTOR

RESTART RESTART

YES

YES

HOLD UNIT HORIZONTAL.

REVERSE 10V ON MOTOR

ROTATE IT IN CLOCKWISE

CHECK MOTOR RUNS

DIRECTION; CHECK

PUSHROD RETRACTS

(STBD SET UP) OR NO CHANGE MOTOR

OK

EXTENDS (PORT SET UP) RESTART

YES

NO CHECK MOTOR CONNECTIONS

OK

AND WIRES

YES

HOLD UNIT HORIZONTAL. NO CHANGE FAULTY

OK

ROTATE IT IN AN ANTI - ITEM(S) RESTART

CLOCKWISE DIRECTION; YES

CHECK PUSHROD

EXTENDS (STBD SET UP) CHANGE PCB

OR RETRACTS (PORT SET UP) RESTART

NO

OK

CHECK FLUXGATE

YES

(SECTION 5.6)

GO TO SeaTalk TEST NO CHANGE FLUXGATE

OK

(NEXT PAGE) RESTART

YES

CHANGE PCB

RESTART

D6149-1

14 ST1000+ and ST2000+ Service Manual 83130-1

ST1000+ and ST2000+

5.2 SeaTalk and NMEA Tests

FROM OVERALL TEST

PRESS STANDBY

SELECT ANY ILLUMINATION

LEVEL (EXCEPT 0) ON

SeaTalk INSTRUMENT

CHECK AUTOPILOT DISPLAY

ILLUMINATION SWITCHES ON

NO CHANGE PCB

OK

RESTART

YES

SELECT ILLUMINATION LEVEL

0 ON SeaTalk INSTRUMENT

CHECK AUTOPILOT DISPLAY

ILLUMINATION SWITCHES OFF

NO CHANGE PCB

OK

RESTART

YES

GO TO NAVIGATOR OR WIND

TEST (ACCORDING TO TEST

RIG SET UP)

NAVIGATOR TEST WIND TEST

SET UP A TRACK ON THE

NAVIGATOR TO GIVE A PRESS STANDBY & AUTO

CROSS TRACK ERROR TOGETHER

BETWEEN 0 & 0.3nm

CHECK AUTOPILOT DISPLAYS

PRESS AUTO LOCKED HEADING

IN FORMAT SHOWN

PRESS +10 & -10 TOGETHER

TO ENTER TRACK MODE

CHECK THAT ALARM SOUNDS

AND DISPLAYS ALTERNATE

BETWEEN NO

OK CHANGE PCB

AND RESTART

YES

NO IS DISPLAY: NO IS DISPLAY: NO

OK

YES YES

RECONFIGURE RELOCATE CHANGE

NAVIGATOR NAVIGATOR FOR PCB

RESTART NAV TEST STRONGER SIGNAL RESTART

RESTART NAV TEST

YES

UNIT OK END OF TEST UNIT OK END OF TEST

D6151-1

5.3 Keypad

The keypad can be checked by pressing each key in turn. All keys should

respond with a tactile metallic click and an audible beep. If this is not the case the

PCB should be replaced.

5.4 Display

To check operation of the display, refer to section 4.2.

ST1000+ and ST2000+ Service Manual 83130-1 15

ST1000+ and ST2000+

5.5 Drive Assembly

Remove the drive assembly from the lower case. Connect a 10V dc supply to the

motor terminals and measure the running current of the drive unit with the drive

running freely and not against either end stop.

<2A - Drive Healthy >2A - Drive Faulty

5.6 Fluxgate Compass Assembly

Remove the fluxgate assembly

The compass can be checked with a DVM.

Connect Meter across Pins Resistance

1 and 2 <10 ohms

3 and 5 <5 ohms

3 and 4 <5 ohms

1 and 3 Open Circuit

83001t4

No Connection

5

4

3

2

1

D3385-1

Figure 7. Fluxgate Electrical Connections

16 ST1000+ and ST2000+ Service Manual 83130-1

ST1000+ and ST2000+

6. Block Diagram and Signal Tables

Main Cable Connectors

Signal

+12VIN Nominal 12V dc

0VIN 0V

SeaTalk Intermittent 12V (nominal) pulse streams

NMEAIN+ Intermittent 12V (nominal) pulse streams

NMEAIN- Intermittent 12V (nominal) pulse streams

83130t10

Fluxgate Compass Connector (SKT1)

Pin No. Signal

1 Not Used

2 VRESET Nominal 2.5V DC

3 F/GB Compass Input (2) Nominal 2.5V DC

4 F/GA Compass Input (2) Nominal 2.5V DC

5 F/G DRIVE AC, 17 cycles at 7.9 KHz, driven twice

every 1/16 second

6 0V 0V DC

83130t11

ST1000+ and ST2000+ Service Manual 83130-1 17

ST1000+ and ST2000+

D3

VBUS

D1

12V

REGULATOR

+12V +5V

IC1 RESET 1

VZ1 RESET 2 VREG

TR1 ZD1

12V

0V 0V

+5V P8.5

INH P8.4 SK

C P8.3 DI

R22

B P8.2 IC7

A R23

P1.6 CS

CH0 P1.4 DO

R24

C15 EEPROM

CH1 0V RST

RESET

F/GA CH2 BUSY

+

SCK

F/GB CH3 IC6 TR12 P3.3 SI

COM C/D

--

FB1 CH4 P1.6 CS

INTEGRATOR COMPARATOR SEG1

FB2 CH5 OSC1 CL1 to

R93 SEG19

CH6 OSC2 CL2

CH7 XL1 +5V VLC1

XTAL

R13

IC2 12MHz VLC2

CRYSTAL R14 COM0

ANALOGUE

VLC3 COM1

MULTIPLEXER

R15 IC3 LCD1

LCD DRIVER DISPLAY

VRESET TO COMPASS 0V

SeaTalk VBUS

RXDATA

DATA TR10 TR11 P3.0

DATA OUT

P3.1 TR9 TR5

TXDATA

NMEA IN + A TR7

WHITE TR9

TR8

C P3.2

NMEA IN -- VBUS

K LED1

GREEN IC9

P1.5 LED TR32 12V

OPTO - ISOLATOR TR33 LED2

VBUS

TR26

P3.4 TR27 BZ1 BUZZER

TR28

VREG

12V

TR14 TR15

P0.7

M1 RED

TR16 TR17 TR18 FB1

SW1 AUTO KBD3 VREG 12V

P1.2

P0.6 TR20 TR19

SW2 STDBY KBD4 M2 BLACK

P1.3

TR23 TR22 TR21 FB2

SW3 --1 KBD5

P1.4 0V 0V

SW4 +10 P0.0 TR29

COMPASS

TR30 DRIVE

SW5 --10 P0.1

KBD1 F/GA F/GA

P1.0

SW6 +1 KBD2 F/GB F/GB

P1.1

IC8

VRESET BIAS

MICROCONTROLLER

N/C

SKT1

Signal flow is left to righf except where indicated.

D3386-1

Figure 8. Block Diagram

18 ST1000+ and ST2000+ Service Manual 83130-1

ST1000+ and ST2000+

7. Software History

Version Change Serial Number

P10 Introduction 12600001

83130t2a

8. Spares numbers

Item Cat. No. Comments

6-Pin Plug D337

6-Pin Socket D338

Plug and Socket D339

Kit

Fluxgate M022

Assembly

Drive Module Q041 ST1000+

Drive Module Q043 ST2000+

Lower Case Q052

Display QO53

Assembly

Gearbox Kit Q054

PCB Q218 LCD not included

Upper Case W113 ST1000+

Upper Case W114 ST2000+

83061t3

ST1000+ and ST2000+ Service Manual 83130-1 19

ST1000+ and ST2000+

9. Circuit Diagram and PCB Layout

D3391-2

Figure 9. PCB Layout

20 ST1000+ and ST2000+ Service Manual 83130-1

ST1000+ and ST2000+

Surface Mount Component Side

C42 C34

C5

R10 R84 R83

C C R11 C23

D4

41 43 R20 TR TR

L1 R21 IC2 C22 30 29

R85 L2 L3 R59 R67 R8 R5 R9

D7 R54 R64 R82 C32

TR TR R7 R12 IC7

R88 22 17 R6

C38 TR TR R112 R81

IC9 C39

14 20 R68 R58 C21 L4

R52 R46 R47 R111 R80

C15 C8 R93

TR R87 C35

C26 R53 R66 TR

31 R69 R103

R100 TR 16

C27 R99 IC6

R R57 23 R110

R56

86 R78 R75 D9 ZD1 C36 R70

C16 R109

R65

TR TR TR R108 IC3

27 26 28 R102 R25 C40 IC8

R74

C31 C30 R79 R33 R45 R27 TR

R36 12 TR

TR5 R26 34

R77 R76 R34 R44

R60 D6 R32 R35 TR

TR1 TR R101 35

R61 R31 11 C14

R38 C18 R13

R4 C20 C19 R14

R62 R3 R24 R

TR C7 C6

TR6 TR7 TR8 16

R63 R2 10

R1 R23

R37 R40 R39 R43

D3 C3 C2 R22 R15

R41 TR9 R42 TR

C13 R107 TR32

33

IC1

R106

Conventional Component Side

M1 +

+12V SKT1

TR15 TR21

M2 C10

NMEAIN- 0V D1

TR19 TR18

NMEAIN+ DATA

V1

+

C28 XL1

+

C1 C37 C4

C29 + + +

Conventional Component Side

S2 S5 S3 LP1

L

E

D

1

LP2

L

S1 S6 E

S4

D

1

D3387-1

Figure 10. PCB Layout

ST1000+ and ST2000+ Service Manual 83130-1 21

ST1000+ and ST2000+

10. PCB Components List

Surface Mount Component Side

RESISTOR 1R0 5% 125mW R80, 99

RESISTOR 8R2 5% 125mW R37, 46, 83, 84

RESISTOR 47R 5% 125mW R106, 107

RESISTOR 82R 1% 125mW R23

RESISTOR 180R 5% 125mW R86, 100

RESISTOR 270R 1% 125mW R9, 10

RESISTOR 390R 5% 125mW R15, 32, 39, 40

RESISTOR 470R 5% 125mW R75, 78

RESISTOR 1K2 1% 125mW R22, 24, 60, 61, 62, 63, 81

RESISTOR 1K5 5% 125mW R13, 14, 85, 88

RESISTOR 2K2 5% 125mW 3, 27, 33, 38, 56, 58, 68, 70

RESISTOR 3K3 5% 125mW R1

RESISTOR 4K7 5% 125mW R43, (47), 52, 53, 65, 66, 74, 79, 82, 87,

102, (103), 108 - 112

RESISTOR 5K6 1% 125mW R7, 8, 21, 76, 77

RESISTOR 10K 5% 125mW R2, 4, 16, 35, 41, 45, 54, 57, 59, 64, 67,

69

RESISTOR 15K 5% 125mW R36

RESISTOR 22K 5% 125mW R34

RESISTOR 33K 1% 125mW R5, 6, 11, 12, 20, 26

RESISTOR 39K 5% 125mW R31, 42, 44

RESISTOR 68K 1% 125mW R25

RESISTOR 180K 1% 125mW R93

RESISTOR 1M0 1% 125mW (R101)

CAPACITOR 33pF 5% COG 50V (C19, 20)

CAPACITOR 100pF 10% CER 50V (C39, 40)

CAPACITOR 470pF 10% COG 50V C35

CAPACITOR 1000pF 2% COG 50V C6, 7, 15, 18, 38, (41, 42, 43)

CAPACITOR 22nF 5% COG 50V C3, 30, 31

83001t6

22 ST1000+ and ST2000+ Service Manual 83130-1

ST1000+ and ST2000+

Surface Mount Component Side (continued)

CAPACITOR 0.1uF 20% 50V AVX C2, 5, 8, 13, 14, 16, 21, 22, 34, 36

CAPACITOR TANT 1uF 10% 16V C26, 27

CAPACITOR 2.2uF 20% 6V3 SIZE A C32, 33

DIODE SOT23 BAS 19 D3, 7

DIODE SOT23 BAV 99 D6

DIODE BAW 56 (D4), 9

DIODE ZENER BZX12V ZD1

TRANSISTOR BC807 SOT23 TR5, 12, 29

TRANSISTOR BC817 SOT23 TR1, 6 - 11, 14, 16, 17, 20, 22, 23, 26,

27, 28, 30, 31, 33

TRANSISTOR BC868 TR32

ANALOGUE SWITCH 74HC401 IC2

LCD DISPLAY DRIVER 7225G-00 IC3

(NEC)

CA3130 OP AMP IC6

EEPROM 16x16 M9306 1M1 SGS IC7

MICROCONTROLLER S83C154 IC8

PLCC

OPTO ISOLATOR PC357 IC9

SOLID CHIP INDUCTOR L1 - 4

PCB 3015 - 166

831301t7

Resistor R101 (1M0) and capacitoprrs (C19, C20) are fitted only if resonator XL1(three legged

version) is replaced by the two legged version.

Conventional component tables follow overleaf.

ST1000+ and ST2000+ Service Manual 83130-1 23

ST1000+ and ST2000+

Conventional Component Side

CAPACITOR ELECTROLYTIC 1uF C28, 29, 37

20% 63V 2mm PITCH

CAPACITOR 100uF TANT 20% 6V3 C4

2.5mm PITCH

CAPACITOR ELECTROLYTIC 100uF C1

20% 25V 7.5mm MAX DIAM

CAPACITOR ELECTROLYTIC 470uF C10

20% 35V

DIODE MR751 D1

TRANSISTOR FET LRFZ34 60V 30A TR15, 18, 19, 21

REGULATOR +5V WITH RESET IC1

LM2925

VARISTOR ERZCO7DK270 ZNR V1

TYPE 0

BUZZER BZ1

FLEXI CONNECTOR SKT1

SPADE TERMINAL 7 off

And either

CERAMIC RESONATOR CERALOCK XL1

(3 PINS)

or

CERAMIC RESONATOR CERALOCK XL2

(2 PINS)

83130t8

See note on use of R101, C19, C20 with XL2.

Conventional Non - Component Side

LED DUAL SIDE FIRING GREEN LED1, 2

MINIATURE AXIAL LAMP (LP1, 2)

ALP SWITCH MINI S1 - 6

83130t9

Raymarine Limited Raymarine Incorporated

Robinson Way, Anchorage Park, Portsmouth, 22 Cotton Road, Unit H, Nashua,

Hampshire, England PO3 5TD. New Hampshire 03063-4219, USA

Tel: +44 (0) 23 9269 3611 Tel: +1 603 881 5200

Fax: +44 (0) 23 9269 4642 Fax: +1 603 864 4756

www.raymarine.com www.raymarine.com

24 ST1000+ and ST2000+ Service Manual 83130-1

You might also like

- ST 4000 Plus Service ManualDocument34 pagesST 4000 Plus Service ManualdudelangeNo ratings yet

- ST 6000 Plus Service ManualDocument8 pagesST 6000 Plus Service ManualstrujaNo ratings yet

- RT50FBPN1 XefDocument43 pagesRT50FBPN1 XefsebNo ratings yet

- Renault TRAFIC: Powerful, Clever and DynamicDocument56 pagesRenault TRAFIC: Powerful, Clever and Dynamicediartmobe100% (1)

- Alpha One Generation Ii Stern Drive: IndexDocument37 pagesAlpha One Generation Ii Stern Drive: IndexNicholas Ribic100% (1)

- 6E0-45361-01-4D 8D Lower Casing Cap For Yamaha Outboard F 4HP 5HP Engine 24 ST PDFDocument16 pages6E0-45361-01-4D 8D Lower Casing Cap For Yamaha Outboard F 4HP 5HP Engine 24 ST PDFMarine Parts ChinaNo ratings yet

- OE Evinrude Portable Outboards - Flat Rate GuideDocument30 pagesOE Evinrude Portable Outboards - Flat Rate GuideJason William100% (1)

- EN - 2012 Evinrude E-TEC Installation and Predelivery GuideDocument100 pagesEN - 2012 Evinrude E-TEC Installation and Predelivery GuideEnimalistNo ratings yet

- M5B ServicemanualDocument57 pagesM5B Servicemanualmarkusweinzierl100% (1)

- Everything You Need to Know About Powerhead Specifications and RepairDocument30 pagesEverything You Need to Know About Powerhead Specifications and RepairBaxter LoachNo ratings yet

- Wayfarer Setup PDFDocument17 pagesWayfarer Setup PDFArboussolsNo ratings yet

- Catalogo Quicksilver 2010Document1,482 pagesCatalogo Quicksilver 2010Gabriella CirielliNo ratings yet

- Alpha One Gen IIDocument1 pageAlpha One Gen IIWanda MarthaNo ratings yet

- Partial Service ManualDocument41 pagesPartial Service ManualchuckNo ratings yet

- Midsection: Section 5 - Clamp and Swivel BracketDocument8 pagesMidsection: Section 5 - Clamp and Swivel BracketpedroNo ratings yet

- 30l Tks Alpha Operation and Service ManualDocument92 pages30l Tks Alpha Operation and Service ManualPierre Balian100% (1)

- Service 2-stroke outboard engineDocument20 pagesService 2-stroke outboard enginepr1sleaNo ratings yet

- Raymarine ST60 Instruments - DigitalDocument36 pagesRaymarine ST60 Instruments - DigitalJulioNo ratings yet

- Mercury Racing Hp1075 Sci Engine Owners ManualDocument128 pagesMercury Racing Hp1075 Sci Engine Owners Manualevangalos0% (1)

- Service Manual Acer Aspire z5610Document210 pagesService Manual Acer Aspire z5610Dorin Pirnog100% (1)

- Mercruiser AnodesDocument41 pagesMercruiser AnodesMarine Parts ChinaNo ratings yet

- Powerhead Section 4 Guide - Specs, Tools, Removal & ReassemblyDocument53 pagesPowerhead Section 4 Guide - Specs, Tools, Removal & ReassemblypedroNo ratings yet

- 2016 Dometic Price List Marine Air ConditionerDocument135 pages2016 Dometic Price List Marine Air ConditionerDildar Alam RaselNo ratings yet

- ST60 Digital Instruments Service ManualDocument36 pagesST60 Digital Instruments Service ManualLeandro ClericiNo ratings yet

- 2003 200 Bow RiderDocument36 pages2003 200 Bow Riderbbenz62No ratings yet

- Mercury Outboard Water Pumps ImpellersDocument20 pagesMercury Outboard Water Pumps ImpellersMarine Parts ChinaNo ratings yet

- 7723924w Operators ManualDocument32 pages7723924w Operators ManualDorothy Mortenson0% (1)

- Channel-to-Frequency Chart and CONCORDE II SPECIFICATIONSDocument18 pagesChannel-to-Frequency Chart and CONCORDE II SPECIFICATIONSbobbyunlockNo ratings yet

- DSM250 Digital Sounder Module Service ManualDocument36 pagesDSM250 Digital Sounder Module Service ManualOkan Taktakoğlu50% (2)

- Yamaha 5CSDocument29 pagesYamaha 5CSLpacNo ratings yet

- Model Number ReferenceDocument80 pagesModel Number ReferenceAlex Vdbussche0% (1)

- Mercedes CLK Cabriolet Owners Manual 2001 PDFDocument341 pagesMercedes CLK Cabriolet Owners Manual 2001 PDFDariusz Bartniak100% (1)

- Mercruiser Certified Pre-Owned Blowout Sale ItemsDocument2 pagesMercruiser Certified Pre-Owned Blowout Sale ItemsmalharNo ratings yet

- Owner's Manual: Outboard MotorDocument85 pagesOwner's Manual: Outboard MotorJasmin PartingtonNo ratings yet

- Trouble Shooting BF75-100 enDocument23 pagesTrouble Shooting BF75-100 enDaot KhoNo ratings yet

- Marine Air AC Control Identification GuideDocument17 pagesMarine Air AC Control Identification GuideiBusinessLogicNo ratings yet

- 1975 Argosy Motorhome Owners ManualDocument111 pages1975 Argosy Motorhome Owners ManualChris MartinezNo ratings yet

- Raymarine ST40 Instruments Service ManualDocument70 pagesRaymarine ST40 Instruments Service ManualOkan Taktakoğlu100% (1)

- Mallikoodi Valmistus Mistä Mihin MalliDocument5 pagesMallikoodi Valmistus Mistä Mihin Mallicombahee50% (2)

- Mercury 30 - 40hp Service OEM ManualDocument532 pagesMercury 30 - 40hp Service OEM ManualwboeremaNo ratings yet

- How To Remove Supercharger From Sea Doo RXP RXT RXPX RXTXDocument15 pagesHow To Remove Supercharger From Sea Doo RXP RXT RXPX RXTXMatthew ConleyNo ratings yet

- Manual Motor Popa 60hpDocument61 pagesManual Motor Popa 60hplucianoNo ratings yet

- Merc Alpha ToolsDocument28 pagesMerc Alpha ToolsVinnie AmicoNo ratings yet

- MPC 3024 AceDocument39 pagesMPC 3024 Acezvh48588No ratings yet

- TCP 42 GT 30 ADocument112 pagesTCP 42 GT 30 AjamorNo ratings yet

- Bosch Bz500Document40 pagesBosch Bz500Emir PanjetaNo ratings yet

- Installation Manual: 9900 Series Models 9900, 9900A and 9900BDocument68 pagesInstallation Manual: 9900 Series Models 9900, 9900A and 9900BRandy SharpNo ratings yet

- mr3018-3020 Service ManualDocument104 pagesmr3018-3020 Service ManualDennis LeeNo ratings yet

- Information: Walkair V2.0 Umn:TedDocument34 pagesInformation: Walkair V2.0 Umn:TedErica BazanNo ratings yet

- R912005856 12Document98 pagesR912005856 12mikeNo ratings yet

- EFCx610 ManualDocument94 pagesEFCx610 Manualmish bernsNo ratings yet

- Uf - 580 590 780 790Document298 pagesUf - 580 590 780 790OFBA srlNo ratings yet

- RaytheonAnschutz Distribution Unit Gyro Compass Service ManualDocument100 pagesRaytheonAnschutz Distribution Unit Gyro Compass Service ManualEdwin Nyange50% (2)

- A Series Training Manual - Maintenance CourseDocument280 pagesA Series Training Manual - Maintenance CourseTetsusaigaNo ratings yet

- DP-3510 PartsDocument368 pagesDP-3510 PartsChung KimNo ratings yet

- Changhong Chassis LS18 Maintenance ManualDocument34 pagesChanghong Chassis LS18 Maintenance Manualphoenix136No ratings yet

- Rexroth Frequency ConverterDocument104 pagesRexroth Frequency ConverterTarek FenterNo ratings yet

- Sle4000-5000 Manual de Servicio p1, p2 y p3, r1, r2 y r3Document398 pagesSle4000-5000 Manual de Servicio p1, p2 y p3, r1, r2 y r3DanielaRestrepoGalvánNo ratings yet

- Dx80s2 Dx90s2 Installation InstructionDocument229 pagesDx80s2 Dx90s2 Installation InstructionAnderson PinheiroNo ratings yet

- Planning Documentation - CTX Beta 1250 TCDocument62 pagesPlanning Documentation - CTX Beta 1250 TCsetmeinNo ratings yet

- Manual for SmartSolar charge controllers MPPT 75/10, MPPT 75/15, MPPT 100/15, MPPT 100/20, MPPT 100/20-48VDocument96 pagesManual for SmartSolar charge controllers MPPT 75/10, MPPT 75/15, MPPT 100/15, MPPT 100/20, MPPT 100/20-48VdanielbouwmeesterNo ratings yet

- Sora 4 - Specification SheetDocument2 pagesSora 4 - Specification SheetdanielbouwmeesterNo ratings yet

- Building Specification Archambault SupriseDocument2 pagesBuilding Specification Archambault SuprisedanielbouwmeesterNo ratings yet

- 2 Apr 2001 Attachment 2Document1 page2 Apr 2001 Attachment 2danielbouwmeesterNo ratings yet

- RedSeaResearch Symposium AgendaDocument8 pagesRedSeaResearch Symposium AgendadanielbouwmeesterNo ratings yet

- Sora 5 - Specification SheetDocument2 pagesSora 5 - Specification SheetdanielbouwmeesterNo ratings yet

- Guide to Offshore Wind Farm DevelopmentDocument72 pagesGuide to Offshore Wind Farm DevelopmentJoe Dagner100% (1)

- Sname - Numerical Prediction of BucklingDocument9 pagesSname - Numerical Prediction of BucklingdanielbouwmeesterNo ratings yet

- PH Miracle Complete Whole Body Alkalizing Program-1201724Document20 pagesPH Miracle Complete Whole Body Alkalizing Program-1201724joao carlos100% (1)

- Divide Fractions by Fractions Lesson PlanDocument12 pagesDivide Fractions by Fractions Lesson PlanEunice TrinidadNo ratings yet

- PSAII Final EXAMDocument15 pagesPSAII Final EXAMdaveadeNo ratings yet

- Publications FireSafetyDesign SDocument369 pagesPublications FireSafetyDesign SJayachandra Reddy AnnavaramNo ratings yet

- Ohta, Honey Ren R. - Activity 7.2 (Reflection Agriculture and Religion)Document5 pagesOhta, Honey Ren R. - Activity 7.2 (Reflection Agriculture and Religion)honey ohtaNo ratings yet

- 2113T Feasibility Study TempateDocument27 pages2113T Feasibility Study TempateRA MagallanesNo ratings yet

- 3170308Document3 pages3170308Dhruv DesaiNo ratings yet

- The Top 10 Strategic Technology Trends For 2020: Tomas Huseby Executive PartnerDocument31 pagesThe Top 10 Strategic Technology Trends For 2020: Tomas Huseby Executive PartnerCarlos Stuars Echeandia CastilloNo ratings yet

- Galley cleaning hazards and controlsDocument9 pagesGalley cleaning hazards and controlsRosalie RosalesNo ratings yet

- Diferencias Gas LP y Gas Natural: Adminigas, S.A. de C.VDocument2 pagesDiferencias Gas LP y Gas Natural: Adminigas, S.A. de C.VMarco Antonio Zelada HurtadoNo ratings yet

- AWK and SED Command Examples in LinuxDocument2 pagesAWK and SED Command Examples in Linuximranpathan22No ratings yet

- The Patient Self-Determination ActDocument2 pagesThe Patient Self-Determination Actmarlon marlon JuniorNo ratings yet

- Relation of Jurisprudence With Other Social Sciences - LLB NotesDocument4 pagesRelation of Jurisprudence With Other Social Sciences - LLB NotesPranjaliBawaneNo ratings yet

- The Collected Letters of Flann O'BrienDocument640 pagesThe Collected Letters of Flann O'BrienSean MorrisNo ratings yet

- MP & MC Module-4Document72 pagesMP & MC Module-4jeezNo ratings yet

- Evolution BrochureDocument4 pagesEvolution Brochurelucas28031978No ratings yet

- Pharma Pathway SopDocument350 pagesPharma Pathway SopDinesh Senathipathi100% (1)

- 2019 ASME Section V ChangesDocument61 pages2019 ASME Section V Changesmanisami7036100% (4)

- Amex Case StudyDocument12 pagesAmex Case StudyNitesh JainNo ratings yet

- Rpo 1Document496 pagesRpo 1Sean PrescottNo ratings yet

- Impression Techniques in Complete Denture Patients: A ReviewDocument6 pagesImpression Techniques in Complete Denture Patients: A ReviewRoja AllampallyNo ratings yet

- C++ Programmierung (Benjamin Buch, Wikibooks - Org)Document257 pagesC++ Programmierung (Benjamin Buch, Wikibooks - Org)stefano rossiNo ratings yet

- A. What Is Balanced/objective Review or Criticism?Document11 pagesA. What Is Balanced/objective Review or Criticism?Risha Ann CortesNo ratings yet

- Fabm1 q3 Mod4 Typesofmajoraccounts FinalDocument25 pagesFabm1 q3 Mod4 Typesofmajoraccounts FinalClifford FloresNo ratings yet

- Gavrila Eduard 2Document6 pagesGavrila Eduard 2Eduard Gabriel GavrilăNo ratings yet

- Illegal FishingDocument1 pageIllegal FishingDita DwynNo ratings yet

- Solidwork Flow Simulation TutorialDocument298 pagesSolidwork Flow Simulation TutorialMilad Ah100% (8)

- Audi A3 Quick Reference Guide: Adjusting Front SeatsDocument4 pagesAudi A3 Quick Reference Guide: Adjusting Front SeatsgordonjairoNo ratings yet

- KS4 Higher Book 1 ContentsDocument2 pagesKS4 Higher Book 1 ContentsSonam KhuranaNo ratings yet

- (V) 2020-Using Extensive Reading in Improving Reading Speed and Level of Reading Comprehension of StudentsDocument7 pages(V) 2020-Using Extensive Reading in Improving Reading Speed and Level of Reading Comprehension of StudentsMEYTA RAHMATUL AZKIYANo ratings yet

- Build Your Own Electric Vehicle, Third EditionFrom EverandBuild Your Own Electric Vehicle, Third EditionRating: 4.5 out of 5 stars4.5/5 (3)

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionFrom EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionRating: 4.5 out of 5 stars4.5/5 (542)

- Operational Amplifier Circuits: Analysis and DesignFrom EverandOperational Amplifier Circuits: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (2)

- The Graphene Revolution: The Weird Science of the Ultra-thinFrom EverandThe Graphene Revolution: The Weird Science of the Ultra-thinRating: 4.5 out of 5 stars4.5/5 (4)

- Understanding Automotive Electronics: An Engineering PerspectiveFrom EverandUnderstanding Automotive Electronics: An Engineering PerspectiveRating: 3.5 out of 5 stars3.5/5 (16)

- High Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsFrom EverandHigh Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsRating: 4 out of 5 stars4/5 (1)

- The Rare Metals War: the dark side of clean energy and digital technologiesFrom EverandThe Rare Metals War: the dark side of clean energy and digital technologiesRating: 5 out of 5 stars5/5 (2)

- Conquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeFrom EverandConquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeRating: 5 out of 5 stars5/5 (8)

- Off-Grid Projects: Step-by-Step Guide to Building Your Own Off-Grid SystemFrom EverandOff-Grid Projects: Step-by-Step Guide to Building Your Own Off-Grid SystemNo ratings yet

- Digital Gold: The Beginner's Guide to Digital Product Success, Learn Useful Tips and Methods on How to Create Digital Products and Earn Massive ProfitsFrom EverandDigital Gold: The Beginner's Guide to Digital Product Success, Learn Useful Tips and Methods on How to Create Digital Products and Earn Massive ProfitsRating: 5 out of 5 stars5/5 (3)

- 8051 Microcontroller: An Applications Based IntroductionFrom Everand8051 Microcontroller: An Applications Based IntroductionRating: 5 out of 5 stars5/5 (6)

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionFrom EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionRating: 4 out of 5 stars4/5 (331)

- Automotive Electronic Diagnostics (Course 2)From EverandAutomotive Electronic Diagnostics (Course 2)Rating: 4 out of 5 stars4/5 (2)

- C++ Programming Language: Simple, Short, and Straightforward Way of Learning C++ ProgrammingFrom EverandC++ Programming Language: Simple, Short, and Straightforward Way of Learning C++ ProgrammingRating: 4 out of 5 stars4/5 (1)

- The Fast Track to Your Technician Class Ham Radio License: For Exams July 1, 2022 - June 30, 2026From EverandThe Fast Track to Your Technician Class Ham Radio License: For Exams July 1, 2022 - June 30, 2026Rating: 5 out of 5 stars5/5 (1)

- Wearable Sensors: Fundamentals, Implementation and ApplicationsFrom EverandWearable Sensors: Fundamentals, Implementation and ApplicationsEdward SazonovNo ratings yet

- Winning in 2025: Digital and Data Transformation: The Keys to SuccessFrom EverandWinning in 2025: Digital and Data Transformation: The Keys to SuccessNo ratings yet

- A Mind at Play: How Claude Shannon Invented the Information AgeFrom EverandA Mind at Play: How Claude Shannon Invented the Information AgeRating: 4 out of 5 stars4/5 (52)

- Electrical Principles and Technology for EngineeringFrom EverandElectrical Principles and Technology for EngineeringRating: 4 out of 5 stars4/5 (4)

- Lithium-Ion Battery: The Power of Electric Vehicles with Basics, Design, Charging technology & Battery Management SystemsFrom EverandLithium-Ion Battery: The Power of Electric Vehicles with Basics, Design, Charging technology & Battery Management SystemsRating: 5 out of 5 stars5/5 (2)